What is a Motor Blower? Understanding Its Function, Types, and Applications

Table of Contents

- Introduction: Why Motor Blowers Matter

- What Is a Motor Blower?

- How Does a Motor Blower Work?

- What Are the Main Parts?

- What Types of Motor Blowers Exist?

- Where Do We Use Motor Blowers?

- How Do You Pick the Right Blower?

- How Do You Keep a Blower Healthy?

- How Loud Are Blowers and How Do You Cut Noise?

- What Trends Should You Watch?

- Air Movement Cheat Sheet: Components, Types, and Uses

- Case Study and Real Data You Can Trust

- Common Questions

- Key Takeaways

- References

Motor blowers move air. They push or pull it where you need it. In homes and in big plants they are the hidden heroes. Read this guide to see what a motor blower is, how it works, and how to pick one that fits your job. I will show you real uses, simple checklists, and smart tips that save energy and money.

Introduction: Why Motor Blowers Matter

Let me start with a simple scene. I walked into a shop on a hot day. The air felt still. The smell of paint hung in the air. Workers looked tired. The problem was clear. Air did not move. The range hood sounded weak. Dust floated in the light. The owner said power bills went up and staff felt sick. He needed help fast.

That is the problem. Poor airflow hurts comfort and safety. It also raises costs. Motors run too hard. Filters clog. Heat builds up. Fumes linger. You feel it at home too. A loud furnace blower can keep you up at night. A dryer takes too long. A bathroom fan fails to clear steam.

Here is the solution. Use the right motor blower. Set it up well. Keep it clean. Match airflow capacity in CFM to system needs. Watch static pressure. Use a variable frequency drive when it makes sense. Pick the right type for the job. In this guide I show you how to do that step by step.

What Is a Motor Blower?

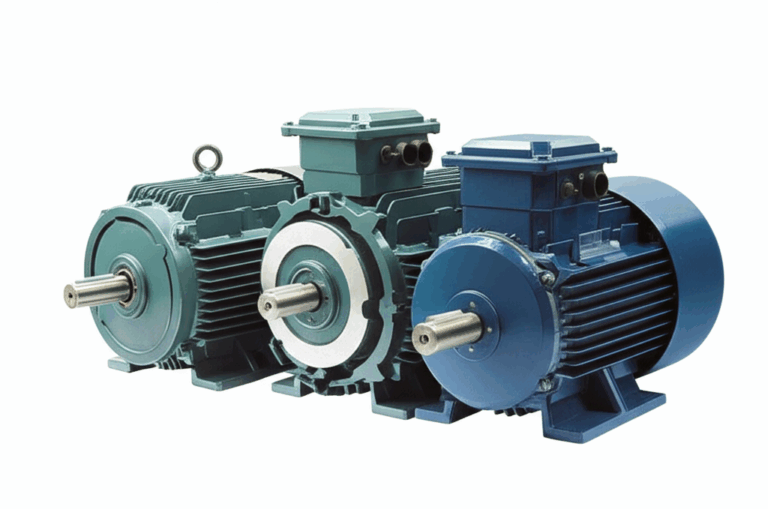

A motor blower is a machine that moves air. An electric motor spins a fan wheel or impeller inside a housing. The moving blades pull air in and push it out. The blower creates pressure or vacuum. Put simply, it is an air mover that works harder than a small fan.

You see motor blowers in HVAC systems, industrial ventilation, dust collection systems, and in many machines. You find them in furnaces, ovens, cooling towers, air handlers, and even in cleanroom air handling. A blower fan vs motor blower sounds like the same thing to some people. A small fan moves air at low pressure. A blower moves air with higher pressure to fight duct and filter resistance. An air compressor vs blower also sounds close. A compressor raises air to very high pressure for storage or tools. A blower lifts pressure a little to keep air moving.

How Does a Motor Blower Work?

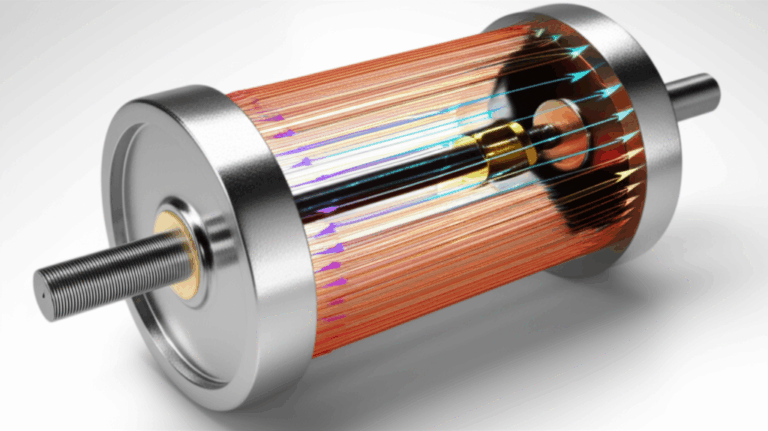

A simple cycle explains it. The motor turns the impeller. The impeller throws air outward or pulls it along the axis. The housing guides the flow. The blower builds pressure on the outlet side and reduces pressure on the inlet side. Air flows from high to low pressure. That is the basic operation cycle.

- The role of the electric motor: The motor provides torque and speed. It can be AC or DC. It can be induction type. Horsepower and RPM set the power and speed. VFD control helps match flow to need. For a quick primer on how motors make motion see the motor principle.

- The impeller or fan is the heart of air movement. Blade shape sets how the air moves. Forward-curved blades push a lot of air at lower pressure. Backward-inclined blades handle higher pressure with better efficiency. Radial blades resist dust.

Centrifugal blower operation throws air outward by spinning. Axial flow fan principle pulls air along the shaft. Regenerative blower explained in one line: it uses a side channel that lets air pass the impeller many times to build medium pressure. Positive displacement blower traps a set volume and moves it from inlet to outlet. It gives constant volume with pressure that rises to match the system.

What Are the Main Parts?

Open a blower and you will see a few key parts that do all the work.

- Electric motor: AC, DC, induction. Power in horsepower, speed in RPM. High-efficiency motors cut energy use.

- Impeller or fan wheel: Forward-curved, backward-inclined, or radial blades. Impeller design principles matter for efficiency.

- Housing or casing: Often a volute or scroll design that directs the flow. It has an inlet and outlet port to guide air.

- Shaft and bearings: These ensure smooth rotation. Bearing types for blowers include ball and roller. Good alignment reduces vibration in blowers.

- Drive mechanism: Direct drive or belt drive with pulleys. Direct drive is simple and tight. Belt drive allows speed changes.

- Shaft seal blower: Keeps air in and dirt out. It protects bearings and motor.

- Accessories: Inlet vane damper, outlet damper control, flexible connector blower, vibration isolators for blowers, sound attenuator blower, filter box for blowers, protective screen blower.

Inside the motor sit the stator and rotor. They use stacks of thin steel sheets to reduce loss and heat. The quality of the stator core lamination makes a big difference. The rotor also needs tight build and balance. See more on the rotor core lamination. These electrical steel laminations cut eddy current loss and improve motor efficiency. Learn why good steel and stamping matter here: electrical steel laminations.

What Types of Motor Blowers Exist?

Different jobs need different types. Here are the big families.

- Centrifugal blowers: High pressure and controlled flow

- Forward-curved

- Backward-inclined or curved

- Radial

- Squirrel cage fans fit here and sit in many air handling unit blower jobs

- Axial flow blowers or fans: High volume at lower pressure

- Propeller fans

- Tubeaxial fans

- Vaneaxial fans

- Positive displacement blowers: A Roots blower is a key type

- Constant volume and variable pressure

- Great for pneumatic conveying and aeration blower function

- Regenerative blowers or side channel blowers

- Medium pressure with compact design

- Good for vacuum blower applications and drying

Other specialized blowers include turbine blowers, cabinet fan units, plenum fan applications, roof exhaust fans, wall-mounted blowers, and inline duct blowers.

Where Do We Use Motor Blowers?

You see them almost everywhere air needs to move.

- HVAC and climate control

- Furnace blower motor and furnace draft inducer

- Air handling units with HVAC blower components

- Exhaust fan motor for restrooms and kitchens

- Cooling tower fans

- Industrial processes

- Dust collection blower and fume extraction fan

- Drying process blowers and process cooling blower

- Material conveying blower in pneumatic conveying systems

- Combustion air blower for boilers and ovens with boiler forced draft fan and oven circulation blower

- Aeration in wastewater treatment blowers and aquaculture

- Vacuum applications for lifting and packaging

- Commercial and residential

- Commercial kitchen exhaust and range hoods

- Central vacuum systems

- Garage ventilation fan

- Special spaces

- Paint booth exhaust blower

- Laboratory fume hood fan

- Cleanroom air handling and clean air solutions

- Mining ventilation equipment and marine ventilation blowers

- Industries

- Textile industry blowers

- Food processing blowers

- Pharmaceutical blowers

- Chemical processing blowers

- Power generation plants

- Semiconductor manufacturing

- Agricultural ventilation fans

- Pollution control systems

How Do You Pick the Right Blower?

This is where many people get stuck. Here is a clear path.

- Start with airflow capacity in CFM or m³/hr. How much air do you need to move

- Check static pressure rating in inches of water gauge or Pascals. This tells you how hard the blower must push

- Look at the fan curve interpretation and match it to your system resistance curve

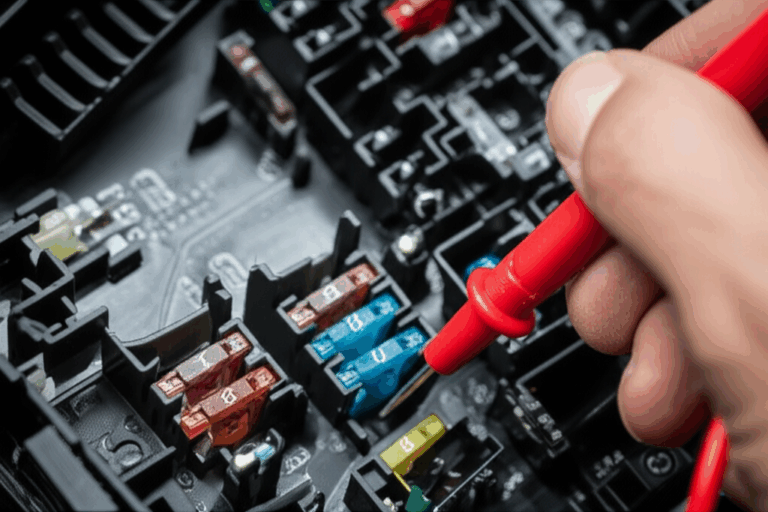

- Estimate power requirements blower and motor horsepower. Size the motor starter for blower and choose a control panel for blower that fits your safety rules

- Consider efficiency. A VFD blower and high-efficiency motor can cut energy consumption of blowers by a lot. Blower efficiency calculation helps you compare

- Check noise level blower and use sound controls if needed

- Study material and environment. Do you need an explosion-proof blower, a corrosive environment blower, or a high-temperature blower. Pick stainless steel blower, aluminum blower construction, or cast iron blower housing as needed

- Think about drive. Direct drive vs belt drive blower makes a difference in maintenance and speed control

- Plan for service. Can you get OEM blower parts and blower repair services. Do you need custom blower solutions

- Add sensors for remote monitoring blower and predictive maintenance blowers

How Do You Keep a Blower Healthy?

A blower can last 10 to 20 years with care. Here is how you do it.

- Regular cleaning: Dust and lint cut flow and raise static pressure. Clean the impeller and the housing

- Bearing lubrication: Use the right grease on schedule. Bearings often need work every 3 to 7 years

- Belt tension checks for belt driven units: Too tight and you load the bearings. Too loose and you slip

- Vibration monitoring: This finds imbalance, misalignment, or looseness. Fix it fast to save the motor and bearings

- Professional inspections: A trained tech can spot cracks or hot spots with thermal imaging. Use a log to track changes

- Filters and screens: Keep the filter box for blowers clean. Make sure the protective screen blower is intact

- Dampers and connectors: Check the inlet vane damper and outlet damper control. Inspect the flexible connector blower

Predictive maintenance strategies can cut downtime by half. They can also lower maintenance costs by up to one third. That saves money and stress.

How Loud Are Blowers and How Do You Cut Noise?

Noise matters at work and at home. Smaller units can run near 70 dB(A). Large industrial blowers can go over 100 dB(A). OSHA sets limits. Long exposure above safe levels hurts hearing.

You can cut noise with good design. Use a sound attenuator blower or an acoustic enclosure. Add vibration isolators for blowers to stop structure-borne sound. A smooth fan curve match reduces surge and rumble. Keep blades clean to cut turbulence. A few smart steps can reduce noise by 10 to 30 dB(A). That feels like a big change.

What Trends Should You Watch?

Three big trends stand out.

- Energy wins: Motor-driven systems eat a lot of power. They can account for 45 to 65 percent of industrial electricity. VFD adoption now shows up in most new systems. Over 60 percent of new industrial blower setups use VFDs. Better impellers and motors boost efficiency too

- Smart control: IoT and smart blowers with sensors track vibration, heat, and speed. Remote monitoring blower features and condition-based care reduce downtime

- Safer and cleaner air: Standards from AMCA International and ASHRAE guide testing and design. OSHA protects workers. IEC and NEMA cover electrical rules. API and NFPA address heavy industry and fire safety. Cleanroom air handling and mechanical ventilation systems keep growing

Air Movement Cheat Sheet: Components, Types, and Uses

Use this quick table to see parts and uses at a glance. It also shows many options you can pick from.

| Topic | What to Know | Notes and Examples |

|---|---|---|

| Core mechanism | Electric motor spins impeller to move air | AC, DC, induction motor; horsepower and RPM matter |

| Impeller types | Forward-curved, backward-inclined/curved, radial | Impeller design principles drive efficiency |

| Blower families | Centrifugal, axial, positive displacement, regenerative | Centrifugal blower operation vs axial flow fan principle vs positive displacement blower vs regenerative blower explained |

| Housing | Volute/scroll design with inlet and outlet | Blower housing structure shapes flow |

| Pressure vs volume | Static pressure rating vs airflow capacity (CFM) | Fan curve interpretation vs system resistance curve |

| Drives | Direct drive vs belt drive blower | Pulleys adjust speed on belts |

| Controls | Variable frequency drive (VFD) blower and motor starter | Control panel for blower adds safety and logic |

| Materials | Stainless steel blower, aluminum blower construction, cast iron blower housing | Match to corrosive environment blower or high-temperature blower |

| Seals and bearings | Bearing types for blowers and shaft seal blower | Smooth rotation and long life |

| Noise and vibration | Noise level blower and vibration in blowers | Sound attenuator blower and vibration isolators for blowers |

| Ductwork | Ductwork design for blowers and flexible connector blower | Filter box for blowers and protective screen blower |

| Dampers | Inlet vane damper and outlet damper control | Simple ways to trim flow |

| Install forms | Roof exhaust fans, wall-mounted blowers, inline duct blowers, cabinet fan units, plenum fan applications | Pick what fits the space |

| Safety and proof | Explosion-proof blower | For hazardous zones |

| Monitoring | Remote monitoring blower and predictive maintenance blowers | Avoid surprise stops |

| Service | Blower maintenance tips, troubleshooting blower issues, blower repair services, OEM blower parts, custom blower solutions | Quick fixes and long-term care |

| Measurement | Airflow measurement techniques and pressure measurement for blowers | Use proper instruments |

| Energy | Energy consumption of blowers and blower efficiency calculation | Fan law calculations help you predict change |

| Compare devices | Blower fan vs motor blower and air compressor vs blower | Use the right tool |

| Special uses | Gas booster blower and vacuum blower applications | Niche needs |

| Where used | HVAC systems, Industrial Ventilation, Dust Collection Systems, Pneumatic Conveying, Wastewater Treatment Plants, Semiconductor Manufacturing, Food and Beverage Industry, Pharmaceutical Industry, Chemical Plants, Power Generation, Material Handling Equipment, Pollution Control, mechanical ventilation systems | Many fields rely on blowers |

Case Study and Real Data You Can Trust

A chemical plant ran an old fixed-speed blower on a process line. Power bills climbed each summer. The team swapped it for a high-efficiency unit with a VFD. They matched the fan curve to the system resistance curve. They also tuned the ductwork design for blowers. Energy fell by about 35 percent for that line. Payback arrived in under two years. Workers also noted less noise and smoother control.

Market facts help too. The global industrial blowers and fans market sits near the USD 8.5 billion mark and keeps growing at a steady pace. Growth drivers include clean air rules and a push for energy savings. In wastewater treatment plants, blowers for aeration can eat 50 to 70 percent of the site’s energy. Small gains here make a big dent in cost.

Here is a simple table with highlights.

| Category | Data |

|---|---|

| Market size and growth | Around USD 8.5B in 2022 with steady growth to 2030 |

| Energy impact | Motor-driven systems use 45–65% of industrial electricity |

| Savings potential | 20–50% energy savings with VFDs and high-efficiency motors |

| WWTP share | 50–70% of plant energy goes to aeration blowers |

| Maintenance win | Predictive care can cut downtime by 50–70% and costs by 20–30% |

Who Makes Blowers and Who Sets the Rules?

You can learn a lot by looking at known names. The groups and brands below shape the field and set standards.

- Standards and safety bodies: AMCA International, ASHRAE, OSHA, IEC, NEMA, API, NFPA

- Notable brands and makers: Siemens, Gardner Denver, Roots Blower by Ingersoll Rand, Chicago Blower, Greenheck, New York Blower, Twin City Fan, Loren Cook Company, Continental Blower, Spencer Turbine, Howden, Aerzen, Atlas Copco, Kaeser Kompressoren, Busch Vacuum Solutions, Ebara Corporation, Tuthill MD-Pneumatics, Donaldson Company, FASCO Regal Beloit, Baldor Electric Company ABB, WEG Industries, Nidec Corporation, Rockwell Automation, Schneider Electric, ABB

These names show up in HVAC systems, dust control, and process air. They also build controls, motors, and drives that make blower systems work better.

PAS in Action: Fix the Real Problem

- Problem: Your space feels hot or stale. Your process sheds dust or fumes. Parts run hot. Bills rise. Staff complain

- Agitate: Poor airflow can trip lines. Dust can harm lungs. Heat can kill motors. Bad air can mess with lab work. You lose time and money

- Solution: Pick the right blower type. Size it to match airflow and static pressure. Use a VFD where load changes. Choose good materials for heat and corrosion. Keep bearings greased. Watch vibration. Upgrade the motor core if you build motors. Quality laminations slash loss and heat. If you need better stator and rotor parts at scale see stator core lamination, rotor core lamination, and electrical steel laminations

Simple Buying and Setup Checklist

Use this list to get it right the first time.

- Define airflow capacity in CFM or m³/hr

- Calculate static pressure rating including filters and ducts

- Pick type: centrifugal, axial, positive displacement, or regenerative

- Select blade style: forward-curved, backward-inclined, or radial

- Choose drive: direct drive vs belt drive blower

- Decide on controls: VFD and motor starter and control panel for blower

- Check materials: stainless steel blower or aluminum blower construction or cast iron blower housing

- Set noise goals: add a sound attenuator blower and vibration isolators for blowers if needed

- Plan maintenance: grease points, access doors, filter box for blowers, protective screen blower

- Verify safety: explosion-proof blower where required by code

- Validate with fan curve interpretation vs system resistance curve

- Measure: use airflow measurement techniques and pressure measurement for blowers

Common Questions

- What is a furnace blower motor

- It is the motor and fan that move air through your furnace and ducts. It pushes warm or cool air into rooms

- Do I need a VFD blower

- If your airflow need changes during the day then a VFD can save a lot of energy. It also gives smooth control

- What is the difference between a fan and a blower

- Fans move large air volume at low pressure. Blowers move air at higher pressure to fight duct and filter loads

- Are positive displacement blowers loud

- They can be louder than some fan types. You can use an enclosure and good mounts to cut noise

- Can an axial fan handle high pressure ducts

- Not well. Axial fans suit high volume and low pressure. Use a centrifugal blower when pressure is high

Key Takeaways

- A motor blower uses an electric motor and impeller to move air at useful pressure

- Pick type and size by CFM and static pressure. Match the fan curve to the system resistance curve

- VFD control can save 20–50% energy in many jobs

- Keep it clean and greased. Watch vibration to prevent failures

- Choose safe materials and housings for heat, fumes, and dust

- Quality motor cores improve efficiency and cut heat

References

- AMCA International. Publication on fan and blower testing

- ASHRAE Handbook. HVAC Systems and Equipment

- U.S. Department of Energy. Improving Fan System Performance

- OSHA. Occupational Noise Exposure Standards

- IEC and NEMA standards for motors and drives

- NFPA and API guidance for industrial ventilation and hazardous locations

Bonus: Glossary of Helpful Terms

- Air movement technology: The science and design of moving air in systems

- Industrial air movers: A broad term for devices that move air in plants

- Industrial machinery components: Parts like blowers that support machines

- Mechanical ventilation systems: Systems that move air in buildings for health and comfort

- Clean air solutions: Filters, blowers, and controls that keep air clean

- Plenum fan applications and cabinet fan units: Compact ways to move air inside HVAC equipment

- Roof exhaust fans and wall-mounted blowers: Common building exhaust solutions

By the way I have seen plants turn around comfort and quality with just one smart change. They picked the right blower and tuned it. Air cleared. Heat dropped. Workers smiled. That can be your story too.