What Is a Motor Mount? An Engineer’s Guide to NVH, Drivetrain Stability, and the Overlooked Role of Motor Laminations

Ever wonder why a 600-pound engine or a high-torque electric drive unit stays put when you floor it. Or why the cabin stays mostly calm while the powertrain thrashes through rotational forces. That quiet competence comes from a simple part with a complex job: the motor mount. If you design or source powertrain systems you already know mounts affect Noise, Vibration, and Harshness. What often gets missed is how much NVH depends on what happens inside the motor core itself. Laminations set the stage for smooth torque delivery which reduces the mount’s workload and your warranty risk.

This guide gives you the full picture. You’ll get a practical definition of a motor mount and how motor mounts work. We’ll decode NVH from both mechanical and electromagnetic sources. Then we’ll compare types of motor mounts and the lamination materials and processes that shape vibration at the source. Finally we’ll help you match solutions to your application and walk away with clear next steps.

In This Article

- The Engineering Problem: NVH, drivetrain stability, and cost targets

- What a Motor Mount Does and Why It Matters

- What’s Really Going On: Vibration fundamentals in engines and electric machines

- Your Options Explained: Motor mount types and tradeoffs

- Core Laminations 101: Materials, manufacturing, and their impact on NVH

- Failure Modes and Diagnostics: Symptoms, inspection, and risks

- Application Fit: ICE, hybrid, and EV considerations

- Procurement and Cost: OEM vs aftermarket, quality, and standards

- Your Engineering Takeaway

The Engineering Problem: NVH, Drivetrain Stability, and Cost Targets

Design teams face a three-way tug-of-war. You need a stable engine support system that holds the engine and transmission case precisely. You want a quiet cabin with minimal chassis vibration. Procurement wants a durable, scalable solution with a predictable motor mount lifespan and cost. If you’re building ICE, hybrid, or EV platforms the questions keep coming.

- How do we reduce vehicle vibrations at idle and under load without overconstraining the powertrain

- Can we prevent stress on drivetrain components and the exhaust system without raising NVH

- Do we chase softer insulator mounts or fix torque ripple and magnetostriction at the source through better stator and rotor design

- What’s the right balance between OEM motor mount cost, aftermarket motor mount alternatives, and total lifecycle value

You solve this by treating mounts and motor core laminations as a system. The mount isolates vibration. The motor core decides how much vibration enters the mount in the first place.

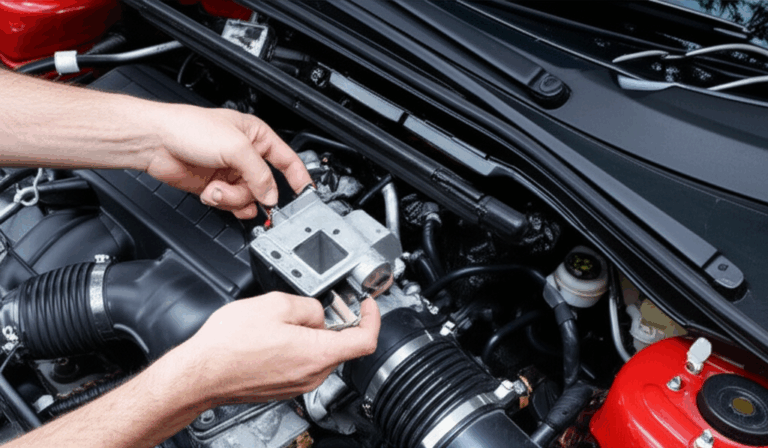

What a Motor Mount Does and Why It Matters

At its core a motor mount is a vibration isolator and structural connector. It secures the engine block or drive unit to the chassis or subframe while it dampens vibrations and manages engine movement under dynamic loads.

- Purpose of motor mounts: Support the mass of the engine and transmission. Maintain engine alignment and transmission alignment. Limit engine rocking and engine pitch control during acceleration and braking. Isolate engine noise and drivetrain vibration from the cabin.

- How motor mounts work: A mount combines a metal housing or bracket motor mount with a flexible element—usually rubber or a fluid-filled chamber—that provides shock absorption and damping material. The flexible element has elastomeric properties that allow limited motion while filtering vibration at specific frequencies.

- Where mounts sit: Most platforms use a front motor mount, a rear motor mount, and a side motor mount attached to an engine cradle or crossmember mount in the engine subframe. Many layouts add a torque strut mount that controls rotational forces. Transmission mount designs support the transmission case and help manage driveline vibration.

- Why engineers care: A well-tuned mount system protects hoses, wires, and the exhaust system. It reduces stress on axle and driveshaft joints. It improves comfort and ride quality which helps perceived vehicle safety and brand quality.

Get the mount wrong and you’ll see excessive engine movement, clunking noise from engine, steering wheel vibration, cabin noise at idle, gear shift clunk, braking clunk, acceleration clunk, shuddering upon acceleration, and vibration at specific RPMs. In bad cases engine sag or engine shifting can damage the engine block attachment points or chassis attachment points. That hits service costs and your reputation.

What’s Really Going On: Vibration Fundamentals in Engines and Electric Machines

Let’s unpack where the vibration comes from. You can split it into two buckets.

1) Mechanical imbalance and excitation

- Combustion pulses create dynamic loads and engine knocking if conditions go off-spec.

- Imbalance in rotating assemblies and accessory drives shows up as vehicle vibrations and chassis vibration.

- Static loads and dynamic loads move the powertrain in all six degrees of freedom.

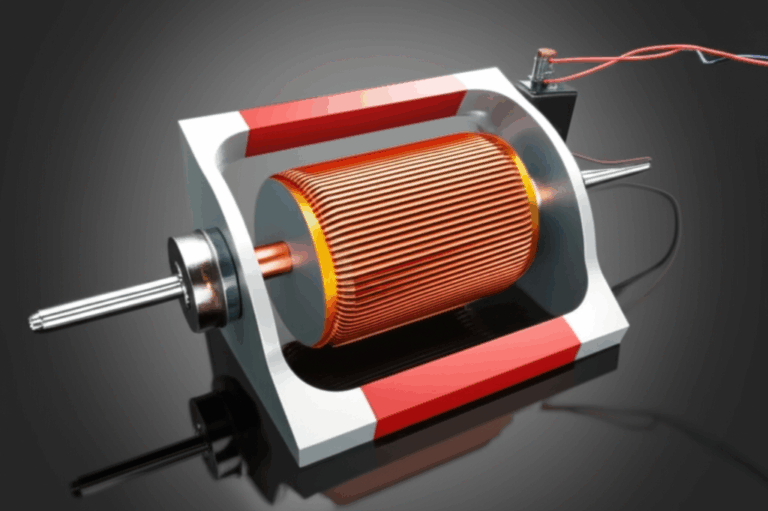

2) Electromagnetic forces inside the motor

- Torque ripple arises from slotting, magnet geometry, and stator/rotor interactions. It introduces periodic excitation that mounts must absorb.

- Magnetostriction in electrical steel slightly changes dimensions under magnetic flux. That creates a high-frequency buzz that feeds NVH.

- Core losses split into hysteresis loss and eddy current loss. Excess loss becomes heat and acoustic noise.

A quick analogy helps. Think of eddy currents like small unwanted whirlpools in a river. Changing magnetic fields induce these electrical whirlpools inside the core material. They waste energy as heat and can add noise. Thinner, insulated laminations break up those whirlpools which reduces loss and keeps the motor quieter and cooler.

That is why the quality of your electrical steel laminations matters when you tune NVH. Better laminations reduce torque ripple and magnetostriction. That cuts the vibration the mounts ever see.

Anatomy of a Motor Mount

Most mounts share a common layout.

- Metal housing or mount bracket for structural integrity.

- Flexible element made from rubber (elastomer) or a hydraulic fluid-filled mount with internal orifices. The flexible element creates frequency-dependent damping.

- Bonded interfaces and bushings to manage durability.

- Optional vacuum-controlled or electronically controlled components that change stiffness under different conditions.

Mounts isolate vibration with the same physics as a tuned shock absorber. They pass low-frequency quasi-static deflection so you can absorb engine displacement under load. They filter mid to high frequency content so the cabin stays calm.

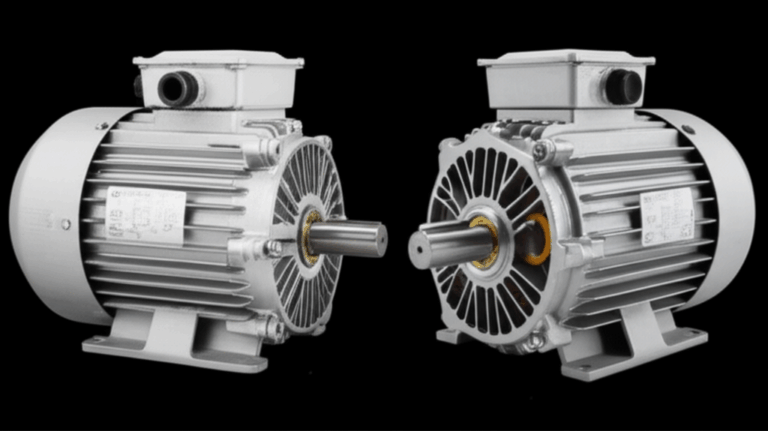

Your Options Explained: Motor Mount Types and Tradeoffs

You have a wide range of types of motor mounts that target different NVH needs.

- Passive rubber motor mount: Simple and cost effective. Rubber bonded to metal plates provides basic vibration isolation. Good for general automotive parts applications. Expect age related wear from heat and fluids.

- Hydraulic motor mount (fluid-filled mount): A chamber with glycol or oil and tuned orifices. It offers superior damping at idle and low frequencies where combustion imbalance is worst. You may see leaking hydraulic mount failures if the housing cracks or the seal fails.

- Vacuum-controlled motor mount: Uses engine vacuum to switch between soft and firm states. The system provides variable stiffness for rough idle versus hard acceleration.

- Active motor mount or electronically controlled mount: Uses sensors and actuators to counter noise and vibration in real time. Often used in luxury vehicles with strict NVH targets. Highest cost with added control complexity and failure modes.

- Solid motor mount and polyurethane motor mount: Popular in performance applications. You’ll get minimal damping with maximum engine stability for power transfer. You’ll also get more NVH in the cabin and more stress on adjacent parts.

Transmission mount tuning usually mirrors the engine mounts. The goal is to create a consistent support system between engine and transmission that keeps driveline angles stable without introducing a new resonance.

Pro tip: Don’t isolate your way out of a design issue that starts in the motor. If torque ripple drives your NVH problem you can optimize mounts all day and you will still hear the buzz.

Core Laminations 101: The Other Half of the NVH Story

Mounts handle the symptom. Laminations reduce the source. If you build electric motors or electrified drivetrains the lamination stack sets your NVH floor. It also dictates efficiency and thermal behavior which affect durability and cabin noise.

Material Considerations

- Nonoriented silicon steels (often called CRNGO lamination in supply chains): General purpose grades like M19 and M27 are common for motors. They balance cost and performance across a range of frequencies. You’ll see lower hysteresis loss and decent magnetic permeability compared to plain carbon steel.

- Grain-oriented silicon steel (CRGO lamination core): Excellent for transformers because it shines in one preferred direction of flux. It usually isn’t used for rotating machines that see changing flux angles in stator teeth.

- Cobalt alloys: Offer superior saturation and lower loss at very high frequencies. They support high-power-density aerospace and specialty applications at a high cost.

- Electrical steel coatings and insulation: Each lamination gets an insulating coating that limits interlaminar eddy currents. Coating class affects punching, bonding, stacking, and loss.

- Key properties:

- Magnetic permeability which describes how easily flux flows through the core.

- Coercivity which is the resistance to demagnetization.

- B-H curve which shows the relationship between flux density and magnetizing force.

- Core loss which combines hysteresis and eddy current loss and is reported in W/kg at specific frequencies and flux densities.

A thinner lamination reduces eddy currents at higher frequencies. That usually cuts NVH and heat. You pay for thinner gauges with tighter tooling and more complex handling.

Reference standards without guesswork. The IEC 60404 series covers test methods and classifications for magnetic materials. ASTM A677 defines requirements for fully processed nonoriented electrical steel sheet and strip used in rotating equipment. Material suppliers also publish M-grade designations and guaranteed core loss tables.

Manufacturing and Assembly Processes

How you cut and stack laminations changes NVH as much as what you buy.

- Stamping: Best for high-volume production. High-quality dies reduce burrs and dimensional spread which improves stack factor and reduces buzz. You’ll need capital for tooling and a process for die maintenance. Heat from stamping is minimal compared to laser processes so you protect magnetic properties.

- Laser cutting: Perfect for prototyping and complex low-volume parts. Edge heat can increase local loss and stress without a post-cut anneal. It delivers fast iteration when you refine slot shapes and skew patterns.

- Annealing: Restores magnetic properties after cutting by relieving stress. It tightens your B-H curve and lowers core loss.

- Interlocking laminations: Works like LEGO bricks and forms a rigid core without welding. You retain magnetic properties and lower assembly labor. You must validate lock strength for high-speed rotors.

- Bonding: Adhesive bonding quiets rattle and reduces micro-slip between laminations which helps NVH. It adds process steps and cure times yet often pays off in acoustic performance.

- Welding, cleating, or riveting: Adds mechanical strength for rotors. Use carefully to avoid localized heat-affected zones that raise loss.

Design choices also change NVH. Skewing the rotor or stator reduces cogging torque which drops tonal noise. Adjusting slot count and tooth geometry shifts excitation frequencies away from cabin sensitivity.

To learn more about the building blocks themselves see these resources:

- Explore base materials and options in electrical steel laminations

- See how the stator core lamination drives flux paths and torque quality

- Compare options for the rotor core lamination where strength and balance meet magnetic performance

- If you need an overview of design-to-production choices look at motor core laminations

Failure Modes and Diagnostics: Symptoms, Inspection, and Risks

You can diagnose worn motor mounts with simple observations and tests. You’ll also want to confirm the root cause. A bad mount can create noise. A noisy powertrain can also destroy a good mount.

Signs of a Bad Motor Mount

- Excessive engine vibration at idle or at specific RPMs. You’ll feel it in the steering wheel and seats.

- Clunking noise from engine or gear shift clunk when you shift from Park to Drive or accelerate or brake. That’s the engine shifting against stops.

- Rough idle and shuddering upon acceleration if the mount allows large deflections.

- Engine rocking you can see when blipping the throttle while parked.

- Visual damage: cracked rubber mount, torn insulator mount, separated bonding, or a leaking hydraulic mount.

- Engine sag relative to reference points which indicates a failed motor mount on one side.

- Cabin noise and chassis vibration especially over bumps. Listen for knocking as the engine hits hard stops.

Motor Mount Failure Causes

- Age related wear and mileage. Heat and time degrade elastomeric properties.

- Oil leak motor mount damage. Engine oil, power steering fluid, or transmission fluid swell and soften rubber until it fails.

- Hard driving and aggressive acceleration. More torque means greater deflection and stress.

- Accidents or curb strikes. Impacts crack housings and deform brackets.

- Manufacturing defects are rare yet real. Poor bonding or material variation shows up early.

Inspection and Diagnosis

- Motor mount inspection starts with a visual. Use a mirror and bright light. Look for tears and fluid residue on a fluid-filled mount.

- How to check motor mounts under load. Set the parking brake. Apply throttle while in gear and observe engine movement with a helper. Large engine movement or a clunk suggests a broken motor mount or bracket damage.

- Consider the system. Check transmission mount condition. Look for exhaust system vibration where hangers bottom out. Evaluate suspension system interaction because harsh impacts can masquerade as mounts.

- Diagnosing motor mount issues versus engine tuning. Rough idle from ignition problems feels like a bad mount. Fix the ignition and the “mount problem” disappears.

Risks and Replacement

Can you keep driving with bad motor mounts. You can limp for a short time if the movement stays small. Prolonged driving with bad motor mounts increases stress on drivetrain components and hoses. It can damage wiring and the radiator. In extreme cases a complete mount separation can cause serious damage and safety risks.

- Motor mount replacement cost varies by vehicle model specific design. Luxury cars with active motor mounts cost more than a simple rubber mount in a compact car.

- DIY motor mount replacement is possible with jacks and safe engine support. Many designs require subframe support and a torque procedure. Professional motor mount installation avoids alignment issues and missed safety steps.

- Choose an OEM motor mount for a known fit and damping curve if NVH is critical. An aftermarket motor mount may offer cost savings or stiffer bushings for performance. Always verify the durometer, fluid type, and mount integrity ratings.

Don’t forget accessory mounts. A loose power steering pump mount or AC compressor mount creates noise and vibration that get blamed on motor mounts. Fix the accessory first then retest.

Application Fit: ICE, Hybrid, and EV Considerations

Every application has a distinct NVH fingerprint. Match your motor mount and motor lamination choices to that fingerprint.

- ICE vehicles: Strong low-frequency excitation from combustion and engine firing order. Hydraulic mounts shine at idle and launch. Transmission mount tuning must control torque reversal clunks.

- Hybrids: Two sources of vibration. The engine and the electric machine. You need mounts with dual-mode behavior and a motor core with low torque ripple. A vacuum-controlled motor mount or electronically controlled mount helps switch behavior as the powertrain switches modes.

- EVs and BLDC drives: You lose combustion pulses. You gain electromagnetic tonal content at higher frequencies from slot passing and inverter switching. That makes lamination choices and rotor-stator geometry critical. Focus on low core loss at your switching frequency and precise manufacturing to reduce imbalance and gear mesh excitation. Mounts can be firmer because low-frequency inputs drop yet you still need to filter tonal noise paths into the cabin.

- Performance and motorsport: Solid motor mounts and polyurethane mounts improve power transfer and responsiveness. Expect higher NVH and more stress on brackets and crossmembers. Use stronger mount brackets and consider torque strut mount reinforcement.

- Industrial and stationary drives: Align the motor to the driven equipment with precision. Transmission alignment issues in gearboxes cause gear mesh noise and premature wear. Laminations and skewing reduce torque ripple that can excite base frames.

Across all cases match mount stiffness to engine displacement and dynamic loads. Match lamination thickness to operating frequency and efficiency targets. Then validate through torsional and modal testing.

Procurement and Cost: OEM vs Aftermarket, Quality, and Standards

Procurement managers juggle cost, quality, and supply risk. Use a simple checklist.

- For mounts:

- Verify durometer, damping curves, and load-deflection data. Ask for durability and fluid exposure test results.

- Confirm corrosion protection on metal housing and fasteners. Check bolt, nut, and washer specs with torque values.

- Validate engine cradle and subframe interfaces. Tolerance stackups drive installation variation that causes NVH variation.

- Decide on OEM vs aftermarket. OEM motor mounts offer consistent NVH. Aftermarket motor mounts can be fine for fleets with different priorities. Vet the supplier’s process capability.

- For laminations:

- Request material certificates to IEC 60404 test methods and ASTM A677 or equivalent specifications for nonoriented electrical steel. Confirm thickness, coating class, and guaranteed core loss at your target frequency and flux density.

- Choose manufacturing routes with intention. Stamping for volume with proper die maintenance. Laser cutting for low volume or prototyping with post-process anneal if needed.

- Evaluate stacking methods. Interlocking, bonding, or welding each bring tradeoffs for NVH, cost, and structural strength.

- Audit burr height, flatness, and stack factor. Small improvements here ripple through to lower NVH and higher efficiency.

Keep documentation clean. If you plan PPAP or IATF 16949 compliance for automotive production make early alignment with your lamination supplier a priority. It saves late-stage changes and the costs that follow.

Motor Mount Glossary in Context

You’ll find these terms throughout spec sheets and work instructions. Here’s a quick refresher in plain language.

- Engine mount and transmission mount: The main supports for the engine and gearbox. They often share similar construction and stiffness targets.

- Insulator mount: The flexible element that isolates vibrations. Usually rubber or a hydraulic unit inside the mount.

- Torque strut mount: Limits rotational forces when you apply throttle or brake.

- Crossmember mount and engine subframe: Structural parts of the chassis where mounts attach.

- Engine block attachment and chassis attachment: The bolt-up points that must meet alignment and torque specs. Misalignment raises NVH and wear.

- Passive motor mount: No external control. It uses material tuning for damping and stiffness.

- Fluid-filled mount: Hydraulic design that handles low-frequency shake.

- Electronically controlled mount or active motor mount: Controlled systems that adjust stiffness or cancel vibration.

- Vibration isolator: The function mounts provide by design.

- Mount integrity: The health of the mount’s structural and damping capability.

Troubleshooting Checklist: When the Cabin Shakes

Use this sequence to avoid parts swapping.

1) Confirm the symptom. Record vibration at specific RPMs and during events like braking clunk or acceleration clunk.

2) Inspect mounts. Look for a cracked rubber mount, broken motor mount brackets, or a leaking hydraulic mount.

3) Check adjacent systems for exhaust system vibration or driveline vibration from CV joints.

4) Evaluate engine tuning. Rough idle can mimic bad motor mount symptoms.

5) Check the lamination story if you’re in EV or hybrid. High torque ripple or inverter harmonics can create tonal cabin noise that no mount will fully hide.

6) Decide on replacement. If you proceed plan the professional motor mount installation and torque steps. Document the root cause to avoid a repeat.

Why Laminations Can Save You Money on Mounts

You can soften mounts and quiet a vehicle for a while. Then the mounts wear faster. Or you can fix the source by improving the magnetic circuit. Lower core loss leads to lower heat which also extends elastomer life near hot components. Reduced torque ripple lowers peak deflection which reduces stress on brackets and improves long-term mount integrity. Addressing the source makes the whole system happier.

Which Solution Fits Your Application

Here’s a candid perspective.

- If you’re prototyping a compact e-axle: Use laser cut laminations to iterate stator tooth shape and rotor skew quickly. Bond the stack to reduce buzz. Use mid-stiffness passive mounts with a tuned torque strut for launch events. Switch to stamping once geometry stabilizes.

- If you’re refreshing an ICE platform with rough idle complaints: Hydraulic motor mounts on the engine side and a firmer transmission mount often help. Fix any oil leak to stop oil leak motor mount damage. Validate ignition and fueling first.

- If you’re chasing weight and cost in a mass-market hybrid: Vacuum-controlled mounts give two modes without full active cost. Tighten lamination thickness and core loss targets to push ripple down rather than chase it later with active mounts.

- If you build performance models: Solid motor mounts or polyurethane motor mounts sharpen response. Inform customers about NVH and inspect crossmember mount welds and torque strut mount bushings more often.

Honesty builds trust. Laser cutting is fantastic for complex low-volume laminations. Stamping dominates for high-volume builds with simple geometries and tight unit cost targets. Interlocking saves welding heat and keeps magnetic properties intact. Bonding helps silence that last bit of rattle in sensitive cabins.

Your Engineering Takeaway

- Mounts and laminations work as a system. The mount isolates. The lamination design decides how much vibration you need to isolate.

- Match mount type to your excitation profile. Hydraulic for low frequency idle shake. Passive rubber for cost. Vacuum-controlled or active for variable conditions. Solid or polyurethane for performance.

- Cut NVH at the source. Choose the right electrical steel grade and thickness. Use proper insulation coatings. Minimize burrs. Consider skewing and bonding to reduce tonal content.

- Diagnose before replacing. Many “bad motor mount symptoms” come from tuning issues or accessory mounts. Confirm failure with inspection and load tests.

- Protect the mount’s environment. Stop leaks and heat soak. Your elastomer will last longer.

- Align procurement with engineering. Specify standards like IEC 60404 and ASTM A677. Ask for core loss data at your operating frequency. Validate damping curves and durability for mounts.

- Use prototypes wisely. Laser cut early and stamp late. Capture lessons about NVH and durability before tooling.

Ready to translate design targets into a reliable stack and a quiet cabin. Bring your performance, cost, and volume constraints to a technical consultation. You will leave with a clear material and process envelope and a plan to validate NVH before it becomes a service bulletin.

Quick Reference: Common Questions

- What causes motor mount failure

- Heat, oil exposure, aggressive driving, and impacts. Manufacturing defects are rare.

- Can I drive with a bad motor mount

- Short trips are possible if deflection stays small. Long-term driving risks safety and collateral damage.

- How much does a motor mount replacement cost

- It depends on design complexity and access. Active mounts and luxury applications cost more than simple rubber mounts.

- How do laminations affect engine mounts in EVs

- Better laminations reduce torque ripple and magnetostriction. That lowers the excitation that hits the mounts.

If you need a deeper dive into stator tooth geometry, rotor skew strategies, or lamination stack construction use the in-depth resources linked above. They cover the practical details that turn a loud prototype into a refined product.