What Is a Motorized Material Handling Device? Understanding Key Equipment and the Motor Laminations That Make It Work

Every engineer who touches logistics, manufacturing, or warehousing runs into the same question sooner or later: which of the following is a motorized material handling device? Forklifts. Conveyors. AGVs. AMRs. AS/RS cranes. Electric pallet jacks. Hoists. You see them everywhere. They move product faster and safer than manual carts or hand pallet jacks ever could.

Here’s the twist that matters to design and procurement teams. The performance, efficiency, and reliability of those devices hinge on the motors inside them. At the heart of those motors sit laminations. Choose the right electrical steel, thickness, and assembly method. You cut losses and heat. You extend service life and reduce energy costs. Choose poorly and you fight avoidable downtime and inefficiency. That’s why we’ll answer the immediate identification question then go deeper. We’ll unpack the engineering behind motor core laminations in plain language. You’ll leave with clear next steps for design, specification, and sourcing.

In short, you’ll get a practical field guide you can use on the shop floor and in the design review.

In This Article

- Quick Answer: Which of the following is a motorized material handling device?

- Defining Motorized Material Handling Devices

- Common Types: Examples and Applications

- Why Motorized Material Handling Is Essential

- The Motor Inside the Machine: Engineering Fundamentals of Laminations

- Material Considerations for Laminations (The Guide)

- Manufacturing and Assembly Processes That Affect Performance

- Matching Solutions to Your Application

- Key Considerations When Choosing Motorized Material Handling Equipment

- Procurement Checklist and Next Steps

- FAQ

- Conclusion and Future Trends

Quick Answer: Which of the following is a motorized material handling device?

If you see a power source doing the work rather than a person’s muscles, you’re in motorized territory. The following are motorized material handling devices:

- Forklifts and lift trucks. Includes counterbalance forklifts, reach trucks, order pickers, walkie stackers, and electric pallet jacks.

- Tow tractors. Used to pull trains of non-motorized carts or trailers.

- Conveyor systems. Belt conveyors, roller conveyors, chain conveyors, screw conveyors, and pneumatic conveying systems.

- Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs).

- Automated storage and retrieval systems (AS/RS). Unit-load cranes, mini-load shuttles, vertical carousels, and horizontal carousels.

- Cranes and hoists. Overhead cranes, gantry cranes, jib cranes, electric wire rope hoists, and electric chain hoists.

- Motorized access and lift platforms. Scissor lifts and boom lifts used in maintenance or warehouse operations.

Not motorized: hand pallet jacks and push carts. Those are manual. An electric pallet jack is motorized. A hand pallet jack is not.

You can stop here if you only needed the quick identification. But if you design or buy this equipment, stick with me. The motor inside these devices drives cost, efficiency, and uptime. Laminations drive the motor.

Defining Motorized Material Handling Devices

A device counts as motorized if a power source drives its motion. That source might be an electric motor with a battery. It might be an internal combustion engine running gasoline, diesel, or propane. Many warehouses now prefer battery electric devices because they cut emissions and noise. Lithium-ion forklift batteries have changed the game on charging and uptime.

Material handling itself covers four core functions:

- Movement. Transporting goods from A to B across floors, aisles, or facilities.

- Storage. Stacking, shelving, retrieving, and staging.

- Protection. Preventing damage during movement and storage.

- Control. Tracking, sorting, and managing flow with systems like WMS or ERP integration.

Motorized devices execute those functions faster and with less strain on people. That’s the simple definition. The benefits ripple across throughput, accuracy, and safety.

Common Types: Examples and Applications

To help your team spot the right tool for the job, here’s a concise, application-driven look at the main categories.

Industrial Trucks (Powered Industrial Trucks)

- Forklifts (Lift Trucks). The workhorses in distribution centers and manufacturing plants.

- Counterbalance forklifts. General purpose. Pallet in. Pallet out. Load trailers. Feed production lines.

- Reach trucks. Narrow aisles and high-density storage. You get deeper reach into racking without moving the base.

- Order pickers. Raise the operator to pick cases or eaches from high racks.

- Electric pallet jacks. Quick horizontal moves. Ideal on docks or for cross-docking.

- Stackers. Lift and stack over short distances with electric drive and lift.

- Tow tractors. Pull trains of carts in manufacturing. Great for lean material handling and just-in-time material delivery.

Powered industrial trucks fall under OSHA material handling standards. Proper forklift operator training and safety protocols reduce risks and insurance exposure.

Conveyor Systems

- Belt conveyors. Move anything from parcels to bulk material. Soft starts reduce product damage.

- Roller conveyors. Gravity or motorized rollers. Ideal for unit loads and accumulation zones.

- Chain conveyors. Robust choice for pallets and tough, dirty environments.

- Screw conveyors. Move granular or powdered materials over short distances with controlled flow.

- Pneumatic conveyors. Use air pressure or vacuum to move powders and granules through pipes with enclosed cleanliness.

Conveyors create continuous material flow and enable sortation system technology. You can pair them with pick and place robots or palletizing robots to automate end-of-line tasks.

AGVs and AMRs

- Automated guided vehicles (AGVs). Follow fixed routes with guidance tape or reflectors. Reliable for repetitive paths and heavy loads.

- Autonomous mobile robots (AMRs). Navigate dynamically with onboard sensors and maps. More flexible for changing layouts and goods-to-person automation.

AGV safety features and AMR navigation technology continue to improve. You can scale fleets as demand changes. That flexibility helps combat labor shortage pressures.

Automated Storage and Retrieval Systems (AS/RS)

- Unit-load AS/RS. Pallet-level storage with cranes or shuttle systems.

- Mini-load AS/RS. Totes and cartons for parts or e-commerce fulfillment.

- Vertical carousels and horizontal carousels. High-density, high-accessibility storage for small parts.

AS/RS can boost order picking accuracy and throughput. You can tie them tightly to a warehouse management system (WMS) and enterprise resource planning (ERP) platform for inventory management.

Cranes and Hoists

- Overhead cranes and gantry cranes. Move heavy machinery or large unit loads across a bay or yard.

- Jib cranes. Support localized lifting at a workstation or cell.

- Electric chain hoists and wire rope hoists. Provide vertical lifting with precise control.

Crane and hoist selection depends on load characteristics and structure. You want a solution that protects product and workers while delivering the lift you need.

Why Motorized Material Handling Is Essential

Motorized handling delivers benefits you can measure.

- Efficiency and productivity. Move more with less. Automated material handling can push throughput up significantly in high-volume operations. Companies often report 1.5x to 3x increases after deploying AS/RS or goods-to-person AMRs in the right context.

- Safety. Manual material handling drives a large share of strains and sprains. Powered devices reduce lift-and-carry exposure. Better ergonomics means fewer injuries and less downtime.

- Cost reduction. Labor hours drop for repetitive moves. Product damage falls when conveyors and lifts handle goods consistently. Space utilization improves with vertical storage. Those savings add up to faster ROI.

- Accuracy. AGVs, AMRs, and sortation systems reduce pick errors. WMS integration drives data-driven decisions and cleaner inventory.

- Flexibility. You can scale fleets. You can change flows as product mix shifts. AMRs shine in dynamic environments.

- Sustainability. Electric trucks and robots run quieter and cleaner. Li-ion batteries re-charge quickly and cut energy waste.

Industry reports from groups like MHI and the IFR point to steady growth in automation because these gains persist across sectors. E-commerce fulfillment pushes speed. Manufacturing seeks leaner flows. Distribution wants resilience. Motorized handling sits at the center.

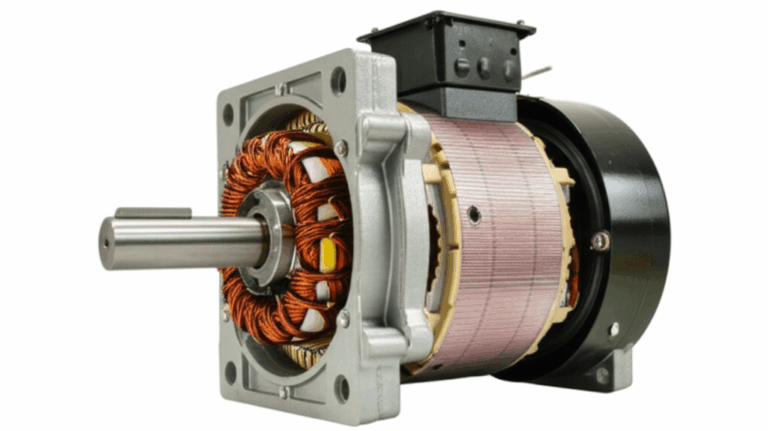

The Motor Inside the Machine: Engineering Fundamentals of Laminations

Let’s open the hood. Forklifts, conveyor drives, cranes, hoists, AGVs, AMRs, and AS/RS shuttles run on motors. The cores in those motors are built from thin steel sheets called laminations. Those laminations do more for your bottom line than most people realize.

Here’s the physics in a nutshell.

- Eddy currents. Think of eddy currents like small whirlpools in a river. A changing magnetic field induces circular currents inside solid steel. Those currents waste energy as heat. Thinner, insulated laminations break big whirlpools into tiny ripples. Less heat. Less wasted power.

- Hysteresis loss. Magnetic materials resist flipping their magnetic state back and forth. That resistance is hysteresis. Every flip costs energy. Materials with lower coercivity, which is the resistance to demagnetization, cut hysteresis loss.

- Frequency matters. Higher electrical frequency ramps eddy current losses fast. Conveyor drives and forklifts often use variable frequency drives. AMRs and AS/RS may run high-speed compact motors. As frequency rises, lamination thickness and insulation become even more important.

This is why you see electrical steel grades chosen for specific frequency ranges and flux densities. Your material choice and stack construction dictate heat rise, efficiency, and torque density. Those metrics drive battery life in AGVs and forklifts. They also drive reliability in cranes and hoists that see high duty cycles.

If you want a deeper primer on the building blocks, start here:

- The role and design of motor core laminations

- How a stator core lamination directs flux and holds windings

- How a rotor core lamination interacts with the stator to produce torque

- Steel choices that underpin performance in electrical steel laminations

Those four links cover the essentials for most motorized material handling devices.

A simple analogy you can share with your team

Picture two frying pans on low heat. One has a thick solid steel base. The other has a base made of thin, insulated layers stacked together. The solid base conducts heat quickly across its body. The layered base resists that heat flow between layers. Laminations work the same way for stray currents. Layers block the sideways flow of eddy currents. The motor runs cooler and wastes less energy.

Material Considerations for Laminations (The Guide)

You have two big knobs to turn: material selection and thickness. Both influence core loss, torque density, and cost.

Silicon steels (M-grades)

Silicon steels form the backbone of motor and transformer cores. You’ll often see “M” grades for motor steels in North America. More silicon generally lowers core loss and raises electrical resistivity. That makes eddy currents smaller.

- Pros

- Good balance of cost and performance.

- Widely available with consistent quality.

- Works well for general-purpose motors and many conveyor drives.

- Cons

- Not the best at very high frequencies compared to specialized alloys.

- Mechanical properties can limit extreme forming or high-speed rotor designs.

CRGO vs CRNGO

Cold-rolled grain-oriented (CRGO) steels align grains during rolling to favor magnetization in one direction. Transformers love that. Motors see fields rotating rather than fixed in one direction. Cold-rolled non-grain-oriented (CRNGO) steels suit motors better because they allow more isotropic magnetic behavior.

- CRGO lamination core. Ideal for transformer lamination cores and EI or UI core shapes in power equipment.

- CRNGO lamination. A common workhorse for motors in industrial trucks, conveyors, and hoists.

If your team crosses between transformers and motors, you already know why the grain texture matters. Pick the steel for the field pattern you expect.

Cobalt and nickel-iron alloys

High-performance alloys can push flux density higher and reduce loss at elevated frequencies.

- Cobalt alloys

- Pros. Very high saturation flux density for compact, high-power-density motors. Useful in aerospace or top-tier servo motors.

- Cons. Expensive. Harder to source at scale. Use only where the performance gain justifies the premium.

- Nickel-iron

- Pros. Lower core loss than standard silicon steels at certain frequencies. Good for specialized high-frequency applications.

- Cons. Cost sits above typical motor steels. Evaluate ROI carefully.

Selecting thickness

Thinner laminations lower eddy current loss. You pay for that with more sheets per stack and higher stamping or cutting time.

- 0.50 mm to 0.35 mm. Common for general-purpose motors in industrial trucks, conveyors, and hoists.

- 0.35 mm to 0.20 mm. Useful for higher frequency or premium efficiency lines. Also common in BLDC motors for AGVs and AMRs with compact, high-speed designs.

- Below 0.20 mm. Niche territory for very high-frequency or ultra-efficient designs. Expect significant cost and manufacturing care.

Coatings and insulation

Each lamination needs a thin insulating coating. That breaks electrical contact between sheets. It also sets how well the stack handles bonding or welding.

- Organic coatings. Good electrical resistance. Watch temperature limits.

- Inorganic or oxide coatings. Handle higher temperatures better. Often used for annealed stacks.

Coating choice drives stacking factor and thermal class. Work with your supplier early to match the insulation to your process.

Tying material choice to your application

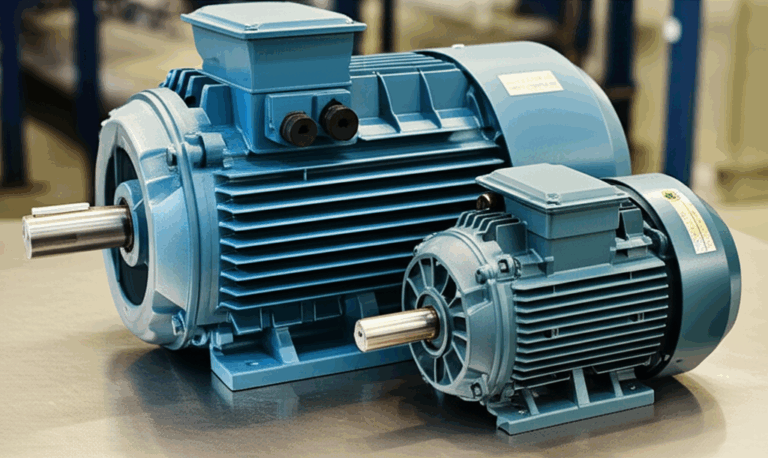

- Forklifts and reach trucks. Duty cycles swing from short bursts to long hauls with heavy loads. Efficiency matters for battery life. CRNGO silicon steel in 0.35 mm to 0.50 mm often hits a solid balance. BLDC designs push thinner gauges where needed.

- AGVs and AMRs. Battery life and compact size sit at the top of the list. BLDC stator designs often use thinner laminations and premium CRNGO grades to reduce loss at higher PWM frequencies.

- Conveyors. Many run at moderate speeds with variable frequency drives. CRNGO steels in mid-range thickness often suffice. High-speed sortation systems may justify thinner gauges.

- Hoists and cranes. High torque at low speed with intermittent heavy load cycles. Material selection must balance loss, torque density, and thermal performance. Overspec for safety and thermal headroom.

Manufacturing and Assembly Processes That Affect Performance

Choosing the right steel is half the battle. How you cut, stack, and join laminations can make or break the design.

Cutting methods

- Progressive die stamping. Best for high-volume production with consistent edges and tight tolerances. Upfront tooling cost pays back at scale.

- Laser cutting. Perfect for prototyping, low volume, and complex geometries. Heat-affected zones can raise local loss unless managed with proper parameters and post-processing.

- EDM or waterjet. Used when you need very tight tolerances or minimal thermal impact. Slower and costlier per part.

Edge quality matters. Burrs increase electrical contact between sheets. That raises eddy current loss and hurts stacking factor. Aim for low burr height and consistent edge condition.

Stress relief annealing

Stamping induces stress in the steel. Stress hurts magnetic properties. Proper annealing can restore performance. Not every stack needs it. High-efficiency or high-frequency designs often do. Coordinate with your coating selection since temperature exposure matters.

Stacking and joining

- Interlocking. Tabs and slots lock laminations together like LEGO bricks. This avoids welding heat. It produces strong stacks for many stators and rotors.

- Bonding. Adhesive bonding layers create rigid stacks with excellent damping and low noise. Great for high-speed BLDC rotors and quiet conveyors.

- Riveting or cleating. Old-school mechanical joining still works in many motor cores. Consider for prototypes or when welding and bonding are constrained.

- Welding. Tig or laser welds create very rigid assemblies. Heat can degrade local magnetic properties. Use sparingly or with mitigation like post-weld annealing where feasible.

Tolerances and quality control

- Dimensional tolerances. Concentricity between stator bore and rotor OD drives air-gap consistency. The air gap affects torque ripple and noise.

- Flatness and runout. Critical for high-speed AMR or AS/RS motors.

- Stacking factor. The ratio of steel to total stack thickness. Coatings and burrs lower the factor. Control it for consistent magnetics.

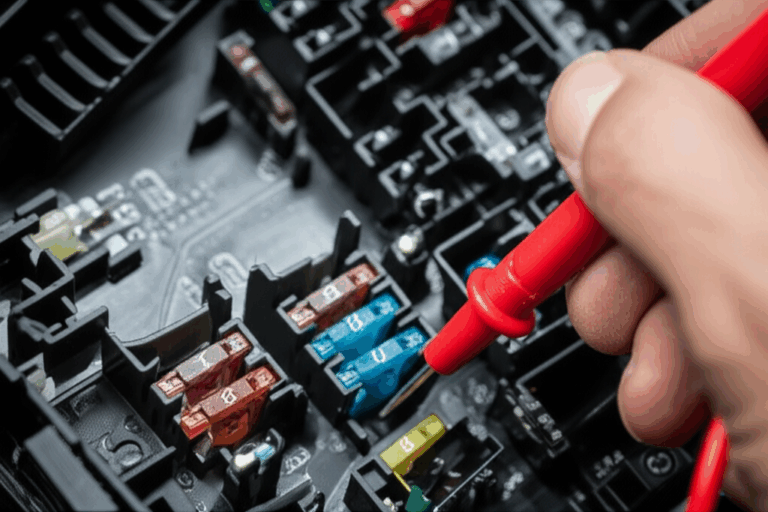

- Electrical tests. Epstein frame or single-sheet testers provide core loss data. Use them during qualification to lock in material and process quality.

Matching Solutions to Your Application

Let’s map common motorized material handling devices to the lamination choices that tend to work best. Use this as a conversation starter with your supplier and mechanical team.

- Forklifts and reach trucks. Battery electric forklifts thrive on efficient motors. Mid-thickness CRNGO with solid coatings and interlocked or bonded stacks delivers reliable torque with manageable heat. BLDC traction motors in advanced models may justify thinner laminations for improved efficiency.

- Electric pallet jacks and stackers. Focus on efficiency at low to moderate speeds. CRNGO M-grades in 0.35–0.50 mm hit a conservative sweet spot.

- Conveyors and sortation systems. Roller and belt conveyors use geared motors with VFDs. Keep eddy current loss in check at switching frequencies. You may not need ultra-thin laminations unless you push high speed or compact footprints.

- AGVs and AMRs. Space and energy dominate. BLDC stator cores with thin laminations and high-grade CRNGO steels reduce loss at higher electrical frequencies. Bonded stacks and precise tolerances help minimize noise and vibration. That matters for sensors and navigation stability.

- AS/RS shuttles and mini-load. Rapid cycles and frequent accelerations favor efficient, compact motors. Consider thinner laminations and bonding for rigidity.

- Hoists and cranes. Duty cycles demand thermal headroom. Pick a steel grade with predictable loss and a joining method that preserves properties. Stress relief can pay off in heavy-duty, high-safety-factor designs.

Environment also matters:

- Cold storage material handling. Low temperatures affect lubricant viscosity and battery performance. Lamination properties hold steady. Select insulation coatings rated for cold soak and thermal cycling.

- Cleanroom material handling. Seek low particulate and low outgassing. Bonded stacks often beat welded options for cleanliness.

- Heavy duty material handling. Robust stacks and conservative temperature rise margins keep uptime high. Avoid edge damage during assembly.

Key Considerations When Choosing Motorized Material Handling Equipment

Before you pick the device, write down your constraints. Then match the device and its motor configuration to that reality.

- Application and environment. Aisle width. Racking height. Floor conditions. Temperature range. Contamination risk.

- Load characteristics. Weight, size, and stability of unit loads. Bulk vs unit load handling. Intermittent vs continuous material flow.

- Throughput goals. Peak and average. Space utilization strategies. Cross-docking equipment needs.

- Power source. Battery electric vs IC engine. Li-ion forklift batteries enable fast charging and opportunity charging. IC engines still rule outdoors and in heavy-duty continuous operations.

- Integration. WMS integration and ERP material handling interfaces. AMR fleet management. Sortation system control. Goods-to-person automation compatibility.

- Safety and ergonomics. OSHA material handling standards. Operator training. Material handling safety devices and guarding.

- Maintenance and uptime. Predictive maintenance material handling strategies pay off. Plan for parts, access, and technician training.

- Budget and ROI. Automated material handling ROI varies by volume and labor intensity. Equipment rental can bridge budget gaps during pilot phases. Model energy savings from efficient motors and better lamination choices.

- Scalability and flexibility. Industry 4.0 material handling trends favor modular equipment and software-driven routing. Aim for upgrades without massive rebuilds.

Procurement Checklist and Next Steps

You want speed without regret. Use this checklist to keep decisions clean and defensible.

- Define the problem. Throughput gap. Safety goal. Labor constraint. Write the measurable target.

- Map the flow. Manufacturing material flow and supply chain material flow paths differ. Sketch both. Identify intermittent vs continuous material handling segments.

- Shortlist equipment. Compare manual vs motorized equipment for each flow. Identify powered industrial trucks, conveyor belt systems, cranes, AGVs, AMRs, and AS/RS where they fit.

- Set motor performance targets. Efficiency class. Duty cycle. Ambient conditions. Noise limits. Use these to drive lamination choices.

- Specify lamination requirements. Steel grade (CRNGO for motors). Thickness range. Coating type. Burr limits. Stacking factor. Joining method.

- Choose a manufacturing route. Stamping for volume. Laser cutting for prototypes or complex low-volume parts. Plan for stress relief if needed.

- Request data. Core loss curves at your flux density and frequency. B-H curve data. Mechanical tolerances. Coercivity and permeability figures in plain English.

- Pilot and test. Validate motors in representative loads. Instrument for temperatures and current. Confirm WMS or ERP integration. Check pick accuracy and productivity in live conditions.

- Plan maintenance. Lock in spare parts. Define predictive triggers. Train operators and techs. Tie to OSHA safety standards.

- Model ROI. Include labor, energy, product damage, and space savings. Model risk. Present options with pros and cons.

If you need a quick technical deep dive on motor cores, share the resources above with your team. They’ll accelerate your design and sourcing conversations.

FAQ

Q: What is the primary purpose of material handling?

A: Move, store, protect, and control materials through manufacturing and logistics. Done right, you increase throughput, improve safety, reduce costs, and raise accuracy.

Q: Is a hand pallet jack considered a motorized device?

A: No. A hand pallet jack is manual. An electric pallet jack is motorized.

Q: How do AGVs differ from AMRs?

A: AGVs follow fixed routes with guided infrastructure. AMRs navigate dynamically using onboard sensors and maps. AMRs adapt faster to layout changes and mixed traffic.

Q: What are the main benefits of using forklifts?

A: They lift and move unit loads quickly and safely. You get flexibility across docks, racks, and staging. Electric models cut emissions and noise. Proper operator training and maintenance improve safety and uptime.

Q: Which equipment fits high-density storage?

A: Reach trucks in narrow aisles, AS/RS unit-load systems, and vertical or horizontal carousels for small parts. Pair with WMS integration for inventory accuracy.

Q: Where do conveyors beat trucks?

A: Conveyors excel in continuous flow and fixed routes. They shine in accumulation, sortation, and packaging material handling lines.

Q: What lamination factors influence motor efficiency most?

A: Steel grade and thickness, insulation coating, edge quality, and joining method. Thinner sheets cut eddy currents. CRNGO steels suit motors. Good coatings and low burrs protect stacking factor and cut losses.

Related Concepts You May Evaluate During Design

To keep this article readable, here’s a compact list of adjacent topics you may review during project planning:

- Types of material handling equipment and material handling device categories

- Industrial trucks explained and powered industrial trucks safety

- Material handling systems definition and components of material handling

- How do conveyors work with belt conveyor applications and roller conveyor design

- Chain conveyor types and screw conveyor principles

- Pneumatic conveying systems and vibrating conveyor uses

- Jib crane functions, gantry crane benefits, and overhead crane types

- Hoist lifting devices including electric chain hoist and wire rope hoist mechanics

- Automated guided vehicle (AGV) vs autonomous mobile robots (AMR)

- Automated storage and retrieval system (AS/RS), vertical carousel system, and horizontal carousel storage

- Pick and place robots, palletizing robots, depalletizing equipment, and sortation system technology

- Warehouse automation technology and intralogistics solutions for goods-to-person automation

- Material handling safety, OSHA material handling standards, and ergonomic material handling

- Productivity in warehouses, efficiency material handling, and cost reduction material handling

- Space utilization strategies, inventory management equipment, and e-commerce fulfillment solutions

- Industry 4.0 material handling, smart warehouse technology, and predictive maintenance material handling

- Battery electric vs IC engine and lithium-ion forklift batteries

- Material handling equipment rental and choosing material handling equipment

- Importance of proper material handling and material handling operator training

- Material handling equipment suppliers and material handling system integrators

- Warehouse design material flow and material flow analysis with lean material handling principles

- Just-in-time material delivery, cross-docking equipment, and trends in material handling

- Raw material handling systems, bulk material handling equipment, unit load handling

- Continuous material flow and intermittent material handling

- Cleanroom material handling, cold storage material handling, heavy duty material handling, and light duty material handling

- Global material handling market and the future of warehouse automation

Use this checklist when you build your specification or talk with vendors. It keeps scope clear and options grounded.

Conclusion and Future Trends

You asked which of the following is a motorized material handling device. The answer includes forklifts, conveyors, AGVs, AMRs, AS/RS, cranes, and hoists. Those devices push productivity higher and lower risk. They also depend on motors that live or die by their lamination design.

Focus on material choice, thickness, coatings, and joining methods. That attention pays off in efficiency, lower temperatures, and longer service life. Companies see faster ROI when motors run cooler and draw less current. Battery electric fleets benefit most.

Looking ahead, you can expect:

- More goods-to-person automation. AMRs and AS/RS will keep growing.

- Deeper WMS and ERP integration. Data closes the loop on throughput and quality.

- Smarter maintenance. Predictive maintenance reduces unplanned downtime.

- Better materials. Electrical steel grades continue to reduce core loss.

- Faster charging and better batteries. Lithium-ion dominates. Solid-state research advances.

- Safer systems. Vision systems and standards keep improving.

Your next step depends on where you stand today:

- If you’re scoping equipment. Map flows. Quantify loads. Set throughput and safety targets. Compare manual vs motorized across each segment.

- If you’re tuning motor performance. Lock in lamination thickness, steel grade, and joining method early. Validate core loss at your frequency and flux density. Watch burrs and coatings.

- If you’re preparing to buy. Request sample stacks and test data. Validate in your environment. Line up training and maintenance plans.

When you want to go deeper, share these primers with your team:

- Overview of motor core laminations

- Details on the stator core lamination that carries your windings

- The matching rotor core lamination that produces torque under load

- A grounding in modern electrical steel laminations and why grade selection matters

Use them to spark strong design reviews and better supplier conversations. The result will show up in your uptime, your energy bill, and your team’s confidence.