What Is a Servo Motor? A Friendly Guide You Can Use Today

Table of Contents

- What Is a Servo Motor? A Friendly Guide You Can Use Today

- What is a servo motor?

- How does a servo motor work?

- What are the key parts of a servo system?

- DC vs. AC servo motors: what is the difference?

- Rotary vs. linear servos: which do you need?

- Servo motor vs. stepper motor: which should you choose?

- What are the pros and cons of servo motors?

- Where do we use servo motors today?

- How do you pick the right servo motor?

- How do you wire, tune, and program a servo?

- How do you keep a servo safe and healthy?

- Common problems and easy fixes

- Real brands, real systems

- Quick comparison: servo vs. stepper

- Mini case studies and ROI

- FAQ

- Summary: key points to remember

- References

A servo motor is not just a motor. It is a smart motor that knows where it is and where it should go. In this guide, I show you how servos work in plain words. You will see why they matter in robots, CNC machines, and more. You will learn how to choose one, wire it, and keep it running well.

Why read this? You want smooth, fast, and exact motion. You want fewer mistakes. You want more uptime. I show you how a servo can help. I also show you how better motor cores and laminations boost torque, cut heat, and lower noise.

What is a servo motor?

Problem: You need a motor to move to an exact spot. A regular motor spins but it does not know its position. You get misses. You get scrap.

Agitate: A small error can ruin a part. It can stop a line. It can waste time and money.

Solution: A servo motor uses a closed-loop system. It reads a sensor. It compares the goal to the real position. It fixes the error fast. You get high precision, repeatability, and smooth control.

In short, a servo motor is a motor plus feedback and control electronics. It can hold a position, set a speed, or follow a motion path. It does this even when the load changes.

How does a servo motor work?

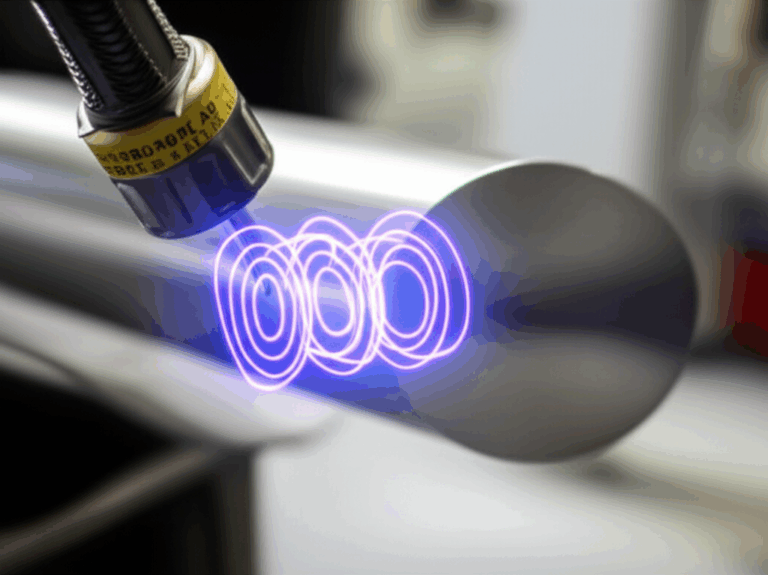

Think of a servo like a smart driver. You tell it “go to 90 degrees” or “run at 500 RPM.” The system reads an input signal. A servo controller acts like the brain. It checks a feedback device like an encoder or a resolver. The controller makes an error signal if the motor is off the target. The servo drive is the muscle. It pushes more or less power to the motor to fix the error. This loop runs many times per second.

This is a closed-loop system. It uses encoder feedback or resolver feedback. It can use a Hall effect sensor too. Many servo systems use a PID controller. The drive often uses pulse width modulation (PWM) and an H-bridge or a three-phase bridge. All this gives you precision motion control and a strong dynamic response. The motor can speed up, slow down, and stop on a dime.

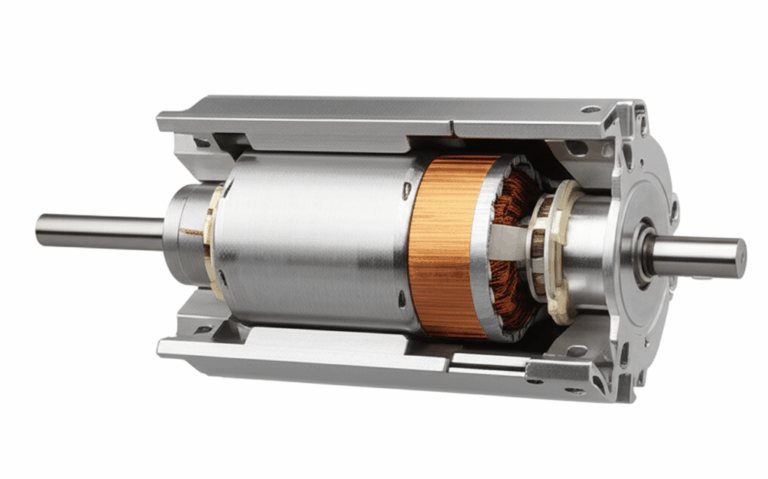

What are the key parts of a servo system?

- The servo motor: DC or AC. Brushed or brushless. Rotary or linear. It turns electrical power into motion.

- The servo drive or amplifier: It takes small control signals. It sends the right voltage and current to the motor. It controls torque, speed, and position.

- The feedback device: An encoder, resolver, or even a potentiometer in small hobby servos. It measures the actual position and speed.

- The servo controller: A PLC or a motion controller. It plans the move, checks feedback, and keeps the loop tight.

Build quality matters. Core steel and laminations change heat, loss, and torque. Better cores cut motor heating and electromagnetic interference. You can see how motor core laminations lift efficiency and lower noise in real machines.

DC vs. AC servo motors: what is the difference?

DC servo motor options include brushed DC and brushless DC (BLDC) servo motors. Brushed DC costs less. It needs more maintenance. Brushes wear. BLDC uses electronic commutation. It runs cooler. It lasts longer. It has better acceleration and deceleration. BLDC is common in industrial servo motor systems.

AC servo motors are often permanent magnet synchronous motors (PMSM). They have high torque and high speed. They fit heavy-duty work. Many CNC machine servo motor axes use AC PMSM. AC servos shine in automation motor tasks and industrial servo motor lines that run 24/7.

Both AC and DC servos can run in current control, velocity control, or position control modes. You choose based on the job.

Rotary vs. linear servos: which do you need?

Rotary servo motors spin a shaft. You add a gearbox, a harmonic drive, a leadscrew, or a ball screw to move a load. Rotary is the most common. You can also use a direct drive servo motor to skip gears. That boosts positional accuracy and cuts backlash.

Linear servo motors move in a straight line. No screw needed. They give very high speed and precision on linear paths. They fit pick and place servo systems and high-speed packaging machinery. Both types can come as micro servo motor for small spaces. You can get continuous rotation servo or a pan-tilt servo for simple robots and cameras.

Servo motor vs. stepper motor: which should you choose?

Problem: You must pick between a servo and a stepper motor. You want accuracy. You also care about cost.

Agitate: Pick wrong and your machine stalls. It loses steps. It vibrates. It fails to meet cycle time.

Solution: Use a servo when you need high speed, high torque, and dynamic loads. Use a stepper when you need low cost and simple indexing at lower speeds.

- Control: Servo is closed loop. It uses a feedback loop. Stepper is open loop in most cases. It assumes each step happens.

- Precision and accuracy: Servo holds positional accuracy under changing loads. Stepper can “lose steps” if pushed too hard.

- Torque and speed: Servo keeps torque at high speed. Stepper torque drops off fast at high speed.

- Cost and complexity: Servo costs more. It needs tuning. Stepper is simple. It costs less.

- Typical use: Servo for robotics motor tasks, CNC machining, and automation. Stepper for 3D printers and basic indexers.

Some systems blend both. A stepper with an encoder makes a low-cost closed-loop system. Yet a true servo motor system components set will still win in fast, heavy, or harsh jobs.

What are the pros and cons of servo motors?

Advantages:

- High precision and repeatability. You get positional accuracy with encoder feedback.

- Excellent speed and torque control. You get strong acceleration and deceleration.

- High efficiency. The drive uses only the power you need.

- Smooth and quiet motion. Less vibration than many steppers.

- Hold torque at standstill. It can lock in place without overheating.

Disadvantages:

- Higher cost than standard motors or many steppers.

- More complexity. You must tune the PID and wire the feedback.

- Needs a feedback device. That adds parts and setup.

- If you tune it wrong you can get hunting or oscillation.

Where do we use servo motors today?

You see servos in many places:

- Industrial automation and robotics. Robot arms and pick-and-place machines use servo drive systems for tight control.

- CNC machining and manufacturing. Milling, lathes, and grinders use servo motor control on axes and spindles.

- Packaging machinery and printing press lines. They control web tension, cutting, sealing, and labeling at speed.

- Medical devices. Surgical robots and diagnostic tables need smooth motion and exact stops.

- Aerospace and automotive. Flight control, power steering, and camera gimbals use servos.

- Consumer electronics. Drones, RC vehicles, cameras, and gimbals use small servo motor parts.

- Material handling. Automated guided vehicle (AGV) servo and automated storage and retrieval systems need precision.

- Textile machinery servo lines and injection molding servo axes also rely on fast motion control.

How do you pick the right servo motor?

Problem: Choosing a servo feels hard. Specs pile up. Choices grow fast.

Agitate: Pick a motor that is too small and it overheats. Pick one that is too big and you waste money. Miss the encoder spec and you miss your accuracy goal.

Solution: Use a simple list. Then size and match.

- Torque: Check continuous torque and peak torque. Match peak for start and stop. Match continuous for steady run.

- Speed: Check rated speed and maximum speed. Make sure the gearbox and load allow it.

- Power: Look at electrical power and mechanical power.

- Encoder resolution: Higher resolution gives finer control. It also increases data rate needs.

- Inertia matching: Match load inertia to rotor inertia. This gives stable control and better dynamic response. Use inertia matching rules from your vendor.

- Voltage and current requirements: Make sure the drive can feed the motor.

- Environmental needs: Check IP rating. Do you need waterproof servo motor parts or food grade servo motor housings. Do you need explosion proof servo motor ratings for hazardous sites.

A quick note on the build. The stator and rotor cores make a big difference. Better laminations cut core loss. They lift efficiency and torque density. If you build or buy motors, look at stator core lamination quality and rotor core lamination design. The grade of electrical steel laminations also matters for EMI, heat, and vibration.

Key specs checklist

- Servo motor power ratings

- Voltage requirements servo motor

- Current requirements servo motor

- Encoder resolution

- Inertia matching servo motor

- Dynamic response servo motor

- Acceleration servo motor

- Deceleration servo motor

- Motor heating servo

- Electromagnetic interference (EMI) servo

- Servo motor noise

- Vibration in servo motor

- Servo motor efficiency

- Energy consumption servo motor

- Servo motor lifespan

How do you wire, tune, and program a servo?

You wire phase leads, feedback cables, and control I/O. You set the drive for current control, velocity control, or position control. You set your motion profile in the servo controller or PLC. You can use a dedicated motion controller for advanced moves.

Tuning matters. Start with auto-tune. Then fine-tune the PID control. Watch for hunting. Raise damping if you see overshoot. Use filters if noise hits the encoder. Good servo motor programming and servo motor tuning save time and cut wear. Use a clean layout to avoid electromagnetic interference. Route power and signal lines apart.

You may use an H-bridge circuit servo for small DC servos. Larger systems use three-phase inverters with PWM. Set safe limits. Limit torque, speed, and travel to protect the machine.

How do you keep a servo safe and healthy?

Safety starts with the right design. Use safe torque off on the drive if you can. Use guards and e-stops. Use the correct IP rating for wet or dusty sites. Pick explosion proof servo motor units for hazardous zones. Use waterproof servo motor housings in wash-down lines. Use food grade servo motor for food plants.

Plan for maintenance. Check cables and connectors. Clean vents. Watch bearing noise. Check logs for faults. Use predictive maintenance servo tools. Monitor vibration, temperature, and encoder counts. This helps you catch issues before they stop your line.

Common problems and easy fixes

Problem: The axis shakes. Or it overshoots.

Fix: Tune the PID. Lower proportional gain or raise damping. Check stiffness and inertia matching.

Problem: The motor runs hot.

Fix: Check load. Check cooling. Check lamination loss. Better cores and tight stacks reduce heat. High-grade steel and good motor core laminations improve efficiency.

Problem: Noise or EMI trips the drive.

Fix: Shield the encoder cable. Ground the motor frame. Use ferrites. Separate power and signal.

Problem: Lost position.

Fix: Check encoder feedback. Check cables. Use a resolver in harsh sites. It resists noise.

If you face a basic open loop system motor, note that it will not correct error. True servo systems run closed loop and will correct.

Real brands, real systems

You will find servo systems from many makers:

- Fanuc, Siemens, Yaskawa, Rockwell Automation, Kollmorgen, Delta Electronics, Mitsubishi Electric, Panasonic, Omron, Bosch Rexroth, Oriental Motor, Sanyo Denki, Wittenstein, Parker Hannifin, Schneider Electric, Estun Automation.

- These brands cover Industrial Automation, Robotics, CNC Machines, Packaging Machinery, Medical Devices, Aerospace Industry, Automotive Manufacturing, Automated Manufacturing, and Precision Engineering.

Servos use many components and ideas:

- Positional Accuracy, Torque Control, Speed Regulation, Acceleration Profile, Feedback Loop, Closed-Loop System, Encoder (Rotary/Linear), Resolver, Hall Effect Sensor, PID Controller, Pulse Width Modulation (PWM), Servo Drive, Servo Amplifier, Brushless DC (BLDC), Permanent Magnet Synchronous Motor (PMSM), Stepper Motor, Gearbox, Harmonic Drive, Leadscrew, Ball Screw, H-Bridge, Mechatronics, Industry 4.0, Motion Control, Robotic Arms, and more.

I have seen how better cores and stacks help. Tight stacks and clean edges reduce loss. High-grade silicon steel makes a cooler motor. That gives you more torque and longer life.

Quick comparison: servo vs. stepper

Here is a simple table that shows the key differences.

| Feature | Servo Motor | Stepper Motor |

|---|---|---|

| Control | Closed loop with encoder feedback | Open loop by steps |

| Precision | High positional accuracy | Good if it does not lose steps |

| Torque at Speed | Strong at high speed | Drops fast at high speed |

| Speed Range | Wide and smooth | Best at low to mid speed |

| Cost | Higher | Lower |

| Setup | Needs tuning | Simple |

| Use Case | Robotics, CNC, automation motor | 3D printers, simple indexers |

Mini case studies and ROI

Case 1: A packaging line had a stepper on a cutter. It lost steps at high speed. They moved to an AC servo with encoder feedback. The servo drive used a tight PID. The motor hit the mark every cycle. Scrap dropped by 80%. The return on investment servo payback took 7 months.

Case 2: A robot wrist needed smooth, fast moves. A BLDC servo with a harmonic drive solved backlash. The system used high encoder resolution. It cut cycle time by 15%. Parts per hour went up. Vibration in servo motor parts went down.

Case 3: A textile machinery servo axis ran hot. The team found high core loss. They switched to higher grade laminations and better stacks. Heat dropped 12°C. The servo motor lifespan improved. Energy consumption servo motor use fell by 6%.

Key terms you will hear (and what they mean to you)

You will meet many terms in servo work. This list helps you spot them fast.

- How servo motor works

- Servo motor vs stepper motor

- Servo motor applications

- Parts of a servo motor

- Servo motor control

- Advantages of servo motor

- Disadvantages of servo motor

- Types of servo motors

- Industrial servo motor

- Small servo motor

- DC servo motor

- AC servo motor

- Servo drive

- Encoder feedback

- PID control servo

- Precision motion control

- Robotics motor

- Automation motor

- Closed loop system motor

- Open loop system motor

- Servo mechanism definition

- Torque servo motor

- Speed servo motor

- Positional accuracy

- Brushless servo motor

- Brushed servo motor

- Servo motor principle

- How to select servo motor

- Servo motor specifications

- Servo motor wiring

- Micro servo motor

- Continuous rotation servo

- Pan-tilt servo

- Digital servo motor

- Analog servo motor

- Servo motor system components

- Servo amplifier

- Servo controller

- H-bridge circuit servo

- Pulse width modulation (PWM) servo

- What is a servomechanism

- Common servo motor problems

- Servo motor maintenance

- History of servo motors

- Future of servo technology

- High torque servo motor

- Low inertia servo motor

- Direct drive servo motor

- Gear reduction servo motor

- Motor feedback devices

- Resolver for servo motor

- Hall effect sensor servo

- Servo motor efficiency

- Energy consumption servo motor

- Dynamic response servo motor

- Acceleration servo motor

- Deceleration servo motor

- Servo motor sizing calculation

- Servo motor tuning

- Servo motor programming

- Servo motor safety

- Explosion proof servo motor

- Waterproof servo motor

- Food grade servo motor

- Medical servo motor applications

- Aerospace servo motor applications

- Automotive servo motor uses

- CNC machine servo motor

- Packaging machinery servo motor

- Printing press servo motor

- Pick and place servo

- Robot arm servo motors

- Textile machinery servo

- Injection molding servo

- Material handling servo

- Automated guided vehicle (AGV) servo

- Drone servo motors

- RC servo motor

- Linear servo motor

- Rotary servo motor

- Current control servo

- Velocity control servo

- Position control servo

- Servo motor power ratings

- Voltage requirements servo motor

- Current requirements servo motor

- Inertia matching servo motor

- Motor heating servo

- Electromagnetic interference (EMI) servo

- Servo motor noise

- Vibration in servo motor

- Servo motor lifespan

- Predictive maintenance servo

- Servo motor troubleshooting

- Servo motor manufacturers

- Servo motor suppliers

- Servo motor cost analysis

- Return on investment servo

- Servo motor training

- Understanding servo systems

Build matters: cores, laminations, and steel

This is short but important. A servo motor’s heart is the stator and rotor. Steel grade and stack quality drive loss and heat. Good stator core lamination and rotor core lamination raise efficiency. They boost torque. They cut EMI and noise.

BLDC and PMSM designs use thin, high-grade steel. Quality electrical steel laminations reduce eddy currents. A well-built BLDC stator core improves dynamic response. It also helps low inertia servo motor designs. Better cores help direct drive servo motor builds too. If you care about smooth motion control and long life, the core stack is not a minor detail. It is a big lever.

PAS in action: how to position your choice

Problem: Your line needs speed and accuracy. Your current motor stalls or drifts.

Agitate: Missed cuts make scrap. Slower moves kill output. Heat hurts bearings and electronics.

Solution: Move to a servo with the right specs and a high-quality core. Use a servo amplifier that supports PWM and high loop rates. Use a high-resolution encoder or a robust resolver. Pair the motor with a tight gearbox or harmonic drive if you need high torque and no backlash. Size the drive for peak and continuous current. This plan gives you precision motion control with less waste.

History and future

The history of servo motors goes back to early control systems. As sensors and drives improved, servos got faster and smarter. Today, Industry 4.0 links servo systems to the IIoT. You get smart motors and advanced communication protocols like EtherCAT and PROFINET. The future of servo technology brings more integration. It pushes miniaturization and enhanced energy efficiency. It brings better algorithms and safer systems.

Specifications table you can use

Here is a short guide you can copy.

| Spec | What it means | Tip |

|---|---|---|

| Torque (continuous/peak) | Force you can deliver steady and in bursts | Match peak for starts. Match continuous for run |

| Speed (rated/max) | Normal speed and safe top speed | Check gearbox and load |

| Encoder resolution | Counts per rev or bits | Higher means finer control |

| Inertia ratio | Load inertia to rotor inertia | Keep ratio low for control |

| Voltage/current | Drive and motor match | Check cable length too |

| IP rating | Dust and water protection | Pick for the site |

| Thermal class | Max winding temp | Leave margin for life |

FAQ

Q: What is a servomechanism?

A: It is a system that uses feedback to control position, speed, or torque. A servo motor is part of this system.

Q: Can a servo run open loop?

A: True servo control is closed loop. Some hobby servos act simple. Yet best results need closed-loop feedback.

Q: Do I need an encoder or resolver?

A: Yes. Feedback gives positional accuracy. Choose encoders for high resolution. Choose resolvers for harsh sites.

Q: What is better, brushed or brushless?

A: Brushless runs cooler and lasts longer. Brushed costs less. Pick based on your needs.

Q: How do I reduce vibration?

A: Tune the loop. Stiffen the mount. Balance the load. Use better cores and stacks to cut loss and ripple.

Summary: key points to remember

- A servo motor is a motor with feedback and control in a closed-loop system.

- It gives high precision, high torque at speed, and smooth motion.

- Use a servo for robots, CNC, packaging, and dynamic loads.

- Size for torque, speed, power, and inertia. Pick the right encoder.

- Build quality matters. Good laminations and steel cut heat and noise.

- Tune the drive. Wire it right. Keep it cool and clean.

- Plan maintenance and predictive checks to protect uptime.

- Use PAS: define the problem, feel the pain, then pick the servo solution that fits.

References

- Siemens, Motion Control Application Guide, Servo Drives and Motors

- Yaskawa, Sigma Series Technical Manual

- Rockwell Automation, Kinetix Servo Drives User Manual

- Kollmorgen, Motion 101 Design Guide

- Bosch Rexroth, IndraDrive Servo System Overview