What Does a Squirrel Cage Induction Motor Do?

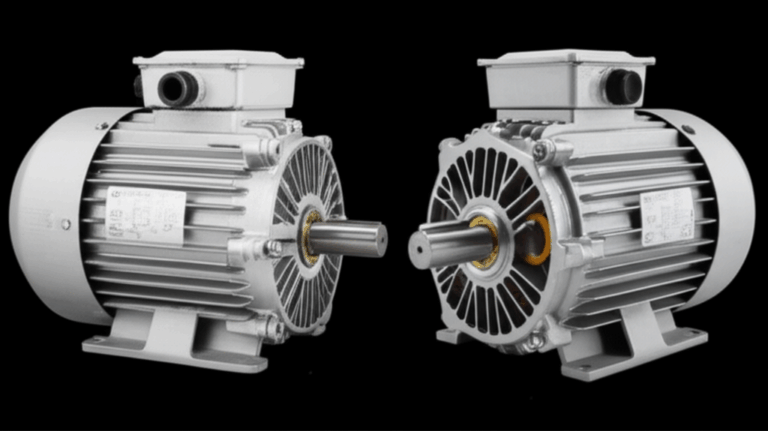

As a design engineer or procurement manager, you constantly face the challenge of selecting components that deliver maximum performance, reliability, and value. When it comes to motion, one name surfaces more than any other: the squirrel cage induction motor. You’ve likely specified them, seen them on factory floors, and heard them humming away in equipment all around you. But what is this machine really doing? How does this seemingly simple device become the powerhouse behind nearly every industry?

If you’ve ever wanted a clear, no-nonsense explanation of how this motor works, why it’s so dominant, and how to think about its role in your designs, you’re in the right place. We’re going to move beyond the spec sheet to understand the fundamental principles that make the squirrel cage motor the undisputed workhorse of the modern world. Its function is straightforward: it brilliantly converts electrical energy into useful mechanical rotational energy. This article will show you how.

What We’ll Cover

- The Core Function: A deep dive into the physics of converting electricity into powerful, rotating motion.

- Key Components: Breaking down the anatomy of the motor and the role each part plays.

- Why They’re So Popular: Exploring the key advantages that make this motor the industry standard.

- Where You’ll Find Them: A look at the vast range of common and critical applications.

- Types and Efficiency: Understanding the differences and the crucial role of modern efficiency standards.

The Core Function: Converting Electricity to Motion

At its heart, a squirrel cage motor performs a kind of magic: it creates motion without any direct electrical connections to its rotating part. The entire operation hinges on a fundamental law of physics known as electromagnetic induction.

Think of it this way: if you move a magnet near a wire, you create an electrical current in that wire. The reverse is also true—if you pass a current through a wire, it creates a magnetic field. An induction motor masterfully exploits this relationship to generate torque.

How it Works: The Principle of Induction

The process unfolds in a beautiful, sequential dance between the motor’s two main parts: the stationary stator and the rotating rotor.

Crucially, the rotor can never quite reach the same speed as the magnetic field. If it did, there would be no relative motion, no induced current, and therefore no torque. This slight difference in speed between the RMF and the actual rotor speed is called “slip,” and it’s essential for the motor to produce torque.

Why Is It Called a “Squirrel Cage”?

The name comes from the simple, robust design of the rotor. If you were to remove the laminated steel core, the remaining structure of conductive bars and two end rings looks remarkably like a hamster or squirrel exercise wheel. This “cage” is typically made of die-cast aluminum or copper bars that are short-circuited by the end rings. This simple, one-piece construction is a major reason for the motor’s incredible durability.

Key Components That Make It Work

While the working principle is elegant, the motor’s physical construction is a marvel of engineering designed for robustness and efficiency. Each component is optimized to perform its role flawlessly for years, often in the harshest environments.

Stator

The stator is the stationary outer part of the motor that houses the “engine” of the operation. It consists of two primary elements:

- Stator Core: This is a hollow cylinder made from a stack of thin, insulated electrical steel laminations. These laminations are crucial for minimizing energy losses from eddy currents, which are wasteful electrical whirlpools that generate heat. The quality of the stator core lamination is a primary factor in determining the motor’s overall efficiency.

- Stator Windings: These are insulated copper wires neatly inserted into slots within the stator core. They are arranged in a specific pattern and connected to the AC power source to generate the all-important rotating magnetic field. The integrity of these windings is critical, as winding failure is a leading cause of motor burnout.

Rotor

The rotor is the rotating heart of the motor. Unlike many other motor types, it has no windings, no brushes, and no commutator. Its simplicity is its genius.

- Rotor Core: Like the stator, the rotor core is made from a stack of thin steel laminations to reduce energy losses. The quality of the rotor core lamination is just as important as the stator’s for achieving high efficiency.

- Conductive Bars & End Rings: Embedded within the rotor core are a series of conductive bars, most often made of cast aluminum. These bars are connected—or short-circuited—at both ends by solid end rings, forming the iconic “squirrel cage” shape. It is within these bars that the current is induced, creating the magnetic field that drives the motor.

Air Gap

The tiny, precisely engineered space between the stator and the rotor is known as the air gap. This gap is a critical design parameter. It must be as small as possible to maximize the magnetic coupling between the stator and rotor, which improves the motor’s power factor and efficiency. However, it must be large enough to prevent any physical contact due to thermal expansion or bearing wear.

Shaft & Bearings

The rotor is mounted on a central steel shaft that extends out from the motor’s frame. This shaft transmits the motor’s rotational energy to the load (like a pump, fan, or gearbox). The shaft is supported by bearings, typically ball or roller bearings, which are seated in the motor’s end bells. Bearing failure is the single most common cause of motor breakdown, accounting for 40-50% of all failures, which underscores the importance of proper lubrication and maintenance.

Frame & Cooling System

The motor’s components are housed within a rugged frame, or enclosure, usually made of cast iron or rolled steel. This frame provides physical protection and serves as the backbone for mounting the motor. Most frames include external cooling fins. An internal fan attached to the rotor shaft pulls air over these fins, dissipating the heat generated by electrical and mechanical losses, thereby preventing the motor from overheating.

What Makes Them So Popular? Advantages of Squirrel Cage Motors

There’s a reason squirrel cage induction motors account for over 90% of all motors used in industrial applications worldwide. Their dominance is no accident; it’s the result of a combination of features that make them uniquely suited for an incredible range of tasks.

- Simplicity and Robustness: Their design is elegantly simple. With no brushes, commutators, or slip rings to wear out, there are far fewer parts that can fail. The rotor is essentially a solid, nearly indestructible block of metal, allowing it to withstand significant mechanical and thermal stress.

- High Reliability & Low Maintenance: This simple construction directly translates into exceptional reliability. A well-maintained squirrel cage motor can have a Mean Time Between Failures (MTBF) exceeding 50,000 operating hours. Their typical design life is 15-20 years, and maintenance is usually limited to periodic bearing lubrication.

- Cost-Effectiveness: Compared to other motor types of similar power ratings, the squirrel cage motor is generally the least expensive to manufacture. This low initial capital cost makes it an attractive choice for nearly any application where precise speed control isn’t the primary concern.

- Good Efficiency: While older models were less efficient, modern squirrel cage motors are designed to meet stringent international efficiency standards. A standard motor operates at efficiencies between 75% and 95%, and premium efficiency models can exceed 96%, translating directly into lower electricity bills.

- Versatility: They are available in a massive range of sizes and power ratings, from fractional horsepower models in your kitchen appliances to massive multi-megawatt units used in heavy industry. They can be designed to operate in virtually any environment, including explosion-proof and hermetically sealed versions.

- Self-Starting Capability: Three-phase squirrel cage motors are inherently self-starting. When connected to a suitable power supply, they immediately generate starting torque without the need for complex external starting circuits, although soft starters or VFDs are often used to manage high inrush currents.

Where You’ll Find Them: Common Applications

If you look around, you’ll see the work of squirrel cage motors everywhere. They are the invisible force powering our infrastructure, manufacturing, and even our homes. Their ability to provide constant-speed rotational power makes them ideal for applications where steady, reliable operation is key.

Industrial Machinery

This is the motor’s home turf. In industrial settings, they are responsible for an estimated 60-70% of all electricity consumption.

- Pumps: Moving water, chemicals, and other fluids in treatment plants, manufacturing facilities, and agricultural irrigation systems.

- Fans, Blowers, and Compressors: Powering HVAC systems, industrial ventilation, pneumatic tools, and process gas compression.

- Conveyor Belts: Keeping production lines moving in factories, sorting centers, and mining operations.

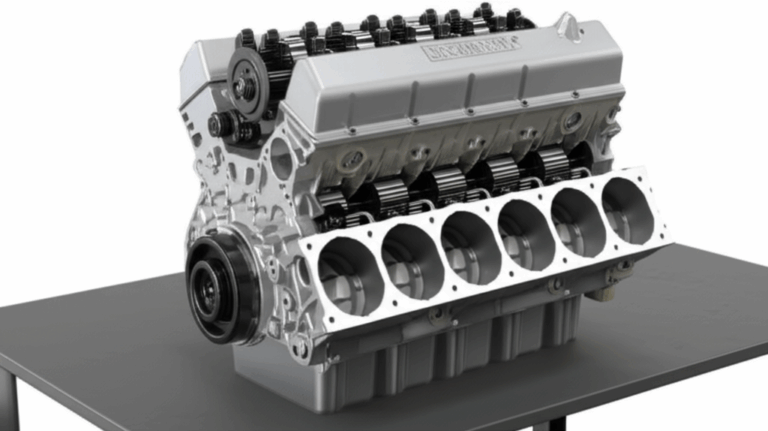

Manufacturing

From raw material processing to finished goods, these motors drive the tools of production.

- Machine Tools: Running lathes, mills, grinders, and drills that shape metal and other materials.

- Mixers and Agitators: Blending ingredients in food processing, chemical plants, and pharmaceutical manufacturing.

- Crushers and Grinders: Breaking down rock, ore, and other raw materials in mining and construction.

HVAC Systems

The air you breathe in large commercial buildings is almost certainly moved by a squirrel cage motor. They are the prime movers in air conditioners, heating furnaces, and large-scale ventilation units.

Home Appliances

While often single-phase variants, the underlying principle is the same. You’ll find them in:

- Washing machines and dryers

- Refrigerators and freezers (powering the compressor)

- Dishwashers

- Garage door openers

Agricultural Equipment

From field to silo, these motors power irrigation pumps, grain elevators, feed mixers, and ventilation fans for livestock barns.

Types and Efficiency

While all squirrel cage motors operate on the same principle, there are important distinctions to be made, primarily in their power supply and efficiency.

Single-Phase vs. Three-Phase

- Three-Phase Motors: These are the most common type found in industrial and commercial settings. They are powerful, efficient, and self-starting due to the nature of three-phase power, which naturally creates a rotating magnetic field.

- Single-Phase Motors: Used in most residential and light commercial applications where three-phase power isn’t available. They are not inherently self-starting and require an additional starting mechanism, such as a start winding with a capacitor, to create an initial rotating field to get them going.

The Critical Importance of Efficiency Standards

With electric motors consuming about 45% of all global electricity, improving their efficiency has become a top priority for governments and industries worldwide. This has led to the creation of international efficiency (IE) codes to classify motor performance.

- IE1: Standard Efficiency

- IE2: High Efficiency

- IE3: Premium Efficiency

- IE4: Super Premium Efficiency

The difference is significant. For example, a large water treatment plant facing high electricity bills from older IE1 motors could see dramatic results from an upgrade. A case study might show that by replacing 20 large pump motors with modern IE3 models paired with variable frequency drives (VFDs), the facility could achieve a 25% reduction in energy consumption. This could translate into annual savings of over $150,000 and a full return on investment in under three years, all while significantly reducing its carbon footprint.

The Enduring Legacy of the Squirrel Cage Motor

The squirrel cage induction motor is more than just a piece of machinery; it’s a foundational technology that has quietly and reliably powered progress for over a century. Its primary function—to convert electrical energy into mechanical motion—is executed with an elegance, simplicity, and robustness that remains largely unparalleled.

From the industrial behemoths that drive our economy to the small appliances that simplify our daily lives, this motor is a testament to brilliant engineering. Its legacy is not just in its past achievements but in its future potential. As we push for greater energy efficiency and smarter control systems, the squirrel cage motor continues to evolve. Paired with modern VFDs and built to super-premium efficiency standards, it is poised to remain the workhorse of choice for decades to come.

Your Engineering Takeaway

When you specify a squirrel cage motor, you’re choosing a solution built on a century of refinement. Here’s what to remember:

- Core Function: It uses a rotating magnetic field in the stator to induce a current in the rotor, creating torque through magnetic attraction and repulsion.

- Key Strength is Simplicity: No brushes or internal electrical contacts on the rotor mean extreme reliability and minimal maintenance.

- Efficiency is Paramount: Always consider the total cost of ownership. Choosing a higher efficiency motor (IE3 or IE4) often provides a rapid return on investment through energy savings.

- The Application Defines the Choice: Its constant-speed nature makes it perfect for pumps, fans, and conveyors. For variable speed needs, pairing it with a VFD unlocks its full potential.

Understanding what the squirrel cage machine does is understanding the heartbeat of modern industry. By appreciating its simple brilliance, you are better equipped to make informed design and procurement decisions that power your projects reliably and efficiently. If you have questions about selecting the right motor or optimizing its components for a specific application, consulting with lamination and motor core specialists can provide the clarity needed for success.