What Is a Permanent Split Capacitor (PSC) Motor? My Field Guide to How It Works, Where It Fits, and Why It Lasts

- Table of Contents

- Introduction: How I Learned to Love PSC Motors

- PSC Motor in One Line: The Simple Definition

- How a PSC Motor Works

- The stator, the rotor, and the magic of phase shift

- Why the run capacitor matters

- Why there’s no centrifugal switch

- Inside the Construction: Windings, Core, Bearings, and Materials

- Main and auxiliary windings

- Laminations and core quality

- Bearings, insulation class, and thermal protection

- Electrical Behavior and Performance Numbers You Should Know

- Efficiency, power factor, torque, and current

- Speed, poles, HP, and voltage

- Key Characteristics and Features of PSC Motors

- Advantages of PSC Motors

- Disadvantages and Real Limits

- Common Applications: Where PSC Motors Shine

- HVAC and refrigeration

- Pumps and small appliances

- Direct-drive fans and quiet duty

- PSC vs Other Single-Phase Motors

- PSC vs shaded pole

- PSC vs split-phase

- PSC vs capacitor-start (CS) and CSCR

- PSC vs ECM motors

- Selecting and Sizing a PSC Motor

- Load type, starting torque, and HP

- Power factor and energy use

- NEMA frames and practical fit

- Wiring, Rotation, and Speed Control

- Basic wiring anatomy

- Reversing direction

- Electronic speed control options and limits

- Maintenance and Troubleshooting in Plain English

- Capacitor failure symptoms and testing

- Bearings, noise, and overheating

- Safety practices you should not skip

- Capacitors 101 for PSC Motors

- Microfarads, voltage rating, and types

- Replacement tips and pitfalls

- Noise Reduction and Comfort Notes

- Energy Savings and Environmental Impact

- FAQs I Get All the Time

- Conclusion: Why PSC Motors Keep Earning Their Spot

Introduction: How I Learned to Love PSC Motors

I started out in residential HVAC service. Day after day I found the same hero hidden behind grilles and shrouds. A humble permanent split capacitor motor kept the air moving. It did not complain much. It ran quietly. It kept energy bills tame when sized right. Over time I learned why this motor keeps showing up in furnaces, condensers, evaporators, and fans. The design hits a sweet spot for continuous duty with easy starts.

If you’ve ever heard a blower hum then spin up after a quick nudge. You’ve probably met a PSC motor with a tired run capacitor. I’ve replaced more of those silver cans than I can count. The good news is that once you understand how a PSC motor works you can pick the right one, wire it correctly, troubleshoot it fast, and squeeze better efficiency out of your system.

Let me walk you through what I’ve learned. I’ll keep it simple. I’ll also share the little checks and choices that make a big difference.

PSC Motor in One Line: The Simple Definition

A permanent split capacitor motor is a single-phase induction motor with a run capacitor wired in series with its auxiliary winding at all times. The capacitor creates a phase shift between the main winding current and the auxiliary winding current. That shift produces a rotating magnetic field that starts the rotor moving and keeps it running. No centrifugal switch. No start-only capacitor. The auxiliary winding stays in the circuit for the life of the run.

How a PSC Motor Works

The stator, the rotor, and the magic of phase shift

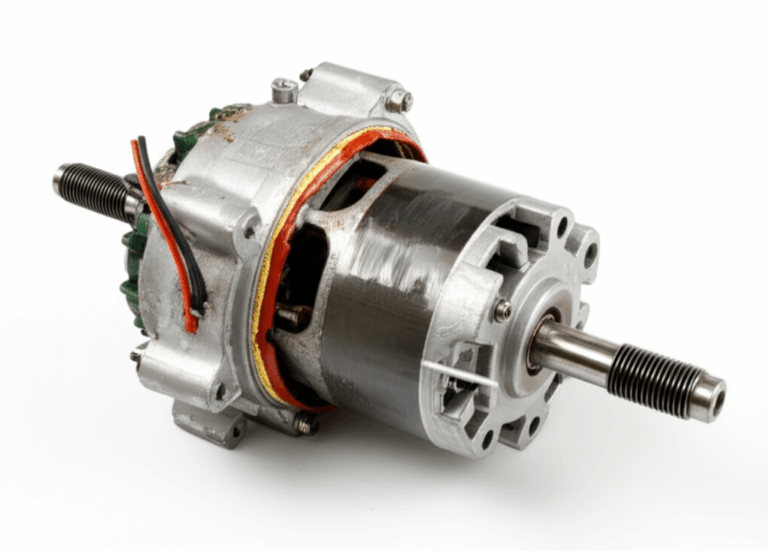

Every induction motor has two big parts. The stationary stator and the spinning rotor. If you want a refresher on how these two dance together you can skim this primer on stator and rotor. In a PSC motor the stator holds two windings. The main winding and an auxiliary winding. They sit at an angle to one another. The rotor sits inside, usually a squirrel cage style.

Single-phase power by itself does not create a naturally rotating magnetic field. It produces a pulsing field that will not start the rotor on its own. We need two currents that are out of phase to fake a two-phase effect. That’s what the run capacitor does.

Why the run capacitor matters

The run capacitor shifts the current in the auxiliary winding relative to the main winding. That shift creates a rotating magnetic field. The motor now produces starting torque and keeps producing smooth torque while running. This is why PSC motors start easily when the load is light. Fans and blowers qualify. Pumps and heavier loads can be a stretch.

Why there’s no centrifugal switch

Some single-phase motors kick in a start winding with a switch then drop it out once the rotor gets up to speed. A PSC motor does not need that. The run capacitor stays in the circuit. The auxiliary winding stays energized at all times. Fewer moving parts means fewer failures. I’ve opened plenty of older split-phase motors with stuck centrifugal switches. PSC motors avoid that headache.

Inside the Construction: Windings, Core, Bearings, and Materials

Main and auxiliary windings

The main winding carries the heavy lifting current. The auxiliary winding works with the capacitor to set up the phase shift. The two windings share the stator slots in a specific pattern that sets the motor’s pole count. Pole count locks in the synchronous speed. A 4‑pole motor targets 1500 or 1800 RPM depending on 50 Hz or 60 Hz supply. Real PSC motors run a bit slower because induction motors slip under load.

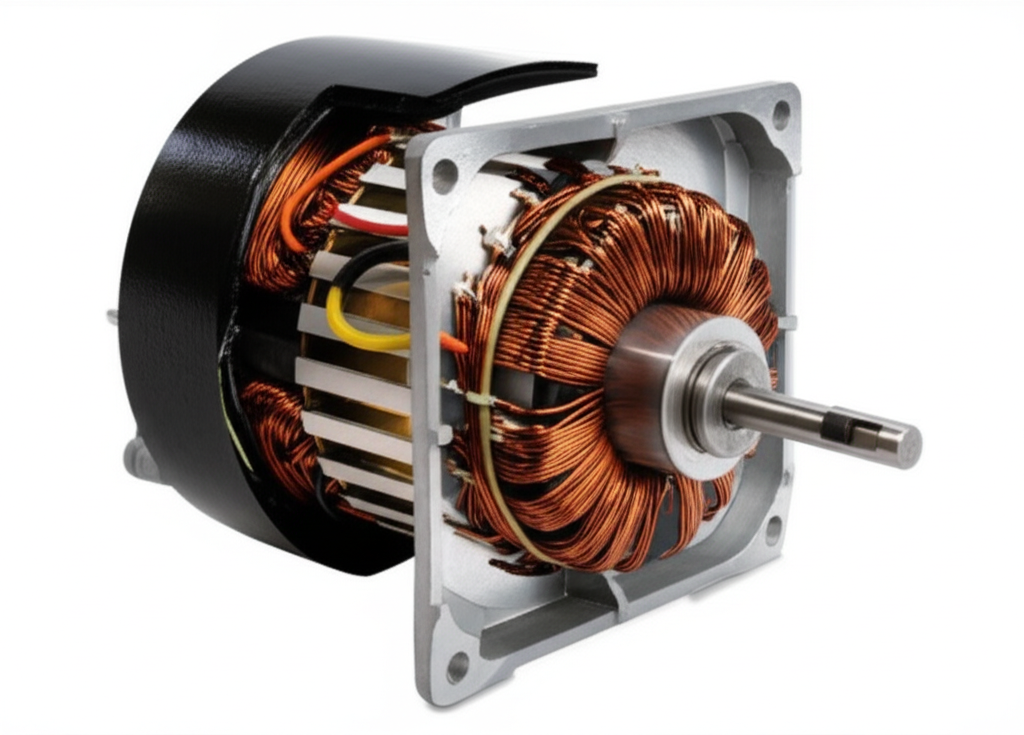

Laminations and core quality

Losses hide in the iron. The stator stack and rotor stack use thin laminations to cut eddy currents. Better laminations reduce heat and improve efficiency. If you want a visual sense of why this matters skim the pages on stator core lamination and rotor core lamination. Both rely on quality electrical steel laminations with tight tolerances. I’ve seen bargain motors that ran too hot. When I checked specs I found cheaper steel or thicker laminations. You get what you pay for in core metal.

Bearings, insulation class, and thermal protection

Bearings matter for sound and life. Sleeve bearings pop up in low-cost PSC motors for fans. They can be quiet. Ball bearings last longer under higher belt loads or higher temperatures. Insulation class sets temperature limits. Class B and Class F are common. A good PSC motor includes thermal protection baked into the windings or mounted as a cutout. That protector saves the motor if airflow gets blocked or if the load jams.

Electrical Behavior and Performance Numbers You Should Know

I keep a short list of typical ranges in my notebook. They help me sanity check expectations for a PSC motor.

- Efficiency range: 50% to 70% in most designs. Some high-quality models break into the mid-70s. This beats shaded pole motors by a mile. It trails capacitor-start or three-phase motors.

- Power factor during run: 0.8 to 0.95. The run capacitor boosts power factor. That lowers reactive current and helps the circuit run cooler.

- Starting torque: about 50% to 100% of full load torque. That’s modest. It fits fan loads or pumps that start with low head.

- Starting current: about 1.0 to 2.5 times running current. That’s gentle compared to many start-capacitor designs.

- Capacitor lifespan: often 5 to 10 years in normal heat. High ambient temperature and voltage spikes shorten life.

- Motor lifespan: 10 to 20 years with basic care and timely capacitor replacement.

- Energy savings vs shaded pole: 30% to 60% in continuous fan duty when replaced like-for-like.

Speed, poles, HP, and voltage

PSC motors come in common single-phase voltages. 120 V, 208–240 V, and sometimes 277 V for light commercial. Horsepower ranges from fractional HP like 1/25 HP for tiny fans up to 1 HP or a bit more in some blowers. Most HVAC PSC motors run at 825, 1050, 1075, 1550, or 1725 RPM nominal. The label usually lists RPM and pole count. You also see amperage, capacitor microfarads, and voltage rating for the capacitor. NEMA frame sizes help you match mounting and shaft dimensions. When I swap a motor I always verify frame, rotation, shaft diameter, and length before I leave the counter.

Key Characteristics and Features of PSC Motors

- Continuous capacitor operation. The run capacitor stays in series with the auxiliary winding.

- Low to moderate starting torque. Great for loads that start easy like blowers and condenser fans.

- Good running efficiency with improved power factor.

- Quiet operation because torque is smoother than split-phase or shaded pole designs.

- Reliable and durable because there’s no centrifugal switch to fail.

- Accepts some electronic speed control. I’ll explain the limits later.

Advantages of PSC Motors

Here’s why I recommend PSC motors for the right jobs.

- Better efficiency than shaded pole motors. That means lower energy use in fans that run all day.

- Low starting current. Lights do not dim as much on startup.

- Smooth and quiet. Less buzz and chatter under steady load.

- Fewer failure points thanks to the simple design. No switch to stick.

- Cost effective in the common sizes used in HVAC and appliances.

- Compact footprint with straightforward wiring.

Disadvantages and Real Limits

No motor wins at everything. PSC motors have clear limits.

- Starting torque stays limited. Heavy inertia, sticky compressors, or high-head pumps push this motor too hard.

- Speed is essentially fixed by pole count. You can trim speed with controls but only to a point.

- The run capacitor can fail and it often fails first. The fix is easy if you can reach it.

Common Applications: Where PSC Motors Shine

HVAC and refrigeration

Most of my field time with PSC motors came in HVAC. Furnace blowers. Condenser fans. Evaporator fans. Attic or exhaust fans. These loads start easy and run for long stretches. PSC motors sip power compared to shaded pole motors. They keep noise down in living spaces.

In refrigeration you see PSC motors on condenser and evaporator fans in refrigerators and freezers. Again the load starts easy. Air moves at a steady clip. Safety and reliability matter more than fancy speed games.

Pumps and small appliances

Condensate pumps. Small circulation pumps with low static pressure. These can run all day without drama. Some dishwashers and washing machines use PSC motors for select functions that start light. Office equipment that needs quiet fans also leans on PSC motors.

Direct-drive fans and quiet duty

Direct-drive fan applications love PSC motors. You bolt the blade on the shaft. You get simple startup and predictable speed. If you need ultra-fine speed control an ECM might fit better. If you need low cost plus quiet operation a PSC motor fits like a glove.

PSC vs Other Single-Phase Motors

This comparison comes up often when I help someone pick a replacement motor. Here’s how I break it down in plain terms.

PSC vs shaded pole

PSC wins on efficiency, torque, and lifespan. Shaded pole motors are cheap and simple. They draw more power for the same airflow. They run hotter. They hum louder. I swap shaded pole for PSC in older fans when the customer wants a quick cut in energy costs.

PSC vs split-phase

Split-phase motors use a start winding with higher resistance then drop it out with a switch. They can offer higher starting torque than PSC in some cases. That switch can fail. PSC runs smoother with better power factor and fewer parts. If you need frequent starts under load you may lean split-phase or CSCR. If you need continuous duty with easy starts I pick PSC.

PSC vs capacitor-start (CS) and CSCR

Capacitor-start motors use a big start capacitor for higher starting torque. CSCR adds a run capacitor for better running characteristics after the start. Those motors beat PSC on starting grunt. They handle compressors and tougher loads. PSC beats them on simplicity and often on noise. Choose CS or CSCR if the load fights back at startup.

PSC vs ECM motors

ECM stands for electronically commutated motor. These are BLDC motors with built-in electronics for precise speed control and very high efficiency. ECM motors win at variable speed and energy savings at part load. They cost more. PSC remains a great choice for fixed-speed, low starting torque jobs where budget matters.

Selecting and Sizing a PSC Motor

Load type, starting torque, and HP

Start with the load. Fan blades and blower wheels start easily which fits PSC torque. Pumps with low static head work too. If the load needs a hard shove at startup you probably want CSCR. Choose HP to match or slightly exceed the original nameplate value. Undersize it and you’ll run hot. Oversize it and you may waste energy.

Power factor and energy use

The run capacitor lifts the power factor which lowers line current. That helps house wiring and breakers. It does not change the real power consumed for a given load. It does help the motor run cooler. PSC typically lands in the 0.8 to 0.95 PF range during steady operation.

NEMA frames and practical fit

Check shaft size, keyway or flat, overall length, stud pattern or belly band, and rotation. NEMA motor classifications help you match the frame. Bring the old motor to the counter or take sharp measurements. I have saved myself many return trips by confirming the mounting method before I left the job.

Wiring, Rotation, and Speed Control

Basic wiring anatomy

A typical PSC motor has two main sets of leads. Line leads for the main winding. Two leads for the auxiliary winding plus the run capacitor. Many models include multiple speed taps on the main winding. Those taps change effective turns which changes slip and speed slightly. Always check the wiring diagram on the label. It shows which color goes to which tap and how the capacitor ties in.

Reversing direction

You reverse a reversible PSC motor by swapping the polarity of the auxiliary winding relative to the main winding. Some motors provide a simple plug or jumper to do this. Others require you to swap two specific leads. Follow the diagram. Do not guess. If the motor label says non-reversible do not force it.

Electronic speed control options and limits

You can slow many PSC motors with a triac style fan speed control or with an autotransformer. Keep the reduction modest. Too low and the motor can stall or overheat because the fan no longer moves enough air to cool the windings. Traditional three-phase VFDs do not play well with standard PSC motors. There are specialized single-phase inverters for PSC designs though they remain niche. In my experience most field speed control on PSC motors uses multi-tap windings or simple fan controllers. If you need wide speed range and high efficiency at part load jump to ECM.

Maintenance and Troubleshooting in Plain English

Capacitor failure symptoms and testing

I treat the run capacitor as a wear part. Most of my “motor hums but won’t start” calls end with a new run capacitor. Here’s what I look for:

- Swollen or bulged case.

- Oil leak if it’s an oil-filled style.

- Motor starts when I spin the fan blade by hand.

- Motor draws higher current than normal and sounds strained.

To test, I disconnect power and discharge the capacitor. Then I use a capacitance meter or a multimeter with a capacitance function. I compare the reading to the microfarad rating stamped on the can. If it’s more than 5–10% low I replace it. I also check for shorts or opens. Replace with the same microfarads and an equal or higher voltage rating.

Bearings, noise, and overheating

Growling or rumbling means bearings. Sleeve bearings can squeal or chatter. Ball bearings growl and vibrate. Overheating shows up as a hot end bell and a smell like hot varnish. Check for blocked airflow. Check the blower wheel or fan blade for debris. Verify voltage is within spec. Low voltage can drive up current which drives up heat.

Safety practices you should not skip

Kill power at the breaker. Verify with a meter. Discharge the capacitor with a resistor or with an insulated discharge tool. Do not short it with a screwdriver. That’s a bad habit that can damage the terminals. Ground the motor properly. Use the right wire size and secure all connections. Replace the fan guard if you removed it. Your fingers will thank you later.

Capacitors 101 for PSC Motors

Microfarads, voltage rating, and types

The label tells you the value in microfarads. For example 5 µF, 7.5 µF, 10 µF, 15 µF, or 20 µF. Some PSC motors use dual run capacitors with two sections. One section serves the compressor in an AC unit and one serves the fan motor. Voltage rating must meet or exceed the original. You’ll see 250 VAC or 370/440 VAC common. Polypropylene film capacitors dominate PSC motor use because they handle AC well and last under heat when built right.

Replacement tips and pitfalls

Match microfarads. Do not “get close” unless the motor manufacturer approves a range. Use a higher voltage rating if needed. Secure the capacitor with the proper strap or bracket. Keep the leads short and neat. Label the wires before you pull the old can out. A quick photo on your phone saves a lot of guesswork later.

Noise Reduction and Comfort Notes

PSC motors run quieter than shaded pole or many split-phase motors. Smoother torque reduces pulsation. You still need to mount them right. Rubber grommets or isolation mounts cut vibration. A bent fan blade or unbalanced blower wheel will roar no matter how quiet the motor tries to be. I balance wheels with a small clip-on weight kit when I see wobble. That small step makes a big difference in sound level.

Energy Savings and Environmental Impact

I have swapped dozens of shaded pole fan motors for PSC units in older equipment. The energy drop showed up on the bill. Savings of 30% to 60% happen in continuous fan duty because shaded pole motors waste a lot of power as heat. PSC cuts that waste. That means lower operating cost and less load on the grid. It also means cooler windings which extends life. If you want the next jump in efficiency consider ECM for variable speed systems. For fixed speed PSC keeps the sweet spot between cost and performance.

FAQs I Get All the Time

- Is a PSC motor the same as a capacitor-start motor? No. PSC uses a run capacitor that stays in the circuit. Capacitor-start uses a big start capacitor that drops out with a switch.

- Why won’t my PSC motor start even though it hums? The run capacitor likely failed. Replace it with the same microfarads and an equal or higher voltage rating.

- Can I slow a PSC motor with a VFD? Standard VFDs are for three-phase motors. Some specialized controllers exist for PSC but they are not common. Use multi-tap windings or a PSC-rated fan controller for modest speed changes.

- Can I reverse my PSC motor? If the label says reversible you can swap the auxiliary winding leads as shown on the diagram. If it says non-reversible do not try.

- Does power factor matter to me? PSC motors run with a good power factor. That reduces reactive current. It helps your wiring run cooler. It usually does not change your residential bill directly though it helps system health.

Conclusion: Why PSC Motors Keep Earning Their Spot

I trust PSC motors for what they are. Single-phase induction workhorses that start easily on light loads, run quietly with good efficiency, and keep going year after year with a simple run capacitor. They fill the gap between cheap shaded pole motors and high-end ECMs. They show up in HVAC fans, refrigeration blowers, small pumps, and countless appliances for good reason.

If you remember just a few things you will do well. Match the microfarads and voltage on the run capacitor. Respect the limits on starting torque. Keep airflow clear so the motor cools itself. Choose quality cores and bearings when you have a say. The laminations inside the stator and rotor matter more than you might think.

I still smile when I hear a blower come back to life after a new capacitor clicks into place. Simple fix. Reliable result. That’s the charm of a permanent split capacitor motor.

Internal links used in this article:

- stator and rotor: https://nfdyzyo.top/stator-and-rotor/

- stator core lamination: https://sinolami.com/stator-laminations/

- rotor core lamination: https://sinolami.com/rotor-laminations/

- electrical steel laminations: https://sinolami.com/electrical-steel-laminations/