What is a Pushrod Motor? Understanding OHV Engine Design & Why It Matters

- Table of Contents

- What is a Pushrod Motor? Understanding OHV Engine Design & Why It Matters

- What is a pushrod motor in simple words?

- How does a pushrod engine work step by step?

- What parts make the valvetrain do its job?

- Why do people still use pushrod engines today?

- What are the main advantages of pushrod design?

- What are the drawbacks you should know?

- Pushrod vs OHC: which should you pick?

- Where do we see pushrod engines now?

- Which classic and modern engines use pushrods?

- How do torque, horsepower, and RPM play together?

- Can you tune and modify a pushrod engine easily?

- How do cost, size, and emissions compare?

- Case studies you can learn from

- How to choose a pushrod for your build or swap

- FAQs

- Pushrod vs OHC quick comparison table

- References

- Key takeaways

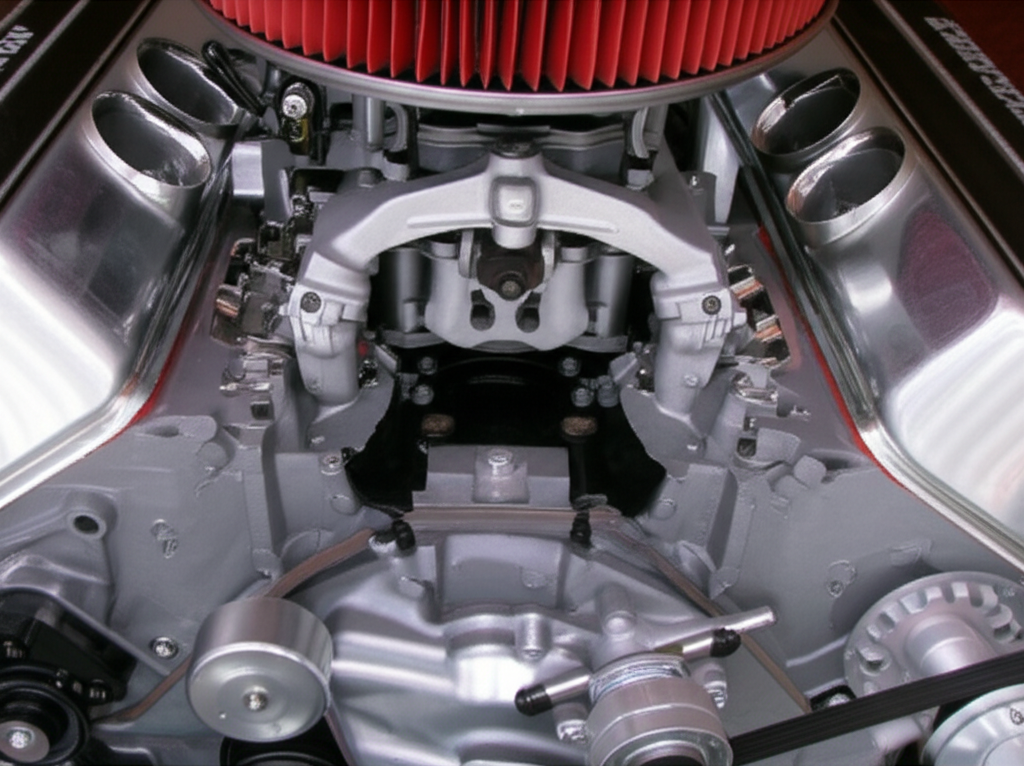

A pushrod motor is also called an OHV engine or overhead valve engine. It uses a cam-in-block design. The cam sits in the engine block and sends motion up to the valves. That makes the engine valvetrain simple and tough. In this guide, I show you how pushrods work, why they matter, where they shine, and where they fall short. If you want clear, simple answers you can use today, you’re in the right place.

Let’s use PAS to make this real. Problem: engines can feel confusing. You need the right facts fast. Agitate: choose wrong, and you waste time and money. You miss torque you need or the horsepower you want. Solution: learn the basics of pushrod engine components and the valve actuation mechanism. I’ll walk you through it so you can make a smart call with confidence.

What is a pushrod motor in simple words?

A pushrod motor definition goes like this. It’s a piston engine with the camshaft located in the engine block. The cam turns. It moves lifters. Lifters push pushrods. Pushrods tip rocker arms. Rockers open and close valves in the head. That’s the basics of pushrod engines.

You may hear other names. People say overhead valve (OHV). They say cam-in-block. They compare it to engine overhead cam designs like SOHC and DOHC. Those put cams in the head. A pushrod motor stays compact and keeps the camshaft location in engine low. That helps engine weight distribution and the center of gravity engine.

I like pushrods because they are clear, reliable, and often durable. When you need simple power that lasts, the OHV layout checks many boxes.

How does a pushrod engine work step by step?

Let’s break the how does a pushrod engine work part into steps you can picture. This is the four-stroke engine cycle at play.

- The cam lobe turns and lifts the lifter (tappet).

- The lifter moves the pushrod up.

- The pushrod tips the rocker arm.

- The rocker arm presses the valve stem and opens the intake or exhaust valve.

- The valve spring snaps the valve shut on time.

You see the chain. Cam to lifter to pushrod to rocker to valve. That’s the valvetrain. It runs the piston engine operation through intake, compression, power, and exhaust. It is the engine architecture that made so many V8 pushrod engines famous in American muscle car engines.

I use a simple mental image. Think of your arm. Your shoulder is the cam. Your elbow is the lifter. Your forearm is the pushrod. Your hand is the rocker. Your finger presses the valve. All the pieces move in sync so the engine can breathe and make power.

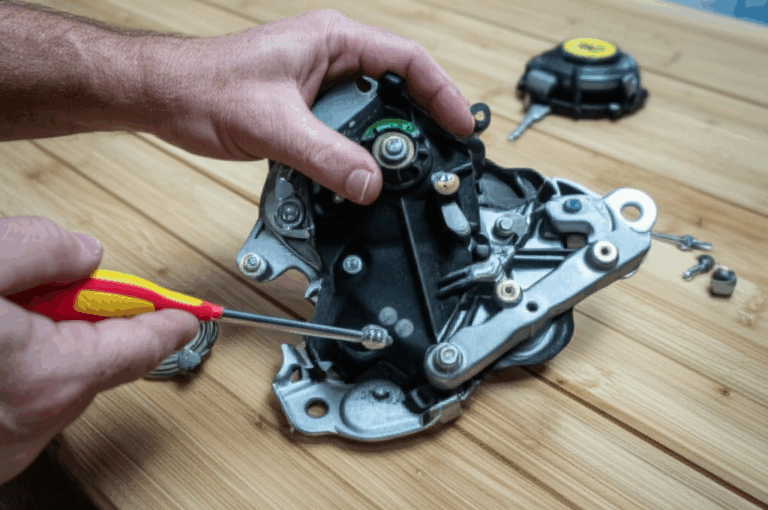

What parts make the valvetrain do its job?

Here are the key pushrod engine components and why they matter:

- Camshaft in the block. It sets valve timing. It drives engine power delivery.

- Lifters (tappets). Hydraulic lifters pushrod setups auto-adjust valve lash. Solid lifters pushrod need valve lash adjustment by hand.

- Pushrods. They link the cam motion to the rocker arms.

- Rocker arms. They tip to open the intake and exhaust valves.

- Valves and valve springs. Springs stop valve float pushrod at high RPM.

- Harmonic balancer pushrod. It calms crank twist which helps the valvetrain at speed.

- Crankshaft position pushrod sensors in modern setups help control spark and fuel.

Around this, you’ll find the intake manifold pushrod, exhaust manifold pushrod, spark plug location pushrod heads, ignition system pushrod, fuel injection pushrod or carburetor pushrod engine parts, engine cooling pushrod passages, and lubrication pushrod engine oiling. All of these play a part in keeping engine friction valvetrain low, heat in check, and parts happy.

Why do people still use pushrod engines today?

Short answer. They work. Modern pushrod engines blend old-school might with new tech. Makers keep them for compact engine design and engine packaging size. The cylinder head design is small, since it does not house cams. That can make room under the hood. It can also help engine rigidity pushrod since the engine block design can be stout.

I’ve seen it on the road and the track. In trucks, you want torque characteristics pushrod down low. In sports cars that use a big-bore V8, you want a broad powerband and a sweet engine sound pushrod. Builders love the feel. Fans love the exhaust note pushrod engine. Teams prize the reliability pushrod engine and durability pushrod engine in long races.

So, why pushrods are still used? Because they hit a strong mix: simple, strong, compact, and proven.

What are the main advantages of pushrod design?

I see four big wins.

- Simplicity and compactness. The valvetrain complexity sits lower. The head has fewer parts. The engine can sit low for a better center of gravity engine.

- Durability and reliability. Fewer fragile parts up top. The system has run for decades. The history of pushrod engines backs that up.

- Cost-effectiveness. The engine manufacturing costs and engine production volume can favor pushrod engine benefits. Heads are easier to cast and build.

- Torque. Strong performance pushrod engines often give great low and mid-range. That helps in towing, street fun, and NASCAR engine design style racing where punch out of corners counts.

These payoffs matter to shops and fans. They make cars and trucks easy to own and fix. They make aftermarket pushrod parts a joy to use.

What are the drawbacks you should know?

No design is perfect. Here are the pushrod engine drawbacks.

- RPM limits pushrod. The extra bits add mass. That means more chance of valve float pushrod. High RPM performance pushrod builds need better springs, lighter parts, and tight control.

- Valvetrain complexity path. The pushrod path is longer than OHC. More parts sit between cam and valve. This can limit very high horsepower pushrod engine targets in small displacements.

- Packaging tradeoffs. Heads are smaller, yet total engine height can still be tall with single large cam in block and long lifters and rods.

- Efficiency and emissions. Engine efficiency pushrod can lag if you chase ultra-fine timing tricks. Emissions pushrod engine control improves with tech like variable cam phasing, direct injection, and cylinder deactivation. Modern systems fix much of this.

Know the cons. Then you can plan a build that avoids them.

Pushrod vs OHC: which should you pick?

Let’s compare pushrod vs OHC. OHC comes as SOHC vs pushrod and DOHC vs pushrod. In OHC, the cam sits in the head. That shortens the path. It cuts moving mass. It helps very high RPM. That’s great for small, rev-happy engines.

In pushrod, the cam sits low in the block. You get a tight package. You get rugged heads. You get strong low-end pull. For many trucks and classic car engines, that’s a win. For high-strung race buzz up to the sky, OHC holds an edge.

I’ve run both. Each shines in its spot. Start with your goal. Do you need tow power and easy install? Pushrod engine explanation says yes. Do you want a compact V8 with wide fit? Pushrod often wins. Do you want sky-high revs with many small valves? OHC may be your pick.

Where do we see pushrod engines now?

You see them in performance pushrod cars and trucks. You see them in heavy-duty and work gear too.

- Performance vehicles. Think LS engine families in Corvette and Camaro. Think modern LT1 and LT4 with direct injection and VVT. Think V8 engine fun in Gen III, Gen IV, Gen V (GM) designs.

- Heavy duty. Diesel pushrod engines like Cummins and Detroit Diesel power big rigs and machines.

- Motorsport. NASCAR still runs big, naturally aspirated pushrod V8 power in Cup cars.

- Other use. You find pushrods in marine engine pushrod, industrial engine pushrod, agricultural engine pushrod, and generator engine pushrod settings. They prize uptime and maintenance pushrod engine ease.

It’s not a fad. It’s a long evolution of engine design that still fits many jobs.

Which classic and modern engines use pushrods?

Here are pushrod engine examples you may know. What engines use pushrods? Many you love.

- Chevrolet small-block. The Chevy Small Block (SBC) and Chevy Big Block (BBC). The Small block Chevy pushrod is the king of swaps. The L31 Vortec heads made great street torque.

- GM LS family. LS1, LS2, LS3, LS7, LS9. The LS7 is a legend with big displacement and pushrod punch. The LS engine line shows modern pushrod engines at their best.

- GM LT. LT1, LT4 (modern) are pushrod with DI and VVT. They prove that engine efficiency pushrod and emissions pushrod engine can meet modern rules.

- Ford. The Ford Windsor pushrod and Ford Cleveland engine. The older Ford Flathead engine used a side-valve layout before OHV took over.

- Chrysler. The Mopar HEMI is a Chrysler HEMI pushrod icon used in Dodge, Challenger, Charger, and Ram trucks.

- Motorcycles. Harley-Davidson built its name in Harley Davidson engine design with pushrods on many V-twins.

- Brands and badges. General Motors (GM), Pontiac, Oldsmobile, Cadillac, Holden, Ford, Chrysler, and Chevrolet shaped the pushrod world.

- Cars. Mustang (older generations) used pushrods. The Corvette used OHV V8s for decades.

Note: The modern LT6 in the C8 Z06 is a DOHC V8, not pushrod. It shows how engine architecture types can vary even inside one brand.

How do torque, horsepower, and RPM play together?

Think about the feel you want. Torque characteristics pushrod shine at low and mid RPM. That’s why trucks and street builds love them. Horsepower pushrod engine rises with RPM. Yet pushrods may face RPM limits pushrod sooner than OHC unless you upgrade parts.

You can raise the limit. Use stiffer valve springs, light valves, and smart cam design. Keep oiling clean. Balance the bottom end with a good harmonic balancer pushrod. Then you can aim for high RPM performance pushrod targets without valve float pushrod.

Your ears will smile too. The engine sound pushrod and exhaust note pushrod engine have a deep rumble. Many call it “that V8 thump.” It is a sound track for a fun drive.

Can you tune and modify a pushrod engine easily?

Yes, you can. The aftermarket pushrod parts world is huge. For engine tuning pushrod, you pick a camshaft, adjust valve lash if you run solid lifters pushrod, or enjoy easy setup with hydraulic lifters pushrod. You can add naturally aspirated pushrod upgrades or go forced induction with a supercharged pushrod engine or a turbocharged pushrod engine.

Here are brands I trust and have used:

- Edelbrock and Holley for intakes and fuel.

- Comp Cams and Lunati for cam profiles.

- AFR (Airflow Research), Dart Machinery, Brodix, and RHS (Racing Head Service) for heads.

- Mahle, Wiseco, and JE Pistons for pistons.

- Callies Performance and Scat Crankshafts for bottom ends.

- ARP for fasteners.

- K&N Filters for intake air.

- MagnaFlow and Borla for exhaust.

- Lucas Oil for lubrication.

- Katech for high-end builds and race-proven parts.

You can order a crate engine pushrod. You can do an engine swap pushrod into a classic. You can plan an engine rebuild pushrod or a custom engine build pushrod with your own mix. The market and engine production volume mean parts are on the shelf.

How do cost, size, and emissions compare?

A pushrod’s cylinder head design is simpler than OHC heads. That helps engine manufacturing costs. It also helps compact engine design and engine packaging size.

Emissions used to be a weak point. Today, modern pushrod engines run features like direct injection, variable valve timing, and cylinder deactivation. That boosts fuel economy pushrod and reduces emissions pushrod engine while keeping reliability pushrod engine.

You get a tough motor that fits many bays. You get strong pull. You get a good price point too.

Case studies you can learn from

I like to learn by example.

- GM LS7. The LS7 is a 7.0L NA pushrod V8 that made about 505 hp. That’s strong power density for a large-cube OHV. It shows how smart engine design principles and materials can push pushrod engine specifications higher.

- Ford Coyote 5.0. This is a DOHC V8 that makes about 450 hp in many trims. It shows how engine overhead cam can rev and breathe with high hp/L. It’s a good DOHC vs pushrod contrast.

- Honda K20. A small DOHC that hits near 100 hp/L. Again it shows what high-rev OHC can do.

- NASCAR. Cup engines use fuel-injected pushrod engine racing V8s. They run hard for hours. That proves durability pushrod engine in the real world.

These cases help you see tradeoffs and pick what fits your build.

How to choose a pushrod for your build or swap

Let’s use PAS again. Problem: you need a motor for your project. You want power and value. Agitate: pick wrong and you fight fit, heat, or upkeep. Solution: match the engine to your goal.

- For trucks and work. Pick a diesel pushrod engines setup like Cummins for torque and uptime. Or a gas LS engine in a pickup for easy service and grunt.

- For street fun. A Chevy Small Block (SBC) or LS3 swap gives compact size and great engine power delivery. A Mopar HEMI brings big-cube fun in Challenger or Charger builds.

- For old-school style. A Ford Windsor pushrod or Chevy Big Block (BBC) fits many hot rod engine types and classic car engines.

Plan your cooling and oiling. Make sure engine cooling pushrod is strong. Keep lubrication pushrod engine clean. Choose fuel. Old builds can use a carburetor pushrod engine. Many new builds run fuel injection pushrod for easy starts and clean burn.

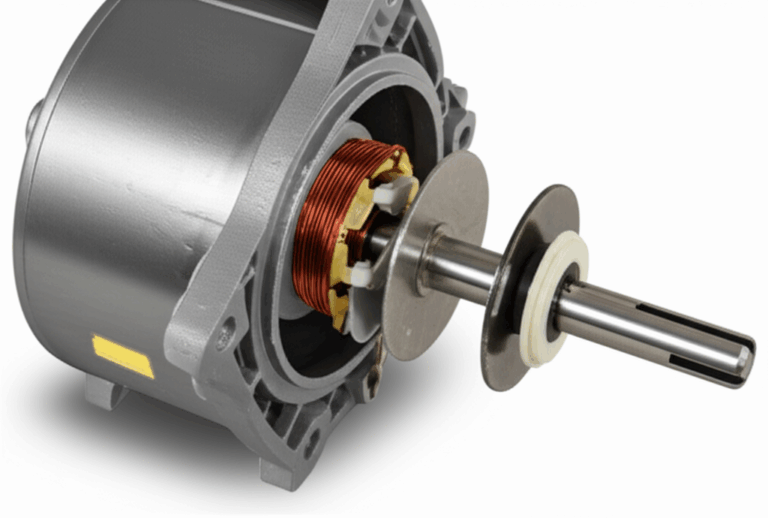

If you want to understand how electric motors differ, you can learn the stator and rotor basics too. It helps you see where electric machines and internal combustion engine types diverge and why.

Curious about the physics behind electric machines? This short guide to the motor principle gives a good overview you can compare to cams and valves in a piston engine.

And if you design electric machines at work, materials matter. The quality of electrical steel laminations or a precise stator core lamination can make or break motor efficiency. That is a different world than cams and pushrods, yet the idea is the same. Better parts make better machines.

FAQs

- What’s the best pushrod V8 for a first swap? An LS1 or L31 Vortec based build is hard to beat. They fit well and parts are everywhere.

- Are pushrods bad for fuel burn? Not by rule. Modern pushrod engines with DI, VVT, and good tuning get solid fuel economy pushrod for their size.

- Can a pushrod rev high? Yes with the right parts. Light valves, strong springs, low mass rockers, and a good harmonic balancer pushrod help tame valve float pushrod.

- Are pushrods only for V8s? No. You can have pushrod inline engines and V6 engines too. Yet the V8 pushrod engines are the most famous.

Pushrod vs OHC quick comparison table

| Feature | Pushrod (OHV) | OHC (SOHC/DOHC) | What it means today |

|---|---|---|---|

| Cam location | In block | In head | Pushrod lowers mass in head and can lower engine height above the block |

| Valve path | Lifter → pushrod → rocker → valve | Cam → follower/rocker → valve | OHC has fewer parts between cam and valve |

| RPM range | Lower by default | Higher by default | Pushrod can rev high with upgrades |

| Size | Compact heads | Larger heads | Helps swaps and tight bays |

| Cost | Often lower | Often higher | Easier head casting and assembly |

| Torque feel | Strong low/mid | Strong at high RPM | Pick based on use case |

| Emissions tech | DI, VVT, deactivation work well | VVT/VVL common | Both can meet rules with good control |

References

- General Motors. GM Small-Block V8 history and technical overviews. GM Media and GM Powertrain resources.

- Chevrolet Performance. LS and LT crate engine catalogs and tech sheets.

- Ford Performance. 5.0 Coyote technical summaries and press materials.

- NASCAR. Cup Series engine technical highlights, NASCAR.com and team releases.

- SAE International. Papers on valvetrain dynamics and valve float control in OHV engines.

- Edelbrock, Holley, Comp Cams, AFR, Dart, Brodix, RHS, Mahle, Wiseco, JE Pistons, Callies, Scat, ARP, K&N, MagnaFlow, Borla, Lucas Oil. Public product data and application notes.

Key takeaways

- A pushrod or OHV engine uses a cam-in-block design with lifters, pushrods, and rocker arms to run the valves.

- It offers simplicity, compact cylinder heads, strong low-end torque, and great reliability and durability.

- Limits show up at very high RPM unless you manage valvetrain complexity and mass to avoid valve float.

- You can build naturally aspirated, supercharged, or turbocharged pushrod power with a vast aftermarket.

- From Chevrolet and Ford Windsor to Mopar HEMI, Cummins, Detroit Diesel, and NASCAR, pushrods still make a big mark.

- For emissions and fuel economy, modern pushrods add DI, VVT, and cylinder deactivation to keep up.

- Know your goal. Pick pushrod vs OHC by use case, budget, and fit. Then enjoy the drive.