What is a Salient Pole? Your Simple Guide to How Big Generators Work

Have you ever looked at a huge dam holding back a river and wondered how all that water power becomes electricity for your home? It seems like magic. But it’s not magic, it’s science. And a key part of that science is something with a funny name: a salient pole.

This term might sound complicated. You might think it’s something only super-smart engineers understand. That’s a problem because if you can’t understand the basics, you can’t see how amazing these machines are. You miss out on the simple genius behind our power grid.

But what if I told you that by the end of this article, you’ll understand exactly what a salient pole is? I’ll break it down with simple examples. You’ll see how it’s built, why it’s special, and where you can find it. Let’s uncover the secrets of these power-making giants together.

Table of Contents

- What Exactly is a Salient Pole?

- How is a Salient Pole Machine Built?

- How Does It Actually Make Power?

- Why Are Salient Poles Perfect for Slow Speeds?

- What Are the Good Things About Salient Poles?

- Are There Any Bad Things About Them?

- Where Can You Find Salient Pole Machines?

- Salient Pole vs. Smooth Pole: A Tale of Two Rotors

- Why Do the Parts Inside Matter So Much?

- The Big Picture: What to Remember

What Exactly is a Salient Pole?

Let’s start with the name. “Salient” is just a fancy word that means “sticking out” or “projecting.” And a “pole” here means a magnet.

So, a salient pole is just a magnet that sticks out from the center of a wheel.

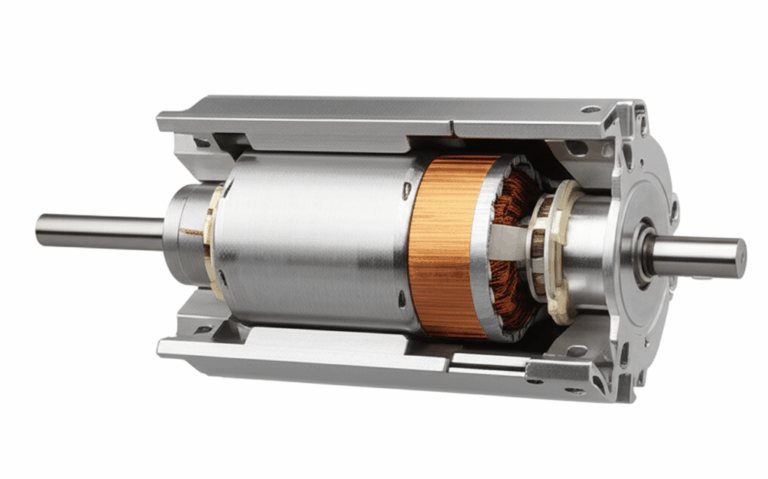

Imagine a big spinning wheel. Now, picture several large, chunky magnets bolted onto the outside of that wheel, all pointing outward. That’s it! You’ve just pictured the main part of a salient pole rotor. This spinning part is called a rotor, and it’s one of the two main pieces in a generator. The other main piece is the stationary part that surrounds it, called the stator. Understanding the relationship between the stator and rotor is the first step to understanding how any electric motor or generator works.

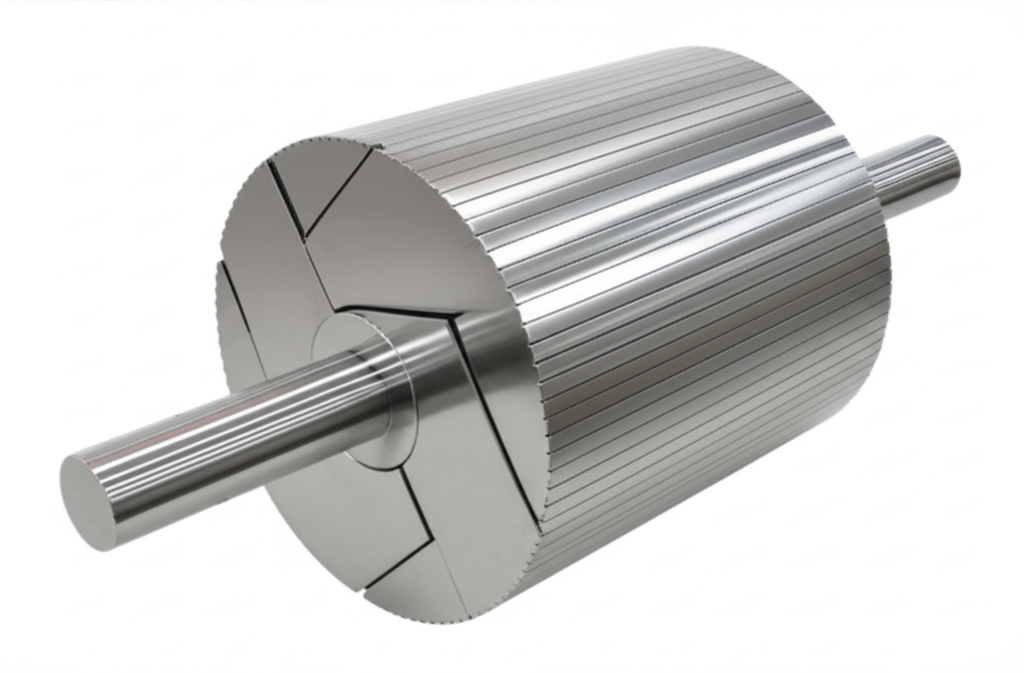

This “sticking out” design is very important. It creates a bumpy, uneven surface on the rotor. Because of these bumps, the distance between the spinning rotor and the stationary stator changes as it turns. This changing gap, called a non-uniform air gap, is the secret sauce that gives salient pole machines their special powers. We’ll talk more about those powers in a bit.

How is a Salient Pole Machine Built?

Building one of these machines is like making a very complex, very powerful layer cake. Each part has a special job.

First, you have the heart of the machine: the rotor. The rotor itself is built from a central hub called a spider. Attached to the spider are the poles themselves. These aren’t just solid chunks of metal. They are made of thin sheets of special steel, stacked together like a deck of cards. This is done to control the magnetic field and reduce energy loss. The quality of the rotor core lamination is critical for the machine’s efficiency.

Next, you wrap the poles with a lot of wire. This is the field winding. When you send a small amount of DC electricity through this wire, each pole becomes a powerful electromagnet. This is what creates the strong magnetic field needed to generate power. The amount of electricity you send through these windings controls how strong the magnets are.

Finally, there are often special bars of metal embedded in the face of each pole. These are called damper windings. Think of them as shock absorbers. When the generator is running, things can get a little shaky. The damper windings help smooth everything out, preventing a problem called “hunting” where the machine’s speed wobbles. They help keep the generator stable and running smoothly. All these parts sit on a heavy-duty shaft that is supported by massive bearings to allow it to spin.

How Does It Actually Make Power?

Now for the fun part! How do these spinning, sticky-outy magnets make the electricity that powers your video games?

It all comes down to a rule in physics: if you move a wire through a magnetic field, you create an electric current in that wire. In a generator, we do the opposite. We move a magnetic field past a bunch of wires.

The salient pole rotor is the part that moves. It’s connected to a prime mover, which is just the thing that makes it spin. In a hydroelectric dam, the prime mover is a giant water wheel called a turbine. As water rushes past, it spins the turbine, which in turn spins the salient pole rotor.

As the rotor’s powerful electromagnets spin, their magnetic fields sweep past coils of wire in the stationary stator. This moving magnetic field pushes the electrons in the stator wires, creating a flow of electricity. Voila! You have power. The speed of the rotor has to be perfectly matched to the needs of the power grid. This is called synchronous speed. Salient pole generators are a type of synchronous machine, meaning they are designed to run at this one, constant speed.

Why Are Salient Poles Perfect for Slow Speeds?

Have you ever tried to spin something really big and heavy? It’s hard to get it going fast. The same is true for the giant turbines in a hydroelectric power plant. Water has a lot of force, but it moves relatively slowly. So, these turbines spin at low speeds, maybe only a few hundred times a minute.

This is a big problem for a normal generator. Most generators are designed to spin very, very fast—thousands of times a minute. So how do you solve this?

You build a generator with a lot of poles! The speed of a generator is directly tied to two things: the frequency of the power grid (which is constant, usually 50 or 60 Hz) and the number of poles it has. The formula is simple: More poles = slower speed.

A salient pole design is perfect for this. Because the poles stick out, you can fit a lot of them around the rotor’s edge. A typical salient pole rotor in a hydro generator might have anywhere from 12 to over 60 poles! This allows it to spin slowly while still producing electricity at the correct frequency. A generator that spins fast, like one in a coal power plant, might only have 2 or 4 poles.

What Are the Good Things About Salient Poles?

So, why do we love this design for big, slow jobs? It has a few key advantages, or superpowers.

- They are strong and stable. The large, heavy poles give the rotor a lot of inertia. This means it doesn’t like to change speed. This is great for the power grid because it helps keep the electricity supply stable, even when people suddenly turn on a lot of lights.

- They have a “bonus” torque. Because of that bumpy, non-uniform air gap we talked about, salient pole machines create something called reluctance torque. You can think of it as a free magnetic pull that the rotor gets just because of its shape. This extra torque helps pull the rotor back in line if it gets knocked out of sync, making it even more stable.

- They are easier to cool. The poles stick out with space between them. This allows air to circulate easily, carrying away the heat that builds up in the windings. Keeping things cool is very important for a machine that runs 24/7.

- They are perfect for their job. They are simply the best tool for generating massive amounts of power from a slow-moving source, like water or a big diesel engine.

Are There Any Bad Things About Them?

Of course, nothing is perfect. The salient pole design has a few weaknesses that make it unsuitable for other jobs.

The biggest disadvantage is that it can’t handle high speeds. Remember those big, chunky poles sticking out? If you try to spin them too fast, the centrifugal force would be enormous. The poles could literally be ripped right off the rotor. This is why you will never find a salient pole rotor in a high-speed generator, like one connected to a steam turbine.

They also create more wind noise and air resistance (called windage losses) because of their bumpy shape. A smooth rotor cuts through the air much more easily. Finally, the complicated shape can make them a bit more difficult and expensive to build compared to their smooth-rotor cousins. But for the low-speed jobs they were designed for, these disadvantages are a small price to pay for their strengths.

Where Can You Find Salient Pole Machines?

The number one place you’ll find salient pole generators is in hydroelectric power plants. From the Hoover Dam in the USA to the Three Gorges Dam in China, nearly every major hydro plant uses these machines. They are the undisputed champions of turning slow-moving water into electricity.

You’ll also find them in diesel generator sets. These are often used for backup power in hospitals or to provide electricity to remote towns. The big diesel engines they are connected to run at medium speeds, which is a great fit for a salient pole design.

Some large synchronous motors also use a salient pole design. These motors are used in factories and industrial plants for jobs that require a constant, steady speed, no matter how much load is put on them. They can also be used as synchronous condensers to help stabilize the voltage on the power grid.

Salient Pole vs. Smooth Pole: A Tale of Two Rotors

To really understand what makes a salient pole special, it helps to compare it to the other main type of rotor: the cylindrical rotor, also called a non-salient pole rotor.

Think of it like a tractor versus a race car.

The salient pole rotor is the tractor. It’s big, heavy, and has huge, chunky wheels (poles) that stick out. It’s not built for speed, but it has incredible pulling power (torque) and stability. It’s perfect for the tough, slow work of a farm (or a hydroelectric dam).

The cylindrical rotor is the race car. It has a smooth, sleek, and perfectly balanced body. Everything is tucked in to reduce wind resistance. It’s designed to spin at incredibly high speeds without shaking apart. It’s perfect for the fast lane of a racetrack (or a steam power plant).

Here’s a simple table to show the differences:

| Feature | Salient Pole Rotor (Tractor) | Cylindrical Rotor (Race Car) |

|---|---|---|

| Speed | Low Speed (50 – 1000 RPM) | High Speed (1500 – 3600 RPM) |

| Shape | Poles stick out | Smooth, solid cylinder |

| Diameter | Very large | Smaller diameter |

| Length | Short | Long |

| Number of Poles | Many (4 to 60+) | Few (2 or 4) |

| Main Use | Hydro and diesel plants | Steam and gas power plants |

| Air Gap | Not uniform (bumpy) | Uniform (smooth) |

Why Do the Parts Inside Matter So Much?

A giant generator is like a champion athlete. For it to perform at its best for a very long time, every single part of its body has to be perfect. If even a small part is weak, the whole machine can fail. This can be a huge problem, causing blackouts and costing millions of dollars to fix.

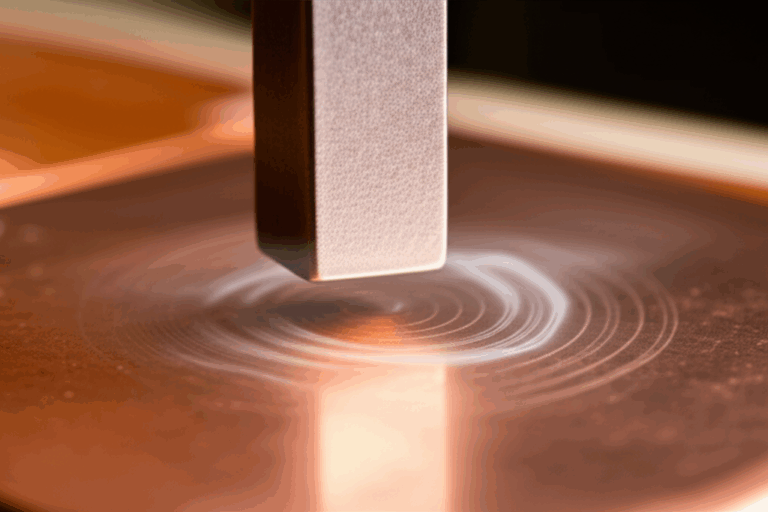

Imagine the powerful magnetic forces and the intense heat inside one of these machines. The materials have to be incredibly strong and efficient. This is especially true for the metal sheets, or laminations, that make up the rotor and stator. Poor quality laminations can cause the machine to waste energy as heat, reducing its efficiency. Even worse, they could lead to a catastrophic failure.

That’s why the work we do at Sino Lamination is so important. We create the super-high-quality core lamination stacks that form the backbone of these powerful machines. We use special electrical steel laminations that are designed to handle intense magnetic fields with very little energy loss. Whether it’s for the stationary part, where the quality of the stator core lamination defines the generator’s output, or for the spinning rotor, precision is everything. By providing the best possible components, we help ensure that these amazing machines can run safely and efficiently for decades, keeping the lights on for all of us.

The Big Picture: What to Remember

We’ve covered a lot of ground, but it all comes down to a few simple ideas. Let’s wrap up with the most important things to remember about the amazing salient pole.

- It’s all in the name: “Salient pole” just means “sticking out magnet.” It’s a rotor with poles that project from a central wheel.

- Built for slow, powerful jobs: Its design is perfect for spinning slowly while making huge amounts of power. This is why it’s the king of hydroelectric dams.

- More poles = slower speed: You can fit many poles on a salient pole rotor, which allows it to match the slow speed of a water turbine.

- It’s super stable: Its heavy weight and special shape (which creates “reluctance torque”) make it very stable, which is great for our power grid.

- Not built for speed: Its biggest weakness is that it can’t be spun too fast, or the centrifugal force would tear it apart.

- Quality parts are key: For these giants to work reliably, every single component, especially the steel laminations, must be of the highest quality.