What Does a Brushless Motor Mean? Understanding BLDC Technology & Its Impact

Table of Contents

- Introduction: Beyond the “Brushless” Buzzword

- The Core Concept: How a Brushless Motor Works

- Brushed vs. Brushless: The Fundamental Difference in Commutation

- Key Components of a Brushless Motor

- The Commutation Process in Action: Electronic Control

- Why Go Brushless? Key Advantages and Benefits

- Superior Efficiency

- Extended Lifespan and Reliability

- Minimal Maintenance

- Lower Noise and Less Heat

- Precise Speed and Torque Control

- Are There Any Drawbacks

- Where Are Brushless Motors Used

- Consumer and Hobby Electronics

- Cordless Power Tools

- Electric Vehicles

- Industrial Automation and Robotics

- Home Appliances and HVAC

- Medical Devices

- Brushless vs. Brushed: A Quick Comparison

- Key Specs Explained: Kv, Torque, RPM, and Pole Pairs

- Control Strategies: ESCs, Trapezoidal vs. Sinusoidal vs. FOC

- Types and Designs: BLDC, PMSM, Inner vs. Outer Rotor

- Materials, Laminations, and Thermal Management

- Common Issues and Troubleshooting

- Cost, Market Trends, and The Future

- Conclusion: The Modern Standard for Motor Performance

Introduction: Beyond the “Brushless” Buzzword

I remember the first time I saw “brushless” stamped on a cordless drill. It felt like a marketing badge. I bought the tool anyway because the runtime promise sounded great. Later I built a small drone and the term stopped being a buzzword. It became real. The motors felt cooler. The battery lasted longer. The control felt precise. That’s when I asked the same question you’re asking now. What does a brushless motor actually mean?

In plain English a brushless DC motor (often called a BLDC motor) means the motor does not use physical brushes or a mechanical commutator to switch current. Instead it uses electronics to do the switching. That simple change unlocks a lot of benefits. Higher efficiency. Longer lifespan. Lower noise. Smarter control. It also shifts complexity into a small box called an ESC or electronic speed controller.

By the end of this guide you’ll know how a brushless motor works, why it outperforms a brushed motor in most use cases, and where you’ll find it in the wild. I’ll share what I learned building drones, choosing power tools, and tinkering with fans and appliances. I’ll keep the jargon light. I won’t skip the details that matter.

The Core Concept: How a Brushless Motor Works

Brushed vs. Brushless: The Fundamental Difference in Commutation

When I tore down my first brushed DC motor I found two parts doing the dirty work: brushes and a commutator. The brushes pressed against the spinning commutator segments. That contact switched current between coils. It kept the rotor’s magnetic field aligned with the stator’s field so the rotor kept turning. Simple. Mechanical. Wear-prone.

Brushless motors flip the script. They remove the brushes and the commutator. The switching we call commutation happens electronically. A controller senses the rotor position then energizes the stator windings in sequence. That sequence creates a rotating magnetic field. The rotor follows that field because it holds permanent magnets. No rubbing contacts. Less friction. Less heat. More control.

If you want the one-line brushless DC motor definition: a BLDC motor uses electronic commutation to drive a permanent magnet rotor with a rotating magnetic field generated by stator windings.

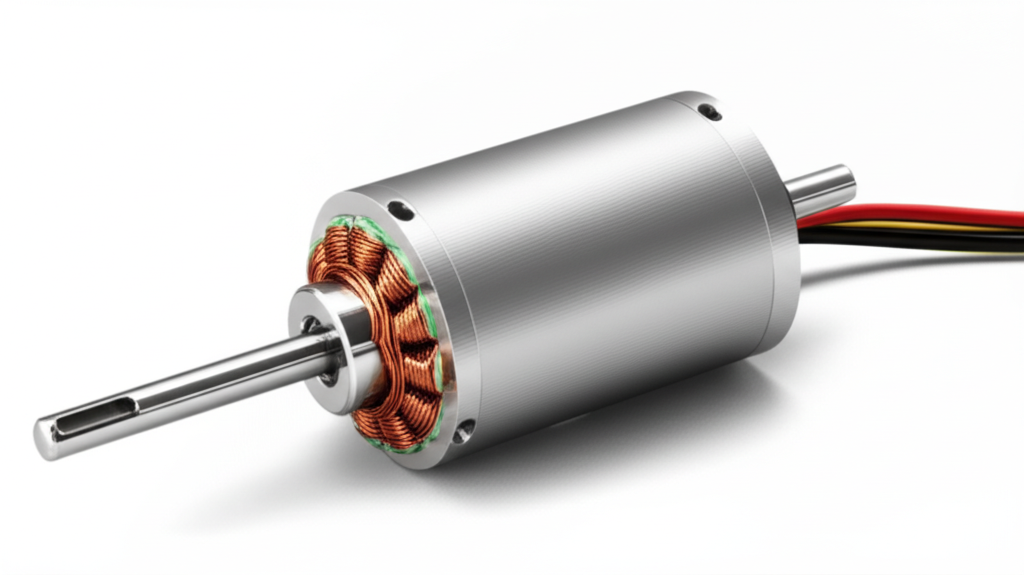

Key Components of a Brushless Motor

Every BLDC motor I’ve used boils down to the same core parts:

- Stator: The stationary body holds the copper windings. Those windings act as electromagnets when the controller powers them with current.

- Rotor: The rotating piece carries permanent magnets. Neodymium magnets show up a lot because they pack strong magnetic flux into a small space.

- Electronic Speed Controller (ESC): This is the brain and the brawn. It switches current to the windings using semiconductors. It manages speed, torque, and direction.

- Sensors (optional): Many motors include Hall effect sensors for rotor position. Others run sensorless using back-EMF sensing.

If you want a good primer on the relationship between the two main parts check out the basics of stator and rotor. That foundation helps everything else click.

The Commutation Process in Action: Electronic Control

Here’s the dance step by step as I’ve measured it on the bench:

I like to picture it as a relay race. The controller keeps passing the baton from one set of windings to the next. The rotor never loses the lead runner to chase.

Why Go Brushless? Key Advantages and Benefits

When I switched my RC car from a brushed motor to a brushless setup I felt three changes on the first run. More punch. Less heat. Longer runtime. Those three show up in almost every brushless application.

Superior Efficiency

Brushless motors waste less energy as heat. You avoid brush friction and arcing. You also get a magnetic circuit designed for precise control. In my projects I’ve seen efficiency bumps of 10 to 30 percent. Industry sources commonly cite BLDC efficiency in the 85 to 90 percent range or higher. That efficiency trickles down. Batteries last longer. Thermal stress drops. Designs can shrink.

Extended Lifespan and Reliability

No brushes means no brush wear. The commutator disappears. That removes two common failure modes. Bearings still matter. So does thermal management. Even so the lifespan range usually looks far better for BLDC motors. Brushed motors often run for hundreds to a few thousand hours. Brushless motors often go tens of thousands of hours if you keep them within spec.

Minimal Maintenance

On brushed motors I used to clean the commutator and replace brushes on schedule. Dust got everywhere. With brushless motors maintenance feels simple. Keep the inlets clear. Watch temperatures. Don’t starve the bearings of lubrication. That’s about it for most hobby and light industrial setups.

Lower Noise and Less Heat

Once I moved to a brushless drill I noticed something right away. It sounded smoother. That’s not a coincidence. Electronic commutation removes brush chatter. Better control means less torque ripple. Less electrical noise. Less mechanical noise. Heat also drops because efficiency goes up. Lower heat lets designers pack more power into the same space. This is why you find brushless motors in drones and compact power tools.

Precise Speed and Torque Control

The magic of a brushless motor sits in the controller. You can dial in exact RPM or create torque limits. You can implement soft start. You can hold a speed under variable load. Field-oriented control (FOC) goes a step further. It aligns current with the rotor’s magnetic field so the motor produces torque with less ripple and better efficiency. On my drone FOC made the motors whisper quiet at hover.

Are There Any Drawbacks?

Nothing comes free. Brushless motors cost more upfront. The magnets add cost. The ESC adds cost and complexity. You need a controller to run the motor at all. That controller must match the motor’s characteristics. This raises the bar for design and troubleshooting. Some ultra low-end applications still pick brushed motors because they are cheap and simple.

Even with that said I still choose brushless for most new projects. The total cost of ownership tilts in its favor. Less maintenance. Longer life. Lower energy use.

Where Are Brushless Motors Used?

Once you know what you’re looking at you start seeing BLDC motors everywhere.

Consumer and Hobby Electronics

- Drones and RC: High power-to-weight ratio and high RPM capability rule the sky. Brushless motors dominate drone motor technology because every gram matters and efficiency buys flight time.

- Computer fans and hard drives: Quiet operation and long life make sense in always-on gear.

- E-bikes and scooters: You’ll see hub motors and mid-drive designs. Both leverage precise control and regenerative braking.

Cordless Power Tools

I replaced my old brushed drill with a brushless model from DeWalt then picked up an impact driver from Milwaukee. The difference in runtime and torque feels obvious. Most premium cordless tools from DeWalt, Milwaukee, and Makita now ship with brushless motors for good reason. Better performance per battery. Less heat. Longer lifespan.

Electric Vehicles

Most modern EVs use permanent magnet synchronous motors (PMSMs) or similar brushless designs for traction. Manufacturers favor PMSMs because they deliver high efficiency and strong torque density across a wide speed range. You’ll also see induction motors in some models for specific drive roles. Either way the traction systems don’t use brushes or commutators. They rely on sophisticated inverters and field-oriented control.

Industrial Automation and Robotics

Robotics runs on precise, repeatable movement. BLDC servo motor systems and stepper-like brushless solutions deliver that. In factories you’ll see brushless motors in conveyors, pick-and-place robots, and automated guided vehicles. The reliability and control make the difference on long duty cycles.

Home Appliances and HVAC

- Washing machines: Direct-drive brushless motors cut vibration and noise. They tune spin speeds precisely.

- Vacuum cleaners: Cordless uprights moved to brushless designs for longer runtime and better suction per watt.

- HVAC: Variable speed brushless blowers can trim energy use by 20 to 30 percent while holding airflow and pressure steady. Quiet operation helps at home and in offices.

Medical Devices

Pumps, surgical tools, and small handpieces need smooth torque and low noise. BLDC motors deliver that. Sterility and reliability matter. No brush dust helps keep environments clean.

Brushless vs. Brushed: A Quick Comparison

Here’s the short version based on what I’ve seen and what industry data shows.

| Feature/Metric | Brushed DC Motors | Brushless DC Motors (BLDC/PMSM) |

|---|---|---|

| Efficiency | Typically 75–80% | Often 85–90% or higher |

| Lifespan | 500–5,000 hours due to brush wear | 10,000–50,000+ hours with proper bearings and cooling |

| Maintenance | Brush replacement and commutator cleaning | Minimal maintenance |

| Noise | Audible brush and commutator noise | Significantly quieter |

| Heat Generation | Higher due to friction and losses | Lower due to better efficiency |

| Power-to-Weight | Lower | Higher power density |

| Speed/Torque Control | Basic and less precise | Highly precise with ESC control |

| Initial Cost | Lower | Higher due to controller and magnets |

| Applications | Toys, basic pumps, low-cost tools | Drones, EVs, premium tools, HVAC, robotics |

Industry analysts estimate the global BLDC market near the tens of billions of dollars with strong growth. A 2023 report from MarketsandMarkets placed the 2022 BLDC motor market around USD 22 billion and projected roughly 10 percent CAGR through 2028. My experience lines up with that trend. Everywhere I look I see brushless adoption rising.

Key Specs Explained: Kv, Torque, RPM, and Pole Pairs

When I built my first quadcopter I ran into a number called Kv. It confused me at first. Then it clicked.

- Kv rating: Kv tells you how many RPM the motor will spin per volt with no load. If a motor has Kv of 1,000 it spins about 1,000 RPM per volt at no load. Kv does not equal torque. Lower Kv motors generally produce more torque per amp at lower speed. Higher Kv motors spin faster with less torque per amp.

- Torque: Torque is rotational force. In BLDC motors torque depends on current and the motor’s design. Controllers regulate current to control torque.

- RPM: Revolutions per minute. ESCs modulate voltage and timing to hit target RPM under load.

- Pole pairs: A pole pair equals one north and one south magnetic pole on the rotor. Pole count affects how the motor commutates and how the controller calculates electrical RPM. More poles often yield smoother low-speed torque.

I also learned to read motor specifications more carefully. You want to check max current, max voltage, winding resistance, and thermal limits. Compare motors on specific power output if you care about size and weight.

Control Strategies: ESCs, Trapezoidal vs. Sinusoidal vs. FOC

All brushless control centers on the ESC. Inside the controller you’ll find a microcontroller, gate drivers, and power semiconductors like MOSFETs. The ESC generates a three-phase waveform to the motor windings. It manages timing and current with PWM. It reads rotor position via Hall sensors or back-EMF.

Control methods vary:

- Trapezoidal control: Also called six-step. It commutates phases in discrete steps. It’s simple and efficient at speed. It can produce more torque ripple and acoustic noise at low speed.

- Sinusoidal control: Creates a smooth sine-wave current. It reduces torque ripple and noise. It costs more in controller complexity.

- Field-Oriented Control (FOC): The heavy hitter. It transforms currents into rotating frames (d-q axis) aligned with the rotor field. It squeezes better torque per amp and improved efficiency across a wide speed range. It also feels buttery smooth.

Sensorless control reads back-EMF to track rotor position. It works well at speed. It can struggle at zero speed. Controllers often inject small signals or use observer algorithms to solve startup and low-speed control. Hall effect sensors give direct rotor position which improves startup torque and slow-speed control at the cost of extra parts.

I’ve flown drones on both six-step and FOC ESCs. Six-step works fine for racing at high RPM. FOC wins for cinema flights because the motors run quieter and hold speed with less twitch.

Types and Designs: BLDC, PMSM, Inner vs. Outer Rotor

You’ll see two terms a lot: BLDC and PMSM.

- BLDC motor: Often driven with trapezoidal control and designed for a more trapezoidal back-EMF.

- Permanent Magnet Synchronous Motor (PMSM): Uses a sinusoidal back-EMF with sinusoidal or FOC control. It runs synchronously with the rotating field.

Both are “brushless” with permanent magnet rotors. The line between them blurs because many controllers can drive either with FOC. In EVs PMSMs are common because they deliver great efficiency and torque density. Some EV powertrains mix PMSM for primary drive and use induction motors where it fits the duty cycle.

Design layout matters too:

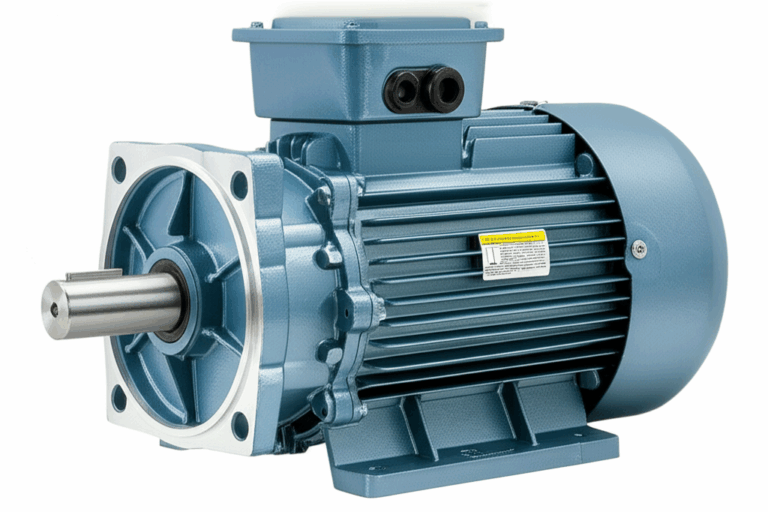

- Inner rotor: The rotor sits inside the stator. This design shows up in most power tools and EV traction motors.

- Outer rotor: The rotor wraps around the stator. Many drone motors and gimbal motors use this layout because it offers high torque at lower RPM.

Servo and stepper flavors exist in brushless form as well. You’ll find brushless servo motors with encoders in automation. You’ll find hybrid stepper-like brushless designs where precise position control matters.

If you want one more layer of fundamentals revisit the motor principle and the interplay between magnetic fields and conductors. Then dive back into BLDC control with a fresh lens.

Materials, Laminations, and Thermal Management

The materials inside a BLDC motor carry a lot of weight. Literally and figuratively.

- Permanent magnets: Neodymium magnets deliver strong fields in small sizes. Magnet grade sets the temperature tolerance. Higher grades cost more but survive more heat without demagnetizing.

- Copper windings: Lower resistance means lower I²R losses. Winding technique affects fill factor and thermal path.

- Laminations in the stator and rotor: Manufacturers stack thin sheets of electrical steel to build the magnetic core. Thin laminations cut eddy current losses which raise efficiency.

I learned the hard way that lamination quality affects motor performance. If the lamination steel resists magnetization or the stack has poor insulation between layers you lose efficiency to heat. For a deeper look at this topic study the details of stator core lamination, rotor core lamination, and the broader role of electrical steel laminations.

Thermal management also plays a key role:

- Better heat sinks and airflow keep windings and magnets healthy.

- Thermal interface materials help conduct heat out of the stator.

- Controllers monitor current and temperature to stay within safe operating areas.

Get thermal design right and you unlock higher continuous power. Ignore it and you cook magnets or insulation.

Common Issues and Troubleshooting

I’ve faced my share of BLDC gremlins. Here are the problems I meet most and how I approach them.

- Cogging or rough low-speed motion: Try sinusoidal control or FOC. Use sensors for better startup behavior. Increase PWM frequency if the ESC allows it.

- Overheating: Check load and gearing. Improve airflow. Verify current limits. Consider a motor with lower Kv or larger frame size for the same job.

- Vibration and noise: Balance the rotor. Check bearings. Verify the controller’s commutation timing. Mount the motor with proper isolation if needed.

- Desync under hard acceleration: Sensorless ESCs can lose track of rotor position during sudden load changes. Enable soft start or tune timing advance. Hall sensors or encoders can fix the root cause.

- Low power or poor efficiency: Verify wiring order of phases. Ensure the supply voltage matches the motor spec. Use thicker wiring to reduce voltage drop. Calibrate the ESC.

- Bearing failure: Bearings still wear. Keep dust out. Consider sealed bearings for harsh environments. Replace at the first sign of play or rumble.

I keep a methodical process. One change at a time. Log temperatures and current. Use an infrared thermometer on windings and a stethoscope-like tool to listen for bearing noise. Small checks save motors.

Cost, Market Trends, and The Future

Brushless motors cost more up front because magnets and controllers add expense. Over the life of a product they often save money. Less maintenance. Lower energy bills. Fewer failures. I’ve watched high-efficiency HVAC systems pay back the premium with 20 to 30 percent energy savings. I’ve watched premium power tools outlast their brushed cousins under the same workload.

Industry trends point one way. Up and to the right. MarketsandMarkets estimated about USD 22 billion for the BLDC market in 2022 with roughly 10 percent CAGR through 2028. Premium cordless power tools have moved heavily to brushless architectures. Drones and RC already made the switch. EV adoption continues to push PMSM and advanced inverter technology. Automation adds more axes every year. The aerospace industry uses compact, high-torque brushless actuators where weight matters. Medical devices lean on quiet operation and long life. All signs point to more brushless motors in more places.

What’s next:

- Better control: FOC continues to spread because microcontrollers and semiconductors keep improving.

- Miniaturization: Higher magnetic energy products and better thermal paths shrink motors while holding power.

- Sensorless advances: Observer algorithms and high-frequency injection improve low-speed control without sensors.

- Materials: Magnet technology keeps evolving. Designers explore ways to reduce rare-earth dependence where they can without losing performance.

- AC vs. DC perspective: We call them “DC” because of the supply source and control interface. The ESC still feeds a three-phase AC waveform to the windings. Expect even more crossover between BLDC and PMSM designs.

I care about the ecological impact too. Higher motor efficiency reduces energy consumption across millions of devices. Standards like Energy Star reward that. This is one of those quiet engineering shifts that adds up.

Conclusion: The Modern Standard for Motor Performance

If you only take one thing away let it be this. “Brushless” means the motor uses electronic commutation instead of physical brushes and a commutator. That swap changes everything. You get higher efficiency, longer lifespan, lower noise, and smarter control. You also get a bit more complexity in the controller. In my experience the trade pays off almost every time.

I’ve seen BLDC motors transform drones with longer flights. I’ve felt the difference in power tools that run cooler and punch harder. I’ve watched HVAC systems save energy with variable speed control. I’ve worked with robotics that repeat precise motions all day without a hiccup. The meaning of “brushless motor” isn’t a buzzword. It’s a modern standard for motor performance.

If you’re choosing between brushed and brushless for your next project look at your priorities. Efficiency and control. Noise and heat. Lifespan and maintenance. If those sit high on your list go brushless. If absolute lowest upfront cost rules the day a brushed motor still has a place.

One last tip before you pick parts. Understand your stator windings and rotor design. Read the specs with care. Pay attention to Kv, current limits, and pole pairs. Match your ESC to your motor and application. Then design for cooling. Those simple steps turn a good brushless system into a great one.