What Does Eddy Current Mean? Understanding the Phenomenon, Its Causes, and Applications

Have you ever wondered how an induction stove heats a pan without a flame? Or how a roller coaster can stop so smoothly without screeching brakes? The answer is a fascinating and invisible force of physics called an eddy current. These little whirlpools of electricity are all around us. Sometimes they are a huge help and sometimes they are a big problem. In this article, I’ll pull back the curtain and show you exactly what eddy currents are, how they work, and why they are so important in our modern world.

Table of Contents

- What in the World is an Eddy Current?

- How Are These Electric Whirlpools Created?

- What Do Eddy Currents Actually Do?

- So, Are Eddy Currents a Bad Thing?

- How Do Smart Engineers Fight Bad Eddy Currents?

- Can We Actually Use Eddy Currents for Good?

- How Do We Use Eddy Currents to See Inside Metal?

- How Does My Cooktop Use Eddy Currents?

- How Can Eddy Currents Stop a Roller Coaster?

- Where Else Can I Find Eddy Currents at Work?

- The Two Sides of Eddy Currents

What in the World is an Eddy Current?

Let’s keep it simple. An eddy current is a loop of electrical current that forms inside a metal or another conductor. Imagine a flowing river. If you place a big rock in the middle of it, the water swirls around the rock in little whirlpools. These whirlpools are called eddies.

Eddy currents are very similar but with electricity instead of water. When a conductor like a piece of copper or aluminum is placed in a changing magnetic field, tiny swirling currents of electricity form inside the metal. These are the eddy currents. They were first observed by the French physicist Léon Foucault in 1851. These currents flow in closed loops, like tiny racetracks, all within the material itself. They are a direct result of a fundamental principle of physics called electromagnetic induction.

How Are These Electric Whirlpools Created?

To get eddy currents, you need two things: a conductor and a changing magnetic field. The science behind this comes from two important laws of physics discovered long ago.

First, there’s Faraday’s Law of Induction. Michael Faraday discovered that if you move a magnet near a wire, you create an electrical voltage in that wire. The same thing happens if the magnetic field itself changes strength. This changing magnetic flux (the amount of magnetic field passing through an area) creates an electrical pressure, called an electromotive force (EMF). This force is what gets the electricity moving.

But which way does the electricity flow? That’s where Lenz’s Law comes in. This law is simple but brilliant. It says the induced currents will always flow in a direction that creates their own magnetic field to oppose the change that created them in the first place. It’s like nature trying to keep things stable. So, if a magnetic field is getting stronger, the eddy currents will create a field that pushes back. This push-back is what makes eddy currents so useful and sometimes so problematic.

What Do Eddy Currents Actually Do?

Once these eddy currents are swirling inside a conductor, they have two main effects.

The first and most common effect is heat. As the currents swirl through the metal, they bump into atoms. This friction generates heat. This is called Joule heating or resistive heating. The metal has electrical resistance, and forcing current through it turns electrical energy into heat energy. This can be a big problem if you don’t want the heat, but it’s the entire point of an induction cooking surface.

The second effect is that the eddy currents create their own magnetic field. As Lenz’s Law tells us, this new field pushes back against the original magnetic field. This push results in a force. If the conductor is moving, this force will try to slow it down. This is called electromagnetic damping or magnetic braking. It’s a braking force that doesn’t rely on any physical contact, which is pretty amazing.

So, Are Eddy Currents a Bad Thing?

In many cases, eddy currents are a huge pain for engineers. They represent a major source of energy loss in many electrical devices.

Think about a transformer, the big green box you might see on a power pole. Its job is to change the voltage of electricity. It does this using changing magnetic fields in an iron core. But this process creates powerful eddy currents inside the solid metal core. This is a problem. These currents do nothing useful. They just heat up the transformer, wasting a ton of energy. This wasted energy is called core losses.

This gets even worse when you think about it on a large scale. An inefficient transformer doesn’t just waste a little bit of power; it wastes it 24/7. When thousands of transformers are losing energy as heat, it adds up to a massive amount of wasted electricity and money. In some transformers, these eddy current loops can account for a shocking 10% to 50% of all the energy lost when the device is on but not doing any work. The same thing happens in electric motors and generators, where eddy currents heat the core, lower efficiency, and can even shorten the machine’s life. This is a major challenge in the power generation industry and the automotive industry.

How Do Smart Engineers Fight Bad Eddy Currents?

You can’t just wish eddy currents away. They are a basic part of physics, thanks to geniuses like James Clerk Maxwell. So, if you can’t get rid of them, what can you do? You can outsmart them.

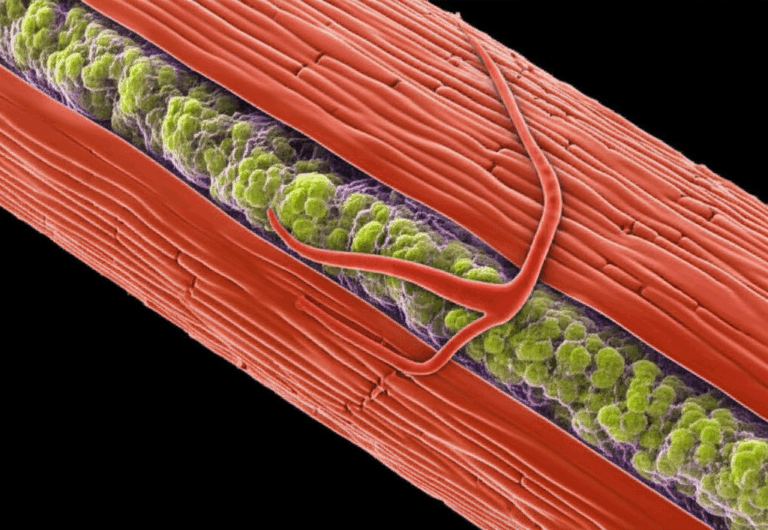

The agitation caused by these energy losses led engineers to find a clever solution. The size of an eddy current depends on the size of the path it can take. If you use a solid block of metal, the currents can be huge. But what if you broke up that path? This is the idea behind laminated cores.

Instead of a solid core, engineers build one from a stack of very thin metal sheets. Each sheet is coated with a thin layer of insulation. This forces the eddy currents to stay within each tiny sheet. They can’t cross over to the next one. This makes the eddy currents very small and weak. The result? Much less heat generation and much lower power loss. This simple idea dramatically improves the efficiency of electrical machines.

At Sinolami, we specialize in creating the perfect solution to this problem. We manufacture high-quality motor core laminations that are designed to minimize these wasteful eddy currents. Using precision-stamped silicon steel laminations, we help build motors and transformers that run cooler, last longer, and save incredible amounts of energy.

| Device Efficiency Comparison | With Solid Core | With Laminated Core |

|---|---|---|

| Energy Loss from Eddy Currents | High (e.g., 20% loss) | Very Low (e.g., <2% loss) |

| Operating Temperature | Very Hot | Cool / Manageable |

| Overall Efficiency | Low | High |

Can We Actually Use Eddy Currents for Good?

Absolutely! The same properties that make eddy currents a problem can be turned into powerful tools. Engineers have found many brilliant ways to harness the power of these swirling currents. What was once a source of waste is now the foundation for incredible technologies that we use every single day.

From cooking our food to ensuring planes are safe to fly, eddy currents have become an essential part of modern engineering. Let’s look at some of the amazing applications where we put these electric whirlpools to work on purpose.

How Do We Use Eddy Currents to See Inside Metal?

One of the most important uses of eddy currents is in a field called Non-Destructive Testing (NDT). This means testing a material for flaws without damaging it. Eddy Current Testing (ECT) is a key method used by NDT technicians.

Here’s how it works: An inspector uses a special probe that contains a coil of wire. An alternating current is sent through the coil, creating a changing magnetic field. When the probe is held near a metal part, like a wing on an airplane or a heat exchanger tube in a nuclear power plant, the magnetic field creates eddy currents in the part. These currents flow in a nice, smooth pattern.

But if there is a tiny crack, some corrosion, or another surface defect, it disrupts the flow of the eddy currents. It’s like putting a big rock in their path. The test instrument is sensitive enough to detect this tiny change in the current’s flow. A signal on the screen tells the inspector that there is a flaw. This method is so precise it can find cracks only 0.5 mm long! This is why ECT is critical for aircraft inspection and quality control in many industries. A good inspection of the stator and rotor in a large generator can prevent catastrophic failure.

How Does My Cooktop Use Eddy Currents?

If you have an induction cooktop, you are using eddy currents every time you cook. It’s a fantastic example of using Joule heating for a practical purpose.

Under the smooth glass surface of the cooktop is a powerful induction coil. When you turn it on, a high-frequency alternating current flows through this coil. This creates a very strong, rapidly changing magnetic field. When you place a pot made of a ferromagnetic material like iron or stainless steel on the cooktop, this magnetic field creates massive eddy currents in the bottom of the pot.

The pot’s own electrical resistance fights against these currents, and this battle generates a huge amount of heat directly in the pot. The cooktop itself stays cool. It’s incredibly efficient, turning about 85-90% of the electrical energy into heat for cooking. For comparison, a gas stove is only about 38% efficient! This is a perfect example of energy conversion in action.

How Can Eddy Currents Stop a Roller Coaster?

The second amazing property of eddy currents—the braking force—is used in magnetic braking systems. These brakes are used on high-speed trains, elevators, and thrilling roller coasters.

They work without any physical contact, so they never wear out. Here’s the secret: Powerful magnets are mounted on the track, and a thick metal fin, usually made of copper or aluminum, is attached to the train or roller coaster car. As the car speeds past the magnets, the motion creates huge eddy currents inside the fin.

Remember Lenz’s Law? These eddy currents create their own magnetic field that pushes back against the magnets on the track. This creates a powerful, smooth braking force that slows the car down safely and silently. The faster the car is going, the stronger the braking force, so it’s a naturally effective system.

Where Else Can I Find Eddy Currents at Work?

The applications of eddy currents don’t stop there. They are at work in many other devices.

- Metal Detectors: A metal detector works by sending out a magnetic field from a coil. When it passes over a metal object, it creates eddy currents in the object. The detector’s receiver coil picks up the weak magnetic field created by these eddy currents and sounds an alarm.

- Metal Recycling: In large recycling plants, eddy current separators are used to sort metals. A conveyor belt carries mixed waste under a rapidly spinning magnetic rotor. This creates strong eddy currents in non-ferrous metals like aluminum cans. The magnetic repulsion force actually flings the aluminum cans off the belt and into a separate collection bin. This process can achieve a separation efficiency of over 95%, which is crucial for the metal recycling industry.

- Industrial Applications: In factories, induction heating is used for heat treatment of metal parts, making them stronger. Eddy currents are also used for welds inspection, thickness measurement of coatings, and material sorting. The technology is constantly evolving with things like Pulsed Eddy Current (PEC) and Eddy Current Array (ECA) making inspections faster and more accurate. This relies on advanced sensor technology and signal processing. To ensure accuracy, these systems are calibrated using reference blocks with known defects. The solution for making these devices more efficient is often a better core, like a high-quality transformer lamination core.

The Two Sides of Eddy Currents

As you can see, eddy currents are a classic double-edged sword in the world of physics and engineering. They are a powerful force of nature governed by the laws of electromagnetism.

Key Things to Remember:

- What They Are: Eddy currents are swirling loops of electricity created in a conductor by a changing magnetic field.

- The Problem: In devices like motors and transformers, they cause unwanted heating and energy loss, reducing efficiency.

- The Solution: Using thin, insulated metal sheets called laminated cores is the best way to reduce these negative effects.

- The Benefit: We can harness eddy currents for amazing applications like non-destructive testing, induction cooking, magnetic braking, and metal sorting.

- The Principle: Their behavior is explained by two key physics principles: Faraday’s Law of Induction and Lenz’s Law.

From wasting energy in a poorly designed motor to safely stopping a high-speed train, eddy currents play a huge and often invisible role in our lives. Understanding them helps us appreciate the clever engineering that makes our world work.