What Causes Your Engine to Knock? My Field Notes on Sounds, Causes, and Fixes

Table of contents

- Introduction: The first time I heard that knock

- Decoding engine knock: types and the sounds they make

- Piston slap

- Rod knock (connecting rod bearing knock)

- Main bearing knock

- Pre-ignition and detonation (spark knock or pinging)

- Valve train noise (lifter tick or valve tap)

- Fuel injector noise

- Why engines knock: primary causes explained

- Low oil pressure and worn engine bearings

- Poor fuel quality or incorrect octane rating

- Excessive carbon buildup

- Incorrect ignition timing

- Lean air-fuel mixture

- Faulty or incorrect spark plugs

- Worn piston components

- Engine overheating

- How I diagnose engine knocking step by step

- Immediate actions and repair solutions that actually work

- Prevention: simple habits that stop knock before it starts

- Quick answers to common “knock” questions

- A quick note on “motor” vs “engine”

- Conclusion: Don’t wait for a louder knock

Introduction: The first time I heard that knock

I still remember the first time I heard a true engine knock. I was climbing a long hill with an older sedan on a hot day. I rolled into the throttle. The car felt sluggish. Then I heard a light, metallic rattle under the hood that sounded like someone shaking a coffee can full of marbles. That was spark knock, also called pinging. I eased off the gas. The rattle faded. Later I filled up with higher octane fuel. The noise disappeared.

A few years later I heard a very different sound. A deep, rhythmic metallic thud that matched engine speed. It got worse when I revved the engine. That car had rod knock. We parked it right away. The bearings had worn out. The oil light flickered at idle. That engine needed major surgery.

Those two experiences taught me a lesson I still lean on. Not all knocks are equal. Some are mild and fixable with fuel or timing. Others mean stop driving now. In this guide I’ll help you tell them apart, find the cause, and choose the right fix.

Decoding engine knock: types and the sounds they make

Engine noise identification starts with your ears. When does it happen? At idle or under load. On cold start or after it warms up. Deep and heavy or light and rattly. I use those clues to sort knocks into buckets.

Piston slap

- What it sounds like: A hollow slapping or rapping sound. It’s sharper than a thud. You’ll hear it most on a cold start. It often fades as the engine warms and parts expand.

- Why it happens: Worn piston skirts or cylinder walls. The piston rocks slightly in the bore and “slaps” the cylinder wall. Loose wrist pins can add a double knock.

- Severity: Often livable for a while if oil pressure is good. It’s still wear. It can worsen.

- When I hear it: Cold mornings. Short drives. High-mileage engines or some designs that are known for it.

Rod knock (connecting rod bearing knock)

- What it sounds like: A deep, rhythmic metallic knock that follows RPM. It gets louder under load. It can feel like the engine has a heartbeat you can count.

- Why it happens: Worn connecting rod bearings due to low oil pressure, dirty oil, wrong viscosity, or simple wear. The bearing clearance grows. The rod clacks on the crank journal.

- Severity: High. Rod knock can turn into a catastrophic failure fast. Think spun bearing or a window in the block.

- Red flags that go with it: Oil light flicker, visible metal glitter in oil, low oil pressure readings.

Main bearing knock

- What it sounds like: Similar to rod knock but often deeper and sometimes slower in rhythm. It can be harder to isolate.

- Why it happens: Worn main bearings on the crankshaft due to low oil pressure or poor lubrication.

- Severity: Severe. You can damage the crankshaft itself. That makes rebuilding more expensive.

Pre-ignition and detonation (spark knock or pinging)

- What it sounds like: A light metallic “pinging” or “rattling” under acceleration or heavy load. It’s more of a high-frequency clatter than a thud.

- Why it happens: The air-fuel mix ignites too early or burns too fast. Low octane fuel, advanced ignition timing, hot spots from carbon buildup, lean mixture, or overheating can trigger it.

- Severity: Moderate to high if ignored. Mild pinging sometimes happens with bad gas. Persistent detonation hammers pistons, rings, and head gaskets.

Valve train noise (lifter tick or valve tap)

- What it sounds like: A consistent, light ticking that often speeds up with RPM. It’s higher in pitch than bearing knock.

- Why it happens: Hydraulic lifters that bleed down, lack of oil to the top end, worn rocker arms, or incorrect valve lash.

- Severity: Usually less severe than bottom-end knocks. It can point to low oil pressure or sludge that starves lifters.

Fuel injector noise

- What it sounds like: A fast, regular clicking. More of a sewing-machine vibe. Easy to confuse with lifter tick.

- Why it happens: Normal operation in most engines. Some injectors are just louder.

- Severity: Usually none. If it’s unusually loud or paired with misfires, then I check for a clogged or failing injector.

Why engines knock: primary causes explained

Noise is a symptom. The cause sits somewhere in oiling, combustion, timing, or mechanical wear. Here’s how I break it down, along with what I’ve learned to check first.

Low oil pressure and worn engine bearings

What’s happening:

- Bearings need an oil wedge to float on. Low oil pressure or thin oil collapses that wedge. Metal kisses metal. That creates rod knock or main bearing knock.

- Common triggers include low oil level, the wrong oil viscosity, a clogged oil filter, sludge from skipped changes, or a failing oil pump.

What I check:

- Oil level and condition. Burnt smell, metallic glitter, sludge under the cap.

- The weight of the oil used at the last change. Some engines hate oil that’s too thin or too thick.

- Mechanical oil pressure with a gauge. I don’t rely only on the dash light.

- OBD-II for related codes. Sometimes you’ll see misfires (P0300–P030X) with severe wear.

Typical fixes:

- If it’s just starved oil due to a clogged filter or wrong oil, an oil and filter change can quiet lifter tick or minor noise.

- If bearings are worn, you’re looking at engine rebuild or replacement. That includes new rod and main bearings, possibly a crank polish or grind, and a full cleaning. It isn’t cheap. It is the correct repair.

Poor fuel quality or incorrect octane rating

What’s happening:

- The octane rating measures resistance to knock. Use lower octane than the engine needs and fuel can detonate under load. Bad or stale gas can do the same. High cylinder temperatures raise the risk.

- Engines with turbocharging or high compression are more sensitive to octane.

What I check:

- Owner’s manual fuel requirements. Some cars require premium. Some only recommend it.

- If I suspect bad gas, I run the tank low and refill with a known good, higher octane fuel.

- Knock sensor operation. A code like P0325 points me toward a faulty sensor or wiring.

Typical fixes:

- Use the correct octane. If you only hear pinging under load with regular fuel, step up a grade.

- Short term you can try a quality octane booster. I treat that as a band-aid, not a lifestyle.

- If pinging persists, I look for carbon buildup or timing issues.

Excessive carbon buildup

What’s happening:

- Carbon builds up on pistons, valves, and in the combustion chamber. Those deposits can glow red hot and ignite the air-fuel mix early. They also raise compression and create hot spots. Direct-injection engines see more intake valve deposits.

- The result can be pre-ignition, detonation, rough idle, and loss of power.

What I check:

- History of short trips and cheap fuel. Those raise risk.

- Borescopes help. I’ve used one through the spark plug hole to eyeball the tops of pistons.

- Misfire codes. Rough idle that clears with RPM often hints at dirty valves on GDI engines.

Typical fixes:

- Fuel system cleaning. Quality detergents can help, especially in port-injected engines.

- Walnut blasting for direct-injection intake valves. That’s the thorough fix.

- A good long highway run at full operating temp can burn off light deposits.

Incorrect ignition timing

What’s happening:

- If spark is too advanced, pressure peaks before the piston crosses top dead center. That invites detonation. A faulty knock sensor or ECU issue can let the engine run too much timing.

- Some older engines allow manual timing adjustment. Most modern cars manage timing through the ECU.

What I check:

- OBD-II data. Timing advance values under different loads. Knock sensor activity. Codes like P0325 (knock sensor) or P0011/P0014 (cam timing) can hint at timing problems.

- Timing chain or belt condition. A stretched chain can throw cam timing off.

Typical fixes:

- Replace a failed knock sensor or repair damaged wiring. Clear the codes and verify the ECU pulls timing under knock.

- Update the ECU calibration if the manufacturer released a fix.

- Correct mechanical timing if a chain jumped or a belt slipped.

Lean air-fuel mixture

What’s happening:

- Too much air relative to fuel raises combustion temperature. Hot chambers knock. Lean conditions stem from vacuum leaks, weak fuel pumps, clogged injectors, MAF or MAP sensor errors, or low fuel pressure.

- Lean mixtures also drive misfires and overheating.

What I check:

- Fuel trims on a scan tool. High positive trims at idle often point to a vacuum leak. High trims under load can point to low fuel pressure or a restricted filter.

- Smoke test for vacuum leaks. That catches cracked hoses and intake gaskets.

- Fuel pressure readings and injector balance tests when possible.

Typical fixes:

- Replace split vacuum hoses and gaskets. Clean or replace a faulty MAF sensor. Fix a weak fuel pump or clogged fuel filter. Clean or replace injectors.

- Reset trims. Road test. Recheck for pinging under load.

Faulty or incorrect spark plugs

What’s happening:

- The wrong heat range or worn plugs become hot spots. That invites pre-ignition. Worn electrodes also trigger misfires that make engines run poorly and hotter than they should.

- Some engines demand specific plug types. Copper, platinum, or iridium behave differently.

What I check:

- Plug condition and part numbers. I pull them and read them. White insulators and speckling can hint at detonation. Oily tips point to other issues.

- Misfire codes by cylinder. P030X codes show a story.

Typical fixes:

- Install the correct plugs in the correct heat range and gap. Replace damaged plug wires or coil-on-plug boots. Clear codes. Recheck under load.

Worn piston components

What’s happening:

- Loose piston-to-wall clearance causes piston slap. Excess skirt wear or tapered bores make cold starts noisy. Loose wrist pins can add a double rap.

- It’s mechanical wear rather than a combustion problem.

What I check:

- Does the noise fade as the engine warms. Does oil pressure stay healthy. Does the engine use oil.

- Compression and leak-down tests for ring sealing.

Typical fixes:

- Live with mild slap in an older engine if it quiets when warm and oil pressure is good.

- Rebuild with new pistons and rings if wear is severe and the owner wants to keep the car.

Engine overheating

What’s happening:

- High coolant temperatures make detonation more likely. Heat also breaks down oil faster. That accelerates bearing wear and lifter noise.

- Overheating rarely comes alone. It magnifies other problems.

What I check:

- Coolant level and leaks. Radiator cap condition. Thermostat operation. Cooling fans. Water pump performance.

- Signs of head gasket failure like milky oil, sweet exhaust smell, or rapid pressure in the cooling system.

Typical fixes:

- Repair leaks. Replace a stuck thermostat, bad fan relay, or failing water pump. Flush the system if clogged. Fix the root cause before chasing knock.

How I diagnose engine knocking step by step

I start simple then get specific. You can follow the same logic at home with basic tools.

1) Listen and test drive safely

- Does it knock cold, hot, at idle, or under acceleration. Does it follow engine RPM or vehicle speed. Deep thud or light ping.

- If it’s a heavy, rhythmic knock that grows with RPM then I don’t push it. I keep RPM low. I head back.

2) Check engine oil and coolant

- Verify oil level and color. Thick sludge or metallic glitter is a big red flag. Smell the dipstick. Burnt oil hints at heat and neglect.

- Confirm coolant level. A low or bubbling reservoir can point to overheating risks.

3) Scan with OBD-II

- I pull codes. P0325 for knock sensor. P0171 or P0174 for lean conditions. P0300 for random misfires. P0420 isn’t about knock but it tells me the cat had a rough time.

- I watch fuel trims, intake air temp, coolant temp, and timing advance. I look for odd values that match the noise.

4) Rule out bad fuel

- If I suspect fuel quality then I add known good fuel with the right octane. I avoid full throttle. If pinging fades after a refill then I know I’m on the right path.

5) Listen with a stethoscope

- A mechanic’s stethoscope or even a long screwdriver helps me localize noise. Top end ticks usually live near the valve covers. Bottom end knocks often transmit through the oil pan and block.

6) Measure oil pressure

- I use a mechanical gauge at hot idle and at a set RPM. If pressure is low then I proceed with extreme caution. Low pressure with knock equals high risk.

7) Check for vacuum leaks and air metering issues

- I smoke test the intake and vacuum lines. I clean or test the MAF sensor. I verify MAP sensor readings. I watch how fuel trims respond.

8) Compression and leak-down tests

- Uneven compression or high leak-down can reveal ring or valve issues. That helps explain misfires that drive lean conditions or detonation.

9) Inspect timing components

- Chain rattle, jumped timing, or a failing tensioner can cause odd noises and rough running. I don’t ignore timing codes.

10) Deep dive only if needed

- If the sound screams rod knock and metal shows in the oil, dropping the oil pan to inspect bearings can confirm it. At that point I talk rebuild vs replacement.

Immediate actions and repair solutions that actually work

Noise severity dictates pace. I always err on the side of protecting the engine.

- Hear a deep, heavy knock that follows RPM. Stop driving. Tow it. Rod or main bearing knock can escalate in minutes.

- Hear light pinging only under acceleration. Try higher octane on the next fill. Don’t lug the engine. If pinging persists then diagnose fuel, timing, or carbon.

- Hear a steady tick from the top end with low oil. Top off and listen again. Then fix the leak and change the oil with the correct viscosity.

Common repairs based on cause

- Oil and filter change with the correct viscosity and a quality filter. This can quiet lifter tick and restore oil pressure that’s on the edge.

- Fuel system cleaning. Quality cleaner in the tank can help injectors. More serious deposits call for professional cleaning or walnut blasting on direct injection.

- Spark plug replacement with the correct type and gap. Replace bad coils or wires. Misfires can mimic knock and cause it by overheating chambers.

- Timing fixes. Replace a faulty knock sensor. Repair its harness. Address stretched timing chains or slipped belts. Verify ECU timing control works.

- Vacuum and sensor corrections. Replace split hoses. Clean or replace MAF or MAP sensors. Fix low fuel pressure issues. Clean or replace clogged injectors.

- Bearing and bottom-end repairs. If you have rod knock or main bearing knock then plan for an engine rebuild or replacement. That repair includes bearings, seals, a crank service, gasket sets, and a deep cleaning. Sometimes a remanufactured engine makes the most sense.

- Cooling system service. Replace a stuck thermostat or dying water pump. Fix leaks. Flush the radiator. Overheating feeds knock. I remove that fuel from the fire.

Expected cost ranges in broad strokes

- Oil service or minor sensor fix: low to a few hundred dollars.

- Fuel system cleaning or injector work: a few hundred to low four figures if injector replacement is needed.

- Spark plug and coil service: typically low to mid hundreds depending on access and parts.

- Carbon cleaning on GDI engines: mid hundreds for chemical cleaning, higher for walnut blasting.

- Timing chain and tensioner work: four figures on many engines due to labor.

- Oil pump or low oil pressure repairs: mid to high hundreds for pump and pickup work. More if damage occurred.

- Engine rebuild or replacement: several thousand to many thousands. Price depends on make, model, and whether you choose a used, reman, or full rebuild.

I never promise exact numbers without looking at the car. Geography, parts availability, and design complexity change the math fast.

Prevention: simple habits that stop knock before it starts

I treat prevention like cheap insurance. It doesn’t take much effort. It pays off over the life of the engine.

- Use the fuel your engine needs. If the manual says premium required then use premium. If it says recommended then treat it like a lever. If you hear pinging on regular then step up to midgrade or premium.

- Keep up with oil changes. Follow the interval. Use the specified viscosity and quality standard. Modern engines tolerate longer intervals on paper. Short trips, heat, and turbochargers don’t.

- Fix cooling issues fast. Low coolant, weak fans, or a sticky thermostat will ruin a good engine. High temps raise knock risk and oil breakdown.

- Replace spark plugs on schedule. Choose the right heat range and design. Don’t guess.

- Keep air metering honest. Clean the MAF when needed. Replace a failing MAP. Inspect intake boots and vacuum lines. Unmetered air drives lean mixtures and detonation.

- Don’t lug the engine. Low RPM in a high gear under heavy load is a recipe for pinging. Downshift. Let the engine breathe.

- Give it a stretch sometimes. Short trips build carbon. A weekly highway run at full operating temp helps.

- Be suspicious of bargain additives. Some work. Many don’t. Pick reputable cleaners and follow directions.

Quick answers to common “knock” questions

Is engine knocking serious?

- Yes when it’s a deep, rhythmic metallic knock that follows RPM. That’s usually rod or main bearings. Park it and diagnose. Light pinging under load can be corrected if you act early.

Can I drive with rod knock?

- I don’t. Every minute risks a spun bearing and collateral damage. Towing often saves money.

Is ticking the same as knocking?

- No. Ticking tends to be top-end valve train or injectors. It’s higher pitched. Knocking from bearings is deeper and heavier. Both need attention if they’re new or loud.

Why does my engine knock on cold start then quiet down?

- That often points to piston slap or lifters that bleed down. It can also signal oil that’s too thin or a filter that drains back. If it fades quickly and oil pressure is healthy then monitor it. If it lingers then diagnose.

What does “engine knocking when accelerating” usually mean?

- Pinging from detonation under load. It can be low octane, carbon buildup, lean mixture, or too much timing. Try higher octane first. If it continues then look at fuel trims, MAF readings, plugs, and knock sensor function.

My engine knocks after an oil change. What happened?

- I check the oil level and viscosity first. Wrong oil weight or low level can trigger noise. A poor quality filter without an anti-drainback valve can cause startup rattle. Fix the oil and filter. If the knock persists then dig deeper.

What about “engine knocking at idle”?

- A heavy knock at idle that worsens with a blip points to bearings. A light tick at idle often points to lifters or injectors. If the oil light flickers then stop driving.

Does “engine knocking when warm” mean anything special?

- Some bearing knocks grow more obvious as oil thins with heat. Piston slap usually quiets when warm. That contrast helps me tell them apart.

Will “engine knocking fuel economy” get worse?

- Yes. Detonation and misfires waste fuel and power. Fix the cause and mileage rebounds.

Can OBD2 help me find a knock?

- Absolutely. Codes like P0325 for knock sensor, P0171 for lean, P0300 for misfire, and cam timing codes point the way. Live data like fuel trims and timing advance help me confirm the root cause.

Will octane booster stop engine knock?

- Sometimes for mild detonation. It won’t mask mechanical knocks. I use it as a test or a temporary aid, not as a crutch.

What does a “knocking noise from engine bay” under the hood mean in general terms?

- If it follows RPM and grows under load then it’s likely internal. If it changes with accessories on and off, consider accessory pulleys or the serpentine belt before blaming the engine.

How do diesel engines fit into this?

- Diesel “clatter” is normal at idle and under load. It’s a different combustion process. True rod or main bearing knocks still sound heavy and dangerous. Don’t ignore deep knocks on any engine type.

A quick note on “motor” vs “engine”

Many people say motor when they mean internal combustion engine. If you came here looking for electric motor noise or failure, that’s a different animal. Electric motors have different components and failure modes. If that’s you, these primers help:

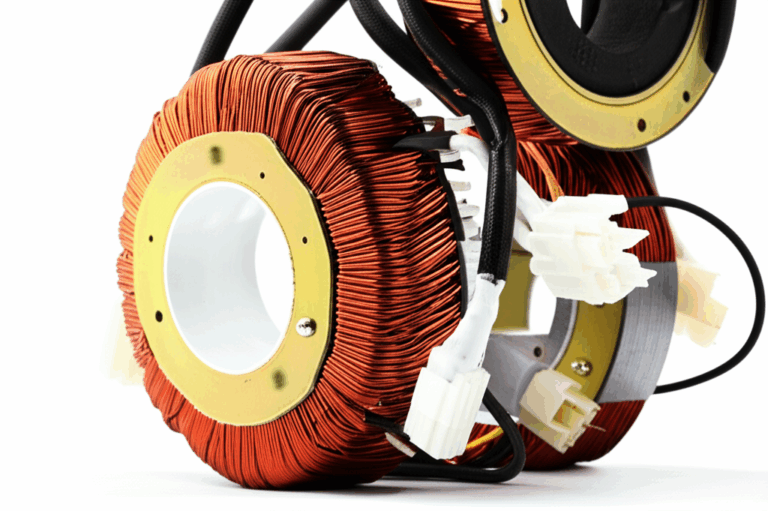

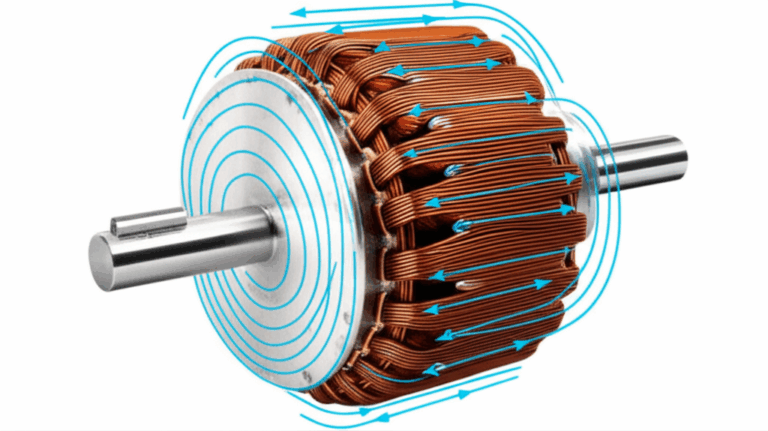

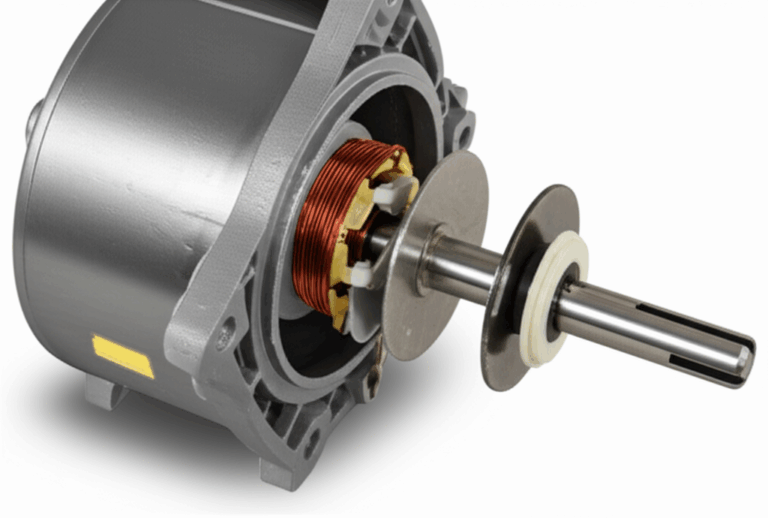

- If you want to understand how motors generate torque, read this overview of the motor principle.

- For a plain-English tour of the two main parts inside a motor, see stator and rotor.

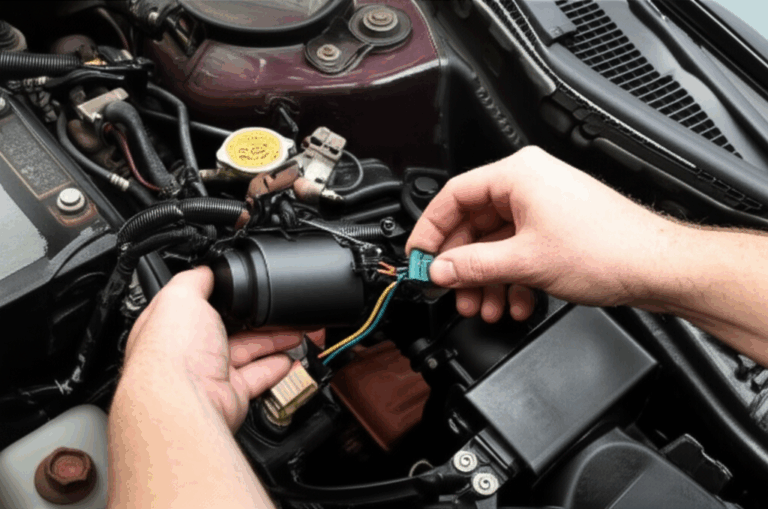

- Troubleshooting an electric drive or pump motor? This guide to finding a motor problem can point you in the right direction.

For the rest of this article I’m talking about internal combustion engines. Pistons, rods, bearings, combustion chambers, and all the noises they make when things go wrong.

Conclusion: Don’t wait for a louder knock

Engines talk. A light ping under load, a tick from the top end, or a deep knock from the bottom end all mean different things. The trick is to listen, match the sound to the situation, and act fast.

Here’s the short version I live by:

- Deep, rhythmic metallic knock that follows RPM. Stop driving. Diagnose oil pressure and bearings. Plan for major repair.

- Light pinging under acceleration or heavy load. Try correct octane. Check timing, fuel trims, intake leaks, and carbon buildup. Fix it before it hurts pistons and gaskets.

- Ticking that speeds with RPM. Check oil, lifters, and injectors. It’s often less severe but still deserves attention.

You don’t need to become an engineer to solve engine knock. You need a calm ear, a simple checklist, and the discipline to fix the root cause. Catch it early and you save money. Ignore it and the engine writes a check you don’t want to cash.

If your car has started talking, listen now. Your wallet will thank you later.