What is a DC Electric Motor? A Comprehensive Guide to How They Work and Their Applications

- Table of Contents

- What is a DC Electric Motor? A Comprehensive Guide to How They Work and Their Applications

- What is a DC motor in simple words?

- How does a DC motor work step by step?

- What are the parts of a DC motor and what do they do?

- What types of DC motors do we use?

- How do torque and speed work in a DC motor?

- How do you control DC motor speed and direction?

- What are the advantages and disadvantages of DC motors?

- Where are DC motors used in real life?

- DC motors vs AC motors: What’s the difference?

- How do you build, choose, and care for a DC motor?

- Who invented the DC motor and how did it grow?

- What’s next for DC motors?

- Key data and statistics

- Frequently asked questions

- Key points to remember

A DC electric motor turns electricity into motion. It uses direct current to make a shaft spin. In this guide, I show you how DC motors work, what parts they use, where you see them, and why they matter. You get plain talk, clear steps, and real uses. If you want to learn fast and choose well, you’re in the right place.

What is a DC motor in simple words?

A DC motor is an electric motor that runs on Direct Current. That means the power flows one way. Here is the electric motor definition I use. An electric motor takes electrical energy and turns it into mechanical energy to do work. So when you switch on a DC motor, it spins a rotor and creates motion you can use.

You can think of it like this. The motor takes electrical energy to mechanical energy, or mechanical energy from electrical, every single second. This direct current motor explanation sets the stage for the rest. You will see this idea again when we talk about torque, speed, voltage, current, and power.

Problem. You need to move something fast or with strong force. Agitate. Your gear sticks, your robot arm stalls, your fan chews up power and runs hot. Solution. A DC motor gives you simple speed control, high starting torque, and a tight fit for many jobs.

How does a DC motor work step by step?

Let’s break down the DC motor working principle. The principle of operation electric motor uses Electromagnetism. When current flows through a wire in a Magnetic field, it feels a push. That push is called the Lorentz Force. The wire sits in the motor armature. The magnetic field comes from Permanent Magnets or a field winding. The result is the Motor principle in action.

Here is the short path. Current enters the armature windings. The windings sit in a magnetic field. The Lorentz force makes a torque. The rotor turns. As the rotor turns, it cuts magnetic lines of Flux. This motion creates an induced EMF DC motor effect. We also call it Back EMF. Faraday’s Law explains that moving conductors in a magnetic field will make an EMF. So you see Faraday’s Law DC motor at work in every spin.

Why DC helps. The Significance of Direct Current is simple. DC makes steady current flow. That steady current flow DC motor builds a steady magnetic field in the coils. So the force stays in the right direction. In a brushed motor, the commutator flips the current at the right time. That keeps the torque pointed the same way. So the rotor keeps turning.

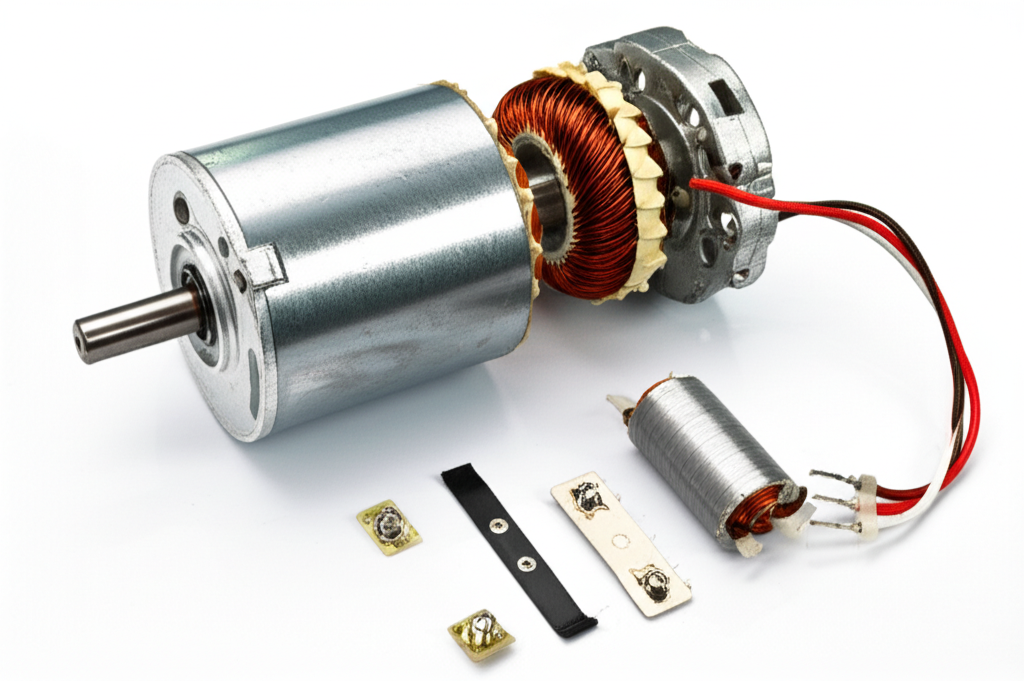

What are the parts of a DC motor and what do they do?

You will hear both components of a DC motor and parts of a DC motor. They mean the same thing. Here are the key parts and how they help.

- Stator. The stationary part. It carries the field. It can use Permanent Magnets or a Field winding DC motor. The stator sets up the Magnetic field DC motor needs.

- Rotor. The rotating part. We also call it the Armature. The armature in DC motor holds Armature windings. It sits inside the magnetic field and turns when current flows.

- Commutator. The commutator in DC motor flips the current in the armature coils at the right angle. It acts like a mechanical rectifier so the torque keeps the same direction.

- Brushes. The brushes in DC motor are often Carbon brushes. They press on the commutator and feed current from the outside circuit into the rotor.

- Shaft and bearings. The shaft carries the load. The bearings let the rotor spin with low friction.

Inside the metal body you also find the magnetic circuit DC motor uses. That includes the stator core, rotor core, Poles in DC motor, and the Air gap DC motor between stator and rotor. Designers care about flux density DC motor in the iron. They also care about winding types DC motor because the coil shape changes torque and speed.

Good cores matter, a lot. The quality of your stator core lamination and rotor core lamination cuts iron losses. Strong motor core laminations made from electrical steel help raise efficiency and lower heat. For BLDC motors, special BLDC stator core designs boost power density and smooth the torque ripple.

Problem. Your motor runs hot and loud. Agitate. Heat wastes power and shortens life. Noise hurts user trust. Solution. Use high grade laminations and tight Air gap. You get fewer iron losses, less windage losses, and better DC motor efficiency.

What types of DC motors do we use?

We group types of DC motors into brushed and brushless.

- Brushed DC motor explained

- Permanent Magnet DC motor (PMDC). The stator uses Permanent Magnets. PMDC motors are simple and common in toys DC motors, hobby motors DC, and consumer electronics DC motors.

- Series wound DC motor. The field winding sits in series with the armature. You get very high starting torque. Traction motors DC and DC motor starter drives love this.

- Shunt wound DC motor. The field winding sits in parallel as a shunt. You get steady speed regulation DC motor.

- Compound wound DC motor. Mix of series and shunt. It balances strong start with stable speed.

- Brushless DC motor (BLDC) explained

- A Brushless DC motor uses electronic commutation not brushes. How? A Controller and Driver circuit switch the currents in the stator coils. A Sensor such as a Hall effect sensor tells rotor position. The controller uses PWM (Pulse Width Modulation) to control current. So the torque stays smooth. You avoid brush wear and sparking.

- BLDC brings high efficiency and high power density. You see it in robotics DC motors, drone motors DC, HVAC DC motors, and electric vehicles DC motors.

Other notable DC motor variations:

- Stepper motor vs DC motor. A Stepper motor moves in steps and holds position. A DC motor spins free and acts smooth. Pick stepper for precision moves. Pick DC for simple speed and power.

- Coreless DC motor. Very light rotor with no iron core. Great for miniature DC motor builds in medical devices DC motors and small robotics.

- Gear motor DC. A DC motor with a Gearbox for more torque or slower speed.

- Linear DC motor. Instead of spinning, it makes straight line motion.

- Servo motors DC. A DC motor plus feedback gives you tight position control.

- Synchronous DC motor and Asynchronous DC motor. People sometimes say these names. They often point to BLDC and related AC types with DC drives. The terms come from AC motor talk. With BLDC, the rotor speed locks with the rotating field from the controller. So it acts “synchronous.”

How do torque and speed work in a DC motor?

DC motor torque comes from the product of armature current and magnetic flux. More current means more Torque. More flux means more Torque. Speed depends on the back EMF. As the rotor spins, Back EMF rises. That EMF opposes the applied voltage. So current drops and speed settles.

Here are core ideas:

- DC motor equation. A simple form is V = E + I × R. V is terminal voltage DC motor. E is back EMF. I is armature current. R is armature resistance.

- Speed law. Speed is roughly proportional to (V − I × R) divided by flux. Raise voltage or lower flux and speed goes up. Raise load current and speed drops.

- Torque-speed curve DC motor. At zero speed, torque can be high. As speed goes up, torque drops. The DC motor characteristics show a near straight line in many designs.

Designers also track DC motor horsepower. Horsepower equals Torque times Speed (with units matched). They study losses in DC motor, like copper losses DC motor in the windings plus iron losses DC motor in the core plus friction losses DC motor in bearings and windage losses DC motor from air.

How do you control DC motor speed and direction?

You have many options for DC motor speed control.

- Voltage control. Raise DC motor voltage and the motor spins faster. Lower it and the motor slows down.

- PWM. With PWM, a driver chops the voltage fast. You vary the duty cycle DC motor to set average voltage and current. PWM is efficient and cool.

- Field control. In wound field types, change the field current to change flux. Less flux gives higher speed with less torque.

Direction is easy. Swap the polarity of the armature or the field. Not both at the same time. A DC motor controller and a driver circuit make all this simple. Many use a power supply for DC motor with built in DC motor starter functions. That limits inrush current so the motor starts safe. Speed regulation DC motor matters too. A feedback loop with a Sensor like a Hall effect sensor helps keep Speed steady as load changes.

You also need clean DC motor wiring and a solid power supply. Size the wires for DC motor current. Check terminal voltage DC motor under load. Bad connections cause heat and drop power.

What are the advantages and disadvantages of DC motors?

Advantages of DC motors:

- Simple speed control with voltage or PWM

- High starting torque for heavy loads

- Great for low voltage DC motor systems like robots and toys

- Mature, low cost parts and drivers

Disadvantages of DC motors:

- Brushes wear in brushed types and add maintenance

- Sparking and electrical noise can be a concern

- Lower efficiency than BLDC in many sizes

- Heat from copper and iron losses can reduce life

Problem. Your team needs tight control and long life. Agitate. Brush wear stops your line and costs money. Solution. Use BLDC for high efficiency and long life or pick a shunt wound DC motor for steady speed with basic control.

Where are DC motors used in real life?

You see DC motors everywhere. Here are common applications of DC motors:

- Automotive DC motors. Power windows, wipers, seats, and a DC motor starter for the engine in older cars. In EVs, you see traction systems that act like BLDC or PM machines.

- Electric vehicles DC motors. Many EV powertrains use BLDC or PMSM cousins since they share the same electronic commutation idea for high efficiency.

- Robotics DC motors. Robot arm DC motors move joints with servo motors DC and gear motor DC designs. Drones use BLDC for high speed and low weight.

- Home appliances DC motors. Vacuum cleaners, fans, and smart HVAC DC motors save energy with BLDC drivers.

- Power tools DC motors. Drills, saws, and other cordless power tools DC motors use BLDC or PMDC for punch and run time.

- Toys DC motors and hobby motors DC. RC car motors DC and hobby drones use small PMDC and BLDC.

- Medical devices DC motors. Pumps and diagnostic tools need quiet, clean, and precise motion.

- Industrial DC motor applications. Conveyors, pumps, and textile machines still use DC for legacy and control ease.

- Aerospace DC motors. Actuators and fans need high power density and reliability.

- Consumer electronics DC motors. Phones and laptops use tiny motors for haptics and fans.

- Industrial automation. DC helps with indexing, pick and place, and AGVs.

Small DC motor uses range from simple fans to smart locks. High torque DC motor drives lift heavier loads. High speed DC motor drives spin tools and fans. You will also find low voltage DC motor rigs in mobile robots and high voltage DC motor sets in big traction systems.

DC motors vs AC motors: What’s the difference?

AC motor vs DC motor comes up a lot. Here is the quick view.

- Power source. DC motors run on Direct Current. AC motors run on Alternating Current.

- Commutation. Brushed DC motors use a mechanical commutator and brushes. BLDC uses electronic commutation. AC motors use line frequency fields or variable frequency drives.

- Control. DC offers simple speed control with voltage and PWM. AC needs VFDs for smooth control.

- Use cases. DC shines in batteries, mobile gear, and quick control. AC shines in mains power, pumps, and compressors.

People ask about power factor DC motor. Power factor is an AC idea. For DC you treat it as unity for the motor input. Losses still matter, so mind Efficiency.

How do you build, choose, and care for a DC motor?

DC motor construction choices shape performance. The magnetic circuit uses laminated steel to cut iron losses. Designers shape Poles and the Air gap to tune flux and torque. They pick winding types and wire size to match DC motor current and DC motor voltage. A basic DC motor diagram shows these parts and their path.

Buying tips:

- Match torque-speed curve DC motor to your load

- Check DC motor horsepower and duty cycle DC motor for your task

- Pick low voltage or high voltage DC motor to fit your power supply

- Choose PMDC for simple and light jobs. Choose BLDC for high efficiency and long life. Choose series wound DC motor for big starts. Choose shunt wound DC motor for steady speed. Choose compound wound DC motor if you want both

Care tips for DC motor maintenance:

- Keep brushes and the commutator clean in brushed types

- Lube bearings on schedule

- Watch heat. High heat kills magnets and insulation

- Use clean DC motor wiring and tight screws

If you hit a snag, start with troubleshooting DC motors basics:

- Motor will not start. Check power supply for DC motor, fuses, and the DC motor starter

- Motor runs slow. Check terminal voltage and look for high current draw and drag

- Motor runs hot. Check load, airflow, and look for friction losses or iron losses

Who invented the DC motor and how did it grow?

The history of DC motors goes back to the early 1800s. Michael Faraday showed the basics of Electromagnetic induction and the motor effect. In 1834, Thomas Davenport received a US patent for a functional DC motor. In 1873, Zenobe Gramme showed that his DC dynamo could run as a motor. People saw the power of this new machine and the industrial world changed. Later, the DC generator and DC motor powered factories and transit.

People still ask who invented the DC motor because they want the roots. The credit spans many hands. Faraday gave us the Motor principle and Faraday’s Law. Davenport and Gramme turned ideas into machines we could use.

What’s next for DC motors?

I see steady growth. Brushless keeps rising in EVs, robots, and HVAC. Power density gets better. Miniaturization continues. Better magnets and better motor core laminations cut losses. Smarter controllers add safe torque, fast response, and strong speed regulation.

Problem. Energy prices keep rising. Agitate. Waste heats your product and drains batteries. Solution. Use high grade laminations, tight stator core lamination, and tuned rotor core lamination. A trusted supplier of electrical steel laminations can help you design for low iron losses and high Efficiency. This helps robotics, Electric Vehicles (EVs), Industrial automation, and Home appliances run cooler and longer.

Key data and statistics

Here are example benchmarks and notes pulled from public sources like IEEE papers, manufacturer datasheets, and market research summaries. Values vary by size and design.

| Category / Metric | Description | Typical Data | Notes |

|---|---|---|---|

| Global Market Size | DC motors within the larger motor market | ~$40–45B in 2023 with ~6.8% CAGR to 2030 | Driven by EVs, Industrial automation, HVAC |

| Efficiency Ranges | Brushed vs BLDC | Brushed small: 50–70% | Brushed industrial: 75–88%. BLDC: 85–95% |

| Average Lifespan | Hours of operation | Brushed: ~2,000–5,000 | BLDC: 10,000–20,000+, limited by bearings and electronics |

| Cost Comparison | Relative upfront cost | Brushed: low | BLDC: higher due to controller |

| Application Growth | Fast-growing sectors | EV traction and auxiliary systems >25% YoY in some reports | Robotics ~18% growth. HVAC BLDC ~10–12% |

| Power Density | Output power per size | BLDC often 1.5×–2× brushed | Helps aerospace and drones |

References:

- IEEE Xplore Digital Library (efficiency and control fundamentals)

- Manufacturer datasheets from major motor makers (performance ranges and lifespans)

- Market research firms such as Fortune Business Insights and Mordor Intelligence (market size and growth estimates)

- Institution of Engineering and Technology (history and engineering practice)

- University motor course notes and standard texts on Electromagnetism and DC motor characteristics

Frequently asked questions

- What is back EMF in DC motors? It is the induced voltage created by the spinning armature cutting Flux. It opposes the applied Voltage and limits Current at speed.

- Do DC motors have a power factor? Power factor is an AC concept. For DC input you treat power factor as 1 at the terminals then subtract losses.

- How do I pick a DC motor controller? Match Voltage, Current, and features like PWM, braking, and direction. Make sure the driver circuit fits your power supply and duty cycle.

Key points to remember

- A DC motor turns Direct Current into motion using Electromagnetism and the Lorentz Force

- The Stator makes the Magnetic field and the Rotor or Armature carries current to make Torque

- The Commutator and Brushes in brushed designs keep torque in the right direction

- BLDC uses sensors and a Controller with PWM for electronic commutation and high Efficiency

- Match torque-speed curve, Voltage, Current, and duty cycle to your load for best results

- Cut copper losses, iron losses, friction losses, and windage losses to raise DC motor efficiency

- Use quality laminations and tight Air gap to boost performance and reduce heat

- Pick Series wound for big starts, Shunt wound for steady speed, Compound wound for a mix, PMDC for simple use, and BLDC for top efficiency

- DC motors power cars, robots, drones, tools, appliances, HVAC, and more every day

- Learn the DC motor equation and Back EMF to tune speed regulation and control

I hope this simple guide gave you clear Electric motor fundamentals and the confidence to choose, use, and care for your next DC motor.