What Is a Fried Motor? Understanding Causes, Symptoms, and Solutions

A “fried motor” sounds scary. It should. It means a motor has suffered major damage. Often from heat. Often from bad power. Sometimes from both. In this guide I show you what “fried” means in simple words. I show you causes. I show you signs. I show you how to diagnose and what to do next. You will learn how to prevent it too. Read on to save time, money, and stress.

Table of Contents

- What Does “Fried Motor” Mean?

- How Does a Motor Work?

- What Gets Damaged First?

- Why Do Motors Burn Out?

- What Are the Signs of a Fried Motor?

- How Do I Diagnose the Damage?

- Repair or Replace: Which Is Best?

- What Will It Cost?

- How Do I Prevent Motor Burnout?

- What About Special Cases like HVAC, Pumps, Fans, and Cars?

- What Does the Nameplate Tell Me?

- Case Study: The Cost of Overheating

- How SinoLami Helps Build Better Motors

- FAQ

- Key Takeaways

- References

What Does “Fried Motor” Mean?

When people say a motor is “fried,” they mean it has severe damage. Often the electric motor windings got too hot. The insulation broke down. A short circuit formed. The motor will not run or it runs very poorly.

A fried motor can come from overheating, electrical overload, a voltage surge, a ground fault, or bearing failure. You might see smoke. You might smell a burning odor. You might trip a circuit breaker the moment you start it. Once a motor fries it often needs major work. Sometimes you must replace it.

I learned this the hard way. I ran a small AC motor too long under load. It got hot. I smelled that sharp scorch smell. The motor slowed down. It stopped. It was fried. I did not forget that lesson.

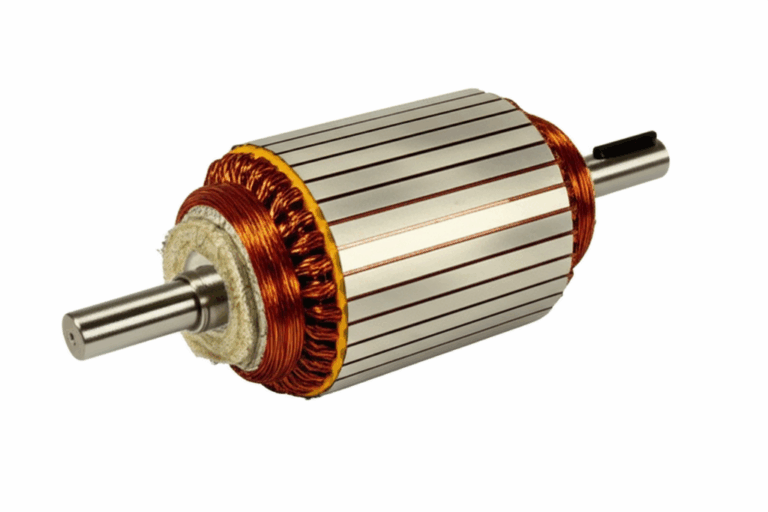

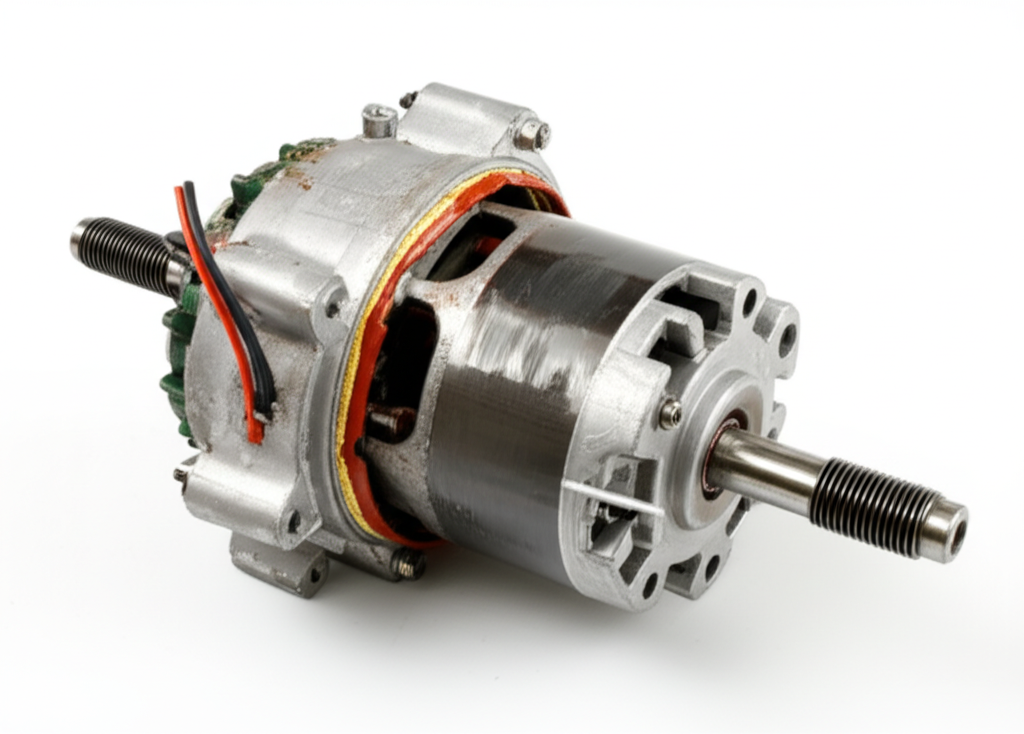

How Does a Motor Work?

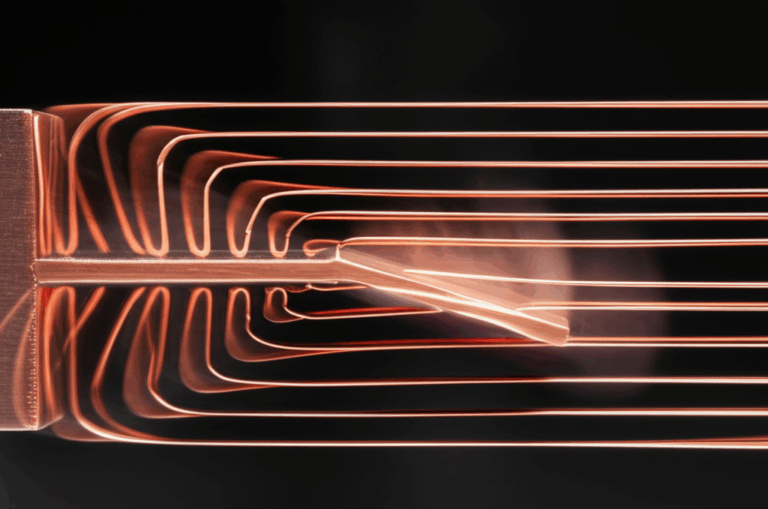

Let’s keep this simple. Think of a motor like a sandwich of key parts that spin a shaft. The stator stays still. The rotor turns. Inside the stator sit motor windings made of copper wire with enamel coating. The windings make a magnetic field when power flows. The rotor reacts and spins.

- In an induction motor the stator makes a moving field. The rotor follows.

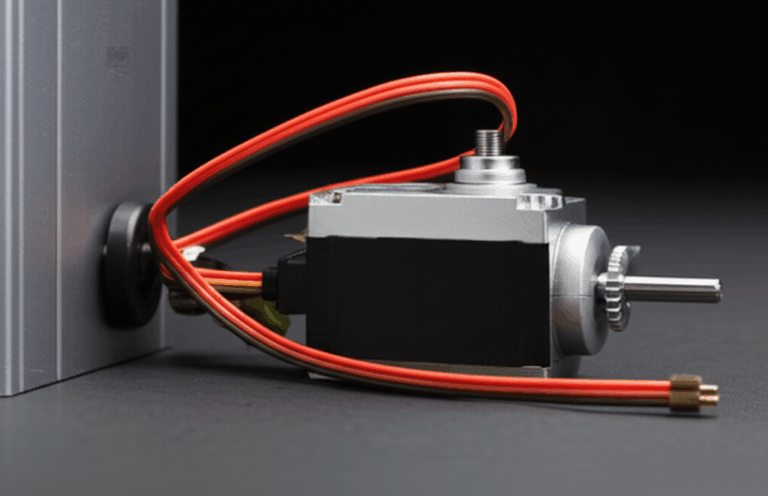

- In a DC motor you may see a commutator and brushes.

- A universal motor runs on AC or DC.

- A fan motor or pump motor or compressor motor all use these basics.

Motors need clean power. They need good lubrication in the bearings. They need cooling from a cooling fan. If any of these go wrong the motor can overheat. Then you risk a fried motor.

What Gets Damaged First?

Heat is the big villain. When windings overheat the motor winding insulation fails. Once the insulation breaks down it can arc. Then you get electrical motor burnout. You may see stator damage. You may see rotor damage. You may even see lamination scorching.

Here is what often gets hit:

- Winding insulation breakdown: The core of a fried motor.

- Stator winding turns short together. This is a motor winding short or motor winding failure.

- Rotor bars can crack. The shaft can get bent.

- Bearings can seize from heat or dirt. That causes rub between rotor and stator and it can destroy windings.

- Capacitor on some motors can fail. Then the motor hums but will not start.

Once the core parts fail you face a hard choice. Fix it or replace it.

Why Do Motors Burn Out?

Let’s break down the big causes. I use the PAS framework here because it works.

- Problem: Motors run hot or pull too much current.

- Agitate: Heat piles up fast. Insulation breaks down. The motor fails when you need it most.

- Solution: Fix the root cause. Protect the motor. Watch the load. Check power quality.

Key causes:

- Electrical overload

- The motor draws too much current or amperage.

- Maybe the motor is undersized. Maybe the load is too heavy.

- Overload makes extreme heat. It speeds up overheated motor damage.

- Overheating (thermal stress)

- Blocked vents. A failed cooling fan. High ambient heat.

- Long run time under heavy load.

- Repeated heat cycles cause cumulative damage and lead to motor overheating causes.

- Voltage irregularities

- Under-voltage makes the motor draw more current. That makes more heat.

- Over-voltage or power surges punch holes in insulation.

- Phase imbalance in 3-phase motors creates extra heat.

- Insulation degradation

- Aging and wear.

- Moisture damage or chemical contamination.

- Vibration and physical stress.

- It ends in short circuits and motor electrical failure.

- Bearing failure

- Lack of lubrication or dirty grease.

- Bearings grind. Heat climbs. The rotor rubs the stator.

- It can wreck windings and cause mechanical motor failure.

- Mechanical stress and external factors

- Hard impacts, shaft misalignment, bad motor sizing issues.

- Dust accumulation. Corrosive agents. Poor motor cooling system problems.

Put simply. Heat kills. Heat from overload. Heat from bad power. Heat from bearings.

What Are the Signs of a Fried Motor?

Use your senses first. Then look at the hardware.

- Sensory indicators

- A sharp burning smell from motor. That scorched insulation odor stands out.

- Visible smoke or white vapor.

- Loud grinding or unusual noises. A harsh humming but not starting sound.

- Operational symptoms

- Motor not turning or complete failure to start.

- Motor tripping breaker or circuit breaker tripping repeatedly.

- Fuse blown motor again and again.

- Motor housing hot to the touch.

- Loss of power or reduced performance.

- Visible motor damage such as sparks from motor, melted parts, or discolored windings.

If you see these you must stop and test it. Do not keep pushing the start button. You can make things worse.

How Do I Diagnose the Damage?

Start with a safe visual inspection. Look for char, melt, broken wires, or loose parts. Then test.

- Electrical testing

- Winding resistance test with a multimeter. Check for open windings or shorts.

- Insulation resistance test motor with a megohmmeter (Megger). This finds insulation breakdown and ground fault motor issues.

- Check motor capacitor testing if the motor uses a capacitor.

- Measure motor current draw and compare to the motor nameplate information.

- If you use a variable frequency drive (VFD) also check settings and cable length.

- Use a thermal sensor or an IR camera to spot hot spots.

- Mechanical checks

- Spin the shaft by hand with power off. Do you feel rough bearings or a seized motor seized up condition

- Listen for bearing noise motor.

- Check for motor shaft damage or rotor rub.

Here is a simple test table you can follow.

| Test | Tool | What It Tells You |

|---|---|---|

| Winding resistance test | Multimeter | Open windings or shorts |

| Insulation resistance (megger test motor) | Megohmmeter | Insulation health and ground faults |

| Current measure | Clamp meter | Overload or phase imbalance |

| Capacitor test | Multimeter with capacitance | Failed start or run capacitor |

| Vibration check | Vibration pen | Bearing issues and misalignment |

| Thermal scan | IR camera or thermal sensor | Hot spots from overload or cooling issues |

If you do not feel safe testing it then get a professional motor diagnosis from a motor repair shop. Safety comes first.

Repair or Replace: Which Is Best?

This choice depends on damage, size, and cost.

- When repair makes sense

- Large or specialized motors (>50 HP).

- When the core steel is good.

- When you can rewind to motor insulation class specs.

- When you want to keep lead time short.

- When replacement is smart

- Small motors (typically <50 HP).

- When windings and core are burnt badly.

- When the motor is old and runs at low energy efficiency.

- When economic non-viability makes repair a poor bet.

A good shop will guide you. EASA members follow best practices. Modern rewind practices can keep motor efficiency close to new. That was not always true in the past.

Here is a simple compare table.

| Factor | Repair | Replacement |

|---|---|---|

| Cost (small motors) | Often high per HP | Often lower |

| Cost (large motors) | Often lower than new | Often very high |

| Lead time | Faster if parts in stock | Can be long |

| Efficiency | Near original with good rewind | Best with new premium motor |

| Risk | Depends on core damage | Low if you size it right |

What Will It Cost?

Let’s be clear. Cost has two parts. The motor cost plus the downtime costs.

- Direct motor costs

- Motor repair costs breakdown vary by size.

- A small rewind can cost hundreds.

- A large rewind can cost thousands.

- New motor cost also ranges from a few hundred to tens of thousands.

- You can try secondhand motor parts to save money. Use caution.

- Downtime costs

- Many plants lose $10,000 to $20,000 per hour when lines stop.

- Some high stakes plants lose $100,000 per hour or more.

- Extra items

- Add labor to remove and install.

- Add shipping.

- Add the price of a new overload protector, thermal overload relay, or motor protection circuit breaker.

A solid plan saves money fast. That means a good spare strategy. It means a repair partner. It means smart preventative maintenance motor and predictive maintenance.

How Do I Prevent Motor Burnout?

You cannot stop every failure. You can cut the risk a lot.

- Regular motor maintenance tips

- Keep vents clear. Clean dust and dirt.

- Add lubrication on schedule.

- Check alignment.

- Tighten lugs.

- Listen for noise and look for heat.

- Load and sizing

- Pick the right size motor for your job.

- Fix motor sizing issues.

- Use a soft starter to limit inrush current.

- Use a VFD to control speed and reduce stress.

- Electrical protection

- Use a surge protector.

- Install a thermal overload relay motor sized right.

- Check voltage. Watch for power fluctuation motor impact.

- Balance phases on 3-phase lines.

- Environment

- Keep out moisture.

- Limit dust accumulation.

- Isolate vibration.

- Control heat around the motor.

- Monitoring

- Track motor current draw.

- Watch motor winding temperature.

- Set alarms on high temperature.

- Use motor diagnostic tools like vibration pens and thermal cameras.

Well run plants use preventative maintenance and predictive maintenance. They claim a 30-50% drop in surprise failures. They see longer life too. Sometimes 50% or more longer.

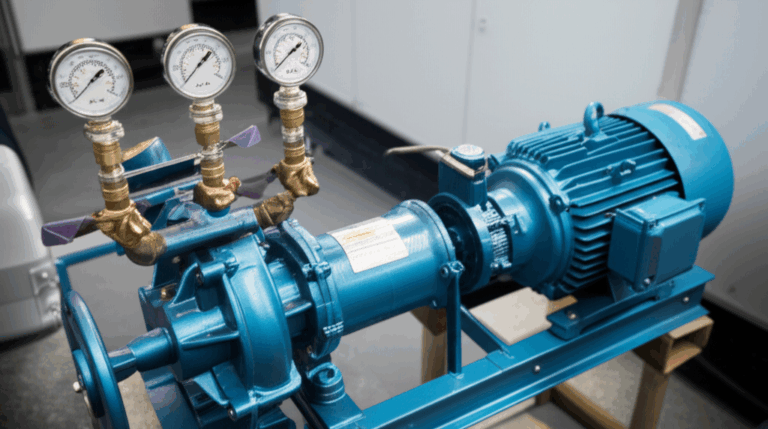

What About Special Cases like HVAC, Pumps, Fans, and Cars?

Different jobs create different stress.

- HVAC and compressors

- Tight cycles and many starts.

- Dirty filters make fan motor hot.

- Coil icing can overload the compressor motor fried risk.

- Pumps

- Dead head or dry run can kill a pump motor.

- Seal leaks let moisture enter.

- Sand and grit add vibration and wear.

- Home appliances

- A washing machine motor fried can come from jammed drums.

- A fan motor burning smell often means dust and heat.

- Automotive

- Car motor fried symptoms may show as smoke or a burnt smell near the motor or alternator.

- Heat soak and poor airflow add risk.

- DC motors

- Worn brushes and commutator arcs.

- You may need motor brush replacement (DC motors).

Each use calls for its own checks. Watch the load. Watch the heat. Keep bearings smooth.

What Does the Nameplate Tell Me?

The motor nameplate information is a gold mine. You see voltage, current, amperage, resistance, service factor, NEMA frame, IEC codes, and speed. You also see the insulation class and temperature rise.

Use it to:

- Match the power supply.

- Size the overload protector and fuses.

- Set the VFD or soft starter.

- Check energy efficiency goals.

- Estimate motor life expectancy under your load.

When you pick a new motor study the nameplate. It helps you avoid improper motor installation and motor principle errors. A good match runs cooler and lasts longer.

Case Study: The Cost of Overheating

Here is a true-to-life story I see all the time. A food plant ran a conveyor hard during peak season. The motor ran near full load every day. The vents clogged with flour dust. The motor overheated again and again.

One day the stator winding insulation failed. The motor fried. The line stopped for 12 hours. Losses hit about $150,000 in product and sales. The plant also paid $8,000 for a rush replacement and install.

What would have helped

- Proper motor sizing with margin

- Airflow checks on the cooling fan

- Load monitoring with alarms

- A better preventative maintenance plan

Small steps prevent big pain.

How SinoLami Helps Build Better Motors

I write a lot about failure. Now let’s talk about better design. Better motors start with better core steel. Low loss. Tight tolerance. Clean stacks. That is how you fight heat at the source.

If you design or buy motors consider the core:

- The stator

- Quality steel cuts core loss.

- Tight stacks improve magnetic performance.

- See how the quality of the stator core lamination affects heat and life.

- The rotor

- Balanced stacks reduce vibration.

- Good steel lowers heat.

- Explore precision rotor core lamination options.

- The full stack

- From small BLDC to large AC machines.

- Match grade and coating to your job.

- Review complete motor core laminations solutions.

- The material

- Use proven silicon steel grades for low loss.

- Work with a supplier who understands tolerances and coatings.

- Learn about high quality electrical steel laminations.

Better cores run cooler. Cooler motors avoid motor efficiency loss and overheated motor damage. That lowers your odds of a fried motor before you even power up.

FAQ

- What causes a motor to fry most often

Overload and heat. Causes of motor burnout include high load, bad power, bearing failure, and poor cooling.

- Can a fried motor be repaired

Yes sometimes. If motor internal damage is light a rewind can save it. If stator and core are burnt bad then replacement is safer.

- How can I tell if a motor is fried

Look for burning smell, smoke, motor not turning, and repeated breaker trips. Check with a megger and a multimeter.

- Will a VFD protect my motor

A VFD helps with soft starts and speed control. It can reduce stress. Add proper filters and cables to avoid voltage spikes.

- What is the risk of DIY repair

High. DIY motor repair risks include shock and fire. You can damage the motor more. Get a pro for high voltage or big units.

A Handy Checklist of Phrases and Problems You Might Hear

Use this list to match what you see and smell with the right fix. These are common terms techs use when they talk about fried motors and motor failure:

- fried motor meaning

- what causes a motor to fry

- signs of a fried motor

- how to tell if a motor is fried

- can a fried motor be repaired

- cost to replace a fried motor

- burnt electric motor symptoms

- motor winding failure

- overheated motor damage

- electrical motor burnout

- causes of motor burnout

- why do motors burn out

- electric motor insulation breakdown

- motor short circuit symptoms

- motor seized up

- motor smoking reasons

- burning smell from motor

- motor not turning

- motor tripping breaker

- capacitor fried motor

- bearing failure motor damage

- motor overload protection

- motor overheating causes

- how to prevent motor burnout

- AC motor failure modes

- DC motor overheating issues

- industrial motor failure

- car motor fried symptoms

- washing machine motor fried

- HVAC motor failure

- compressor motor fried

- fan motor burning smell

- pump motor failure causes

- diagnosing a fried motor

- troubleshooting motor issues

- motor repair vs replacement

- voltage surge motor damage

- power fluctuation motor impact

- lack of motor lubrication

- motor winding short

- motor stator damage

- rotor damage symptoms

- motor housing hot

- visible motor damage

- sparks from motor

- motor humming but not starting

- circuit breaker tripping repeatedly

- motor efficiency loss

- motor maintenance tips

- extended motor lifespan

- motor protective devices

- thermal overload relay motor

- fuse blown motor

- ground fault motor

- motor internal damage

- motor electrical failure

- mechanical motor failure

- environmental factors motor

- moisture damage motor

- dust accumulation motor

- vibration motor damage

- improper motor installation

- motor sizing issues

- motor cooling system problems

- motor fan failure

- motor capacitor testing

- motor winding resistance test

- insulation resistance test motor

- megger test motor

- motor diagnostic tools

- preventative maintenance motor

- predictive maintenance motor

- motor repair shops near me

- how much to fix a motor

- new motor cost

- secondhand motor parts

- motor breakdown analysis

- common motor failures

- motor life expectancy

- motor insulation class

- motor winding temperature

- motor current draw

- causes of electric motor failure

- electric motor troubleshooting guide

- signs of a bad motor

- why an electric motor fails

- can an overheated motor be saved

- motor repair costs breakdown

- professional motor diagnosis

- DIY motor repair risks

- understanding motor specifications

- motor nameplate information

- motor protection circuit breaker

- variable frequency drive motor protection

- soft starter motor protection

- motor winding material

- motor lamination damage

- bearing noise motor

- motor shaft damage

- motor brush replacement (DC motors)

And the core entities to keep in mind during diagnosis and selection:

- Electric Motor

- Motor Winding

- Stator

- Rotor

- Insulation (electrical)

- Bearings

- Capacitor

- Circuit Breaker

- Overload Protector

- Voltage

- Current

- Amperage

- Resistance

- Short Circuit

- Overheating

- Lubrication

- Power Supply

- Thermal Overload Relay

- Multimeter

- Megohmmeter (Megger)

- Electrical Safety

- Preventative Maintenance

- Predictive Maintenance

- Motor Diagnostics

- Motor Repair Shop

- Automotive Industry

- HVAC System

- Industrial Machinery

- Home Appliances

- AC Motor

- DC Motor

- Induction Motor

- Universal Motor

- Fan Motor

- Pump Motor

- Compressor Motor

- NEMA (National Electrical Manufacturers Association)

- IEC (International Electrotechnical Commission)

- Energy Efficiency

- Downtime Costs

- Copper Wire

- Enamel Coating

- Shaft

- Commutator (DC motors)

- Brushes (DC motors)

- VFD (Variable Frequency Drive)

- Soft Starter

- Surge Protector

- Thermal Sensor

- Cooling Fan

Key Takeaways

- A “fried motor” means severe damage to windings or insulation. Heat is the main cause.

- Watch for burning smell, smoke, breaker trips, hot housing, and no start.

- Test with a multimeter and a megger. Check current and temperature.

- Small motors often make sense to replace. Large motors often make sense to repair.

- Prevent failure with right sizing, clean cooling, good bearings, and strong protection.

- Better core steel and laminations lower heat and improve life.

- Work with pros for safe testing and reliable results.

References

- Electrical Apparatus Service Association (EASA). Best practices for rewind and repair.

- IEEE papers on electric motor failure modes and insulation aging.

- Noria and reliability industry studies on failure causes and maintenance ROI.

- EPRI and reliability engineering reports on downtime costs.

- Maintenance and CMMS vendor reports on predictive maintenance outcomes.