What Does the Blower Motor Resistor Do? Your Guide to Car Fan Speed Control

Table of contents

- Introduction: The little part that controls your comfort

- What is a blower motor resistor

- How a blower motor resistor works

- Ohm’s Law in plain English

- Series circuit design and speed steps

- What’s inside the resistor pack

- Why this part matters more than most people think

- Symptoms of a bad blower motor resistor

- Common causes of blower resistor failure

- Where to find it and how I troubleshoot it

- Blower motor resistor vs. PWM control module

- Replacement: DIY or call a pro

- Real-world costs, lifespan, and prevention tips

- Quick comparisons and common confusions

- FAQs

- Final thoughts

Introduction: The little part that controls your comfort

The first time I chased a “fan only works on high speed” complaint I learned a lesson I never forgot. The blower motor spun like a champ on maximum. Every other setting felt dead. The customer thought the AC compressor was failing. I checked the blower motor resistor first. Ten minutes later the fan worked on every speed again. That tiny resistor pack turned out to be the unsung hero of the entire HVAC system.

If you’ve ever wondered what controls car fan speed or why your car’s ventilation has low, medium, and high settings you’re in the right place. I’ll walk you through what a blower motor resistor does, how it works, where it lives, why it fails, and how I test it with a digital multimeter. I’ll also explain how newer vehicles use a different animal called a PWM module that does the same job with solid-state electronics.

What is a blower motor resistor

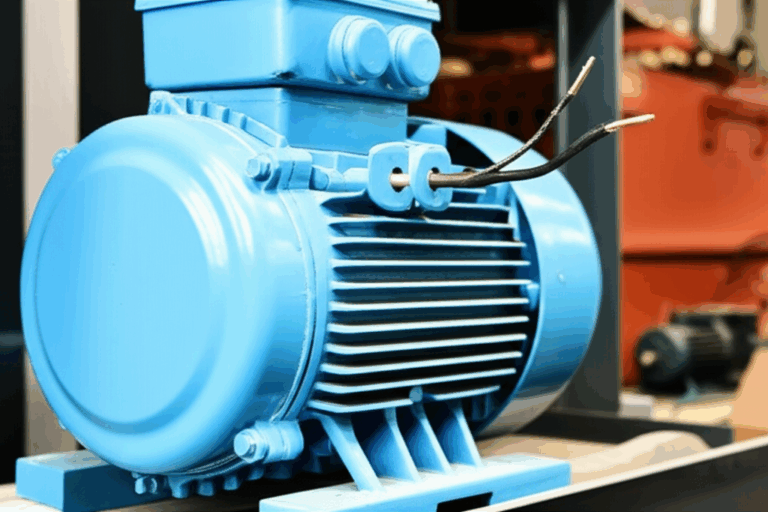

In simple terms a blower motor resistor is an electrical component that controls the speed of your car’s HVAC fan. Think of it like a dimmer switch for the blower motor. When you select low or medium on the dashboard control panel the resistor reduces the electrical current to the motor. Less current means the fan spins slower. Select high and the resistor gets bypassed so the blower motor gets full voltage.

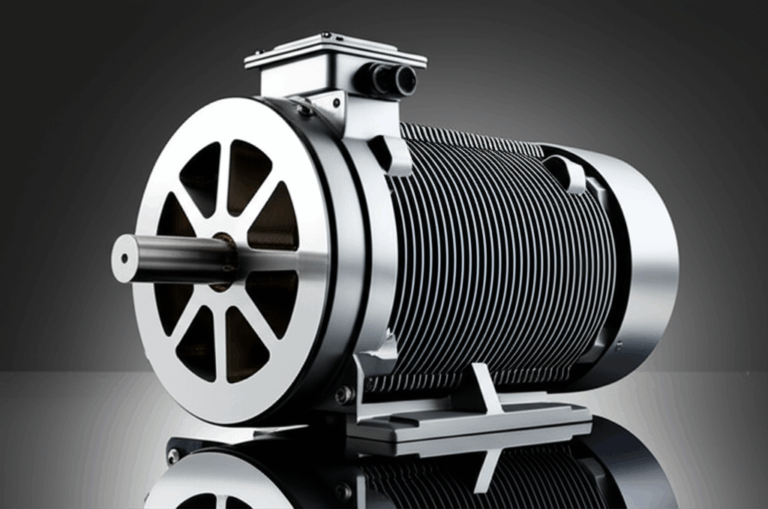

It’s not the same thing as the blower motor. The blower motor is the electric motor that physically spins the fan to push air across the evaporator or heater core. The blower motor resistor or resistor pack or fan speed control unit regulates that motor’s speed by controlling voltage and current in a series circuit.

How a blower motor resistor works

Ohm’s Law in plain English

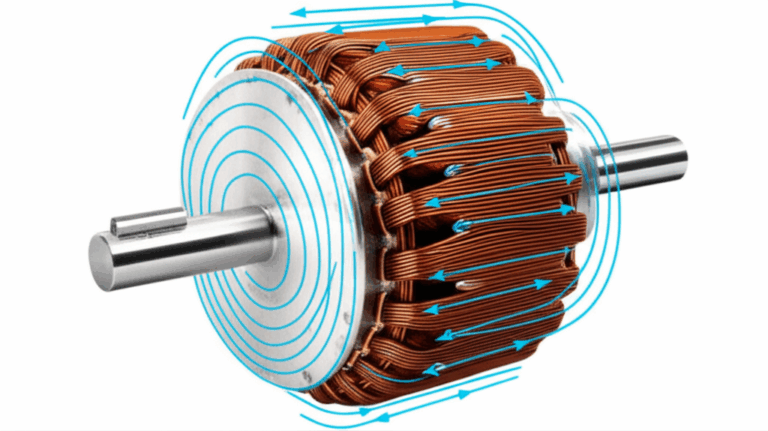

You don’t need to be an electrical engineer to get this. Ohm’s Law says voltage, current, and resistance are tied together. Increase resistance and current goes down for a given voltage. Lower current means the motor turns slower. That’s the essence of fan speed control in many vehicles. You select a speed. The circuit routes power through a specific resistor value. The resistor creates a voltage drop across itself. The motor sees the reduced voltage and spins slower.

- Voltage drop across a resistor is normal by design.

- Electrical resistance in the car fan circuit limits current.

- Current flow to the motor determines speed.

Series circuit design and speed steps

Traditional blower motor resistors use several resistive coils or wires in a series circuit. Each fan speed button or knob position selects a different path through those resistors.

- Low speed: current passes through the most resistance. The motor gets the least voltage. The fan turns slow.

- Medium-low and medium-high: current passes through fewer resistors. The motor gets more voltage. The fan speeds up.

- High speed: the circuit bypasses the resistor pack entirely using a relay or direct path. The motor receives full power from the power supply.

That’s why a common symptom shows up as “fan only works on high speed.” The high speed route avoids the resistor pack so even if the resistors burn out high still works.

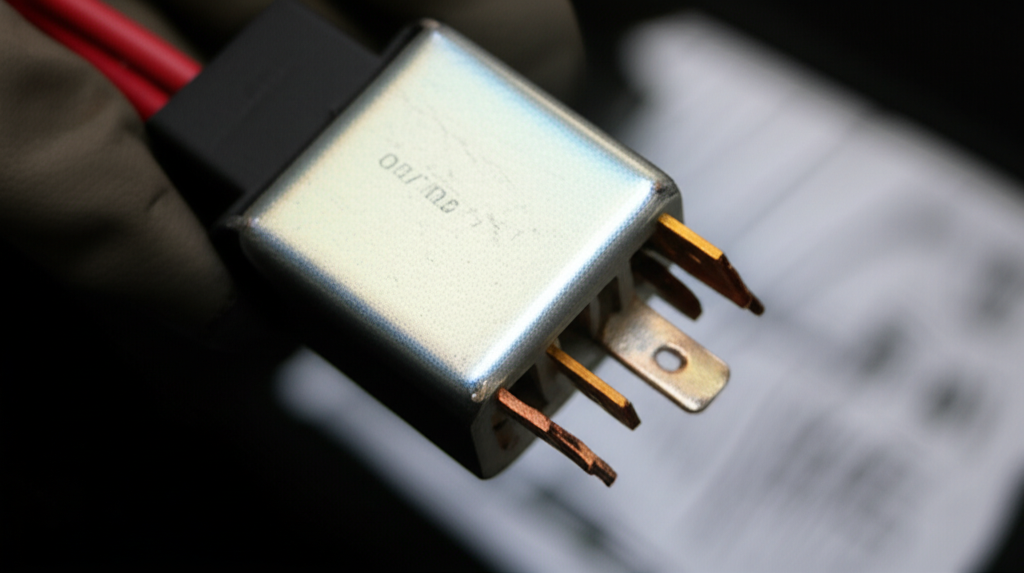

What’s inside the resistor pack

When I open a failed resistor pack I usually find:

- Resistive coils or resistance wire sized for specific steps.

- A thermal fuse that acts as a safety. If the resistor overheats the thermal fuse opens the circuit to prevent a melt-down.

- A connector that mates with the wiring harness. Corrosion or heat damage at this connector is common.

- Sometimes a simple heat sink or mounting in the blower housing to keep things cool.

This component is a classic series circuit. It has no moving parts. It sits close to the blower motor for a reason. The moving air helps cool the resistor pack because it sheds heat while dropping voltage.

Why this part matters more than most people think

A healthy blower motor resistor or its modern equivalent keeps your cabin comfortable. That means consistent car ventilation fan control for heating, cooling, and defrosting. When you need to clear a fogged windshield quickly you rely on the blower’s multiple speeds. You also want airflow you can fine tune. A weak fan on a cold morning feels miserable. A strong fan on high can be noisy. The resistor lets you pick your sweet spot.

On older designs the resistor also played a small part in energy efficiency. Lower speeds reduce power draw because the resistor limits current. Modern vehicles went further and adopted PWM modules for better efficiency and variable control. We’ll get to that in a moment.

Symptoms of a bad blower motor resistor

Over the years I’ve seen the same patterns again and again. If your car shows any of these signs you’re probably dealing with a faulty resistor or control module.

- Fan only works on high speed. This is the classic. Low and medium settings do nothing. High still blows strong because the circuit bypasses the resistor.

- No AC fan speeds at all. The fan doesn’t work on any setting. That can be a completely failed resistor, an open thermal fuse, a dead blower motor, a bad relay, or a blown fuse. I always start with the basics.

- The fan works intermittently or only on certain speeds. That usually points to partial failure of the resistive elements or poor solder joints or corrosion on resistor contacts.

- Inconsistent fan speed or fluctuations. Less common on resistor packs. More common on PWM modules or when the ground connection or wiring harness has issues.

- Burning smell in extreme cases. Overheating of the resistor can produce a hot electronics smell. I don’t ignore that.

- AC not blowing on certain settings or the fan works only on maximum setting. Different wording. Same underlying failure.

One more tip. Symptoms similar to blower motor failure can mislead you. A blower motor drawing too much current can burn up a good resistor. A restricted cabin air filter can strain the motor which overheats the resistor. Diagnose both parts together. That saves repeat failures.

Common causes of blower resistor failure

Here’s what I look for when a resistor pack dies.

- Overheating. This is the number one cause. Resistors turn extra voltage into heat. If airflow is weak or the motor draws heavy current the resistor can cook itself. The thermal fuse can open by design to protect the system.

- Blower motor drawing too much current. Worn bearings, debris on the fan wheel, or failing windings make the motor work harder. Excess current flows through the resistor pack which accelerates burnout.

- Corrosion and moisture. These parts live near the blower housing which can trap condensation. Corrosion on resistor contacts or the connector raises resistance and heat.

- Age and wear. Heat cycles fatigue the resistive coils and solder joints. Older vehicles show this a lot.

- Power surge or short circuit. I’ve seen damaged resistor packs after wiring harness faults or a short to ground. Less common but real.

- Poor ventilation around the resistor pack. Some designs put the resistor in dead air. That’s a recipe for overheating.

I’ve also diagnosed open circuit resistors where a section breaks. Sometimes I find a short circuit in a degraded coil that cooked nearby plastic. The thermal fuse often tells the story when it’s blown.

Where to find it and how I troubleshoot it

Most blower motor resistors sit near the blower motor. I usually access them from the passenger side footwell or glove compartment. Many cars place them behind the glove box with two or three small screws and a single wiring harness plug. I’ve removed some in under five minutes. A few are tucked higher in the dash. Those test your patience.

When I troubleshoot I follow a simple path.

1) Check the fuse box and related relays. A blown fuse or relay fault can mimic resistor failure.

2) Inspect the cabin air filter. A clogged filter increases current draw and heat. Replace it if it looks bad.

3) Perform a visual inspection. I look for burnt components, melted plastic, a discolored connector, or corrosion on resistor contacts.

4) Test with a digital multimeter. I check for power and ground at the connector. Then I measure resistance across the resistor terminals if the design allows. I also check voltage drop across the resistor with the fan commanded on different speeds. Ohm’s Law for resistor testing isn’t fancy. If there’s no voltage drop on a supposed low speed path the resistor might be open.

5) Verify the blower motor current draw. I use a clamp meter or check specifications. A motor that draws too much current will kill a new resistor pack. I’ve learned that the hard way.

If you prefer wiring clarity grab a wiring diagram for your vehicle. It will show the series circuit paths for each speed and the high-speed bypass. On many Ford F-150 or GM trucks you can test at the glove box opening with ease. Honda and Toyota often provide good access too.

Blower motor resistor vs. PWM control module

Not every vehicle uses a simple resistor pack. Newer vehicles and models with automatic climate control often use a blower motor control module that adjusts speed with Pulse Width Modulation or PWM. I treat the two systems differently when I diagnose them.

- Traditional resistor pack. Uses electrical resistance and heat dissipation to drop voltage. It offers discrete speeds. It’s simple and cheap. It’s less efficient because heat wastes power.

- PWM control module. Uses a solid-state device like a power transistor or MOSFET on a circuit board to switch voltage rapidly. It changes the average voltage with duty cycle control. That gives precise digital blower motor control with variable fan speed. It’s more efficient and smarter. It’s also more expensive and more complex to test.

When you see a heat sink bolted to a duct with a multi-pin connector you probably have a PWM module. The climate control unit sends a control signal. The module uses semiconductors to deliver the commanded speed. I sometimes see DTCs related to this module when the vehicle supports HVAC diagnostics. A traditional pack usually doesn’t set codes.

Replacement: DIY or call a pro

I’m a fan of DIY when it makes sense. Replacing a blower motor resistor or resistor pack often qualifies.

- DIY potential. If the resistor sits behind the glove box or low in the passenger footwell you can do it with a screwdriver or small socket set. Unplug the wiring harness. Remove the screws. Swap the resistor. Inspect for heat damage on the connector. Reassemble. Many owners finish in under an hour.

- Professional help. If access is a nightmare or your vehicle uses a PWM module that requires reprogramming or advanced diagnostics bring in an automotive technician. If your blower motor draws too much current fix that first or with the resistor. Otherwise you will burn the new part.

Cost ranges I’ve seen:

- Average part cost for a basic resistor pack runs $20 to $100. OEM parts from an auto parts store may cost more than aftermarket parts.

- Some PWM modules cost $120 to $300 or more.

- Labor cost ranges from $50 to $200 based on accessibility and shop rate. Simple access jobs take 0.5 to 1.0 hours. Dashboard-heavy jobs can take more time though that’s rare for the resistor itself.

- Total replacement cost usually falls between $70 and $300 for a basic resistor pack. PWM modules or difficult access can push the total higher.

I prefer OEM when the failure rate for aftermarket parts is high on a specific model. Some aftermarket resistor packs work well. Some don’t. Vehicle forums can be helpful for model-specific advice.

Real-world costs, lifespan, and prevention tips

From what I’ve seen blower motor resistors fail moderately often. They rank with other common automotive electrical components like alternators and relays in the “it might fail as the car ages” category. Failure rates rise with vehicle age past five to seven years. Heat kills electronics. That never changes.

Lifespan varies widely. I’ve seen resistor packs run for ten years. I’ve also seen them fail in three. The design of the resistor pack, the quality of the thermal fuse, and the cooling airflow from the blower housing all matter. The health of the blower motor matters even more.

Prevention tips that work:

- Replace the cabin air filter on schedule. A clogged filter makes the blower motor work too hard which overheats the resistor pack.

- Address a noisy or weak blower motor quickly. If you hear a chirp or feel weak airflow that isn’t in line with fan setting get the motor checked. A motor drawing too much current will burn a resistor.

- Keep the cowl area clear of leaves. Debris can steal airflow and raise heat.

- Inspect the connector and wiring harness for heat damage. If the plastic looks brown or brittle replace the pigtail along with the resistor. A loose connection raises resistance and heat which creates a vicious cycle.

Quick comparisons and common confusions

A few things trip people up. Here’s how I explain them.

- Blower motor vs blower motor resistor. The motor spins the fan. The resistor controls speed. A dead motor won’t spin on any setting including high. A dead resistor often leaves high speed working.

- Fuse vs resistor. A fuse protects a circuit by opening during an overcurrent event. A resistor intentionally drops voltage and sheds heat to control current. Both can open the circuit when they fail. They aren’t the same.

- Resistor pack vs control module. The traditional resistor pack uses resistive coils. The modern control module uses PWM with semiconductors. Both regulate blower speed.

- Motor drawing excessive current vs resistor failure. A failing motor can cause a new resistor to die early. Always measure motor current draw if you want a lasting fix.

A quick detour for the curious: how motors are built

If you like to understand the guts of electric motors you might enjoy learning how stators and rotors come together. The blower motor itself is a compact electric motor that relies on laminated iron cores to reduce eddy currents and heat. The design of the stator core lamination and the rotor core lamination affects efficiency and noise. Those laminations are made from specialized steels. If you want a wider view of the material science behind that you can explore electrical steel laminations. For a refresher on how motors convert electricity into motion you might like this primer on motor principle. None of this is required to fix your fan. It can deepen your understanding though.

How I differentiate problems fast

When a customer says “my AC fan is weak” or “my car heater fan isn’t working” I follow a quick decision tree.

- Fan only works on high speed. I suspect the blower motor resistor or thermal fuse. I check the resistor pack first.

- No speeds work. I check the fuse box, the relay, and the ground connection. Then I power the blower motor directly to see if it runs. If it runs the resistor or control module might be open. If it doesn’t the motor likely failed.

- Intermittent fan speed problem. I wiggle the wiring harness and look for a loose connector or corroded terminal. I test voltage drop across the resistor for each selected speed. I check the control panel output if needed.

- Fan speed fluctuates by itself. On PWM systems I check the control signal and the module. I also examine the circuit board for cracked solder joints or heat damage near the transistor or heat sink.

For vehicles with automatic climate control I sometimes scan for HVAC Diagnostic Trouble Codes. A DTC can point to a failed blower motor control module or a temperature sensor fault. Not all systems set codes for blower issues. I never rely on codes alone.

Tools I keep handy

- Digital multimeter for checking resistance, voltage, and continuity.

- A clamp meter for measuring blower motor current draw.

- A test light for quick power and ground checks.

- Torx and Phillips screwdrivers for glove box resistor access.

- A wiring diagram for the specific vehicle.

- Dielectric grease for connectors if appropriate. I use it sparingly.

- Replacement pigtails for melted connectors. Heat damage often means the connector needs love too.

Vehicle examples I’ve seen

- Ford F-150 blower resistor failures show the “high only” symptom often. Access is usually easy behind the glove box.

- GM trucks and SUVs with manual climate controls often share similar resistor pack issues. The connector can discolor from heat.

- Honda and Toyota sedans place the resistor near the blower housing in the passenger footwell. Two screws out. Job done.

- Luxury vehicles and late-model cars with automatic climate control favor PWM modules. These can fail due to overheating or moisture. I’ve replaced a few where a heat sink screw loosened which killed thermal transfer.

Safety notes and good habits

I always disconnect the battery if I’m working near airbag wiring or digging into the dashboard. I never poke blindly into the ducting. Sharp edges exist. I also resist the urge to “test” a circuit with a paperclip that can cause a short. Use a proper jumper wire with a fuse if you need to bypass a relay or feed the motor directly. Small habits avoid big headaches.

Keywords you might recognize in manuals and parts listings

When you shop or read service info you’ll see terms like blower motor resistor location, wiring harness blower resistor, fan speed control unit, resistor pack function, resistor module vs traditional resistor, open circuit resistor, resistor short circuit, voltage regulator for blower motor, current limiting resistor, and pulse width modulation module. All those terms point to the same basic job. The device controls current to the blower motor to adjust fan speeds.

If you search for parts you’ll also see OEM vs aftermarket options. You might see “solid state blower resistor” which is another way of saying control module. Some listings mention “thermal fuse” as a replaceable item though many resistor packs use non-serviceable fuses. Replace the pack if the fuse is integrated.

FAQs

Q: Can I drive with a bad blower motor resistor?

A: Yes you can drive. You won’t damage the engine or brakes. You might not defog your windshield quickly which hurts safety. If your fan only works on high it can blast you with noise and not much else. I fix this sooner rather than later.

Q: How long does a blower motor resistor last?

A: I’ve seen them last three years. I’ve also seen them last ten or more. Heat, moisture, and blower motor condition matter most. Replace the cabin air filter on time and address a noisy blower right away. You’ll extend the resistor’s lifespan.

Q: Is a blower motor resistor expensive to replace?

A: Not usually. Parts often cost $20 to $100. Labor ranges widely based on access. Many cars take less than an hour. Control modules on newer cars cost more.

Q: What’s the difference between a blower motor and a blower motor resistor?

A: The blower motor is the electric motor that spins the fan. The resistor or control module regulates current to control speed. If high works yet low and medium don’t the resistor or module is the suspect. If nothing works the motor could be dead or the fuse blew or the relay failed.

Q: Why does my fan only work on high?

A: High speed bypasses the resistor pack in most designs. Lower speeds depend on the resistive coils or a thermal fuse. When the coils burn out you lose those speeds. The fix is to inspect the resistor pack, the connector, and the blower motor current draw. Replace what failed. Don’t ignore a clogged cabin air filter.

Q: How do I test a blower motor resistor with a multimeter?

A: I back-probe the connector with the fan commanded on different speeds. I check for voltage drop on each speed path. On bench tests I measure resistance values across the coils. Infinite resistance means an open circuit. Zero or near zero can mean a short. I also verify power and ground integrity in the wiring harness.

Q: Where is the blower motor resistor located?

A: It’s usually near the blower motor housing. Many cars place it behind the glove compartment or in the passenger footwell. Look for a small rectangular plate held by two screws with a multi-wire connector.

Q: What causes a resistor to burn out repeatedly?

A: Excessive current from a failing blower motor, poor connector contact that creates heat, blocked airflow due to a dirty cabin filter, or water intrusion can kill resistors early. Fix the root cause or you’ll be replacing it again.

Q: Do newer vehicles still use resistors?

A: Many modern vehicles use PWM modules that control the blower motor with a transistor on a heat sink. The job is the same. The approach is more efficient and offers finer speed control.

Q: Is it safe to buy aftermarket resistors?

A: I’ve had good luck and bad luck. Some aftermarket resistor packs match OEM quality. Others run hot or fail early. If a particular model has lots of complaints with aftermarket parts I stick with OEM.

Final thoughts

A blower motor resistor doesn’t look like much yet it makes your car’s climate control feel right. It regulates blower motor voltage, drops current where you need it, and keeps your cabin comfortable. When it fails you notice it fast. The good news is you can diagnose it with basic tools and fix it for a reasonable cost.

I always follow a simple plan. Confirm the symptom. Check the fuse and relay. Inspect the resistor and connector. Test voltage and current. Verify the blower motor’s health. Replace what failed with a quality part. Then replace the cabin air filter if it’s due. That’s it. Do that and your fan speeds will return to normal. Your windows will clear. Your drive will feel comfortable again.