What Is a Direct Drive Motor? Understanding Gearless Precision and Power

Every engineer has asked a version of this question. Do I really need a direct drive motor for this axis or can a geared motor do the job? If you are weighing precision, efficiency, lifecycle cost, and control complexity, you are in the right place. Direct drive motors remove mechanical transmission elements like gearboxes, belts, and chains, and they connect the motor straight to the load. That simple architectural choice changes nearly everything about performance, reliability, and design trade‑offs.

This guide explains what direct drive motors are, how they work, why they excel in high‑precision applications, and where they fit best. We also go one level deeper to the foundation that makes or breaks direct drive performance: motor core laminations, materials, and manufacturing processes. Whether you are an engineer, a product designer, or a procurement manager, you will find practical answers here.

In This Article

- Why this question matters for your design and budget

- Direct drive fundamentals in plain language

- How direct drive motors work from stator to controller

- Advantages that drive the business case

- Disadvantages and design considerations

- Direct drive vs geared motor at a glance

- Lamination fundamentals that shape direct drive performance

- Material choices for the stator and rotor core

- Manufacturing and assembly processes that affect losses and noise

- Best‑fit guidance by application

- Control, feedback, and tuning essentials

- Thermal management and duty cycle

- Real‑world numbers engineers care about

- Where the technology is heading

- Your engineering takeaway and next steps

Part 1: The Relatable Hook — Is Direct Drive the Right Approach for Your Application?

You need clean motion. You want high accuracy and smooth speed control with minimal noise. You also have a budget and a delivery timeline. Traditional geared systems feel familiar, yet they bring backlash, friction, lubricant maintenance, and long‑term wear. Direct drive motors replace those mechanical intermediaries with a high‑torque, low‑speed, gearless motor that couples directly to the load.

Here is the core design question. Does your application benefit more from gear reduction or from eliminating it entirely? If you need near‑zero backlash, tight position control, and faster dynamic response, direct drive often pays for itself over the life of the machine. If your environment is harsh, your torque is high at very low speed, and downtime is expensive, direct drive can be the quiet hero behind the scenes.

If you are designing robotics joints, precision indexers, semiconductor tools, medical imaging systems, or even a quiet washing machine drive, the answer trends toward yes. For general‑purpose conveyors or cost‑sensitive duty cycles with generous tolerances, a conventional geared approach may still fit. Let’s make this decision simple and grounded in engineering fundamentals.

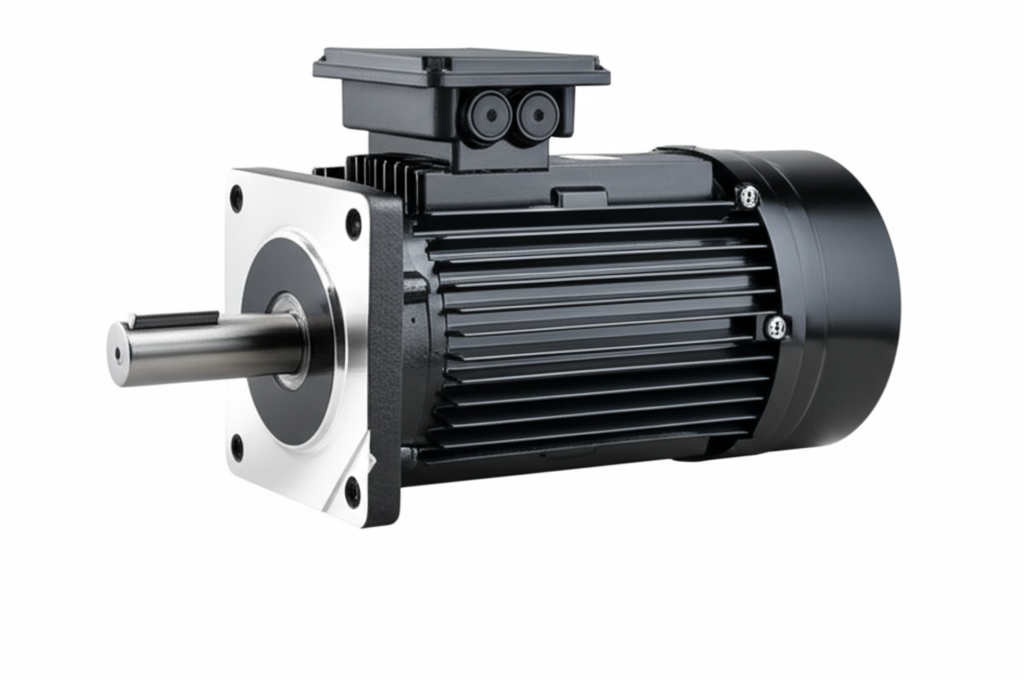

Part 2: What Exactly Is a Direct Drive Motor?

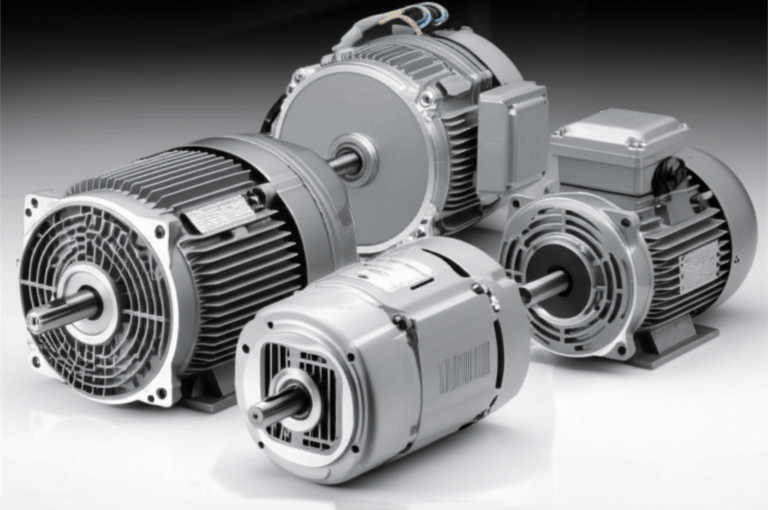

A direct drive motor is a rotary or linear motor whose rotor or moving element couples directly to the load. No gearbox. No belt. No chain. The motor converts electrical energy into mechanical torque or force right where you need it. With nothing in between, you eliminate backlash and compliance from mechanical transmissions. The result is precise, repeatable motion and a shorter mechanical power path.

Common forms include:

- Rotary torque motors for indexers, turntables, and robotic joints

- Direct drive servo motors for high‑precision positioning

- Direct drive linear motors for gantries and stages

You will also see direct drive technology in wind turbine generators, electric vehicles, washing machines, and high‑end audio turntables. Different markets same idea. Gearless torque at the load with ultra‑smooth motion.

Part 3: How Direct Drive Motors Work — The Gearless Mechanism Explained

At the heart of a direct drive motor you will find a stator and a rotor. The stator houses tightly packed copper windings that create a rotating magnetic field when energized. The rotor holds permanent magnets and connects directly to the machine element you want to move. When the stator’s magnetic field acts on the rotor magnets, torque appears. The controller times and shapes the currents so the motor delivers exactly the position, speed, or torque your application commands.

Key components:

- Stator: Laminated steel core with distributed or concentrated windings that shape the magnetic flux. The lamination design and quality set the stage for core losses and efficiency.

- Rotor: Permanent magnets arranged to produce high torque at low speed. In a torque motor the rotor often has many poles for high torque density.

- Feedback: High‑resolution encoders or resolvers provide precise position and velocity data. Some systems use sensorless control algorithms for specific applications.

- Servo drive: A closed‑loop controller regulates current, speed, and position. It also handles commutation, torque linearization, and reduction of torque ripple.

The servo loop does the steering. The stator and rotor do the heavy lifting. With no gearbox to amplify friction or backlash, the motion feels like a well‑tuned sports car on fresh pavement.

Part 4: Why Direct Drive — The Advantages That Move the Needle

When you remove mechanical transmissions, you cut out common sources of error, noise, and maintenance. Engineers often choose direct drive for these reasons:

- High precision and accuracy: With no gear teeth or belt stretch, you get virtually zero backlash. That improves positioning accuracy and repeatability, especially at reversal.

- High efficiency: You avoid gearbox friction losses, belt slip, and oil churn. More electrical energy turns into useful torque at the load.

- Reduced maintenance: Fewer wearing parts. No gear lubricant to change. No belt tensioning. Downtime drops and MTBF rises.

- Smooth and quiet operation: No gear mesh. No belt harmonics. Torque ripple can be very low with good design and control.

- High torque at low speed: Torque motors produce significant torque even at zero rpm. That removes the need for reduction stages in many cases.

- Fast response and high dynamics: The control loop sees the load directly, so it can accelerate and settle quickly with less compliance in the system.

- Compact integration: Removing a gearbox can shrink the mechanical package. You reclaim the space and simplify the layout.

Engineers also care about system stiffness and servo bandwidth. Direct coupling raises stiffness and boosts achievable bandwidth which leads to better disturbance rejection and stability at high speeds.

Part 5: Disadvantages and Design Considerations

Direct drive is not a magic wand. It brings real trade‑offs you should weigh early.

- Higher initial cost: Magnet arrays and precision feedback devices drive price. For some duty cycles a geared solution costs less upfront.

- Control complexity: You need a capable servo drive and good tuning. High‑resolution encoders and advanced current control matter.

- Thermal management: High torque at low speed means limited airflow. You must manage heat with conduction paths, heat sinks, or liquid cooling in high‑duty applications.

- Inertia matching: The motor sees load inertia directly. Large inertia ratios can impact control stability and settling time. Good tuning and motor sizing mitigate this.

- Cogging and torque ripple: Permanent magnet motors can exhibit cogging torque from slotting and magnet geometry. Proper lamination slot design, skewing, and control reduce it.

Plan for cabling, grounding, and EMI mitigation as well. High‑performance drives need clean power and careful shielding to prevent sensor noise.

Part 6: Direct Drive vs Geared Motor — A Quick, Practical Comparison

- Transmission: Direct coupling vs mechanical gear, belt, or chain

- Backlash: Near zero vs inherent backlash that grows with wear

- Efficiency: High across the speed range vs friction and lubrication loss

- Maintenance: Bearings and occasional checks vs lubrication, gear inspection, belt tensioning

- Noise and vibration: Very low vs noticeable gear or belt noise

- Precision: Higher accuracy and repeatability vs limited by gearbox compliance and backlash

- Response time: Fast with high bandwidth vs slower, affected by compliance and friction

- Initial cost: Higher for direct drive vs lower for geared in many cases

- Control complexity: More demanding servo control vs simpler control with mechanical reduction

- Peak torque at low speed: Excellent in direct drive torque motors vs often requires reduction

Some applications land in the middle. You might pair a high‑torque motor with a low‑ratios planetary gear if you need a modest reduction and a compact package. If the spec calls for sub‑arc‑second positioning or ultra‑quiet motion, direct drive stands out.

Part 7: The Often‑Missed Foundation — Laminations and Core Design for Direct Drive Performance

Here is where many evaluations fall short. The way you design and manufacture the laminated cores in the stator and rotor has an outsized impact on torque density, efficiency, heat, acoustic noise, torque ripple, and long‑term stability. Electrical steel laminations limit eddy current losses by breaking the core into thin insulated sheets. That lowers heat and keeps efficiency high at the fundamental electrical frequency and its harmonics.

Think of eddy currents like tiny whirlpools in a river. A changing magnetic field tries to spin these currents in the steel. Thinner, insulated laminations break those whirlpools into smaller ones that waste less energy and generate less heat. Hysteresis losses also matter. Materials with low coercivity switch magnetization more easily, which reduces energy lost every cycle.

Why this matters more in direct drive:

- Many‑pole torque motors run higher electrical frequencies at a given mechanical speed. Higher frequency raises eddy current and hysteresis losses in the core.

- Direct drive often runs at low speed with high current and high magnetic loading. That increases core flux density and local heating.

- Low torque ripple and low cogging require precise lamination geometry and tight tolerances.

In short, core laminations are not a commodity in high‑performance direct drive. They are the bedrock.

For a deeper overview of how laminated stacks are designed and sourced see this primer on motor core laminations.

Part 8: Material Considerations — Choosing the Right Electrical Steel or Alloy

Material choice sets the ceiling for performance. Match your application’s frequency, flux density, thermal profile, and cost target with the right material.

- Non‑oriented silicon steel (NOES, M‑grades): The workhorse for general‑purpose motors and many direct drive servos. These steels offer good permeability, moderate core losses, and reasonable cost. They handle multi‑directional flux paths which suits stator teeth and yokes in rotary machines.

- High‑grade NOES and thin gauges: As frequency rises, thinner laminations lower eddy current loss. You trade material cost and handling difficulty for lower heat and higher efficiency.

- Cobalt‑iron alloys: Exceptional saturation flux density and strength. Ideal for high power density and high‑temperature environments such as aerospace or compact medical devices where every cubic centimeter counts. The downside is cost and more demanding processing.

- Amorphous or nanocrystalline alloys: Ultra‑low core losses at high frequency. Manufacturing can be more complex and the form factor often suits transformers and select motor topologies rather than conventional torque motors. Use selectively for niche designs.

- Soft magnetic composites (SMC): Powdered iron with insulation that enables 3D flux paths. SMC can simplify some topologies. Losses can run higher at given frequencies vs laminated steels. Use case dependent.

Coatings matter too. Insulation coatings between laminations prevent interlaminar eddy currents. Choose coatings rated for your operating temperature and forming process. In torque motors that see long dwell times and high current, thermal stability of the coating is crucial.

For a quick refresher on the base materials and what separates one from another here is a useful overview of electrical steel laminations.

Part 9: Manufacturing and Assembly Processes — How They Influence Losses, Noise, and Cost

How you cut, stack, and join laminations affects magnetic properties and torque ripple. Small process errors can show up as heat, noise, or position error at the load.

- Stamping: The go‑to for high volume. With good dies and controlled burr height you get consistent parts and low cost per piece. Tooling cost is the trade‑off. Over‑burnishing or high burrs can raise losses.

- Laser cutting: Great for prototypes and low volumes or complex shapes. Heat‑affected zones must be controlled because they can increase local core losses if too wide. Laser excels at quick design iteration.

- Wire EDM: Precise edges with minimal heat‑affected zone for specialty parts. Slower and more expensive.

- Annealing: Relieves stress induced by cutting and improves magnetic properties. Not all materials and coatings require the same cycle. Follow supplier specifications closely.

- Insulation coating and thickness: Stable coatings preserve interlaminar resistance at temperature. Coating choice influences stacking factor which affects torque density.

- Stacking methods: Interlocking, bonding, welding, or riveting. Interlocks can resemble LEGO bricks and avoid heat input. Bonding with resins offers stiffness and low noise. Welds can create local stress and loss hot spots if not carefully controlled. Choose the method that serves precision, acoustic goals, and cost.

- Skewing and slot geometry: Skewed stator slots or rotor magnet arc optimization reduce cogging and torque ripple. Skew adds manufacturing complexity, yet it pays off in smoother motion.

- Tolerances and runout: Precision in lamination ID/OD and tooth geometry keeps air‑gap uniform which helps reduce harmonic content and torque ripple.

If your design hinges on very low ripple torque or sub‑micron positioning, pay extra attention to slot shape, tooth tip design, and magnet segmentation. Bring your lamination supplier into the loop early so tolerances and coating choices support your targets.

Need a refresher on the stator side details? This overview of stator core lamination covers key considerations engineers track from slot design to stacking. For the rotor magnet carrier and steel path, see this guide to rotor core lamination.

Part 10: Control, Feedback, and Tuning — Getting the Best Out of the Hardware

Hardware sets the limit. Control unlocks it. A capable servo drive and feedback device bring direct drive performance to life.

- Encoders: High‑resolution optical or magnetic encoders provide the precision needed for tight position loops. For sub‑arc‑second positioning, resolution and accuracy must match the goal, not just the marketing brochure.

- Resolvers: Rugged and temperature tolerant. Common in harsh environments. Resolution requires interpolation in the drive.

- Sensorless control: Attractive for some cost‑sensitive or compact designs. Position at standstill and low speed can be challenging without a sensor.

- Current loop and torque linearization: Field‑oriented control with fast current loops minimizes torque ripple. Include feedforward terms for rapid response.

- Disturbance rejection: With the load directly coupled, the servo loop can detect and correct small disturbances quickly. Tune filters to avoid amplifying structural modes in the machine.

- Safety and functional safety: Integrate safe torque off and speed limits when needed. Direct drive joints in collaborative robots often require layered safety strategies.

You can deliver whisper‑quiet motion with the right control plus well‑designed laminations and magnet geometry. All three matter.

Part 11: Thermal Management — Quiet Heat Is Still Heat

Direct drive motors often deliver high torque at low speed with limited airflow. Heat from copper losses and core losses must go somewhere. If the path is poor, magnets and insulation see elevated temperatures, which shortens life.

- Conduction paths: Provide solid thermal interfaces to the machine frame. Use thermal pads or pastes where appropriate.

- Liquid cooling: Torque motors in compact envelopes benefit from cooling jackets or internal channels. Liquid cooling pulls heat efficiently at steady high loads.

- Temperature sensors: Embed sensors in windings or the stator yoke. Tie them into the drive to limit current when temperatures rise.

- Duty cycle modeling: Model both copper and core loss under realistic motion profiles. Many duty cycles look benign in RMS terms yet still spike temperatures at dwell due to core loss.

Plan for heat early and you avoid nasty surprises in test.

Part 12: Common Applications and Why Direct Drive Wins There

- Industrial automation and robotics: High‑speed pick‑and‑place, collaborative robot joints, and SCARA arms benefit from low backlash and high dynamic response. Lighter joints improve payload and cycle time.

- CNC machining and machine tools: Direct drive rotary tables and linear axes improve contour accuracy and surface finish. No gearbox backlash to fight in tight corners.

- Semiconductor manufacturing: Wafer handling, lithography stages, and inspection tools demand ultra‑smooth, contamination‑free motion. Direct drive reduces particles and noise.

- Medical devices: Surgical robots and imaging equipment like MRI or CT use quiet, precise motion. Reduced vibration improves image quality and patient comfort.

- Renewable energy: Direct drive wind turbines eliminate gearboxes in nacelles which improves reliability and lowers maintenance at height.

- Electric vehicles: Some architectures use direct drive for propulsion. Others deploy it in subsystems and e‑axles where backlash and noise reduction help.

- Consumer appliances: Quiet operation and energy savings matter in washing machines and premium turntables. Direct drive delivers both.

- Printing and packaging: Accurate web handling, tension control, and fast indexing improve throughput and reduce waste.

Across these examples, you see a pattern. Precision, efficiency, low noise, and long life push teams toward direct drive.

Part 13: Direct Drive Pros and Cons for Procurement and Program Managers

You own cost, schedule, and risk. Direct drive affects all three.

- Total cost of ownership often favors direct drive when downtime and maintenance drive cost. Upfront hardware may cost more.

- Lead times can be longer for custom torque motors and matched feedback devices. Early engagement mitigates this risk.

- Supplier capability matters. The quality of laminations, magnet sourcing, and assembly processes show up in torque ripple and heat. Audit and qualify suppliers carefully.

- Spares and service are simpler with fewer mechanical parts. Electronic spares and diagnostics dominate instead of gear sets and lubrication procedures.

Direct drive is a strategic choice. It often lowers lifetime cost and raises performance if the program can absorb the initial investment.

Part 14: Real‑World Numbers Engineers Care About

Published industry data and vendor case studies consistently show:

- Overall system efficiency tends to land in the 85 to 95 percent range for direct drive systems, while comparable geared systems often run 70 to 85 percent after mechanical losses.

- Backlash in direct drive is effectively zero for practical purposes. High‑grade gearboxes advertise arc‑minute performance which can drift with wear.

- Maintenance drops to bearing checks and periodic inspections. Gearbox lubrication and belt replacements leave the picture.

- Mean time between failures often improves because the gearbox is no longer the limiting factor.

- Torque ripple can be held to a few percent with good design and control. Gear wear can worsen ripple and noise over time in mechanical transmissions.

- Response time improves because the drive sees the load without compliance and friction in between.

Take these as directional benchmarks. Actual numbers depend on motor sizing, lamination grade and thickness, magnet design, slot geometry, drive tuning, and the duty cycle you care about.

Part 15: Which Application Is This For? A Best‑Fit Guide

- High‑precision robotics joints: Direct drive torque motors shine when you need low backlash and fast response. Verify inertia ratio and cooling.

- Semiconductor and metrology stages: Choose direct drive linear or rotary with tight lamination tolerances and skewed slots to minimize cogging. Use high‑resolution encoders and clean cable routing.

- Machine tools and indexing tables: Direct drive improves contour accuracy and cycle time. Confirm thermal behavior under worst‑case dwell and cutting loads.

- Medical imaging: Direct drive reduces vibration and acoustic noise. Ensure materials and coatings meet cleanliness and magnetic compatibility requirements.

- Wind turbines: Gearless generators reduce maintenance in hard‑to‑reach nacelles. Control strategies and thermal design must support long life under variable wind profiles.

- Cost‑sensitive conveyors and pumps: A geared motor may still win on upfront cost and simplicity. If tolerances are modest and downtime is manageable, stay pragmatic.

Be honest about constraints. Laser cutting is perfect for prototypes and complex, low‑volume shapes. Stamping owns high volume with tight cost targets. Bonded stacks deliver low noise which helps in medical and semiconductor equipment while interlocking can reduce heat input and preserve magnetic properties.

Part 16: Direct Drive, Harmonic Drives, and Other Alternatives

Sometimes you want low backlash but do not want to go fully gearless. Harmonic drives offer very low backlash in compact packages. They introduce compliance and can wear under high reversals. Planetary gearboxes deliver high torque density with modest backlash at reasonable cost. Belt drives isolate vibration and can run quietly, yet they bring compliance and periodic tensioning.

Ask the hard question. Do I need zero backlash at the output or is low backlash good enough with less control complexity? If the answer is zero or near zero, direct drive is the cleaner path.

Part 17: Practical Sizing and Selection Tips

- Start with load torque and speed. Direct drive motors are happiest at low speed with high torque.

- Look at electrical frequency at target speed. Many‑pole designs increase electrical frequency. Choose lamination thickness and grade accordingly.

- Model thermal behavior for your exact duty cycle. Include dwell torque and holding current.

- Check inertia ratio. If the load inertia dwarfs the rotor, include feedforward control and avoid over‑aggressive position loop gains.

- Specify torque ripple limits and cogging torque targets up front. These requirements drive lamination shape, magnet geometry, and skew.

- Confirm encoder resolution and accuracy. Do the math against your position tolerance at the load.

- Plan the mechanical interface early. Bolt patterns, air‑gap uniformity, and mounting stiffness matter as much as the datasheet.

Close the loop with your lamination supplier once your torque ripple and loss targets are clear. Good laminations make good motors. It really is that simple.

Part 18: Entities and Components You Will See in Specs and Quotes

Expect to discuss:

- Stator, rotor, and permanent magnets

- Bearings and cooling systems

- Encoders, resolvers, and feedback systems

- Servo drives and controllers

- Torque, speed, efficiency, cogging, torque ripple, harmonics, and inertia

- Synchronous motors, brushless DC motors, and stepper motor variants used in direct drive configurations

- Integrations in robotics, CNC machining, semiconductor manufacturing, medical technology, renewable energy, and industrial automation

- Names like Kollmorgen, Siemens, Bosch Rexroth, Yaskawa, and Parker Hannifin in the ecosystem

Tie those nouns back to your outcomes. Higher motion precision. Lower operating temperature. Less maintenance. Longer life.

Part 19: Future Trends — Where Direct Drive Technology Is Headed

- Higher power density: Better magnet materials and refined lamination stacks push torque up in smaller packages.

- Miniaturization: Micro direct drive actuators enter lab automation and medical devices.

- Advanced sensorless control: Improved estimators make sensorless operation more reliable at low speed for some classes of machines.

- AI‑assisted tuning and predictive maintenance: Drives learn your machine dynamics and flag bearing or insulation issues before they cause downtime.

- Better thermal paths: Integrated liquid cooling and 3D heat‑spreading structures keep temperatures in check.

- Cleaner assembly: Low‑outgassing bonding and cleaner coatings expand adoption in vacuum and cleanroom environments.

These advances widen the window where direct drive beats mechanical reduction on both performance and cost of ownership.

Part 20: Tying It Back to the Stack — Why Your Lamination Partner Matters

Your lamination stack is not a back‑office detail. It is the spine of your direct drive motor. Tight control over material grade, thickness, coating, slot geometry, skew, and stacking method drives the headline metrics you sell to your customers. Torque density. Efficiency. Acoustic noise. Torque ripple. Thermal behavior. If you need a quick standby resource, this page on motor core laminations gives a solid overview. Then dive into the stator side with stator core lamination, and round out your rotor design with rotor core lamination. For material baselines and coatings revisit electrical steel laminations.

Work with your supplier as an engineering partner. Share torque ripple targets and thermal constraints early. Align on annealing, coating, and stacking before tooling locks in. That collaboration shortens your path to a quieter, cooler, more precise direct drive system.

Part 21: Your Engineering Takeaway — Problem, Explain, Guide, Empower

Problem:

- You must pick between direct drive and geared motion. Precision, efficiency, and lifecycle cost all hang in the balance.

Explain:

- A direct drive motor couples the rotor directly to the load. No gearbox. You remove backlash and transmission losses. Laminations, magnet geometry, and control shape torque ripple, losses, and heat.

Guide:

- Choose direct drive when you need high precision, low noise, and fast dynamics. Weigh higher upfront cost against lower maintenance and higher efficiency. Match lamination material and thickness to electrical frequency and thermal limits. Pick manufacturing methods that preserve magnetic properties and support your noise targets.

Empower:

- Next steps you can take this week:

- Define your required torque, speed range, and position accuracy at the load. Include duty cycle and dwell conditions.

- Set torque ripple and cogging targets in your spec. Aim for a few percent or better if the application is sensitive.

- Select lamination material and thickness based on frequency and temperature. Confirm coating class and stacking factor with your supplier.

- Decide on manufacturing for your volume. Laser for prototypes and complex low volume. Stamping for production with controlled burrs and post‑process annealing as needed.

- Choose encoder resolution and a servo drive that supports fast current loops plus torque linearization.

- Model thermal paths early. Add conduction or liquid cooling if continuous torque runs high.

- Engage your lamination and motor suppliers with real numbers. Ask for loss models and stack drawings tied to your targets.

You now have a clear view of what a direct drive motor is and why it matters. You also know how lamination choices and manufacturing processes drive the results you care about. If you want a second set of eyes on material selection or stack construction, reach out to your preferred lamination partner for a technical review. A short conversation now prevents costly redesigns later.