What Do Motors Do? The Core Function of Electric Motors Explained

Motors turn electrical energy into mechanical energy. In plain words, they take electricity and make things move. This matters because motors power your fan, your fridge, your car, and even big machines in factories. Read this to learn how motors work, why they matter, and how to pick and use them well. I will use simple language. I will give clear examples. I will show you how smart choices save energy and money.

Table of Contents

- What Do Motors Do in Plain Words?

- How Do Motors Turn Electricity Into Motion?

- What Are the Main Parts: Stator and Rotor?

- AC vs DC: What Is the Difference?

- What Do Torque, Speed, Horsepower, and Efficiency Mean?

- Where Do You See Motors in Daily Life?

- How Do Motors Drive Industry and Transport?

- What Special Motors Do Special Jobs?

- Why Do Motors Waste Energy and How Can You Save It?

- How Do You Pick the Right Motor?

- What Goes Wrong With Motors and How Do You Fix It?

- Do Generators Do the Opposite of Motors?

- Who Invented and Improved Motors?

- Key Data and Why It Matters

- The Future of Electric Motors

- FAQ

- Summary of Key Points

- References

What Do Motors Do in Plain Words?

Here is the simple truth. An electric motor takes electrical energy and turns it into mechanical power. That power makes rotational motion or linear motion. We use this to spin a fan or drive a pump. We use it to move belts or lift elevators. We use it to push wheels on electric vehicles (EVs). The core job stays the same. Make movement from electricity.

Problem. Many people do not know how motors work. They see motion. They do not see the hidden force inside. That gap leads to poor choices. Bad choices waste energy. Bad choices hurt performance.

Agitate. I have seen motors run hot. I have seen high power bills. I have seen machines fail on busy days. People feel stuck. They ask why the motor is loud. They ask why it trips breakers. They blame the motor. Often the problem comes from wrong type, poor parts, or weak control.

Solution. Learn the basics. Pick the right motor. Use good motor components. Add smart motor control systems like variable speed drives (VSD) or variable frequency drives (VFD). Upgrade to high motor efficiency models like IE3 or IE4. Small steps make a big change.

How Do Motors Turn Electricity Into Motion?

Motors use electromagnetism. When current flows through a wire, it makes a magnetic field. This is Oersted’s discovery. When a magnetic field changes, it can push charges and make current. This is Faraday’s law of induction. Put these ideas together and you get motion.

Inside the motor, you have two fields. One field comes from the stator windings. The other comes from the rotor conductors or magnets. The fields pull and push. That makes force and motion. We call the rotating force torque. We keep the spin going by switching the direction at the right time. That switch is called commutation in DC motors. In AC motors, the stator makes a rotating magnetic field that the rotor follows.

In short, motors convert electrical energy to mechanical energy through magnetic fields in motors. Think of it like a dance. The stator leads. The rotor follows. The steps change fast. The spin stays smooth.

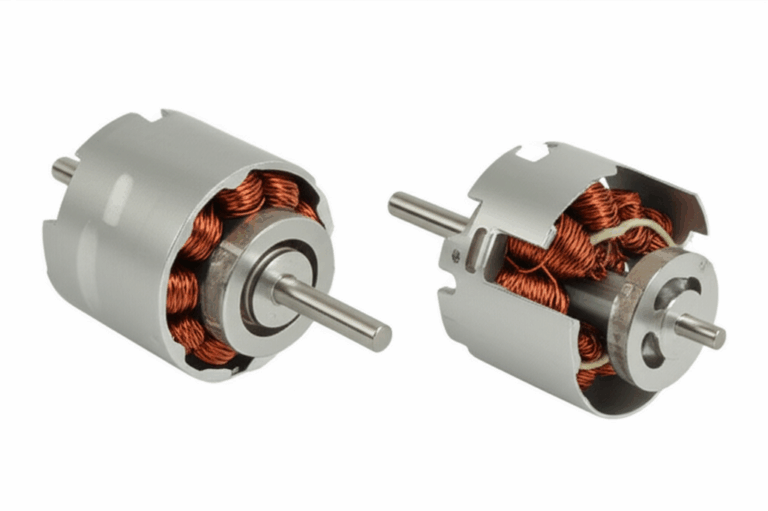

What Are the Main Parts: Stator and Rotor?

Every motor has two key parts. The stator is the still part. The rotor spins inside. The small space between them is the air gap. In the stator, you see windings or coils. In the rotor, you see conductors, magnets, or bars. Some motors have brushes and a commutator. Others do not.

- The stator makes the main electromagnetic field. It holds the stator windings and the stator core. The core is made with electrical steel sheets called laminations. Good laminations reduce motor losses and heat.

- The rotor takes the force and turns. It can be a squirrel cage in an induction motor. It can be permanent magnet in a brushless DC motor (BLDC) or a permanent magnet synchronous motor (PMSM).

If you design or repair motors, the quality of the lamination stack matters. See how the right stator core lamination improves performance. Pair it with a precise rotor core lamination to cut loss and noise. Better cores help you get higher motor output power with lower heat.

AC vs DC: What Is the Difference?

Two big families rule the motor world. AC motors and DC motors.

- DC motors explained: They use brushes and a commutator to reverse current in the rotor. That keeps the torque in one direction. You can also use brushless DC motor operation with electronic commutation. DC motors give smooth control. They work well at low speed. They are great for variable speed jobs.

- AC motors explained: The stator makes a rotating magnetic field. In an induction motor, the rotor gets current by electromagnetic induction. The rotor chases the stator field. In a synchronous motor, the rotor locks in step with the field. AC motors are tough. They are efficient at constant speed. They rule in industrial motor uses.

Both convert input power to mechanical power. They just use different ways to do it.

What Do Torque, Speed, Horsepower, and Efficiency Mean?

Let’s keep it simple.

- Torque is twist. It is how hard the motor can turn.

- Speed is how fast it spins. We measure it in rpm.

- Horsepower tells you how much work a motor can do over time. It links torque and speed.

- Motor efficiency shows how well the motor changes electrical power into mechanical power. High efficiency means less heat and waste.

You control speed with motor speed control tools like VFDs or VSDs. You can adjust motor current and voltage. You can also gear down using a gearbox. Right control gives you the torque you need with less energy.

Where Do You See Motors in Daily Life?

You see motors everywhere. Here are clear motor applications in daily life.

- Household appliance motors: Washing machine motor, refrigerator compressor motor, fans, vacuum cleaners, blenders.

- Personal devices: Electric toothbrushes, drones, power tools, electric vehicle motors in EVs and hybrid electric vehicles (HEVs).

- Home systems: Pumps and motors, fans and motors, compressors and motors for heat and air.

Motors give rotational motion to things that need to spin. Motors also make linear motion in linear motors. They can push a slide or a robot arm straight ahead.

I use a simple rule. If something moves and you do not see a flame or an engine then a motor likely runs it.

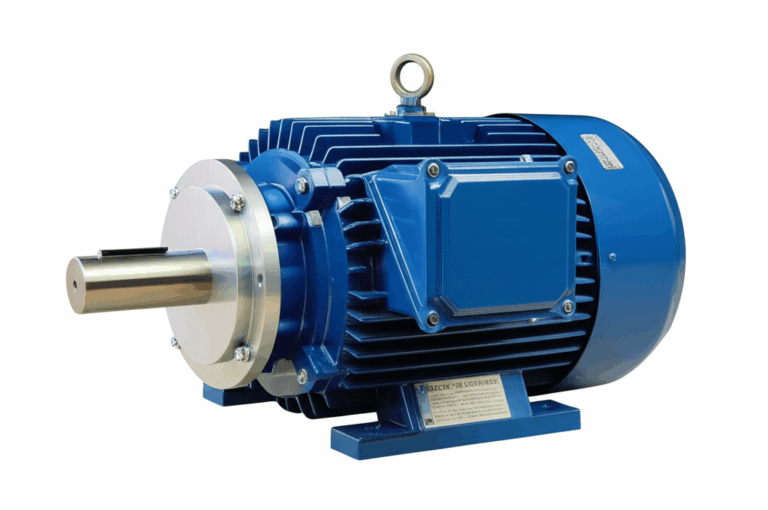

How Do Motors Drive Industry and Transport?

Industry runs on motors. They power conveyor systems, pumps, fans, compressors, and automation motors. They drive industrial automation in robotics and CNC machines. They keep water treatment plants running. They roll steel in mills. They move goods in manufacturing.

Transport relies on motors too. Electric trains use large AC motors. Elevators and escalators use synchronous motor or induction motor drives. Electric vehicles use PMSM, BLDC, or induction motors for propulsion. The motor is the heart of the machine. It turns electricity into motion with grace.

What Special Motors Do Special Jobs?

Not every job is the same. So we use special motors.

- Stepper motor applications: Stepper motors move in small steps. They are great for robotics motors, 3D printers, and places where you need precise rotational motion explained.

- Servo motor functionality: Servo motors use closed-loop control. They hold position well. They work in industrial automation and CNC machines.

- Brushless DC motor operation (BLDC): BLDC motors use electronic commutation. They are efficient and quiet. They shine in fans, drives, drones, and EVs. For better BLDC performance, consider an optimized bldc stator core.

- Synchronous motor uses: These motors lock to the stator field. They fit constant speed tasks.

- Induction motor working: Simple. Strong. Low cost. A workhorse in factories.

- Switched reluctance motors: Rugged and simple. They use reluctance torque. They fit harsh jobs.

- Permanent magnet motors: High power density. Great for EVs.

- Universal motor function: Runs on AC or DC. Found in tools and small appliances.

- Linear motor explanation: Makes straight motion without a rotary-to-linear conversion.

Each type meets a need. The trick is to match the job to the motor.

Why Do Motors Waste Energy and How Can You Save It?

Motors waste energy in heat. Losses come from windings, core, and bearings. You also see loss in motor insulation classes, friction, and poor cooling methods. Old motors run less efficient. They can be noisy. They can run hot.

Problem. High energy bills hurt. In plants, motors can use 70 to 80% of all electricity. That is huge.

Agitate. I have watched old motors bake. Bearings cry. You pay more each month. You lose uptime. Your carbon footprint grows.

Solution. Use high-efficiency motors like IE3 or IE4 under the IEC 60034-30-1 standard. Add variable speed drives (VSD) where loads change. Use predictive maintenance. Pick good motor cooling methods. Choose strong cores and stacks. Better motor core laminations make a real difference. Learn how optimized motor core laminations cut motor losses and heat. Get the right electrical to mechanical conversion with less waste.

Material choice also matters. High grade steel lowers hysteresis and eddy current losses. See how premium electrical steel laminations help boost motor efficiency.

How Do You Pick the Right Motor?

Start with the job. What do you need the motor to do. Think motor sizing and selection.

- Load type: Pumps, fans, compressors, belts, conveyor belts motors. Each uses torque in a different way.

- Duty cycle: Run time and rest time.

- Motor output power: How much work you need.

- Motor speed control: Fixed speed or variable speed with VFD.

- Motor current and voltage: Match your supply. AC or DC.

- Motor design considerations: Space, noise, cooling, insulation classes, and motor noise reduction.

- Environment: Hot, cold, dusty, or wet.

Use the data sheet. Read understanding motor ratings. Look at horsepower and motors. Check efficiency standards. If you run a generator vs motor set, size the system well. When in doubt, ask a pro. A small mismatch can mean big loss.

What Goes Wrong With Motors and How Do You Fix It?

Motors fail for many reasons. I have seen the top three again and again.

- Bearing failure: 40 to 50% of cases. Dirt or poor lube. Misalignment.

- Stator winding failure: 30 to 40%. Heat or overload. Weak insulation.

- Rotor bar failure: 5 to 10%. Fatigue or cracks.

Problem. When a motor stops, your work stops.

Agitate. You lose hours. You miss orders. Your team scrambles.

Solution. Do motor maintenance. Keep a simple plan. Lube bearings on time. Check heat. Monitor vibration. Use predictive maintenance motors with sensors and IoT in motors. Fix small motor problems fast before they grow. If noise rises or heat climbs, act first. Clean vents. Check cooling. Replace weak parts. Use better cores and windings next time.

Do Generators Do the Opposite of Motors?

Yes. A generator turns mechanical energy into electrical energy. It does the reverse of a motor. The physics connect both. You still use electromagnetic induction. A motor can act like a generator if you drive it. That is why regenerative braking in EVs pushes power back to the battery. Motor and generator form a team.

Who Invented and Improved Motors?

We stand on the shoulders of giants.

- Michael Faraday showed how fields and currents interact.

- Nikola Tesla patented the AC induction motor in 1888.

- Thomas Edison pushed DC power in early days.

- Firms like General Electric (GE), Siemens, ABB, Nidec, and Regal Rexnord built and improved modern motors. They work on motor innovation, smart motors, and advanced motor materials every year.

From lab to factory, the motor story keeps growing.

Key Data and Why It Matters

Here is a quick set of facts. They show the size of the motor world and why smart choices help you.

| Category | Metric / Data Point | Notes |

|---|---|---|

| Global Market Size | ~$140B in 2023, ~\$230B by 2032 | Motor demand grows fast |

| Energy Consumption | Motors use 45–50% of global electricity | Huge room for savings |

| Industrial Usage | 70–80% of plant power goes to motors | Focus your efforts here |

| Energy Savings | IE3/IE4 + VSD can save 20–30% | More in variable-load cases |

| EV Motor Growth | ~$10B in 2022 to ~$30B by 2027 | EVs are the future |

| Motor Lifespan | 15–20 years with care | 5–7 years with poor care |

| Efficiency Steps | IE1 to IE4 adds about 2–5% each step | Better cores help |

| Failures | Bearings 40–50%, Windings 30–40%, Rotor bars 5–10% | Plan maintenance |

| Global Motor Stock | Billions in use | From tiny to huge |

| VSD Savings | Up to 60% in variable load | Pumps and fans benefit most |

These numbers tie back to the importance of motors. They show why sustainability matters. They highlight the impact of motors on industry and on your bills at home.

The Future of Electric Motors

The future looks bright. We see motor technology advancements everywhere.

- Better permanent magnet motors with higher power density.

- Wider use of VFD and VSD for smarter motor speed control.

- Growth in electric vehicle motors and renewable energy systems like wind turbine yaw/pitch control and solar tracking.

- More smart motors with sensors. Better IoT in motors. Stronger predictive maintenance.

- Use of advanced motor materials like silicon steel laminations, new magnets, and new cooling. Cleaner processes lower the motor carbon footprint.

I believe the motor will stay the silent hero. It will help us cut fuel use. It will power automation with ease. It will make life quiet and clean.

FAQ

- What is the purpose of an electric motor?

It converts electrical energy into mechanical energy to make motion.

- How do motors generate rotation?

Fields in the stator and rotor push and pull. That makes torque. Commutation or a rotating field keeps the spin going.

- AC motor or DC motor for my project?

Pick DC for fine speed control at low speed. Pick AC induction for tough, low-cost tasks at constant speed. Pick BLDC or PMSM for high efficiency and power density.

- Can a motor act like a generator?

Yes. Spin it with an outside force. The motor will make power.

- How can I make my motor system more efficient?

Use IE3/IE4 motors. Add VFD/VSD. Improve cooling. Keep bearings clean. Use better laminations and windings.

Summary of Key Points

- Motors turn electricity into motion. That is the core job.

- They use electromagnetic induction and magnetic fields to make torque.

- Main parts are the stator and rotor with a small air gap.

- AC motors and DC motors serve different needs.

- Choose motors by load, speed, power, and environment.

- Save energy with IE3/IE4, VFD/VSD, and good materials.

- Fix common failures with simple care and predictive maintenance.

- New trends include EVs, robotics, smart motors, and better materials.

- Good cores like quality laminations cut loss and heat. See linked resources for stator, rotor, BLDC, and motor core options.

References

- International Energy Agency (IEA). Energy use in motors and industry.

- International Electrotechnical Commission (IEC 60034-30-1). Motor efficiency classes IE1–IE4.

- IEEE and EPRI reports on motor reliability and failure modes.

- International Federation of Robotics (IFR). Industrial robot growth statistics.

- Historical records on Nikola Tesla and the AC induction motor patent of 1888.

- Manufacturer data and white papers on VFD/VSD savings and variable-load systems.

Notes on Materials and Related Components

If you make or buy motors, look at the core of the machine. Strong laminations lower heat and boost efficiency. We talked about stator core lamination, rotor core lamination, bldc stator core, and motor core laminations. These parts support electromagnetism, reduce loss, and improve noise. They help all types: induction motor, synchronous motor, brushless DC, stepper, servo, universal motor, and linear motor. Choose the right electrical steel and silicon steel grades. Pick the right insulation classes. Get the right cooling methods. Then your motors will run cooler and last longer.

Extra: How Electricity Makes Things Spin

Picture a tug of war around a circle. The stator team holds ropes tied to the ground. The rotor team grabs ropes that wrap around the circle. When you switch which team pulls and when, the rotor team always chases the strongest pull. That chase makes the rotor spin. Commutation or a rotating field sets the timing. That is the basic motor mechanics at work.

Real-World Examples That Tie It All Together

- In a washing machine motor, the control unit changes speed with a VFD. It boosts torque for spin. It slows for gentle wash.

- In HVAC fans and motors, a VSD tracks load. It cuts power at night. It saves up to 60% in variable flow.

- In EV motors, a PMSM or induction motor gives high torque from zero. You get smooth acceleration. Regenerative braking sends power back to the battery.

- In robotics, servo motors and stepper motors give precise moves. You get precision motors for repeat tasks.

These stories show the principles of electromagnetism at work. They show power conversion devices in action. They show why motor control systems matter.

A Quick Glossary in Simple Words

- Electromagnetic induction: A changing magnetic field makes current.

- Commutator: A switch in a DC motor that keeps torque in one direction.

- Induction motor: The rotor gets current from the stator field.

- Synchronous motor: The rotor locks with the stator field.

- Brushless DC (BLDC): DC motor with no brushes. An electronic circuit switches current.

- Stepper motor: Moves in steps. Great for precise moves.

- Servo motor: Uses feedback to hold position or speed.

- Linear motor: Makes straight motion.

- VFD/VSD: Changes frequency or speed to save energy.

- IE3/IE4: High efficiency standards for motors.

- Horsepower: How much work per time.

- Torque: Twist force that turns the shaft.

Positioning the Solution: How Better Parts Solve Tough Problems

Problem. You need motors that run cool and last long. You need low noise. You need high efficiency. You want strong torque at the right speed. You want lower bills.

Agitate. Poor cores waste energy. Weak stacks hum. Bad laminations heat up. Bearings suffer. Windings fail. You spend more. Your team spends nights fixing things.

Solution. Use better cores and smart control. Pick high grade electrical steel laminations. Choose precise stator and rotor stacks. Use BLDC or PMSM where weight and power density matter. Add VFD. Follow maintenance tips. With the right parts, you get more mechanical power, less heat, and longer life.

Closing Thoughts

Motors are the quiet heroes of our world. They power your home and your work. They cut waste when you pick well. They push us toward clean sustainable motor solutions. Learn the fundamental motor concepts. Match motor to job. Use smart motor drive types. Choose strong cores and good materials. Then your systems will run smooth and strong for years.

I use this simple line when I talk with teams. Motors make life move. Treat them well and they treat you even better.