What Is a Motor Shaft Journal End? Your Guide to This Critical Component

If you work with motors, you know the machine lives or dies on small details. One unsung detail is the motor shaft journal end. If that surface fails, bearings run hot, rotors rub, and your uptime craters. If you are designing, buying, or maintaining motors, you need to understand it. Not at the “buzzword” level. At the level where you can make a confident call on finish, fit, lubrication, and monitoring.

You’re in the right place. I’ll explain what a motor shaft journal end is, how it works with journal or sleeve bearings, why it matters, and how to spec and maintain it. I’ll also connect it to the bigger system that includes the rotor, stator, laminations, and housing. Because nothing in a motor operates in isolation.

Before we dive in, here’s your quick map.

In This Article

- Introduction: The Unsung Hero of Motor Performance

- Decoding the Motor Shaft Journal End: Definition and Location

- The Critical Purpose and Function of the Journal End

- Key Components and Principles at Play

- How Journal Ends and Bearings Interact: The Science of Hydrodynamic Lubrication

- Common Issues and Failure Modes Affecting Motor Shaft Journals

- Ensuring Longevity: Maintenance and Care for Motor Shaft Journal Ends

- Journal Ends in the Bigger Picture: Stator, Rotor, and Laminations

- Your Options Explained: Materials, Geometry, Fits, and Manufacturing

- Which Application Is This For? Matching Design to Use Case

- Your Engineering Takeaway and Next Steps

1. Introduction: The Unsung Hero of Motor Performance

Here’s the problem many teams face. A motor runs too hot at the non-drive end. Or vibration climbs after a bearing change. Or a brand-new unit shows high no-load current. The root cause often hides in plain sight. The motor shaft journal end seems simple, yet that precisely machined cylinder controls how loads transfer, how lubricant behaves, and how efficiently the rotor turns.

If you design motors or specify industrial equipment, you need a clear, actionable understanding of the journal bearing function, shaft bearing surface requirements, and journal surface finish. If you maintain motors, you need to know how to inspect journals, what clearance in journal bearings looks like in practice, and how to prevent wear, pitting, or overheating.

We’ll keep it practical. We’ll use concrete examples, define each term, and show how to choose the right path for your application.

2. Decoding the Motor Shaft Journal End: Definition and Location

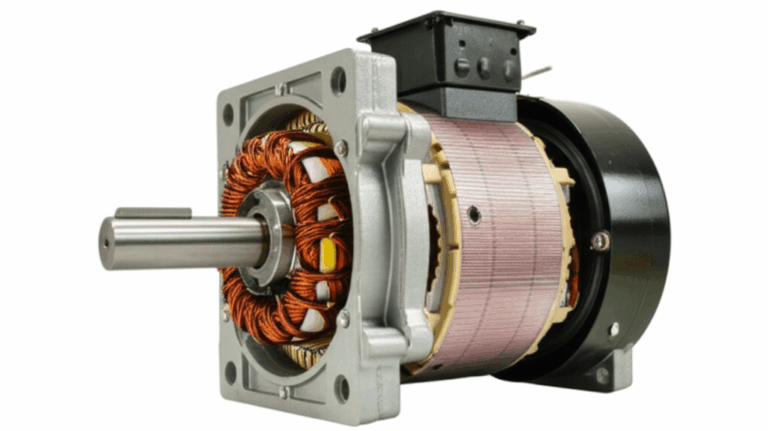

Let’s define it. A motor shaft journal end is the precisely machined cylindrical portion of the shaft that runs inside a plain bearing, also called a sleeve bearing or journal bearing. This bearing supports the rotor with a thin oil film that separates metal from metal under steady operation. The journal end is the bearing’s mating surface. Think of it as the tire that runs on a road of oil inside the bearing.

Where do you find it? At each end of the rotor shaft. Motors have a drive end (DE) and a non-drive end (NDE). In sleeve-bearing motors, both ends usually have journals sized to the bearing bores with a designed radial clearance. The journal end sits inside the bearing housing, and it aligns with the bearing’s hydrodynamic geometry.

How is it different from other shaft sections?

- Coupling end: Designed for torque transmission, often with a keyway, spline, or shrink fit hub. It sees axial alignment requirements yet doesn’t run in oil like a journal.

- Seal or labyrinth regions: These control oil migration and contamination. They sit near the bearing but don’t carry radial loads.

- Shoulder and fillet transitions: These control stress distribution at changes in diameter, and they influence stress concentration at the journal end.

- Rolling-element bearing seats: If your motor uses ball or roller bearings, the shaft has bearing seats rather than true journals. The seats require tight fits, surface finish control, and roundness, yet they rely on rolling elements rather than an oil wedge.

3. The Critical Purpose and Function of the Journal End

The journal end does the heavy lifting. Literally.

- Bearing support: It provides a stable, low-friction surface that the journal bearing uses to support the rotor.

- Load transfer: It transfers radial load from the rotor to the motor frame via the pressurized oil film in the bearing. It may also help manage axial load depending on the thrust bearing design.

- Smooth rotation: It enables consistent rotation with low vibration when alignment, shaft straightness, and runout are within tolerance.

- Friction and wear control: It works with hydrodynamic lubrication to minimize direct metal contact. This reduces power loss, heat generation, and wear.

- Reliability: It allows the bearing to develop proper oil film thickness which directly affects temperature, vibration, and fatigue life.

If the journal end geometry or surface finish drifts off spec, the bearing pays the price. Oil film collapses. Temperatures rise. You see scoring, pitting, and rapid wear.

4. Key Components and Principles at Play

Several elements come together at the journal.

The Shaft Journal Itself

- Materials: Motor shafts often use steel alloys chosen for strength, machinability, and fatigue resistance. Through hardening, induction hardening, or case hardening appears in high-load or high-wear applications. Surface hardening motor shaft journals can improve life, yet don’t overdo hardness at the expense of toughness.

- Geometry: Concentricity, roundness, taper, and cylindricity make or break performance. Manufacturing tolerances for journals matter since hydrodynamic films are microns thick.

- Surface finish: Journal surface finish requirements matter for film stability and bedding-in. Typical finishes land in the low micrometer Ra range for oil-lubricated journals. You want smooth enough for stable film yet not mirror-slick that impedes oil retention.

Journal Bearings

- Types: Plain bearing design includes solid sleeve bearings, split shell bearings, and Babbitt-lined bearings. Babbitt metal provides a soft, conformable bearing surface that supports hydrodynamic pressure and embeds small contaminants.

- Geometry: Many bearings use offset or elliptical bores to promote wedge formation and stability. Others use features like grooves and pockets to manage lubricant flow.

- Materials: Bearing shells may use steel or bronze backings with Babbitt linings. Choices depend on load, temperature, and lubricant chemistry.

Lubrication

- Hydrodynamic lubrication: The rotating journal drags lubricant into a narrowing wedge that creates hydrodynamic pressure. That pressure supports the load with a fluid film.

- Lubricant types: Most journal bearings use oil. Grease can appear in certain slow-speed designs yet doesn’t suit high-speed hydrodynamic film formation. Oil viscosity, additives, and cleanliness determine film thickness and durability.

- Oil film thickness: Film thickness depends on viscosity, speed, load, and clearance. Too thick wastes power and elevates churning loss. Too thin causes boundary lubrication and wear.

Bearing Housing and System Alignment

- The bearing housing holds the bearing and must provide alignment. Misalignment distorts the oil film. The housing also manages seals, oil supply, and cooling.

5. How Journal Ends and Bearings Interact: The Science of Hydrodynamic Lubrication

Picture a boat planing on a thin film of water at speed. That’s your journal on oil. The shaft rotates inside the bearing, and its surface drags oil into a narrowing gap. The wedge forms because the journal center shifts slightly under load. Pressure builds in the wedge, and the oil film lifts the shaft off the bearing surface.

Key points to understand:

- The oil wedge: Rotation draws oil into the converging gap. The wedge is directional and depends on journal rotation and load direction.

- Fluid film formation: Once at speed, the film separates the journal from the bearing. This prevents metal-to-metal contact under normal conditions.

- Load carrying capacity: Hydrodynamic pressure supports radial load. If load spikes or speed drops too low, the film can collapse into mixed or boundary lubrication.

- Start-stop reality: At startup and shutdown, speeds cross through low regimes. The film may not fully form which leads to brief boundary lubrication. Surface finish and proper lubricant chemistry matter in these moments.

- Temperature control: Oil carries heat away. Proper flow, viscosity, and cooling keep temperature in check.

When the wedge is healthy, you reduce friction, vibration, and wear. When the wedge fails, you see scoring, overheating, and quick degradation.

6. Common Issues and Failure Modes Affecting Motor Shaft Journals

Journal problems often show up first in bearing temperature trends, vibration data, oil analysis, and visual inspection. Spot them early, and you prevent a forced outage.

- Surface wear

- Abrasive wear from contaminants that ride the oil film and scratch the journal.

- Adhesive wear or galling when films break down under load or poor lubrication.

- Corrosive wear when water or chemical contaminants attack the surface.

- Pitting and scoring

- Particles trapped in the contact zone score the surface during mixed lubrication.

- Electrical discharge can pit journals if grounding fails and circulating currents arc through the oil.

- Fatigue

- Repeated stress cycles can initiate microcracks at the surface or subsurface. This shows up as spalling or flaking in severe cases.

- Lubrication failure

- Starvation from blocked supply lines or low sump levels.

- Incorrect lubricant selection that fails to develop a stable film at operating speed and temperature.

- Degraded oil with poor viscosity and additive depletion.

- Misalignment

- Improper installation or foundation movement shifts bearing alignment. This skews the oil wedge and drives uneven loading.

- Excessive loads

- Radial load beyond design shortens life. Axial loads that the thrust bearing cannot handle cause heat and wear.

- Overheating

- Heat from friction or external sources lowers viscosity and thins the film. That sets a vicious cycle in motion.

Instrumentation helps you catch issues before they cascade.

- Vibration analysis for electric motors flags imbalance, misalignment, oil whirl or whip, and bearing distress.

- Thermography of motor bearings highlights hot spots and cooling problems.

- Oil analysis reveals viscosity shifts, oxidation, particles, water, and wear metals.

- Acoustic emission monitoring can detect early-stage film breakdown in some setups.

7. Ensuring Longevity: Maintenance and Care for Motor Shaft Journal Ends

A journal end rewards consistent care. Build a simple program, and you’ll see the payoff in lower temperatures and longer bearing life.

- Regular inspection

- Visual checks during outages for scoring, discoloration, and wipe patterns.

- Measure shaft runout with a dial indicator. Excess runout disturbs film formation.

- Use non-destructive testing if you suspect cracks or hardening defects.

- Lubrication management

- Select the right oil viscosity for speed, load, and temperature.

- Keep it clean. Use filter systems for lubrication oil sized for your flow and target cleanliness.

- Schedule oil analysis. Watch for particles, wear metals, and water. Trend data beats spot checks.

- Validate supply. Confirm flow rates, pressure, and temperature at the bearing.

- Alignment checks

- Align motor to driven equipment under operating conditions when possible. Soft foot and thermal growth matter.

- Recheck after foundation work or piping changes.

- Vibration analysis

- Trend amplitude and frequency content. Look for changes in sub-synchronous components that suggest oil whirl.

- Temperature monitoring

- Bearing metal temperature and oil outlet temperature tell you how the film is doing. Trend them over time.

- Repair and refurbishment

- Regrinding motor shaft journal to restore roundness and finish.

- Hard chroming journal surface or applying specialized coatings to regain diameter and improve wear resistance.

- Welding and re-machining for deeper defects when appropriate.

- Replace bearings and address root causes like contamination and misalignment.

Treat the journal end like a precision part. It is one.

8. Journal Ends in the Bigger Picture: Stator, Rotor, and Laminations

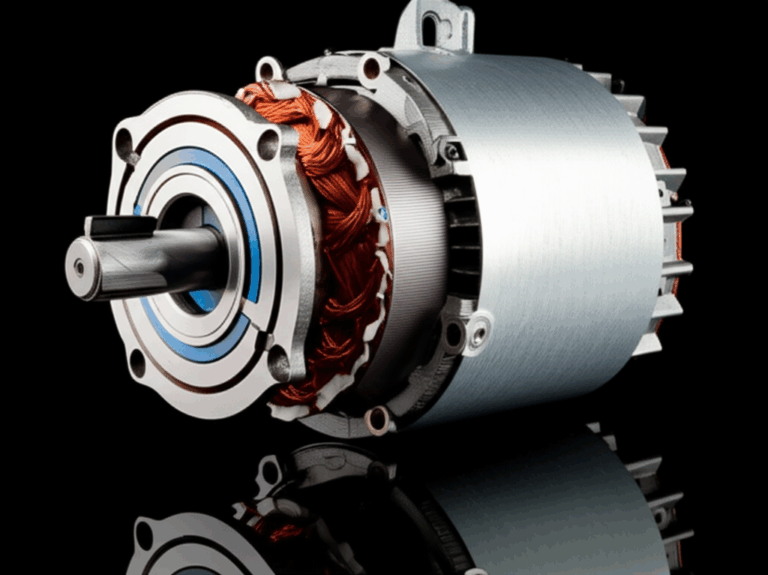

The journal end does not stand alone. It sits at the intersection of the rotor system, the bearing system, and the motor’s magnetic core. That means choices you make about laminations, stack tolerances, and rotor balance show up at the journal.

- Rotor dynamics and balance

- The rotor core lamination stack contributes to mass distribution. Any eccentricity or uneven stack clamping shows up as imbalance that loads the journal end.

- Dynamic balancing of journals and rotor assemblies reduces hydrodynamic instabilities. You’ll see smoother operation and lower oil temperatures.

- Alignment with stator

- The stator bore, rotor OD, and air gap concentricity rely on precise lamination stacking and machining. If the air gap varies, electromagnetic forces fluctuate which can drive vibration that the journal must absorb.

- Magnetic forces and thermal growth

- High magnetic pull from off-center rotors increases radial load on one side of the journal. Thermal expansion of the rotor and stator changes clearances and can shift the running position.

If you manage lamination quality well, the journal end’s life gets easier. For more context on how the core influences mechanical performance, see these resources:

- How the quality of the stator core lamination affects air-gap consistency and vibration.

- Why a precisely stacked and balanced rotor core lamination matters for journal load and oil film stability.

- The upstream material that makes the difference: high-grade electrical steel laminations.

- A broader look at options, stack methods, and applications in motor core laminations.

These decisions don’t just impact efficiency. They shape the mechanical life of bearings, seals, and journal ends.

9. Your Options Explained: Materials, Geometry, Fits, and Manufacturing

Let’s shift to the “guide” part. You have options for shaft materials, heat treatments, journal geometry, bearing types, and fits. Your goal is straightforward. Pick a combination that carries radial and axial loads with stable hydrodynamic lubrication while managing cost, manufacturability, and maintenance.

Material Considerations for Shafts and Journals

- Steel alloys

- Common motor shafts use medium-carbon or alloy steels for strength and machinability.

- Through hardening improves wear resistance yet can increase brittleness.

- Induction hardening allows a hardened surface with a tough core. Useful for surface wear without sacrificing shaft toughness.

- Case hardening yields a hard skin and ductile core. Not as common for oil-lubricated journals yet seen in harsh wear environments.

- Surface treatments

- Hard chroming provides wear resistance and a controlled finish. It helps when you must restore diameter.

- Thermal spray or specialized coatings offer tailored properties like corrosion resistance or improved tribology.

- Compatibility

- Match hardness so the bearing lining remains the sacrificial element. Babbitt should wear before the journal does in most standard designs.

Journal Geometry and Surface Finish

- Cylinder quality

- Control roundness, taper, and cylindricity. Target tight tolerances because film thickness is small.

- Fillets and shoulders

- Use generous fillet radii to reduce stress concentration at transitions near the journal end.

- Finish

- A fine, consistent Ra supports film stability and repeatable start-stop behavior. Avoid roughness that tears the film and avoid mirror finishes that reduce oil retention.

Bearing and Fit Choices

- Sleeve bearings vs rolling bearings

- Sleeve bearings support high loads quietly with long life at speed, and they rely on oil film. They suit large industrial motors, compressors, pumps, turbines, and generators.

- Rolling bearings offer simplicity and easier installation for small to medium motors. They need controlled fits on seats rather than hydrodynamic journals.

- Fits for bearings on journals

- Slip fit journal bearings are typical since the journal rotates within the fixed bearing bore. The fit is defined by designed clearance that allows the oil film. You control radial clearance based on speed, viscosity, and load.

- Press fit journal bearings appear in special assemblies or where the bearing shell must be fixed in the housing. The journal itself still runs with clearance inside the bearing lining.

- Straight vs tapered shaft journal design

- Straight journals dominate because they simplify manufacturing and measurement.

- Tapered designs appear where assembly needs a locating surface or where thrust interfaces are integrated.

Lubrication System Design

- Hydrodynamic lubrication principles

- Size radial clearance to form a stable oil wedge at operating speed and load. Use manufacturer guidance and clearance charts to choose the range.

- Lubricant selection

- Base oil viscosity must match bearing diameter, speed, and temperature. Additives help with anti-wear and oxidation. Avoid overloading additive packages that can attack soft Babbitt.

- Supply and control

- Flood lubrication, ring oilers, or forced-feed systems each have pros and cons. Forced-feed improves control of temperature and cleanliness at the cost of complexity.

- Filtration

- Filter systems for lubrication oil remove wear particles and dirt. Cleaner oil extends journal and bearing life.

Manufacturing and Quality Control

- Precision machining of journal surfaces

- Use stable processes, controlled tool wear, and in-process gauging to hold roundness and finish.

- Bearing journal manufacturing process

- Coordinate shaft machining with bearing bore geometry and housing alignment. Split bearings demand precise halves and proper crush.

- Quality checks

- Measure runout, size, and finish. Balance the rotor assembly dynamically since journal vibration rises with imbalance.

- Standards and references

- Use relevant ISO standards for dimensions and fits. Reference ASTM International specifications for steel alloys and heat-treat processes. Follow bearing supplier recommendations for clearances and oil viscosity.

Cost and Reliability Trade-offs

- You can tighten tolerances, upgrade materials, and improve lubrication systems. That reduces friction and raises reliability, and it costs more.

- For high-power-density machines, improvements pay back through efficiency, lower temperatures, and extended maintenance intervals.

- For general-purpose industrial motors, pick a balanced approach. Align spec with load profile, duty cycle, and environment.

10. Which Application Is This For? Matching Design to Use Case

Not every motor needs the same journal end strategy. Match your choices to the application.

Industrial Fans and Pumps

- Typical configuration: Sleeve bearing motors with moderate speed and steady loads.

- Priorities: Stable oil film, clean oil, and alignment with the driven shaft. Good for slip fit journal bearings with standard Babbitt linings.

- Watchouts: Contamination from process environments and shaft misalignment can drive wear.

Compressors and Turbines

- Typical configuration: Sleeve bearings with forced lubrication and tight control of temperature.

- Priorities: High-speed hydrodynamic stability, precise rotor balance, and strict runout limits.

- Watchouts: Oil whirl or oil whip can appear at high speed. Control clearance and use bearing geometries designed for stability.

Generators

- Typical configuration: Large, slow to medium speed with heavy rotors and sleeve bearings.

- Priorities: Robust load carrying capacity and reliable oil supply. Attention to axial alignment and thrust bearing design.

- Watchouts: Long spans increase shaft deflection. Verify shaft straightness and journal concentricity to the rotor lamination stack.

General-Purpose Motors

- Typical configuration: Often rolling element bearings rather than sleeve bearings. If journals are used, they tend to be smaller and simpler.

- Priorities: Cost control and ease of maintenance.

- Watchouts: Don’t port sleeve-bearing requirements over to ball-bearing designs. The seat finish and fits follow different rules than oil film journals.

High-Frequency or Variable-Speed Drives

- Typical configuration: Sleeve bearings can perform well with controlled lubrication. Rolling bearings may struggle with electrical discharge.

- Priorities: Manage electromagnetic forces and ensure grounding to prevent electrical pitting on journals.

- Watchouts: Harmonics and variable speeds affect film stability. Validate clearance and oil viscosity across the operating range.

11. Practical Troubleshooting: From Symptom to Cause

When something feels off, take a methodical approach.

- Rising bearing temperature

- Check oil level, flow, and viscosity. Confirm cooler performance. Inspect filters for blockage.

- Verify alignment and foundation integrity. Thermal growth can change alignment between cold and hot conditions.

- New vibration at sub-synchronous frequencies

- Suspect oil whirl or whip. Review clearance, oil viscosity, and bearing geometry. Confirm shaft runout and rotor balance.

- Audible scraping or metal debris in oil

- Shut down and inspect. Look for scoring on the journal surface and wipe patterns in the bearing. Check for contaminants and seal failures.

- Frequent lubricant breakdown

- Analyze oil. If oxidation or water shows up, fix the root cause. Consider a different base oil or additive package that suits temperature and load.

Instrument your decisions. Vibration analysis, oil analysis, thermography, and acoustic emission monitoring give early warnings that beat failure every time.

12. Design Tips That Move the Needle

A few practical design considerations go a long way.

- Control shaft straightness

- Excessive bow or deflection changes the running position and disturbs the wedge.

- Manage stress at transitions

- Use smooth fillets at journal shoulders to reduce stress concentration at the journal end.

- Account for thermal expansion

- Shaft and bearing grow with temperature. Choose clearances that hold the wedge at operating temperature, not only at ambient.

- Confirm axial load paths

- Thrust loads must go through a thrust bearing designed for them. Don’t let axial load sneak into radial journal surfaces.

- Keep contaminants out

- Use seals, clean assembly practices, and filtered oil supply. Dirt is sandpaper in slow motion.

13. How Manufacturing Choices Affect Reliability

Manufacturing is not just about hitting a drawing. It is about building a stable process that repeats day in and day out.

- Machining strategy

- Use rigid setups and sharp tooling to hold geometry and finish. Track tool wear and compensate before the finish drifts.

- Metrology discipline

- Measure roundness and runout where it matters. Use consistent measurement methods and environmental control.

- Balanced assembly

- Balance the rotor with its coupling and any critical accessories. Dynamic balancing of journals and the rotor reduces bearing load and oil film perturbations.

- Documentation and traceability

- Record heat treatments, surface treatments, and measurements. Traceability helps when you investigate a failure or plan a life extension.

14. Frequently Asked Design Questions

You asked. Here are clear answers that help you move forward.

- What is a shaft journal, and how is it different from a bearing seat?

- A shaft journal is the surface that runs inside a plain bearing supported by oil. A bearing seat is the surface where a rolling bearing’s inner ring mounts. Journals rely on hydrodynamic lubrication. Seats rely on interference or transition fits.

- How smooth should the journal be?

- Aim for a fine, uniform finish that supports film formation and protects during start-stop. Your bearing supplier will give a recommended range suited to your oil and speed.

- Do I need hardened journals?

- Not always. Many sleeve bearing applications run on unhardened or moderately hardened steel that balances wear resistance and toughness. Use induction hardening or coatings when environments are abrasive or when loads are high.

- What causes overheating in journal bearings?

- Thin oil, poor flow, misalignment, excessive load, or a collapsing film. Check viscosity, supply, alignment, and rotor balance.

- How do I decide on clearance?

- Use supplier clearance charts and consider speed, oil viscosity, and load. Clearance affects film thickness, temperature, and stability.

15. Tying It Together With Risk and Cost

Reliability engineering comes down to risk management and smart spending. You will weigh the cost of precision machining against the cost of unplanned downtime. Here’s a simple way to think about it.

- If the application is critical, carries heavy radial load, or runs at high speed, invest in tighter runout control, better surface finishes, and robust lubrication control.

- If the application runs clean and steady at moderate speeds, standard practices with good oil management perform well.

- Predictive maintenance pays. Vibration analysis for electric motors, oil analysis, and thermography reduce surprises.

The price of journal bearing failure includes lost production, repair hours, and possible secondary damage to the rotor, stator, and coupling. A sound design and maintenance plan costs less than a single outage.

16. The Bigger Engineering Picture: From Materials to Monitoring

You will face choices that touch metallurgy, tribology, and manufacturing. You will also coordinate with electrical design because electromagnetic forces drive mechanical loads.

- Tribology is the science of friction, wear, and lubrication. It underpins hydrodynamic lubrication principles and explains boundary lubrication and mixed regimes.

- Metallurgy affects how the journal surface responds to stress, heat, and wear. Choose steel alloy and heat treatment to match the job.

- ISO standards and ASTM specifications guide dimensions, tolerances, and material properties. Use them as guardrails. Don’t treat them as a substitute for application-specific engineering.

Bring your reliability team into the conversation. They see the day-to-day data on vibration and temperature. They can tell you which motors run hot, which ones show early warning signs of journal distress, and where contamination sneaks in.

17. Problem → Explain → Guide → Empower: Your Next Steps

Let’s wrap this up with the promised framework.

- Problem

- You need a dependable way to define, spec, and maintain motor shaft journal ends so your motors run cool, quiet, and long.

- Explain

- The journal end is the shaft surface that runs in a sleeve bearing. Hydrodynamic lubrication creates an oil wedge that carries radial load and separates metal surfaces. Success depends on geometry, finish, lubrication, and alignment.

- Guide

- Choose shaft materials and treatments that balance wear resistance and toughness. Control runout and finish. Size clearance from supplier charts. Keep oil clean and at the right viscosity. Instrument the system with vibration, temperature, and oil analysis.

- Empower

- Document your design assumptions, set up a lubrication and monitoring plan, and work with suppliers who understand sleeve bearings and journal surfaces. Tie rotor balance and lamination quality to mechanical outcomes like vibration and oil film stability.

18. Your Engineering Takeaway and Next Steps

If you remember nothing else, pin these to your checklist.

- The journal end and the bearing act as a system. Treat them as a matched pair with clear targets for geometry, clearance, and finish.

- Hydrodynamic lubrication lives on speed, viscosity, and alignment. Keep oil clean and cooling effective.

- Most failures trace to contamination, misalignment, or poor lubrication. Instrument and trend the basics to catch problems early.

- Rotor balance and lamination quality affect journal loads. Better concentricity and balance mean a calmer oil film.

- Repair methods like regrinding or hard chroming work well when you correct the root cause that damaged the journal.

Ready to move forward? Here’s a short, practical plan you can act on this week.

- Gather data on your top five critical motors. Record bearing temperatures, vibration spectra, oil condition, and any recent work on journals or bearings.

- Review clearances and lubricant choices against supplier recommendations for your speeds and loads.

- Add or upgrade filtration on systems with recurring particle issues.

- Plan a focused inspection at the next outage. Check journal surface condition, runout, and shaft straightness.

- Align your mechanical and electrical teams on rotor balance, air-gap concentricity, and journal bearing health. Cross-functional collaboration pays.

If you need a second set of eyes on a design or a persistent field issue, reach out to your trusted bearing and lamination partners. A short technical consultation can save you weeks of trial and error and it can uncover low-cost changes that boost reliability.

By understanding what a motor shaft journal end does, how it interfaces with journal bearings, and how lubrication creates a protective oil film, you can design better machines and keep existing assets healthy. The payoff is real. Higher efficiency, lower temperatures, and longer service life with fewer surprises. That is the kind of quiet success every engineer can live with.