What Does a Capacitor Do in a Motor? Essential Role in Performance & Efficiency

Every engineer runs into this sooner or later. A single‑phase AC motor hums yet refuses to turn. Someone points to the capacitor. You ask the core question. What does a capacitor do in a motor and why does it matter so much for performance, efficiency, and reliability?

Short answer. In many single‑phase AC motors the capacitor creates a phase shift in an auxiliary winding that produces starting torque then it often improves running efficiency and power factor. Without it the motor may stall at start. With the right capacitor the motor starts decisively runs smoother and lasts longer.

You likely need more than an elevator pitch. You want to know how this ties to magnetic circuit design, winding choices, laminations, procurement decisions, and real‑world efficiency. You’re in the right place.

In This Article

- Why Single‑Phase Motors Need Capacitors

- Start vs Run vs Dual Run Capacitors

- How Motor Capacitors Work: The Engineering Fundamentals

- Benefits: Torque, Efficiency, Power Factor, and Reliability

- Where You’ll Find Them: Common Applications

- Troubleshooting and Testing: Symptoms, Safety, and Replacement

- Design Deep Dive: Phase Shift, Windings, and Laminations Working Together

- Material and Manufacturing Options for Motor Cores

- Matching the Right Approach to Your Application

- Engineering Takeaway and Next Steps

I. Introduction: The Unseen Powerhouse in Your Motor

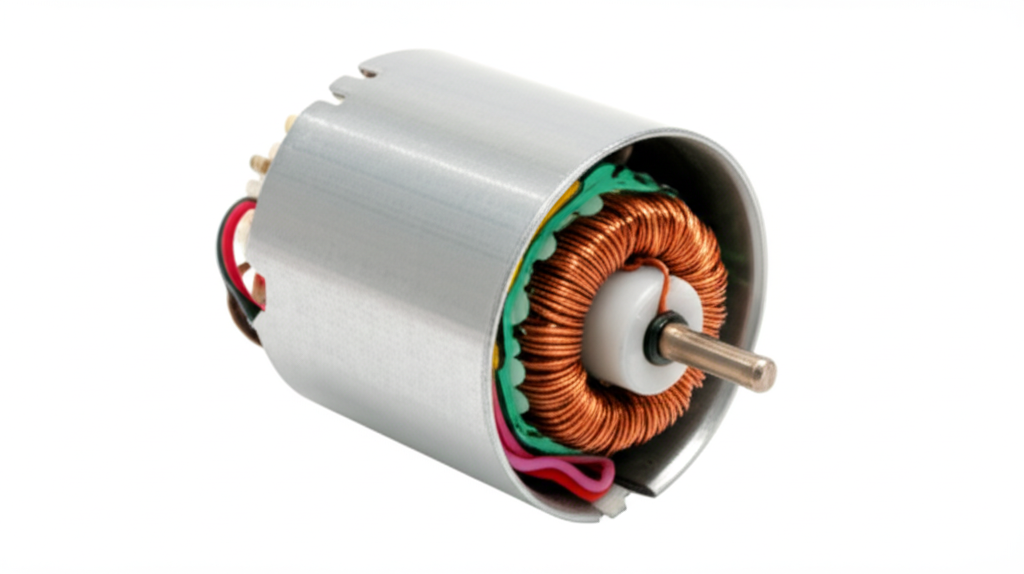

Capacitors in AC motors do two big jobs. They kickstart rotation by creating a second current path that is out of phase with the main winding then they keep the motor running efficiently with better power factor and smoother torque. Because the supply is single phase the stator’s magnetic field does not naturally rotate at standstill. The capacitor solves that core problem.

Why is this part so often misunderstood? Because it sits on the periphery of the motor yet it influences core electromagnetic behavior. It looks like a simple can yet it shapes current phase angle, torque production, temperature rise, and motor life. We’ll unpack how it works, why it fails, how to size it, and how decisions around laminations and windings raise or lower the required capacitance.

We’ll also connect the engineering dots from component‑level choices to supply chain decisions that your design team and your procurement managers must align on.

II. Why Do Single‑Phase Motors Need Capacitors? (The Core Problem)

- Single‑phase power delivers one alternating voltage wave. It energizes a stator that produces an alternating field that pulsates but does not rotate at standstill.

- The rotor sees no net starting torque from a purely pulsating field. So a single‑phase induction motor can hum loudly and not turn. That’s why you hear “motor hums won’t start.”

- You need a phase shift to create a rotating magnetic field. Introduce an auxiliary or start winding that is electrically displaced from the main winding then force its current to lead the main current using a capacitor. The two currents create a synthetic two‑phase effect which produces starting torque.

This is the heart of “single phase motor capacitor working.” No phase shift no starting torque.

III. The Two Main Roles: Start vs. Run Capacitors

A. Start Capacitors: The Initial Boost

- Function: Provide a strong burst of reactive current to create high initial starting torque. This can push a motor from 30–50% of rated starting torque to 200–300% or more when correctly sized.

- How it works:

- Connects to an auxiliary start winding with higher resistance.

- Creates a large phase shift often near 90 degrees between the start winding current and the main winding current.

- That phase difference generates a temporary rotating magnetic field that kicks the rotor into motion.

- Operation: Only active during startup for a few seconds.

- Disengagement: A centrifugal switch or an electronic relay removes it around 70–80% of synchronous speed to prevent overheating. This is your classic “centrifugal switch capacitor motor.”

- Common types: Electrolytic start capacitors designed for intermittent duty.

- Symptoms of failure: Motor hums yet won’t start. It may trip a breaker after a short delay. You’ll often see “how to test a motor capacitor” come up at this point.

What happens if the start capacitor fails? The motor draws high locked‑rotor current and buzzes. The shaft may twitch yet it won’t produce enough starting torque under load. In severe cases the winding overheats.

B. Run Capacitors: Sustained Performance & Efficiency

- Function: Maintain a controlled phase shift between the main and auxiliary windings during operation. Typical run phase angles land between 30 and 60 degrees.

- How it works:

- Keeps current in the auxiliary or run winding slightly out of phase with the main winding.

- Produces a more circular rotating field with reduced torque ripple.

- Improves power factor and overall motor efficiency especially in Permanent Split Capacitor (PSC) motors.

- Operation: Stays in the circuit whenever the motor runs. Designed for continuous duty.

- Common types: Oil‑filled or polypropylene film capacitors due to long life and stable ESR/ESL.

- Symptoms of failure: Overheating, excessive current draw, reduced torque, motor humming while running, poor power factor, nuisance trips.

What happens if the run capacitor fails? The motor may still run yet it runs hot and inefficient. You’ll see lower running torque and higher full load current which shortens insulation life.

C. Dual Run Capacitors: Two‑in‑One Convenience

- Function: Package two run capacitors in one can with a shared common terminal. Common in HVAC where one section serves the compressor motor and the other serves the condenser fan.

- Application: Used wherever two AC motors or two windings need continuous phase shift. That’s your standard HVAC capacitor role in a single can.

IV. How Capacitors Work: A Simplified Explanation

Think of a capacitor as a tiny energy reservoir. It stores energy in an electric field across a dielectric then releases it as the AC voltage swings. Because current through a capacitor leads voltage the capacitor forces the auxiliary winding current to lead the main winding current. That lead current creates the phase shift that mimics a two‑phase supply. Result. A rotating magnetic field appears from a single‑phase source.

- Capacitive reactance (Xc) sets how much current the capacitor passes at a given frequency. Xc = 1/(2πfC).

- Inductive reactance (Xl) from the windings and the magnetic circuit lags current. The capacitor offsets that lag.

- Adjust C and you adjust phase angle. Too little capacitance gives weak starting torque. Too much capacitance spikes current and stresses the winding and switch.

In short the capacitor manipulates phase angle so the stator produces the right rotating field geometry. It’s a simple device that delivers a very targeted electromagnetic job.

V. Key Benefits of Capacitors in Motors

- Enhanced starting torque: With a properly sized start capacitor a motor can produce 200–300% of rated torque at start. That’s essential for compressors and pumps with high load at zero speed.

- Improved efficiency: A healthy run capacitor can cut energy use by 5–10% in PSC motors under variable load. Less reactive current means less heat and fewer losses.

- Better power factor: A lagging 0.6–0.7 power factor can improve to 0.95–0.99 with run capacitance in the circuit. That reduces kVAR draw and helps the grid.

- Smoother operation: Reduced torque ripple lowers vibration and noise. You’ll hear the difference on fan motors and blowers.

- Extended motor life: Lower current and heat slow insulation aging. A 10°C rise roughly halves insulation life. Keep it cool and you push mean time to failure out.

VI. Common Motor Applications That Use Capacitors

- HVAC systems: Air conditioners, heat pumps, furnaces with PSC blower motors, and condenser fans use run capacitors. Compressors often rely on start capacitors or hard‑start kits.

- Refrigerators and freezers: Start and run caps appear in older designs and some specialty compressors.

- Washing machines and dryers: Split‑phase and capacitor start motors handle agitator loads and drum inertia.

- Water pumps: Well and pool pumps often rely on a run capacitor for continuous duty and efficiency.

- Air compressors: High starting torque requirements make start capacitors common.

- Garage door openers and small industrial single‑phase motors: Start and PSC styles show up here as well.

VII. Troubleshooting: Signs of a Failing Capacitor

- Motor fails to start or starts slowly under load.

- Motor hums loudly and the shaft does not rotate.

- Overheating and excessive amps at the same load.

- Reduced performance and weak output torque.

- Physical signs: Bulging, leaking oil, cracked case, or a burnt odor.

- Testing: Use a capacitance meter to check microfarad rating. Verify ESR and look for a grounded case if it is metal. Always discharge the capacitor before handling.

If you face a persistent “motor hums won’t start” scenario test the capacitor first. It’s often the first component to fail especially electrolytic start caps.

VIII. Design Deep Dive: Phase Shift, Windings, and Laminations Working Together

A capacitor does not act alone. The motor’s electromagnetic design determines how much capacitance you need, how the current splits between windings, and how robust your starting and running torque curves look.

- Winding design: The start or auxiliary winding often has higher resistance which increases phase displacement. The combination of winding resistance and reactance with capacitance sets the phase angle. Start winding resistance and run winding resistance both matter for phase control and copper loss.

- Slot geometry and core design: Stator tooth width, slot depth, and rotor bar geometry shape inductive reactance and leakage. These influence the needed capacitive reactance to hit your target phase angle.

- Laminations and material properties: Higher magnetic permeability lowers magnetizing current and helps power factor. Thickness and grade of electrical steel impact hysteresis and eddy current loss. Better laminations reduce heat which widens your thermal margin if the running capacitor drifts with age.

- Skew and torque ripple: Rotor skew reduces cogging and torque ripple which smooths operation alongside the run capacitor.

Capacitor selection works best when you pair it to the magnetic circuit honestly. If the core stacks run hot or suffer high core loss you’ll see less margin for increased current from an oversized capacitor. A poor magnetic circuit can turn a capacitor into a bandage rather than a performance tool.

For engineers reviewing supplier capability and stack quality see how the vendor manages stamping burrs, interlam insulation, and stack integrity. Those choices directly affect inductive reactance and iron loss which in turn shape your capacitor sizing window.

If you want a refresher on how the magnetic circuit sits at the heart of motor performance review the quality of the motor core laminations. It is not a side note. It is the stage on which your capacitor performs.

IX. Your Options Explained: Materials and Manufacturing That Influence Capacitor Choice

A. Material Considerations

- Silicon steels (CRNGO and CRGO):

- Non‑oriented electrical steel (CRNGO) works well for rotating machines where flux rotates through all directions in the sheet plane. It balances cost and performance for general‑purpose single‑phase motors.

- Grain‑oriented electrical steel (CRGO) is optimized for transformers where flux aligns with the rolling direction. You rarely select CRGO for motors although some specialized axial flux or one‑direction designs appear in research.

- Pros: Readily available, cost effective, predictable B‑H curves.

- Cons: Losses climb at higher frequency which matters for small high‑speed motors.

- Higher performance alloys:

- Cobalt‑iron alloys offer very high saturation and low loss at elevated frequencies. They cost more yet deliver power density for aerospace or high‑speed compressors.

- Pros: Lower iron loss and higher saturation push torque density up.

- Cons: High cost and tougher stamping or machining requirements.

- Lamination thickness:

- Thinner laminations lower eddy current loss by breaking up the electrical path. They also raise manufacturing cost.

- Thinner stacks support higher frequency operation which reduces the capacitor’s needed reactive power for the same phase angle since magnetizing current drops with better materials.

- Dielectric considerations inside the capacitor:

- Polypropylene film run capacitors offer stable ESR and low losses across temperature.

- Electrolytic start capacitors are compact and inexpensive but only for intermittent duty.

For a quick resource on the sheet material used in cores look into electrical steel laminations. The grade and coating choice directly influence core loss and your power factor targets.

B. Manufacturing & Assembly Processes

- Stamping vs laser cutting:

- Stamping dominates high volume. It delivers tight tolerances and speed. Tooling cost is the trade‑off.

- Laser cutting suits prototypes or low volumes with complex geometries. It may introduce heat‑affected zones if not controlled which can alter magnetic properties at the edge.

- Interlocking, welding, bonding:

- Interlocking tabs assemble laminations like LEGO bricks. This speeds production and avoids thermal damage from welding.

- Bonding with resin reduces vibration and noise. It can improve stack rigidity which reduces audible buzz during running torque ripple.

- Skewing and rotor bar design:

- Skew helps suppress slot harmonics and torque ripple. This complements the smoother rotating field produced by a run capacitor.

- Quality control:

- Insulation coating consistency reduces interlam shorting which directly impacts eddy current loss and temperature rise. Tighter QC buys you longer life for both windings and run capacitors.

If you are tuning phase shift and chasing lower losses the lamination stack matters as much as the capacitor can. The quality of the stator core lamination and the balance of the rotor core lamination fix the baseline magnetizing current your capacitor must correct.

X. Selection, Sizing, and Testing

A. Capacitor Sizing for Motors

- Microfarad rating (µF): Start capacitors run high µF per HP because they must deliver a large phase shift fast. Run capacitors use lower µF values selected to optimize efficiency and torque at the operating point.

- Voltage rating: Choose a rating that exceeds the motor’s applied voltage with margin for transients. A common HVAC run capacitor might be 370 VAC or 440 VAC rated.

- Service factor and duty:

- Start capacitors are intermittent duty. Do not leave them in circuit or they will overheat.

- Run capacitors are continuous duty with self‑healing film dielectric in quality designs.

- Sizing effects:

- Undersized run capacitor: Poor power factor, high current, hot motor.

- Oversized run capacitor: Elevated circulating reactive current, risk of over‑current in the auxiliary winding, and possible resonance in motor circuits. It can reduce life.

If you mis‑size the capacitor you change locked rotor current and full load current. That can trip breakers and stress the motor control unit.

B. How to Test a Motor Capacitor

- Safety first: Disconnect power. Verify with a meter. Discharge the capacitor with a resistor before you touch it.

- Capacitance measurement: Compare measured µF to the nameplate ± tolerance. A 10% deviation often signals aging for run caps. Start caps can drift more.

- ESR and leakage: Elevated ESR or visible bulging means replacement.

- Visual inspection: Oil leaks, cracks, or swelling show failure.

C. Replacement and Safety

- Discharge before handling: Even a small film capacitor can hold a sting.

- Match µF and equal or higher voltage rating. Replacing with a lower voltage part invites short life.

- Follow the schematic. A wrong connection can put a start capacitor across the line continuously which will destroy it.

- Observe local codes: The National Electrical Code (NEC) and your facility’s standards dictate safe installation and grounding practices.

XI. Where Capacitors Fit in Common Motor Types

- Capacitor Start Induction Run (CSIR) Motor: Uses a large start capacitor and a centrifugal switch. High starting torque then the start circuit opens after spin‑up.

- Permanent Split Capacitor (PSC) Motor: Uses a run capacitor only. Lower starting torque yet excellent efficiency and power factor during operation.

- Capacitor Start Capacitor Run (CSCR) Motor: Uses both a start and a run capacitor. Delivers high start torque and strong running efficiency. Common in heavy residential and light industrial loads.

- Split‑phase motor without capacitor: Uses resistor‑based phase shift. Cheaper yet offers lower starting torque and worse power factor.

- Shaded pole motor: Uses a shading coil instead of a capacitor. Cheap and simple for very low power fans. Capacitors rarely used here.

- Universal motors and three‑phase induction motors: Three‑phase motors do not need capacitors for phase shift because the supply already provides a rotating field. Universal motors run on AC or DC and use brushes with different physics.

XII. Data and Business Case: What the Numbers Say

- Starting torque boost: Without a start capacitor a single‑phase induction motor often produces only 30–50% of full load starting torque. A properly sized start capacitor can push that to 200–300% or more. This prevents stalls and overheats at startup.

- Power factor improvement: Run capacitors can lift power factor from 0.6–0.7 lagging to 0.95–0.99 lagging. That reduces kVAR costs for industrial users.

- Energy savings: Healthy run capacitors often reduce energy use by 5–10% in PSC motors under variable loads. The savings compound over the equipment life.

- Thermal life: Every 10°C over the insulation rating can halve winding life. A correct run capacitor keeps current down and temperatures in check.

- Failure patterns and costs: Start capacitors often fail first. Run capacitors typically last 5–10 years depending on temperature and duty. Replacing a capacitor costs a fraction of replacing a failed compressor or pump motor.

These outcomes align with field data from HVAC service organizations plus well‑established motor theory from standards bodies like NEMA MG 1 and IEC 60034. Consult manufacturer datasheets for your exact platform since each winding and core design shifts the optimal µF and voltage window.

XIII. Power Quality, Protection, and Reliability

- Voltage spikes: Motors see transients during switching. A higher voltage rating on the capacitor provides margin. Some systems add surge protection upstream to protect both windings and capacitors.

- ESL and ESR: Equivalent series inductance (ESL) and resistance (ESR) determine ripple current and self‑heating. Film capacitors boast low ESR for long life. Elevated ESR creates heat which accelerates failure.

- Resonance in motor circuits: A poorly selected capacitor can resonate with motor inductance at supply frequency or harmonics. You’ll hear noise and see elevated current. Avoid by following application notes and testing across load range.

- Utility harmonics: Distorted waveforms raise capacitor stress. Specify quality film dielectrics and verify temperature rise under worst case THD.

XIV. Procurement Notes: What to Ask From Suppliers

- Tolerance and stability: Ask for run capacitors with tight capacitance tolerance and data on drift over temperature and time.

- Life test data: Seek IEC or UL endurance testing results. Film self‑healing data helps you understand failure modes.

- Environmental ratings: Temperature class, vibration resistance, and enclosure requirements matter in pumps, compressors, and outdoor HVAC.

- Traceability: Labeling, lot tracking, and RoHS/REACH compliance streamline your quality system.

- Integration with motor design: Ask your motor supplier to document phase angle, power factor, and current for your chosen capacitor under full load and part load. Verify across your voltage tolerance window.

XV. Frequently Asked Engineering Questions and Key Terms

You might be searching for several of these topics. Here’s a concise cross‑reference that ties back to concepts covered above.

- Motor start capacitor function and how a capacitor starts a motor: It forces phase shift in the start winding to generate starting torque. See CSIR and CSCR.

- Run capacitor purpose and benefits of a run capacitor: Improves power factor, smooths torque, and enhances efficiency in PSC and CSCR designs.

- Difference between start and run capacitor: Start is electrolytic and intermittent duty with high µF. Run is film and continuous duty with lower µF.

- Single phase motor capacitor working and split‑phase motor capacitor: Both rely on phase shift. Split‑phase may use resistance or a small capacitor for start.

- Capacitor start induction run motor vs permanent split capacitor motor: CSIR delivers higher starting torque. PSC focuses on running efficiency.

- Dual run capacitor purpose: Two capacitors in one can for compressor and fan motors in HVAC.

- Phase shift in induction motor and capacitor phase angle: Run caps typically target 30–60 degrees. Start caps push toward 90 degrees.

- Creating rotating magnetic field with auxiliary winding capacitor: That’s the two‑phase effect from one phase supply.

- Power factor correction motor capacitor and reduced current draw motor capacitor: Run caps lower magnetizing current and reactive power.

- Improve motor efficiency with capacitor and energy savings motor capacitor: Expect 5–10% in many PSC applications.

- How to test a motor capacitor and replacing a faulty motor capacitor: Measure µF and ESR. Replace with equal µF and higher or equal voltage rating.

- Signs of a bad motor capacitor or capacitor failure symptoms motor: Bulging can, oil leakage, humming, overheating, and slow starts.

- Motor capacitor wiring diagram and motor winding capacitor connection: Start cap to start winding via switch or relay. Run cap in series with auxiliary winding for PSC.

- Capacitor sizing for motors and importance of correct capacitor sizing: Mis‑sizing causes heat, poor PF, or resonance. Size by test for your winding design.

- Microfarad rating motor capacitor and common motor capacitor values: Values scale with HP and geometry. Always confirm against the motor nameplate and manufacturer recommendation.

- Dual run capacitor purpose in HVAC capacitor role: Shared can reduces footprint and wiring clutter.

- Compressor motor capacitor function and fan motor capacitor explanation: Compressors need start boost. Fans often use PSC with run caps for smooth low‑noise operation.

- Washing machine motor capacitor and refrigerator motor capacitor: Start and PSC arrangements both appear in appliance motors.

- Electric motor starting torque, running torque improvement capacitor, torque ripple reduction capacitor: Start caps raise starting torque. Run caps smooth running torque.

- Overheating motor capacitor issue and what happens if run capacitor fails: Elevated current and temperature reduce insulation life. Replace promptly.

- Energy storage in motor capacitor and capacitor discharge motor: Capacitors store energy and must be safely discharged before service.

- Voltage boost motor capacitor and starting current reduction capacitor: The phase shift creates an effective rotating field that improves start without indefinite locked‑rotor current.

- Motor capacitor voltage rating and motor capacitor service factor: Use a voltage rating with transient margin. Check duty class for ambient temperature.

- Motor performance without capacitor and impact of incorrect capacitor on motor: Expect poor start, poor efficiency, and overheating risks.

- Capacitor types for electric motors: Electrolytic for start and film for run. Oil‑filled can indicate heat dissipation and longevity.

- Oil‑filled motor capacitor vs dry motor capacitor vs film capacitor motor application: Film with oil bath or dry package for run duty. Electrolytics stay dry and intermittent.

- Ceramic vs electrolytic motor capacitor: Ceramics rarely used for motor power. Electrolytics dominate start duty due to high capacitance density.

- Capacitor ESL and ESR motor: Low ESR improves life. Control ESL to avoid resonance spikes.

- Capacitor lifespan motor, capacitor failure causes, and safety when handling motor capacitors: Heat and overvoltage drive failure. Always discharge before touching.

- Motor capacitor surge protection and voltage spike protection motor capacitor: Upstream surge suppression and higher voltage rating increase reliability.

- Starting current reduction capacitor, locked rotor current motor capacitor, and full load current motor capacitor: Proper capacitance lowers reactive current and magnitudes at both conditions in PSC.

- Horsepower rating and capacitor: µF often scales with HP but geometry and frequency matter.

- Motor vibration reduction capacitor and noise reduction motor capacitor: Better phase balance reduces torque ripple which cuts noise.

- How motor capacitor protects winding: By improving PF and limiting current which reduces heating.

- Motor start‑up procedure capacitor and capacitor for reversing motors: Reversing swaps auxiliary connections. Start circuitry must support direction change if required.

- Why capacitor is not needed for 3 phase motor: Three phases already provide a rotating field.

- Capacitor bank for industrial motors: Distinct from motor run caps. Facility PF correction sits at the distribution level rather than inside the motor.

- Understanding motor starting mechanisms and understanding electrical motor components: Capacitors integrate with windings, rotor, and stator to deliver practical torque from single phase.

XVI. “Which Application Is This For?” Matching the Approach

- Light‑duty fans and blowers:

- PSC motor with a run capacitor. Focus on low noise, high efficiency, and low cost.

- Optimize stator slots for low loss. Select a polypropylene film capacitor with tight tolerance for smooth operation across speed taps.

- Compressors and pumps:

- CSCR or CSIR when load is heavy at zero speed. You need a strong start capacitor and a robust switch or electronic relay.

- Validate locked‑rotor current and ensure branch circuit protection aligns with NEC.

- Appliances with frequent starts:

- Emphasize run capacitor quality and thermal class. Repeated starts heat the auxiliary winding and the start cap. Duty cycling matters.

- High‑speed or high‑power‑density machines:

- Consider better lamination materials and thinner gauges to reduce iron loss. That reduces magnetizing current so the run capacitor can be smaller for the same phase shift.

For context on core construction that supports these choices review the fundamentals of motor core laminations. Choices in lamination grade and stack finish ripple into ESR heating in caps and winding temperature rise.

XVII. Standards, Codes, and References

- NEMA MG 1 Motors and Generators: Defines motor ratings, temperature rise limits, and testing practices used widely in North America.

- IEC 60034 Rotating electrical machines: International standard for performance, efficiency classes, and test methods.

- UL and IEC component safety standards for capacitors: Specify test regimens for endurance, self‑healing, and fault behavior.

- Manufacturer application guides: Most motor OEMs and capacitor vendors publish selection notes for CSIR, PSC, and CSCR platforms. Use their test data and not rule of thumb alone.

These references help procurement teams anchor specifications and help engineers target realistic phase‑angle and thermal margins.

XVIII. Safety and Field Work Best Practices

- De‑energize and lock out before service. Check with a meter. Do not trust the switch alone.

- Discharge capacitors safely with a resistor. Never short terminals with a screwdriver since that can damage the component and create a spark hazard.

- Replace bulging or leaking capacitors immediately. Oil leakage signals dielectric failure.

- Verify wiring against the schematic. Dual run capacitor terminals can confuse even seasoned techs. Label C, FAN, and HERM correctly.

- Record measured µF and compare across visits. Trend data catches drift before a mid‑season failure.

XIX. How Laminations Tie It All Together

Your capacitor strategy works only as well as the magnetic core allows. If you want smoother operation, lower current draw, and higher efficiency then you must control iron loss and magnetizing current. That starts with sheet selection and stack build quality.

- Material: Choose grades with suitable loss curves and permeability across your operating induction. Better materials reduce the needed reactive current that the run capacitor must offset.

- Thickness: Thinner laminations cut eddy current loss. At higher frequencies this becomes decisive.

- Insulation coatings: High‑quality coatings keep interlam resistance high and iron loss low. They also stabilize performance over time in humid or high‑temperature environments.

- Stator and rotor stacks: Tight tolerances maintain air‑gap uniformity. A consistent air gap reduces negative sequence fields that otherwise inflate current and heat at off‑nominal operating points.

If you want a quick overview from a manufacturing perspective scan the sections on electrical steel laminations. For deeper dives into stack‑level design details the pages on stator core lamination and rotor core lamination show how geometry and process control underpin torque quality and efficiency. These choices make your capacitor work smarter not harder.

XX. Your Engineering Takeaway

- A capacitor in a single‑phase motor creates the missing phase shift. That phase shift produces starting torque and improves running efficiency.

- Start capacitors deliver short bursts of high µF then disconnect via centrifugal switch or relay. Run capacitors stay online and boost power factor while smoothing torque.

- Correct sizing matters. Too small gives weak start and poor PF. Too large risks overcurrent, resonance, and heat.

- Laminations and winding design set the baseline. Better magnetic circuits reduce required reactive current which lightens the run capacitor’s burden and improves thermal life.

- Testing and safety count. Always discharge before handling. Verify µF, ESR, and physical condition. Replace suspect parts proactively to protect the motor.

- Procurement should ask about tolerance, drift, voltage rating, endurance data, and compliance. Align capacitor specs with the motor’s magnetic and thermal design.

- Expect real business value. Proper capacitors deliver faster starts, 5–10% energy savings in PSC scenarios, higher PF, and longer motor life.

Ready to validate a design or spec a production build? Bring your motor nameplate data, winding layout, target torque, and operating conditions. A short engineering review can set the right start/run capacitance, confirm voltage margin, and align lamination choices with your efficiency and cost goals. If you’re working through stator and rotor stack decisions explore the resources on motor laminations linked above then reach out for a technical consultation with your preferred supplier.

Notes on terminology and entities covered: Capacitor, start capacitor, run capacitor, dual run capacitor, single‑phase induction motor, PSC motor, CSIR motor, CSCR motor, auxiliary winding, main winding, phase shift, microfarad rating, voltage rating, torque, starting torque, power factor, efficiency, overheating, ESR, ESL, reactance, impedance, Hertz, horsepower, compressor, fan motor, pump motor, washing machine, refrigerator, alternating current, voltage spikes, surge protection, dielectric material, polypropylene film capacitor, electrolytic capacitor, National Electrical Code, and related electrical circuit concepts.

Final check on internal links:

- motor core laminations: https://sinolami.com/motor-core-laminations/ (used once)

- electrical steel laminations: https://sinolami.com/electrical-steel-laminations/ (used once)

- stator core lamination: https://sinolami.com/stator-laminations/ (used once)

- rotor core lamination: https://sinolami.com/rotor-laminations/ (used once)

Total internal links: 4. Each used only once.