What is a Permanent Magnet Motor? Understanding Its Efficiency & Applications

Of course. Here is the article, written according to your instructions.

Table of Contents

- The Rotor: The Heart of the Matter

- The Stator: The Powerhouse

- The Air Gap: Small but Mighty

- The Brains of the Operation: Motor Controller/Inverter

- Permanent Magnet Synchronous Motor (PMSM)

- Brushless DC Motor (BLDC)

- Permanent Magnet DC Motor (PMDC)

- A Quick Word on Design: IPM vs. SPM

- Unbeatable Efficiency

- Incredible Power Density

- Amazing Torque and Control

- Lower Maintenance Headaches

- The Sticker Shock: Higher Initial Cost

- The Risk of Demagnetization

- The Rare Earth Conundrum

- The Need for Smart Electronics

- Electric Vehicles (EVs)

- Industrial Automation & Robotics

- HVAC and Home Appliances

- Renewable Energy

Introduction: My First Encounter with a Game-Changing Motor

I’ll never forget the first time I held a modern permanent magnet motor in my hands. I was working in an industrial automation lab, and we were swapping out an old, bulky induction motor from a conveyor system. The replacement, a sleek permanent magnet motor, was literally half the size and weight. I remember thinking, “There’s no way this little thing can do the same job.”

Boy, was I wrong.

Not only did it do the job, but it did it better. It was quieter, more responsive, and a quick check on the power draw showed it was using significantly less energy. That was my lightbulb moment. I realized I was looking at the future.

So, what is a permanent magnet motor? In the simplest terms, it’s an electric motor that uses permanent magnets, rather than electromagnets, on its rotating part (the rotor). This might sound like a small change, but it’s the secret sauce behind their incredible efficiency and compact design. These motors are the unsung heroes powering everything from the electric car you drive to the drone buzzing overhead and the air conditioner keeping you cool.

If you’ve ever wondered why our gadgets are getting smaller, more powerful, and more energy-efficient, the permanent magnet (PM) motor is a huge part of the answer. Let’s dive into how they work and why they’ve become so important.

How Does a Permanent Magnet Motor Actually Work? A Simple Explanation

To understand how a PM motor works, let’s go back to a basic science class experiment. Remember playing with magnets? You know how the north pole of one magnet repels the north pole of another but attracts the south pole. A permanent magnet motor uses this fundamental principle of attraction and repulsion to create motion.

Here’s the breakdown:

Think of it like dangling a carrot on a stick in front of a donkey. The stator’s rotating magnetic field is the carrot, and the rotor is the donkey, always trying to catch up. This constant “chase” is what generates the torque that turns the motor’s shaft. It’s an elegant and incredibly effective way to turn electricity into motion with very little energy wasted as heat.

Let’s Look Inside: The Key Components of a PM Motor

When you break it down, a permanent magnet motor isn’t overwhelmingly complex. I’ve taken apart my fair share, and they all boil down to a few critical parts working together seamlessly. Understanding these components really helps clarify why these motors are designed the way they are. A motor is essentially composed of two main parts: the stator and rotor, but there’s a bit more to it than just that.

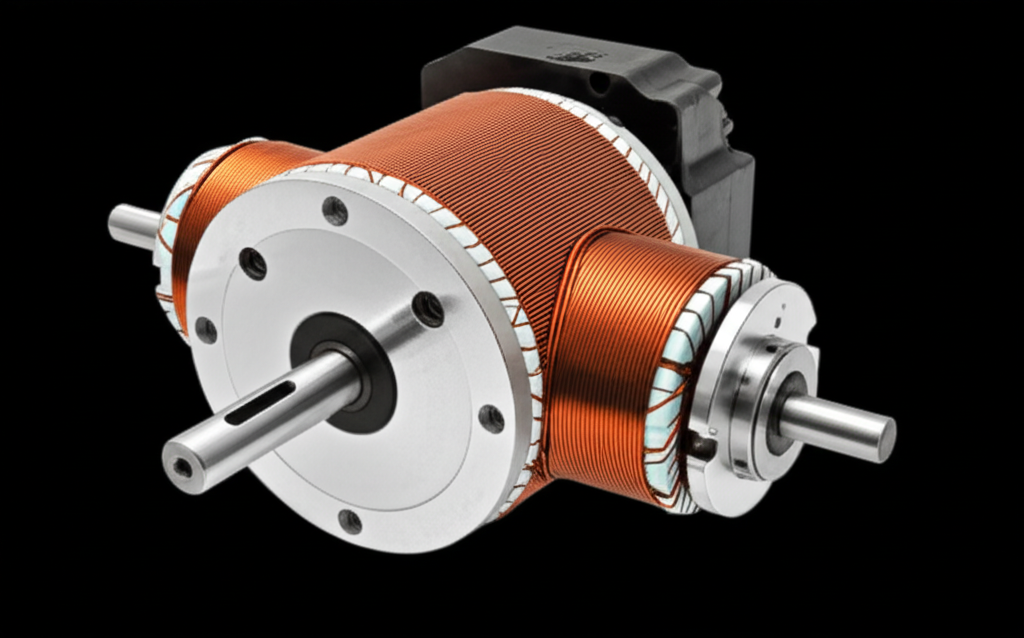

The Rotor: The Heart of the Matter

The rotor is the rotating component—it’s what ultimately turns the shaft and does the work. In a PM motor, this is where the permanent magnets live. These aren’t your average refrigerator magnets; they’re typically made from powerful rare-earth materials like neodymium or samarium-cobalt, or sometimes more common ferrite magnets for lower-cost applications. The choice of magnet material is a huge deal, as it dictates the motor’s strength, temperature resistance, and cost. The magnets are mounted on a core, and the quality of the rotor core lamination is critical for minimizing energy losses and ensuring smooth operation.

The Stator: The Powerhouse

If the rotor is the heart, the stator is the muscle. This is the stationary outer part of the motor that doesn’t move. It consists of a stack of thin steel plates, called laminations, with slots cut into them. Copper wire is wound through these slots to create a series of electromagnets. The design of the stator core lamination is crucial for directing the magnetic field efficiently and reducing energy losses called eddy currents. When the controller sends electricity through these windings, the stator generates the rotating magnetic field that drives the rotor.

The Air Gap: Small but Mighty

The air gap is the tiny, precise space between the rotor and the stator. It might seem insignificant, but it’s one of the most critical design elements in a motor. The smaller the air gap, the stronger the magnetic force between the rotor and stator, and the more efficient the motor. However, making it too small increases manufacturing complexity and the risk of the rotor rubbing against the stator. Engineers spend a lot of time optimizing this gap to get the best possible performance.

The Brains of the Operation: Motor Controller/Inverter

Especially for AC types like PMSMs and BLDCs, you can’t just plug them into the wall. They need a sophisticated electronic controller, often called an inverter or a variable speed drive. This controller is the motor’s brain. It takes the incoming power (AC or DC) and converts it into precisely timed electrical pulses sent to the stator windings. By controlling the frequency and voltage of these pulses, the controller can manage the motor’s speed, torque, and direction with incredible accuracy. This is what makes PM motors so great for applications requiring precise control, like robotics or electric vehicles.

Not All PM Motors Are Created Equal: The Main Types

When people say “permanent magnet motor,” they’re usually referring to a family of motors. In my experience, knowing the differences between the main types is key to understanding why one is chosen over another for a specific job.

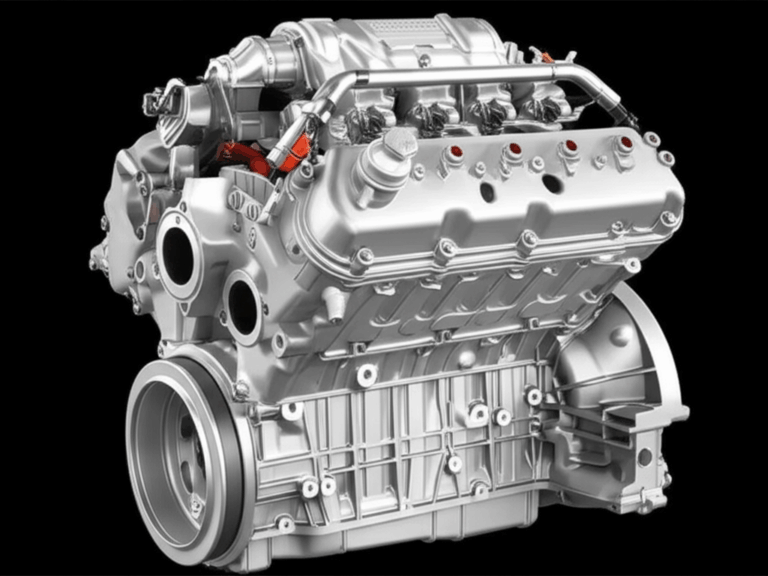

Permanent Magnet Synchronous Motor (PMSM)

This is the superstar of the PM motor world right now. A PMSM is an AC motor where the rotor spins at the exact same speed—in sync—with the stator’s rotating magnetic field. This synchronous operation makes them incredibly efficient (often 97% or higher) and allows for extremely precise control over speed and position.

- Key Characteristics: Highest efficiency, smooth torque delivery, and excellent power density. They require a sophisticated controller using algorithms like Field-Oriented Control (FOC).

- Where I’ve Seen Them: They are the dominant choice for electric vehicle traction motors (think Tesla, Toyota Prius), high-end industrial automation, and servo motors where precision is everything.

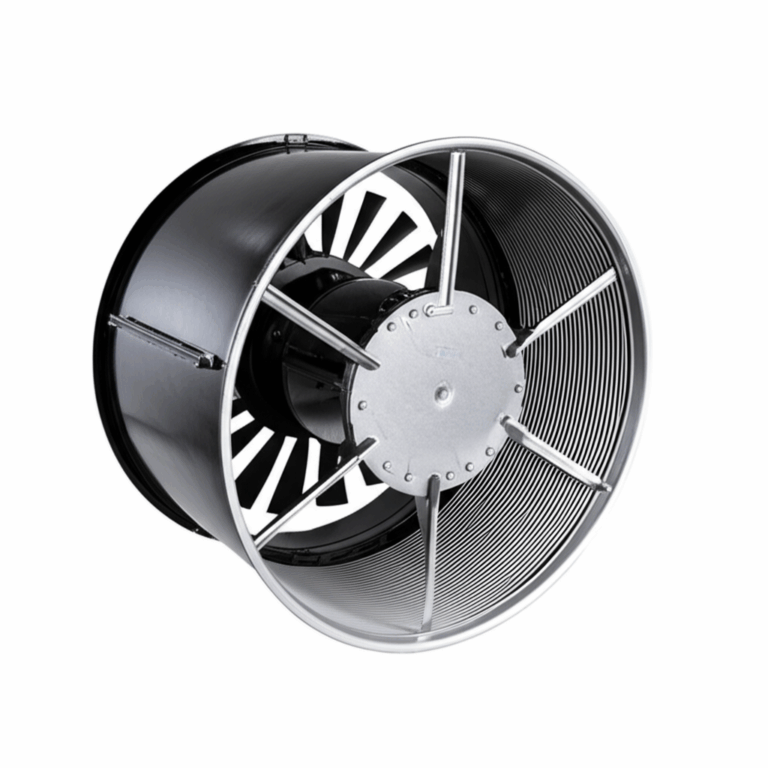

Brushless DC Motor (BLDC)

A BLDC motor is often confused with a PMSM, but there are subtle differences. While it’s also powered by an AC-like waveform from a controller, its internal design and control method are a bit simpler. They are known for their reliability and good performance over a wide speed range. When designing one, the quality of the bldc stator core is paramount for achieving the desired torque and efficiency.

- Key Characteristics: Highly reliable (no brushes to wear out), good efficiency (typically 90-95%), and simpler control than a PMSM.

- Where I’ve Seen Them: Everywhere! Drones, computer cooling fans, cordless power tools, hard drives, and even some washing machines and refrigerators. They are the workhorses of modern electronics.

Permanent Magnet DC Motor (PMDC)

This is the old-school version. Unlike its brushless cousins, the PMDC motor has brushes and a mechanical commutator to switch the direction of the current in the windings. The stator has the permanent magnets, and the rotor has the windings.

- Key Characteristics: Simple design, low cost, and easy to control (just apply a DC voltage). However, the brushes wear out over time, creating maintenance needs and limiting lifespan.

- Where I’ve Seen Them: They’re still used in less demanding applications where cost is a major factor, like car windows, windshield wipers, and children’s toys.

A Quick Word on Design: IPM vs. SPM

Within PMSMs, you’ll often hear the terms Interior Permanent Magnet (IPM) and Surface Permanent Magnet (SPM). This just refers to how the magnets are placed on the rotor.

- SPM: The magnets are glued to the outside surface of the rotor. This is simpler to manufacture but can be less robust at very high speeds.

- IPM: The magnets are embedded inside the rotor laminations. This is more complex to build but protects the magnets, allows for higher speeds, and even adds a bit of “reluctance torque” for an extra efficiency boost. Most modern EV motors use an IPM design for these reasons.

The Big Question: Why Are These Motors So Popular?

I saw the benefits firsthand when I swapped out that old industrial motor. The reasons PM motors are taking over are practical and powerful.

Unbeatable Efficiency

This is the number one advantage. Because the rotor’s magnetic field is created by permanent magnets, the motor doesn’t have to expend energy creating that field, which is a major source of energy loss in induction motors. This means more of the electrical energy going into the motor is converted into useful mechanical work. We’re talking efficiency ratings of 95-98% for some PMSMs, which can lead to massive energy savings over the life of the motor, especially in applications that run continuously, like pumps and fans.

Incredible Power Density

Power density means getting more power out of a smaller, lighter package. Since permanent magnets are so strong, you can build a very powerful motor without it being huge and heavy. For an application like an electric vehicle, this is a game-changer. A lighter motor means the car needs less energy to move, extending its range. For a handheld power tool, it means less fatigue for the user.

Amazing Torque and Control

PM motors, particularly PMSMs, can deliver high torque right from a standstill and maintain it across a wide range of speeds. This is perfect for an EV, which needs instant acceleration. Paired with their advanced electronic controllers, they also offer incredibly precise control over speed and position, which is why they are the go-to choice for robotics and CNC machines where every millimeter counts.

Lower Maintenance Headaches

For the brushless types (BLDC and PMSM), the lack of brushes is a huge advantage. Brushes are physical contacts that wear down over time, creating dust and requiring periodic replacement. By eliminating them, brushless PM motors are far more reliable and can operate for years in sealed environments without needing any service. This reduces downtime and maintenance costs significantly.

It’s Not All Perfect: The Downsides and Limitations

As with any technology, PM motors aren’t a silver bullet for every application. It’s important to be aware of their limitations.

The Sticker Shock: Higher Initial Cost

The biggest hurdle is often the upfront cost. The high-performance rare earth magnets (neodymium and samarium-cobalt) used in the best PM motors are expensive. The complex controllers and inverters needed to run them also add to the overall system cost, making them more expensive to purchase than a traditional induction motor.

The Risk of Demagnetization

Permanent magnets can lose their magnetism—a process called demagnetization. I learned this the hard way once when I pushed a servo motor way past its temperature limit. Excessive heat is a magnet’s enemy. A strong opposing magnetic field, caused by a massive current overload, can also damage them. Motor designers have to build in thermal protections and current limits to prevent this from happening.

The Rare Earth Conundrum

The reliance on rare earth elements is a significant geopolitical and environmental issue. The vast majority of these materials are mined and processed in a handful of countries, leading to supply chain vulnerabilities and price volatility. There are also environmental concerns associated with their extraction. This is driving a huge amount of research into developing powerful motors with reduced rare earth content or alternative magnet materials.

The Need for Smart Electronics

You can’t just hook up a PMSM or BLDC motor to a switch. They absolutely require a sophisticated controller to function. This adds complexity and another potential point of failure to the system. While these controllers are incredibly powerful, they also require careful programming and tuning to get the most out of the motor.

Where You’ll Find Permanent Magnet Motors in Your Daily Life

Once you know what to look for, you start seeing the impact of PM motors everywhere. They’re the hidden workhorses of our modern technological landscape.

- Electric Vehicles (EVs): This is the most high-profile application. The high efficiency and power density of PMSMs are what give EVs their impressive range and instant torque. Nearly every major EV manufacturer, from Tesla to Hyundai, uses PM motors in at least some of their models.

- Industrial Automation & Robotics: In a factory, precision is king. PM servo motors provide the fast, accurate, and repeatable movements needed for robotic arms, CNC machines, and automated assembly lines. Their compact size allows for more agile and complex robot designs.

- HVAC and Home Appliances: Your high-efficiency air conditioner or washing machine likely has a PM motor. By allowing the compressor or drum to run at variable speeds, they match energy use to the actual demand, saving you money on your electricity bill.

- Renewable Energy: Many modern, large-scale wind turbines use direct-drive permanent magnet generators. By eliminating the need for a complex and maintenance-heavy gearbox, they become more reliable and efficient—a huge plus when your turbine is sitting miles offshore.

PM Motors vs. Induction Motors: A Quick Showdown

For decades, the AC induction motor was the undisputed king of industry—it’s cheap, rugged, and reliable. So when should you choose a PM motor instead?

Here’s my simple rule of thumb:

- Choose an Induction Motor if your top priorities are low initial cost and extreme ruggedness in a simple, fixed-speed application where top-tier efficiency isn’t the primary concern. They are brutes that can take a lot of abuse.

- Choose a Permanent Magnet Motor if your application demands the highest possible energy efficiency, a compact size and low weight, variable speed operation, or precise control over speed and torque. The higher upfront cost is often paid back quickly through energy savings and improved performance.

What’s Next? The Future of Permanent Magnet Motor Technology

The field is moving incredibly fast. The biggest push right now is to reduce the dependence on rare earth magnets. Researchers are experimenting with new magnetic materials and clever motor designs, like synchronous reluctance motors, that use little to no magnets while still offering high efficiency.

We’re also seeing continuous improvements in control algorithms. Advanced software is making controllers smarter, allowing them to squeeze even more performance and efficiency out of the motors, while also making them quieter and smoother. As regulations demand ever-higher energy efficiency (like the IE4 and IE5 standards), the adoption of PM motor technology is only going to accelerate.

Conclusion: The Quiet Force Driving Our Modern World

From that first moment I held one in my hand, I knew the permanent magnet motor was special. It represents a fundamental shift in how we think about converting electricity into motion—a shift from brute force to elegant efficiency.

They are the reason our electric cars can travel farther, our factories can produce more with less energy, and our gadgets can pack more power into smaller spaces. While they often operate silently in the background, their impact is everywhere. They are, without a doubt, one of the key technologies driving us toward a more sustainable and electrified future.