What is a PSC Motor? Understanding Permanent Split Capacitor Motors

Table of Contents

- I. Introduction: My First Encounter With a PSC Motor

- II. What Exactly Is a Permanent Split Capacitor (PSC) Motor?

- A. Full form and core idea

- B. The defining feature: a run capacitor in series with the auxiliary winding

- C. How PSC differs from other single-phase induction motors

- III. How a PSC Motor Works: The Operating Principle

- A. Two windings that share the load

- B. The run capacitor’s job: phase shift and rotating magnetic field

- C. No centrifugal switch and why that matters

- D. Starting and running characteristics

- IV. Key Components of a PSC Motor

- A. Stator and its windings

- B. Rotor and the squirrel-cage design

- C. The run capacitor: types and connections

- D. Bearings, shaft, and enclosure

- V. Advantages of PSC Motors

- VI. Disadvantages of PSC Motors

- VII. Common Applications of PSC Motors

- VIII. PSC vs Other Single-Phase Motors

- A. PSC vs capacitor-start

- B. PSC vs shaded-pole

- C. PSC vs split-phase

- IX. Specs That Matter in the Real World

- Efficiency, power factor, torque, RPM, voltage, current, horsepower

- Service factor, NEMA frame, insulation class, ambient rating, enclosures

- X. Maintenance, Testing, and Troubleshooting

- Capacitor health and capacitor sizing

- Humming, failure to start, overheating, vibration, bearings

- Basic electrical tests and overload protection

- XI. Speed Control and Modern Alternatives

- Multi-speed PSC, variable speed tricks, ECM vs PSC

- XII. Buying and Replacing a PSC Motor

- Cost, certifications, OEM notes, and practical tips

- XIII. Conclusion: Why PSC Motors Still Win So Many Jobs

I. Introduction: My First Encounter With a PSC Motor

I still remember the first time I traced a “mystery hum” to a tired run capacitor on a furnace blower. The blower would groan and stall. I could spin the wheel by hand and it would run. That clue pointed straight to the run capacitor on a permanent split capacitor motor. I swapped in a properly sized capacitor. The hum vanished and the blower came to life. That day I learned something simple and powerful. A PSC motor lives or dies by a humble component the size of a small soda can.

Over the years I have worked with PSC motors in HVAC systems, refrigerators, ventilators, sump pumps, and all sorts of fans and blowers. I have wired them, tested them, sized capacitors for them, and replaced burned ones in tight attic spaces with sweat in my eyes. What I learned will save you time and money. If you understand how a PSC motor works you can diagnose it quickly and choose the right one for your application.

II. What Exactly Is a Permanent Split Capacitor (PSC) Motor?

A. Full form and core idea

PSC stands for Permanent Split Capacitor. It is a single-phase AC induction motor that uses a run capacitor permanently connected in series with an auxiliary winding. That simple split gives the motor its name and its personality.

B. The defining feature: a run capacitor in series with the auxiliary winding

Unlike a capacitor-start or split-phase design that drops the start circuit once the rotor is up to speed a PSC keeps its auxiliary winding and run capacitor in the circuit the whole time. The run capacitor creates a phase shift between the main winding current and the auxiliary winding current. That phase shift produces a rotating magnetic field that keeps the rotor turning smoothly.

C. How PSC differs from other single-phase induction motors

A PSC motor does not use a centrifugal switch to take a start winding out of the circuit. That alone makes it simpler and quieter. A capacitor-start motor uses a larger start capacitor and a start switch for high starting torque. A shaded-pole motor uses copper shading rings on part of the stator poles for a weak rotating field and low efficiency. PSC motors sit in the middle. They offer better efficiency than shaded-pole motors and smoother operation than split-phase motors yet they do not match the starting torque of a capacitor-start design.

III. How a PSC Motor Works: The Operating Principle

A. Two windings that share the load

You will find two sets of windings in the stator. The main winding is sometimes called the run winding. The auxiliary winding is sometimes called the start winding even though it stays energized. Both create magnetic fields that interact with the rotor. The PSC uses both windings all the time. That teamwork delivers smooth torque at steady state.

B. The run capacitor’s job: phase shift and rotating magnetic field

The run capacitor sits in series with the auxiliary winding. Its capacitance shifts the current in that winding relative to the main winding. The currents end up out of phase by a useful angle. That phase angle generates a rotating magnetic field inside the stator. The rotor chases that rotating field. That is induction in action. Pick the capacitance poorly and you get weak torque and poor power factor. Pick it well and you get efficient, quiet operation with good power factor.

C. No centrifugal switch and why that matters

Because the PSC design keeps the run capacitor and auxiliary winding in play you do not need a centrifugal switch. One less mechanical part means one less failure point. You also dodge the click-clack noise a switch can make at every start and stop. That is a big reason PSC motors sound smooth in HVAC blowers and condenser fans.

D. Starting and running characteristics

A PSC motor starts best under light load. It develops starting torque from about half to roughly full load torque depending on the design and the capacitance. Once it is spinning the motor runs quietly with low vibration. Starting current sits lower than many split-phase designs. Running current stays modest for a given horsepower. You get a power factor that often lands between 0.85 and 0.95 which utility companies like. You also get decent efficiency for a fractional horsepower motor.

IV. Key Components of a PSC Motor

A. Stator and its windings

The stator holds the main and auxiliary windings in slots around the inner diameter. Laminated electrical steel reduces eddy current losses. Winding material can be copper or aluminum. Copper usually yields better efficiency. The way the stator is stacked and insulated makes a difference. If you want a deeper dive into the steel stacks that form a motor’s core you can explore motor core laminations and see how those laminations impact losses and performance. For a PSC motor the integrity of the stator stack and the winding insulation class both affect heat rise and lifespan. Insulation class B or F is common in HVAC duty motors.

For more background on the relationship between these two core parts in any motor check this concise refresher on stator and rotor. It helps new techs picture how the stationary field and the moving conductor interact.

If you want a specific look at stator stacks and how they get built you can also review this overview of stator core lamination. The material quality and slot geometry influence flux density and acoustic noise which you will hear as whine or hum under load.

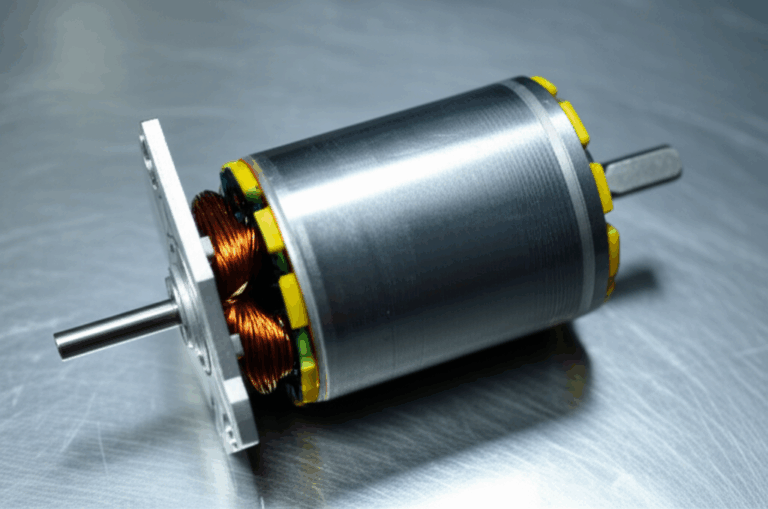

B. Rotor and the squirrel-cage design

PSC motors use a squirrel-cage rotor. Think of aluminum or copper bars cast into slots and shorted by end rings. The spinning shaft presses into this cage through a laminated steel core. The rotating field from the stator induces currents in the cage which create torque. Rotor design has a real say in starting torque and slip. Designs aimed at fans tend to favor smooth running at moderate slip over brute-force starting torque. If you need a closer look at the rotor’s structure this quick read on rotor core lamination shows how those stacked laminations keep losses in check.

C. The run capacitor: types and connections

PSC run capacitors are usually oil-filled metallized polypropylene film units rated for continuous duty. Values often range from a few microfarads up to several dozen microfarads depending on motor horsepower and voltage. You will find common ratings like 370 VAC or 440 VAC. Many HVAC units use a dual run capacitor with three terminals labeled C, FAN, and HERM. “HERM” feeds the compressor run winding which is not always a pure PSC design. The fan terminal feeds the condenser fan motor which is usually PSC.

A correct run capacitor value puts the phase angle in the sweet spot. An undersized value gives weak starting and low torque. An oversized value can raise current and heat which cuts motor life.

D. Bearings, shaft, and enclosure

Bearings are either sleeve bearings or ball bearings. Sleeve bearings run quiet and cost less. Ball bearings last longer under higher loads. The shaft carries the blower wheel or fan blade. Balance and alignment matter. Enclosures vary. Open drip proof (ODP) enclosures only work indoors or where you can keep falling water and debris out. Totally enclosed fan cooled (TEFC) enclosures add protection for dusty or damp areas.

V. Advantages of PSC Motors

- High efficiency for single-phase fractional horsepower duty. Typical PSC efficiency runs about 60% to 75% in the 1/4 to 1 HP range which beats shaded-pole designs by a mile.

- Excellent power factor. That run capacitor gives you a PF often between 0.85 and 0.95 which trims reactive power draw.

- Quiet smooth operation. No centrifugal switch to clack. Balanced phase shift delivers steady torque.

- Simple design and high reliability. Fewer parts mean fewer failures. You mostly worry about bearings or capacitor wear.

- Cost-effective for continuous duty. You get a great balance of price, performance, and energy use.

VI. Disadvantages of PSC Motors

- Lower starting torque than capacitor-start motors. A PSC is not your heavy lifter for high-inertia loads.

- Fixed capacitor compromise. You cannot tune one capacitor for perfect starting and perfect running at once. You pick a value that does both jobs fairly well.

- Typically single speed. You can get multi-speed taps or use voltage based speed control yet the basic design is not as flexible as an ECM.

VII. Common Applications of PSC Motors

I see PSC motors everywhere in HVAC systems. Condenser fan motors on air conditioners use them. Evaporator blowers use them. Furnace fans rely on them for quiet airflow. Refrigeration units lean on PSC motors for evaporator fans and sometimes small condenser fans. Most hermetic compressors are not pure PSC because they need higher starting torque. Many use capacitor-start capacitor-run or solid-state start assists.

Outside HVAC you will find PSC motors in small pumps like sump pumps and spa pumps where the impeller starts under low head. They live in ventilators, exhaust fans, axial fans, and centrifugal blowers. You will spot them in residential appliance motors for dishwashers or older washing machines where the load is gentle at start. They show up in water pump motors and blower wheel drives in countless commercial ventilation systems.

VIII. PSC vs Other Single-Phase Motors

A. PSC vs capacitor-start

A capacitor-start motor uses a large start capacitor and a centrifugal switch for two to three times the starting torque. That makes it better for compressors and high-inertia loads. A PSC motor skips the start switch and uses a smaller capacitor continuously. You get quieter operation and simpler wiring with lower starting torque.

B. PSC vs shaded-pole

Shaded-pole motors are cheap and easy to make. They waste a lot of energy. Efficiency can drop into the 20% to 40% range. PSC motors deliver a huge bump in efficiency and power factor which shows up as cooler operation and lower bills. If you are upgrading a fan motor and you have the choice pick PSC over shaded pole unless cost is the only concern.

C. PSC vs split-phase

A split-phase motor uses a start winding with higher resistance and no capacitor. It has a start switch and moderate starting torque. PSC motors beat split-phase in efficiency and power factor. PSC also runs smoother because the phase shift is controlled by a capacitor rather than just winding resistance.

IX. Specs That Matter in the Real World

When I spec or replace a PSC motor I keep a short list handy. You can too.

- Voltage and frequency. Match the system voltage and either 50 or 60 Hz. A mismatch ruins performance or the motor.

- Horsepower (HP). Do not downsize to save a buck. Match the load with some margin if the service factor allows it.

- RPM and poles. PSC motors commonly come in 2-pole or 4-pole designs. On 60 Hz a 2-pole PSC runs around 3200 to 3450 RPM under load. A 4-pole runs around 1550 to 1750 RPM. Remember slip pulls real RPM below the synchronous speeds of 3600 or 1800.

- Frame size and mounting. NEMA frame standards guide shaft height, bolt patterns, and mounting options. IEC frames do the same outside North America. Match the frame or be ready to modify brackets.

- Enclosure type. Open drip proof (ODP) works in clean dry spaces. Totally enclosed fan cooled (TEFC) handles dust and spray. Motor enclosure choice matters for reliability and safety.

- Efficiency. Expect 60% to 75% for fractional horsepower PSC motors. Higher efficiency versions exist and they cut energy use over the long haul.

- Power factor. PSC motors often deliver 0.85 to 0.95 at full load thanks to the run capacitor.

- Torque characteristics. PSC starting torque often sits between 50% and 100% of full load torque. Capacitor-start motors trounce that with 200% to 300% but you do not always need it.

- Current. Check both starting current and running current ratings. PSC starting current is lower than many split-phase motors. That helps on lights-dimming complaints in homes.

- Insulation class and temperature rise. Class B or F insulation is common. Higher class equals higher thermal tolerance which helps in hot attics and rooftops. Check the ambient temperature rating too.

- Service factor. A service factor of 1.15 gives you a bit of headroom for occasional overloads. Do not abuse it.

- Bearings. Sleeve bearings for quiet low-cost operation. Ball bearings for longer life and higher radial loads. Replace like for like unless you understand the mounting and lubrication differences.

- Compliance and listings. Look for UL or CSA marks. RoHS compliance shows the manufacturer manages restricted substances. A marked motor gives you confidence that testing and safety reviews happened.

- Winding materials. Copper versus aluminum is a long-running debate. Copper tends to reduce I2R losses and boost efficiency. Aluminum can cut cost and weight. Both can work well if the design is solid.

- Motor winding resistance and insulation testing. Those numbers tell you a lot about the health of used motors or spares that sat on a shelf too long.

X. Maintenance, Testing, and Troubleshooting

I have learned to start with the simple checks first. Airflow paths get clogged. A blower wheel loads up with lint and it drags. A fan blade gets bent and it wobbles. Fix those first then look at the electrical side.

Capacitor health and sizing

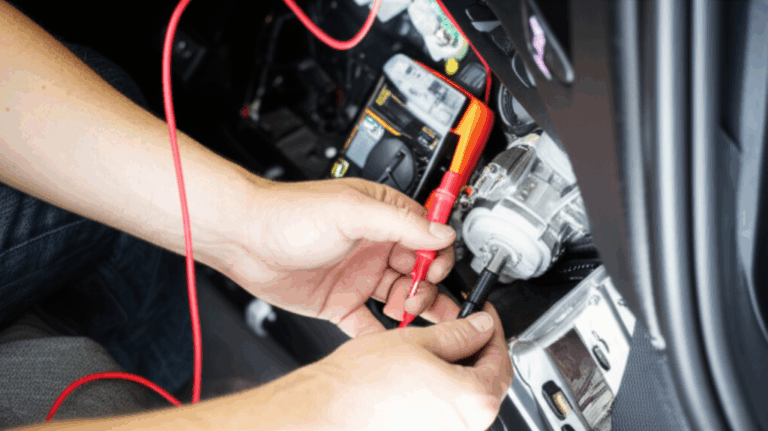

A weak or open run capacitor sits at the top of my suspect list for a PSC motor that hums or barely starts. Here is how I approach it.

- Visual inspection. Look for bulging, oil leakage, or burn marks on the run capacitor. If you see any of those swap it out.

- Discharge safely. Use a resistor or a discharge tool across the capacitor terminals before you touch it. Never short the terminals with a screwdriver.

- Measure capacitance. Use a meter with a capacitance function. Compare to the nameplate microfarad rating. A rule of thumb says plus or minus 5% to 10% is the usual acceptable range. If it is out of range replace it.

- Check voltage rating. If the system spikes or runs hot step up to a 440 VAC rated capacitor if the wiring and motor allow it. Do not downrate voltage. That ends badly.

Capacitor sizing for PSC motors matters. If you size smaller than recommended torque drops and the motor labors. If you size larger running current rises and heat builds. Stick with the nameplate value when you can. When replacing a condenser fan or blower on an HVAC unit that uses a dual run capacitor match the microfarad rating on FAN and HERM to the original design.

Humming, failure to start, and overheating

- Humming with an easy spin start. Classic sign of a weak run capacitor or a seized sleeve bearing. Replace the capacitor first. Oil serviceable sleeve bearings if the design allows it. Many modern motors are permanently lubricated.

- Trips on thermal overload. Check airflow and load. A clogged filter or blocked coil forces the blower to work harder. Measure running current and compare to nameplate. High current with low airflow hints at wrong pulley size in belt-drive systems or a mismatched motor speed tap in direct-drive blowers.

- Overheating. Verify voltage at the motor terminals. Low voltage pushes current up which overheats windings. Check the insulation class and ambient temperature rating. An ODP motor in a hot attic can cook itself in summer.

- Vibration and noise. Look for imbalanced blower wheels or bent fan blades. Check set screws and keys on shafts. Worn bearings thrum and growl at speed. Replace them before the rotor scrapes the stator.

Basic electrical tests

- Motor winding resistance. Measure the main and auxiliary winding resistances. The auxiliary winding usually measures higher resistance. If both read open the thermal protector may be tripped or the winding failed. If both read near zero you have a short. Replace the motor.

- Insulation test. Use a megohmmeter to check insulation resistance to ground if you have one. Moisture and age lower this number. A very low reading means the motor needs drying or replacing.

- Overload protection. Many PSC motors include a thermal overload protector embedded in the windings. If it trips repeatedly fix the root cause. Do not bypass it.

If you want a straightforward companion resource for troubleshooting mindsets you might like this primer on common motor problem patterns. It will not replace your meter or your judgment. It does give you a checklist feel when you are stuck.

Bearing service and replacement

Sleeve bearings can run for years in clean air. Dirt and heat shorten that life. If the motor allows re-lubrication use the correct oil and do not overfill. Ball bearings come sealed or shielded. Once they rumble or growl replace them. A new bearing can make an old motor feel young again.

XI. Speed Control and Modern Alternatives

You can control PSC motor speed in a few ways. Multi-speed motors use tapped windings with separate leads for low, medium, and high. You can switch taps to change speed. You can also use a triac-based voltage controller for fans and blowers where torque demands fall with speed. That works better on light loads. It is not ideal for constant torque loads.

Variable speed PSC designs exist with more sophisticated controls. They improve comfort in HVAC systems by shaving speed and noise off shoulder seasons. Still they cannot touch an ECM for range and efficiency.

ECM vs PSC

ECM stands for electronically commutated motor. It is a brushless DC motor with permanent magnets and onboard electronics that run off AC power. ECM motors can hit 80%+ efficiency. They hold torque well at low speeds and they sip power. They cost more and they require careful control integration. I recommend ECMs for systems that run long hours or need tight airflow control. PSC motors still win when you need a simple, reliable, and cost-effective drive for a fan or blower that starts under light load.

XII. Buying and Replacing a PSC Motor

Here is how I shop and spec replacements.

- Match voltage, HP, RPM, frame, and rotation. These five get you most of the way there.

- Check the run capacitor value and voltage rating. Replace the capacitor when you replace the motor if the old one looks tired or if you changed the motor’s microfarad requirement.

- Confirm enclosure and mounting. ODP for clean spaces. TEFC for dusty or wet areas. Direct drive or belt drive will decide shaft length and keyway use.

- Verify speed taps. HVAC blower motors often offer multiple speeds for heating and cooling modes. Wire the correct tap to the control board.

- Look for UL and CSA listings. You want a motor that meets safety and performance standards. Many manufacturers also note RoHS compliance which speaks to restricted substances.

- Consider service factor. A higher service factor gives you elbow room for short overloads like filter loading.

- Mind the budget. PSC motors typically fall in a moderate cost band. Expect something like $50 to $200 for common fractional horsepower units. High efficiency or severe duty versions cost more.

If you want a visual feel for the steel packages that define a motor’s performance envelope the gallery of motor core laminations can help you connect design choices with loss and noise behavior in real machines.

XIII. Conclusion: Why PSC Motors Still Win So Many Jobs

I keep coming back to PSC motors because they deliver a sweet spot. They run quiet and smooth. They draw reasonable current with a strong power factor. They last for years with basic care. They do not like heavy starting loads. They do not match ECM efficiency. They do offer a practical blend of performance and price that fits HVAC blowers, condenser fans, evaporator fans, ventilators, and many small pumps.

I will leave you with a brief story. A regional HVAC manufacturer I worked with needed better blower efficiency without pricing themselves out of the market. They moved from shaded-pole to PSC motors on their furnace blowers. Energy use dropped by about a third for that subassembly. Noise complaints fell. Warranty claims dropped because they no longer dealt with brittle start switches snapping in cold basements. That shift boosted their SEER-related ratings which made sales easier. PSC motors played the dependable workhorse again.

If you are troubleshooting a humming fan today start with the run capacitor. If you are choosing a motor for a new design list your load and ambient conditions then pick a PSC if you need simplicity and continuous duty under light starting load. Match voltage, HP, RPM, frame, and enclosure. Size the run capacitor right. Verify the power factor and efficiency meet your goals. Then install it with care so it can do what PSC motors do best. They show up. They spin. They keep spinning.

Internal links used in this article: