What Does Motoring Mean? A Practical Guide to Motor Laminations and Modern Mobility

Every engineer who ships rotating machines knows the core question that sits behind motor performance. How do your lamination choices turn electrical energy into useful torque without wasting power as heat. If you work in automotive, industrial drives, or electrified logistics you feel this with every specification you sign. Lamination thickness, material grade, coating, and stacking method feed directly into efficiency, thermal behavior, noise, cost, and long‑term reliability. Make the wrong call and you pay twice. First in energy losses. Then in manufacturing headaches.

Here’s the twist. “Motoring” means two things to your audience. In everyday language it’s road travel and vehicle operation. In electric machines it’s the mode where electrical input produces mechanical output. Both senses meet inside the steel core. Get the laminations right and you improve vehicle range, cooler operation, and lifetime costs. Get them wrong and you fight heat, noise, and customer complaints.

You’re in the right place if you’re weighing trade‑offs like these:

- How does lamination thickness affect motor efficiency at different frequencies

- What’s the best material for a high‑speed BLDC traction motor

- When should you use bonded stacks versus interlocks

- Where does stamping beat laser cutting and when does it not

You design. I’ll give you the engineering fundamentals, clear options, and practical next steps.

In This Article

- The Core Definition of Motoring

- What’s Really Going On: Core Losses, Flux, and Lamination Physics

- Material Considerations for Motor Laminations

- Manufacturing and Assembly Processes That Matter

- Which Application Is This For

- The Far‑Reaching Impact of Motoring

- The Future of Motoring

- Your Engineering Takeaway

The Core Definition of Motoring

When people ask “what does motoring mean” they usually mean road travel, car driving, and the whole culture around vehicle operation. Motoring includes the act of driving, the use and ownership of a motor vehicle, the regulations and road networks that support transportation by car, and the lifestyle from commuting to long‑distance journeys. It touches traffic regulations, speed limits, parking regulations, car insurance, vehicle registration, road tax, driver education, and safety features like ABS, airbags, and seatbelts. It spans the automotive industry from car manufacturing to the global automotive market, plus motor sports like Formula 1 and rally driving. It also includes modern dynamics like ride‑hailing, car sharing, charging infrastructure for electric vehicles, and connected cars with GPS and telematics.

Inside the machine world motoring has a precise meaning. An electric machine “motors” when it converts electrical power into mechanical power. Generating is the opposite. When your traction inverter commands positive torque on a Tesla or Toyota e‑axle the machine runs in motoring mode.

These two meanings meet in one uncompromising set of decisions. The laminations in the stator and rotor shape how efficiently your vehicle moves down the road. That’s true for induction machines in commercial vehicles and for BLDC or PMSM drives in passenger EVs. It’s true for motorcycles and buses too. In short, motoring in society rides on motoring in machines.

If you’re new to laminations here’s the first anchor point. A motor core uses very thin, insulated sheets of electrical steel stacked into a stator and rotor. Those thin sheets slash eddy currents and hysteresis losses so you get torque instead of heat. The quality of your motor core laminations directly sets the ceiling for efficiency, thermal margin, noise, and cost.

What’s Really Going On: Core Losses, Flux, and Lamination Physics

Let’s strip it down to fundamentals without the fog.

- Magnetic permeability: Think of it as how easily a material lets magnetic field lines move through it. Like a sponge soaking up water. Higher permeability in your electrical steel helps you carry flux with less magnetizing current.

- B‑H curve: This curve tells you how much field (H) it takes to reach a given flux density (B). The loop you get when cycling the material shows hysteresis loss. Wide loop equals more loss.

- Coercivity: The material’s resistance to being demagnetized. Lower coercivity usually means lower hysteresis loss.

- Core losses: Two main buckets dominate in electrical steels.

- Hysteresis loss comes from flipping magnetic domains each cycle. It scales roughly with frequency and with a power of flux density. A first‑order model uses Ph ~ kh f B^n where n often sits between 1.6 and 2 depending on grade.

- Eddy current loss comes from circulating currents induced by changing flux. Think of eddy currents like small whirlpools in a river. The changing magnetic field tries to spin little electrical loops inside the steel that turn power into heat. Lamination thickness and resistivity are your breakwaters. Thinner sheets and good insulation chop the big whirlpools into tiny ones. Eddy loss scales strongly with lamination thickness, frequency, and flux density. A common model is Pe ~ ke t^2 f^2 B^2.

- Excess loss or anomalous loss: A catch‑all for microstructural effects that don’t cleanly fit the simple models. It shows up more at higher frequencies.

- Frequency and waveform: Higher frequency and richer harmonics raise loss. PWM inverters add harmonic content that drives additional core heating. Smooth sinusoidal excitation behaves better than a choppy waveform.

- Stress and burrs: Mechanical stress from stamping, interlocking, welding, or even tight fits increases local losses. Burrs create shortcuts for eddy currents. Good edges matter.

- Temperature: Loss behavior drifts with temperature because resistivity and magnetic properties shift as the core heats.

In practical design you balance these levers:

- Use thin laminations when frequency climbs.

- Choose grades with low core loss at your operating B and f.

- Maintain sharp edges and low burr height.

- Add appropriate insulation coating for higher interlaminar resistance and safe stacking.

- Manage mechanical stress through process selection and post‑processing.

Typical lamination thickness ranges

- 0.50 to 0.35 mm for general‑purpose motors at line frequency.

- 0.35 to 0.27 mm for higher performance industrial machines.

- 0.20 to 0.10 mm for high‑speed, high‑frequency machines like traction drives, aerospace pumps, and compact BLDC motors.

The stator does the heavy lifting because it carries concentrated slots and teeth. Slotting introduces space harmonics and local saturation at tooth tips. The rotor responds differently depending on topology. Induction rotors handle cage effects and rotor bar resistance. PMSM rotors concentrate flux around magnets and bridges. Both benefit when you control flux paths with well‑designed laminations.

If you prefer a picture, imagine your core as a stack of LEGO bricks. Each plate has a thin insulating film. That film forces currents to stay tiny and local. The brick stack guides flux around the stator teeth and across the air gap to develop torque with minimal waste. Interlocking tabs join the bricks without overheating the steel. Bonded stacks glue them into a monolith without welding heat‑affected zones. You keep the flux where you need it and block the currents you don’t.

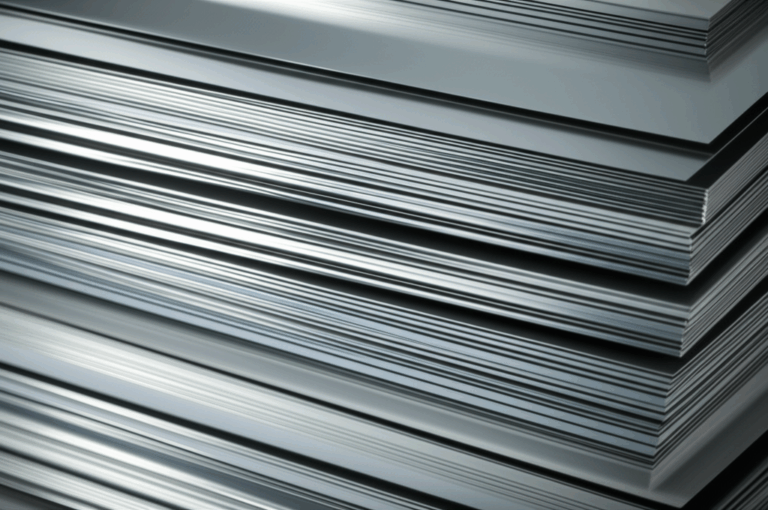

Material Considerations for Motor Laminations

Picking a lamination material feels like choosing the right blade for a cut. You can always cut with the wrong blade, but you won’t like the finish or the time it takes. Here’s a clear, unbiased look at common options and where they shine.

Silicon Steels (Non‑oriented Electrical Steels, NOES, M‑grades)

- Use cases: General‑purpose motors, induction motors, BLDC stators, alternators.

- Why engineers pick them: Good balance of cost, permeability, and core loss. Isotropic properties in the plane of the sheet help with rotating fields.

- Grades: Often described with M numbers such as M19, M27, M29, M36. Lower numbers generally indicate lower loss at a given thickness. Standards like ASTM A677 and IEC 60404 outline performance and test methods. Manufacturers also publish Epstein frame data so you can compare P1.5/50 or similar points.

- Pros: Widely available. Cost effective. Good performance across a range of flux densities and frequencies.

- Cons: Not the lowest loss at high frequencies. Not suitable where grain direction optimization matters.

For an overview of the role and range of electrical steel laminations in rotating machines, start with the basic property set: loss, thickness, permeability, yield strength, and coating class.

Grain‑Oriented Electrical Steels (GOES)

- Use cases: Transformers and devices with near‑unidirectional flux like E‑I and UI laminations. Less common in rotating machines.

- Why: Very low loss along the rolling direction.

- Pros: Best‑in‑class efficiency for transformer cores in power grids and chargers.

- Cons: Rotating machines see flux rotating through many angles. GOES loses its advantage off the rolling direction. That is why you rarely use it in motor stators or rotors.

You’ll see GOES in classic transformer cores like E‑I and UI stacks, CRGO material, and amorphous ribbon cores. Those matter for onboard chargers and power conversion but not often for traction motors.

Cobalt‑Iron Alloys

- Use cases: Aerospace actuators, high power density motors, high‑speed spindles.

- Why: Higher saturation flux density than silicon steels. You can run at higher B before saturation.

- Pros: Supports compact designs and higher torque density. Useful when you want more headroom at elevated B.

- Cons: Expensive. Harder to process. Higher mechanical hardness can affect tool wear and burr management.

Amorphous and Nanocrystalline Alloys

- Use cases: High‑frequency transformers, some specialized axial flux motors.

- Why: Very low core loss at high frequency because of high resistivity and unique domain behavior.

- Pros: Excellent for power electronics magnetics and certain niche motor topologies.

- Cons: Brittle ribbon. Challenging to stamp. Limited standard motor geometries.

Soft Magnetic Composites (SMC)

- Use cases: 3D flux machines, integrated stator housings, compact axial flux designs.

- Why: Powdered iron particles with insulating coatings allow 3D flux paths and low eddy currents in all directions.

- Pros: Good for complex 3D flux and integration with cooling features. Often near‑net‑shape compaction.

- Cons: Lower permeability and higher hysteresis loss than premium laminations at lower frequencies. Mechanical properties can limit thin features.

Lamination Coatings

Insulation coatings raise interlaminar resistance and manage corrosion and assembly friction. Inorganic phosphate, organic varnish, and hybrid coatings each offer different dielectric strength and weldability. You’ll often see coating classes called out by manufacturers with stacking factor targets. You want a high stacking factor so your net magnetic cross‑section stays close to the nominal stack height.

Typical Data You Should Ask For

- Epstein frame or single‑sheet tester loss curves across B and f. Look for P1.0/400, P1.5/50 etc. to match your application.

- B‑H curves and permeability versus B.

- Mechanical properties for stamping and handling.

- Coating class, dielectric breakdown, and stacking factor.

- Post‑processing guidance for temper or stress relief anneals if needed.

Standards and methods worth knowing

- IEC 60404 series for magnetic measurements of electrical steels.

- ASTM A677 for non‑oriented electrical steel. ASTM A343 covers alternating current magnetic properties by Epstein frame.

- NEMA MG 1 for motor design and performance categories.

Manufacturing and Assembly Processes That Matter

Materials set the ceiling. Manufacturing decides how much of that ceiling you keep.

Stamping

- Best when: You need high volume, consistent quality, tight tolerances, and low piece cost per part.

- Pros: Progressive dies deliver speed and repeatability. You can control burrs and establish high stacking factors with stable geometry.

- Cons: Upfront tooling cost. Tool maintenance. Die stress can elevate local losses unless you mitigate with good tool steel, sharpness, and sometimes a stress relief anneal.

Laser Cutting

- Best when: You prototype, run low volumes, or need complex shapes with fast design iteration.

- Pros: No hard tooling. Quick changes. High precision for intricate slot geometries and PM pockets.

- Cons: Heat‑affected zones raise local loss. Edge recast layers may need removal. Lower throughput than stamping for volume runs.

Wire EDM and Waterjet

- EDM: Excellent edge quality and tight tolerances with minimal burrs. Slow and costly for production. Good for test rings and sample stacks.

- Waterjet: Avoids thermal effects but often leaves rough edges that increase local loss. More common in heavy plates than thin laminations.

Post‑Processing and Stress Management

- Stress relief anneal: Can recover magnetic performance after aggressive cutting or stamping, especially in thick or high grade steels. Follow material supplier guidance for time and temperature to avoid grain growth that hurts mechanical properties.

- Deburring and edge conditioning: Keep burr height low to prevent interlaminar shorts. Check burr direction versus stacking direction.

- Cleaning: Maintain coating integrity. Avoid solvents or abrasives that degrade insulation.

Stack Assembly Methods

- Interlocking: Tabs formed in the lamination connect layers mechanically. Think LEGO bricks snapping together. Good for speed and avoiding weld heat. It can slightly reduce stacking factor and create micro‑stress areas.

- Welding: Spot weld or laser stitch the stack. It offers rigidity at the cost of local heat‑affected zones that raise loss around welds.

- Riveting or cleating: Simple, robust, and familiar. Adds hardware and can introduce local stress.

- Bonding: Adhesive bonded stacks reduce vibration, lower audible noise, and eliminate interlaminar fretting. You cure the adhesive to create a rigid monolith without welding heat. Bonding often improves loss and NVH performance at the cost of process complexity and cycle time.

When you evaluate assembly, ask for data on stack concentricity, slot opening uniformity, runout, and stacking factor. Those directly impact electrical performance, rotor‑stator airgap quality, and mechanical balance.

For geometry specifics on stator laminations used in everything from pumps to traction drives you can review a dedicated primer on stator core lamination. For the matching rotor topologies see rotor core lamination.

Which Application Is This For

Different motor types live by different rules. Let’s match typical lamination choices to the jobs engineers ask them to do.

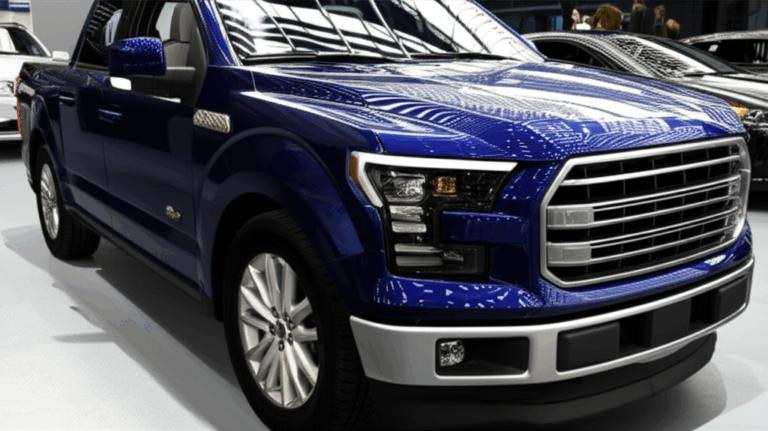

BLDC and PMSM Traction Motors

- Context: Electric vehicles in the automotive industry from Tesla and BMW to Volkswagen, Mercedes‑Benz, Honda, and Nissan. You find these in motorcycles, buses, and commercial vehicles too.

- Design drivers: High efficiency across a broad speed range. Low core loss at high electrical frequencies. Tight NVH targets. Strong thermal margins for fast charging and repeat accelerations.

- Materials: Thin NOES, 0.20 to 0.27 mm typical for mainstream drives. High‑speed units may push thinner. Some designs consider Co‑Fe for higher B in compact packages.

- Processes: Stamping for production. Laser for prototyping. Bonded stacks for NVH control and loss reduction. Interlocking when you want fast assembly without heat input.

- Notes: PM rotor design demands careful web and bridge geometry to control flux leakage and mechanical stress at speed. Use skew and slot geometry to reduce cogging.

If you are working through an early prototype of a BLDC stator stack with complex slot shapes and skew options you may find this overview of a BLDC stator core helpful as a starting point for tolerances and stack strategies.

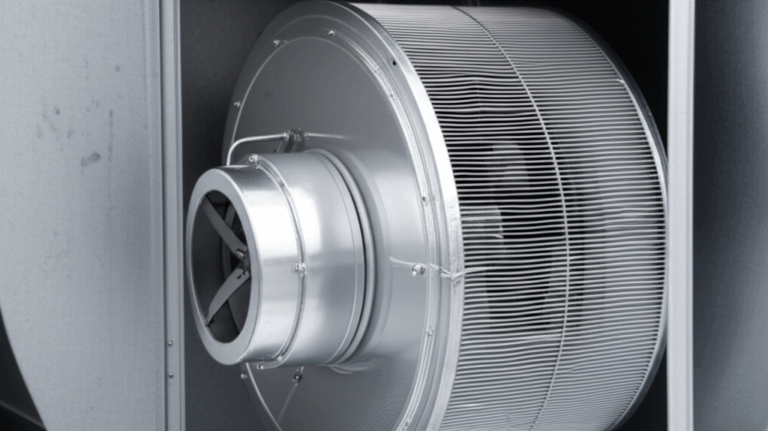

Induction Motors

- Context: Industrial drives, pumps, fans, compressors, and legacy automotive auxiliaries. Durable and cost effective.

- Design drivers: Robustness and cost. Efficiency standards like IE3/IE4 push toward better steels and thinner laminations.

- Materials: NOES M27 or better with thickness 0.35 mm common. High performance units move to 0.27 mm and lower.

- Processes: Stamping plus interlocking or welding. Copper rotor bars for premium efficiency. Aluminum die cast for cost.

Switched Reluctance Motors (SRM)

- Context: Applications where simplicity and fault tolerance win. Some traction drives and pumps lean this way.

- Design drivers: Wide constant power range with rugged construction. Acoustic noise can be a challenge.

- Materials: NOES with lower loss grades because high ripple currents and harmonics raise core heating.

- Processes: Stamping for both stator and rotor. Tight control of burrs and coating integrity.

Transformers and Power Electronics Magnetics

- Context: Onboard chargers and DC/DC converters that support EVs and hybrids. Grid equipment and charging infrastructure.

- Design drivers: Very low core loss under near‑unidirectional flux. Frequency ranges from line to tens of kHz for power electronics.

- Materials: GOES for line frequency. Amorphous or nanocrystalline for high frequency.

- Processes: E‑I, UI stacks, toroids, and ribbon wound cores.

- Notes: These are cousins to motor stacks yet they answer different physics because the flux direction is mostly fixed.

High‑Frequency Actuators and Aerospace

- Context: Flight controls, compressors, and pumps where power density rules.

- Design drivers: Size and weight first. Efficiency and heat next. Cost can be secondary.

- Materials: Co‑Fe alloys. Very thin laminations.

- Processes: Precision stamping or EDM. Bonding preferred for rigidity without weld heat.

Prototyping vs Production

- Prototyping: Laser cut or EDM for speed and iteration. Accept higher loss for a few parts. Target fast learning.

- Production: Progressive die stamping for volume and cost. Plan for die amortization. Qualify coating adhesion and stacking factor early.

A final note on standards and verification. Validate your laminated stacks using recognized methods. IEC 60404 for magnetic properties. NEMA MG 1 for machine performance. ISO 9001 for quality systems. If your application faces regulated environments like the Department of Transportation or NHTSA guidelines for vehicle safety, your documentation discipline matters. Test early. Measure loss. Confirm that the numbers you expect at P1.0/400 make sense in the assembled core under inverter excitation.

The Far‑Reaching Impact of Motoring

You might wonder why an engineering guide about laminations spends time on the broader motoring picture. Because your design choices ripple outward. They shape how people move, what they pay, and how clean the air stays.

- Scale: The global vehicle fleet topped roughly 1.446 billion vehicles in operation in 2022 according to OICA. That is a lot of machines turning electrical and chemical energy into motion.

- Economics: The automotive industry directly and indirectly employs tens of millions and drives around 3 percent of US GDP and about 5 percent of EU GDP per recent ACEA and OICA summaries. Your sourcing decisions in vehicle operation and vehicle manufacturing echo through supply chains and logistics.

- Safety: Road safety remains a pressing challenge. The World Health Organization estimates about 1.19 million road traffic deaths per year. Better drivetrains will not fix every cause of accidents yet smoother torque control, fewer thermal events, and reliable operation support safer vehicles. Add vehicle safety features like ABS, airbags, seatbelts, lane keeping assist, adaptive cruise control, and parking assist, and you see why motoring’s safety story keeps improving although it has more work left.

- Environment: Road transport produces nearly three quarters of transport CO2 emissions and around 15 percent of total global CO2 per the IEA. That’s why electric vehicles, hybrid cars, and sustainable transport options attract so much attention. Lower core losses translate to longer EV range or smaller battery packs. You reduce carbon emissions at the source and cut energy costs over the vehicle life.

- Daily life: Commuting times in major cities run 20 to 60 minutes or more with London near 40 minutes and New York near 36 minutes. Traffic congestion, parking regulations, and speed limits affect personal mobility and public perception of motoring. Better efficiency and smarter controls help reduce fuel consumption and range anxiety whether you burn gasoline or run lithium‑ion batteries.

- Policy and regulation: Agencies like the EPA, DOT, NHTSA, and state DMVs shape emissions standards, safety certification, and driver’s license requirements. Outside the US, EU vehicle emissions standards, UNECE regulations, and local departments do the same. Your motor’s efficiency plays a quiet but real role in meeting fleet CO2 targets and in satisfying charging infrastructure constraints.

- Culture and sport: From vintage motoring and classic car rallies to Formula 1 and the World Rally Championship, performance innovations often trickle down. Motor sports push materials, bearing designs, and cooling strategies that eventually land in road cars. Many of those improvements begin with the magnetic core.

As you choose lamination stacks for industrial drives, you also influence urban commuting, urban planning, and infrastructure development. Motoring sits inside a wider mobility ecosystem that includes public transport, ride‑hailing, car sharing, logistics and transport for supply chains, and commercial vehicles that keep cities supplied.

The Future of Motoring

Where does it go from here. You see the signals every day.

- Electrification: Global EV sales surpassed 10 million in 2022 and took roughly 14 percent of the new car market per the IEA. That’s a fast step up from 9 percent in 2021 and less than 5 percent in 2020. Electrification places your lamination selections at center stage. Better steels, thinner sheets, and smarter stacking cut loss so your traction battery goes farther.

- Alternative fuels: Hydrogen fuel cell vehicles need high‑efficiency electric machines for air compressors and traction drives. Your lamination choices affect the entire energy chain. Fuel cells reward low parasitic loads.

- Autonomous driving and smart mobility: Self‑driving technology from companies like Waymo, Cruise, and Tesla depends on reliable actuators, power steering pumps, and traction motors. Connected cars use telematics and GPS to optimize routes and improve safety. That puts a premium on reliability and thermal stability in every drive unit.

- Mobility as a Service: Car sharing and ride‑hailing change the duty cycle. Vehicles run longer hours with fewer cool‑downs. Thermal margins and core losses that were once “fine on average” can push you into the red. Design for elevated average temperatures and plan for predictive maintenance.

- Manufacturing innovation: Expect more adhesive bonding in stacks to reduce noise and loss. Expect finer lamination thicknesses where cost allows. Additive manufacturing for soft magnetic composites grows as 3D flux designs expand.

- Sustainability: Emissions standards toughen. You will see more stringent vehicle emissions standards for manufacturing and operation. Sustainable transport policies and resilient charging infrastructure expand. Material traceability rises in importance. Recyclability of electrical steels and magnets gets more attention.

No single answer will fit every motor. The best engineering follows the use case wherever it leads.

Your Engineering Takeaway

Here’s the concise playbook you can use this week.

- Define the duty. Quantify your electrical frequency range, waveform quality, peak and average flux density, and thermal envelope. Duty cycle beats anecdotes.

- Pick the material to fit the frequency. Use thinner NOES for higher frequency. Consider Co‑Fe only when power density demands it and the cost makes sense.

- Keep the edges clean. Control burr height. Protect coatings. Reduce stress or use a stress relief anneal when the process demands it.

- Choose the stack method for performance and cost. Bonded stacks lower loss and noise. Interlocks speed assembly. Welding locks geometry at the price of local loss.

- Validate with data. Request Epstein frame curves and B‑H data that match your operating points. Test a sample stack under inverter PWM to confirm real losses.

- Prototype at speed. Laser cut or EDM early then translate to stamping for production. Expect small shifts in loss from process change. Measure them.

- Design stator and rotor together. Flux focuses in the stator teeth yet rotor features drive mechanical margin and cogging. Use skew, slot geometry, and bridge design to hit NVH and efficiency targets. A deeper reference on stator core lamination and rotor core lamination can guide tolerances and cost levers.

- Plan for your application. Traction drives differ from pumps. BLDC motors in scooters differ from industrial servos. Match stack height, lamination thickness, and bonding to the real job. For BLDC geometries specifically, review a BLDC stator core. For the material portfolio and coating classes across applications see electrical steel laminations. When you need a broad orientation on stack categories start with motor core laminations.

A quick glossary to tie back to “motoring”

- Motoring, everyday: Car driving, road travel, vehicle operation, urban commuting, and long‑distance journeys on road networks and highways with traffic. It includes driver education, driver’s license requirements, vehicle registration, and car insurance regulated by agencies like DOT, DMV, EPA, and NHTSA. Service organizations like AAA, the RAC, and the AA support motorists with roadside assistance and travel planning. It spans benefits of driving like personal mobility and the challenges of motoring such as traffic congestion, air pollution from cars, and parking rules.

- Motoring, machine mode: Electrical input becomes mechanical output. It happens in induction motors, PMSM and BLDC motors, switched reluctance motors, and more. The stator and rotor laminations control core losses that show up as heat under load.

- Why laminations matter to both: Better laminations improve fuel efficiency in ICE vehicles by lowering alternator and pump losses. They stretch EV range by reducing motor losses. They enable smaller, lighter, and cooler powertrains that support the evolution of driving from gasoline and diesel to electric vehicles and hybrids.

Final call to action

If you want a second set of eyes on your lamination stack for a new design, bring your duty cycle, space claim, and target efficiency to a technical consult. We can walk through material options, likely manufacturing paths, and a test plan that de‑risks your next iteration. Clear data beats guesswork. Your motor will thank you when it runs cooler, quieter, and longer.

Additional context and signal to your procurement team

- Entities and ecosystems: Automobile manufacturers like Ford Motor Company, General Motors, Tesla, Toyota, BMW, Mercedes‑Benz, Volkswagen, Honda, and Nissan drive supply chain priorities for electrical steel. Public transit and urban planning shape demand for buses, trucks, and logistics vehicles. Charging stations for EVs shape cooling and footprint constraints. Hydrogen fuel cell development may shift the balance toward high‑frequency auxiliaries. Lithium‑ion battery advances tighten the range targets you have to hit.

- Standards and testing: Reference IEC 60404 for magnetic testing. Align material specs with ASTM A677 for non‑oriented electrical steel. Use IEEE papers and conference proceedings for the latest on eddy current models and loss prediction under PWM excitation. Follow NEMA MG 1 when you align motor nameplate performance with system requirements.

- Operations and maintenance: Telematics and GPS allow predictive maintenance. Low loss cores run cooler which improves bearing and winding life. That lowers total cost of ownership across fleets, especially for ride‑hailing, car sharing, and logistics and transport operators running long duty cycles.

- Public and private priorities: Emissions standards and sustainability goals push toward efficient machines. Smart mobility and connected cars will keep adding electric actuators that depend on sound lamination choices. That is true from parking assist motors to high‑voltage traction drives.

- Culture matters too: Motor sports like Formula 1 and rally championships push efficiency, power density, and cooling. Lessons learned often migrate into mainstream design. Vintage motoring and classic car rallies keep older technologies alive and interesting, yet the trajectory points toward electrification, smart mobility, and sustainable transport.

Motoring in the broad sense touches almost everything we build and buy. Motoring inside your machine decides whether you win on efficiency, cost, and reliability. Nail the laminations and you make both kinds of motoring better.