What is a Short Block Motor? Your Complete Guide to Engine Basics

Every engineer has faced this moment. A bottom-end failure halts a project or a vehicle. Budgets get tight. Lead times grow. You need a solution that balances cost, reliability, and time to get back on the road or back to test. If you are asking “What is a short block motor” you are right where many product designers, procurement managers, and mechanics find themselves when an engine fails or a performance build ramps up. This guide explains what a short block includes, how it differs from a long block and a bare block, when it makes sense to choose one, and how to evaluate quality, warranty, and installation risks. You will see both the engineering logic and the practical costs.

We will follow a simple model: Problem → Explain → Guide → Empower. You will leave with a clear path forward.

In This Article

- Core Components Included in a Short Block

- What a Short Block Doesn’t Include

- Short Block vs. Long Block vs. Bare Block

- When to Choose a Short Block Motor

- Advantages and Disadvantages of Opting for a Short Block

- Factors to Consider When Buying a Short Block

- FAQs About Short Block Motors

- A Note for Electric Motor Teams: Laminations vs Engine Blocks

- Conclusion: Making an Informed Decision

Core Components Included in a Short Block

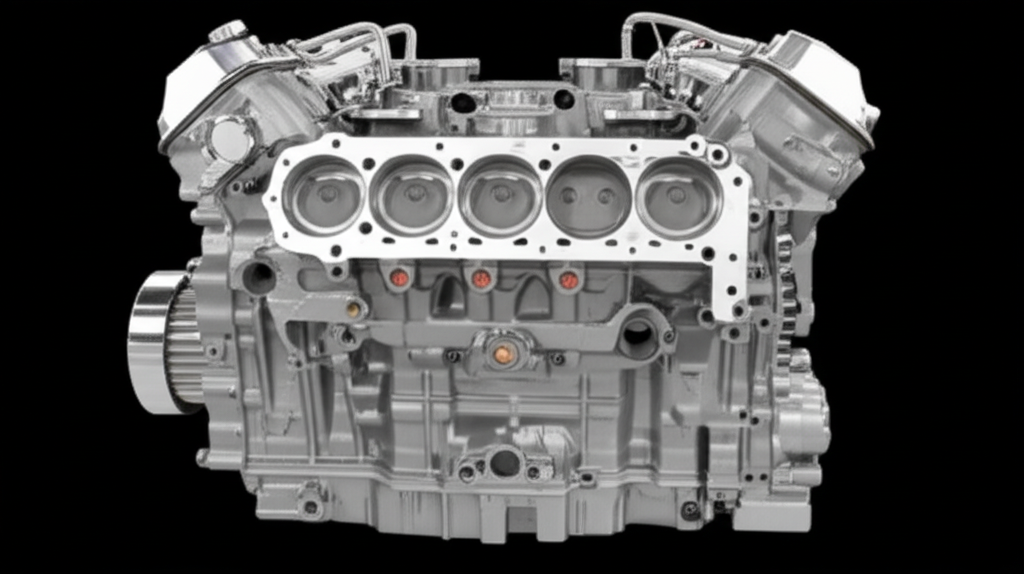

Let’s start with the definition because precision matters. A short block is a partially assembled internal combustion engine that includes the core “bottom end” of the engine. At a minimum, a standard short block assembly typically includes:

- Engine block (cylinder block)

- Crankshaft

- Pistons with piston rings and wrist pins (piston pins)

- Connecting rods

- Main bearings and rod bearings

- Thrust bearings

- Crankshaft main caps

Depending on the OEM or remanufacturer, some short blocks also include:

- Oil pump and related lubrication system components

- Cam bearings installed in the block

- Freeze plugs and gallery plugs already fitted

You will also see the term bottom end and rotating assembly used to describe the major moving internals. The crankshaft, connecting rods, and pistons comprise the rotating assembly. The engine block houses the rotating assembly, defines the cylinder bore, and sets the engine displacement. Short block specifications can include bore size, stroke, compression ratio targets, and balance details for the rotating assembly.

A performance short block may add features like:

- Forged pistons and forged connecting rods

- A forged or billet crankshaft

- Upgraded main bearings and rod bearings

- Blueprinted clearances and balancing

- Block machining and preparation for higher horsepower and torque

- Specific materials such as a cast iron engine block for durability or a sleeved aluminum block for weight reduction and rebuildability

Diesel short block and gasoline short block options differ in piston design, compression ratio, and typical block materials. Diesel engines often use stronger components and different piston crown geometries. Gasoline engines focus on rev capability and weight. Both are available as new short block or remanufactured short block units.

What’s included in a short block is standard across many brands with some variation. Always read the short block specifications line by line. Confirm what comes with a short block so you avoid surprise parts purchases or delays during assembly.

What a Short Block Doesn’t Include

Short blocks replace the engine’s core but not the top end or accessories. Expect to transfer or purchase the following:

- Cylinder heads

- Valvetrain components: camshaft, valves, valve springs, retainers, lifters, pushrods, rockers

- Timing components: timing chain or timing belt, gears, guides, tensioners

- Gaskets and seals for final assembly

- Oil pan and valve covers

- Intake manifold and exhaust manifold

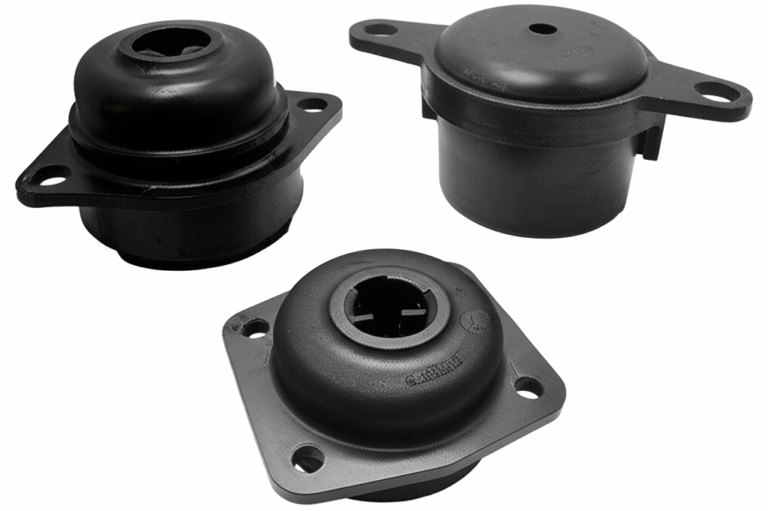

- External accessories: alternator, starter motor, water pump, fuel injectors or carburetor, spark plugs, AC compressor, engine mounts, flywheel or flexplate, front accessory drive

- Sensors and harnesses as needed for modern engine management

A short block is not a complete engine assembly. It does not arrive ready to drop in and turn the key. It requires careful engine building practices, correct torque sequences, new gaskets and seals, and attention to timing and lubrication systems.

Short Block vs. Long Block vs. Bare Block

You have three major options when an engine fails. Bare block, short block, or long block. There is also the complete engine or crate engine route. Let’s break them down.

The Bare Block: Foundation Only

- What it is: A machined engine block with cylinder bores and main bearing saddles ready for assembly.

- Includes: Just the engine block. No rotating assembly. No bearings. No pistons. No rods.

- Where it fits: Highly specialized custom builds, race programs, or when you want to control every detail of the engine assembly process. It demands extensive machining and parts selection. You must source the crankshaft, connecting rods, pistons, bearings, piston rings, and more.

- Pros: Maximum control of engine internals and clearances. Ideal when you want custom displacement, sleeves, or exotic materials.

- Cons: Highest assembly complexity. Significant engine building time. Not cost effective if you only need a standard repair.

The Short Block: The Middle Ground

- What it is: A semi-complete bottom end with the crankshaft, pistons, connecting rods, and bearings installed in the engine block.

- Includes: Block, rotating assembly, main bearings and rod bearings, piston rings and pins. Often includes cam bearings. May include the oil pump.

- Where it fits: A damaged bottom end with good cylinder heads and valvetrain. A performance build that needs a stronger base but wants to choose cylinder heads and camshaft. A project that needs cost control and reasonable lead time.

- Pros: Lower short block motor price than a long block or complete engine. Lets you re-use good top-end components. Flexible for custom builds and performance engine build projects. Good mix of quality and cost.

- Cons: Requires cylinder head and timing assembly. Demands attention to compatibility and engine blueprinting. More parts and labor than a long block.

The Long Block: A More Complete Solution

- What it is: A short block plus cylinder heads, complete valvetrain, and timing components installed.

- Includes: Short block + camshaft, valves, springs, lifters, timing chain or timing belt, gears, often a valve cover and an oil pan depending on supplier.

- Where it fits: When you want a faster path to a running engine with fewer variables. Excellent for engines with both bottom-end and top-end wear or failure.

- Pros: Less assembly time than a short block. Strong warranties from reputable remanufacturers or OEM suppliers. Lower risk of mix-and-match issues.

- Cons: Higher cost. You replace cylinder heads even if yours are good. Reduced flexibility for custom top-end parts.

The Complete Engine / Crate Engine: Ready to Install

- What it is: A long block with external accessories and sometimes a break-in dyno test. Often marketed as a crate engine.

- Includes: Long block + intake and exhaust systems, oil pan, valve covers, sensors, and accessory drive. Some arrive ready to run.

- Where it fits: You want maximum convenience and a comprehensive warranty. You want minimal assembly risk. Great for fleet service when uptime is king.

- Pros: Easiest installation. Strong warranty coverage. Known configuration with compatibility matched.

- Cons: Highest price. Least flexibility. You replace many components that might not need replacing.

Typical cost bands vary by engine, brand, and whether it is new or remanufactured. You will see bare blocks around a few hundred to low thousands of dollars. Short blocks often run from roughly $1,500 to $4,000 for standard engines. Long blocks can land in the $3,000 to $7,000 range. Complete engines routinely exceed $4,000 and can cross $10,000 for performance or specialty units. Performance short block pricing can climb sharply with forged parts and custom machining.

DIY feasibility rises as you move from bare block to crate engine. Short blocks sit in the middle. If you have strong mechanical skills and the right tools you can assemble the top end. If not you will want a professional mechanic or engine builder.

Warranty coverage often tracks completeness. Many remanufactured short blocks carry 1 to 3 years or 12,000 to 36,000 miles. Long blocks can reach 5 years or 60,000 miles depending on the supplier. Complete engines sometimes push to 100,000 miles. Always read the fine print because warranty coverage applies to parts included in the assembly.

When to Choose a Short Block Motor: Ideal Scenarios

Short blocks shine when the bottom end fails but the top end remains healthy. They also make sense for performance builds that need a strong base.

Cost-Effective Engine Repair

You hear an ominous knock. Oil pressure drops. Metal flake appears in the oil filter. After inspection your shop confirms main bearing failure, rod bearing damage, or a seized crankshaft. The cylinder heads, valvetrain, and external accessories test fine. In this situation a short block replacement targets the exact failure.

- You replace the engine bottom end and rotating assembly.

- You keep your good cylinder heads, intake, exhaust, alternator, starter, water pump, and accessory drive.

- You save on parts and labor compared to a long block or crate engine.

This aligns with common engine repair options where you balance cost against risk. It also limits waste because you avoid discarding good components.

Performance Upgrades and Custom Builds

You want more horsepower and torque. You need stronger internals or different displacement. A performance short block gives you a foundation for a custom top end.

- Use forged pistons and rods. Upgrade to a stronger crankshaft.

- Increase displacement via overbore or a stroker crank while watching cylinder wall thickness and cooling. This is part of engine blueprinting.

- Pair the short block with aftermarket cylinder heads, a chosen camshaft, and induction upgrades.

- Select the desired compression ratio and piston crown for your fuel and tune.

Builders like short blocks because they control the top-end configuration while getting a solid bottom-end assembly. This hybrid approach lets you match engine components to your goals. You tune for driveability or peak power as needed.

Availability and Lead Times

Short blocks for popular engines often sit in distributor inventory. Long blocks and crate engines can have longer lead times. If your vehicle or product line needs to get moving again quickly a short block can be the fastest path to return to service.

An Illustrative Case Study

- Scenario: A 2017 Honda CR‑V with a 2.4L engine suffers a main bearing failure at about 95,000 miles. Cylinder heads and accessories test fine after teardown.

- Options:

- Crate engine: roughly $7,500 to $9,500 installed. Highest convenience with broad warranty coverage.

- Long block: roughly $5,500 to $7,500 installed. Balances convenience and cost.

- Short block: roughly $4,000 to $6,000 installed. Most cost effective because it targets the bottom-end failure.

- Outcome: The short block path saves about $1,500 to $3,500 versus the other choices while maintaining reliability because the top end is in excellent condition.

Numbers vary by region and supplier. The pattern holds because you only replace the failed subsystems.

Advantages and Disadvantages of Opting for a Short Block

Let’s keep it practical. Here are the tradeoffs that matter to engineering, purchasing, and maintenance teams.

Pros

- Lower initial cost than a long block or complete engine assembly

- Ability to re-use good cylinder heads, valvetrain, and external accessories

- Flexibility for customization and performance engine building

- Often better availability for common engine types

- Targeted solution when the bottom end failed and the top end checks out

Cons

- More assembly work and added parts required to finish the engine

- Greater risk of issues if reused components are not inspected thoroughly

- Requires specialized tools and expertise to assemble the top end and set timing

- Warranty covers only the parts included in the short block assembly

- Compatibility checks add engineering time when mixing OEM and aftermarket parts

Short blocks are a middle-ground solution. They deliver value if you manage assembly risk and verify component compatibility.

Factors to Consider When Buying a Short Block

Procurement decisions hinge on more than price. You want reliability, compatibility, and support.

New vs. Remanufactured Short Blocks

- New short block: All-new components, usually from the OEM or a premium performance builder. You pay more for new castings and new rotating assemblies.

- Remanufactured short block: The block and sometimes the crankshaft start as cores that get inspected, machined, and returned to service with new wear components. A quality remanufactured engine follows strict machining and assembly standards and can deliver excellent reliability and warranty coverage.

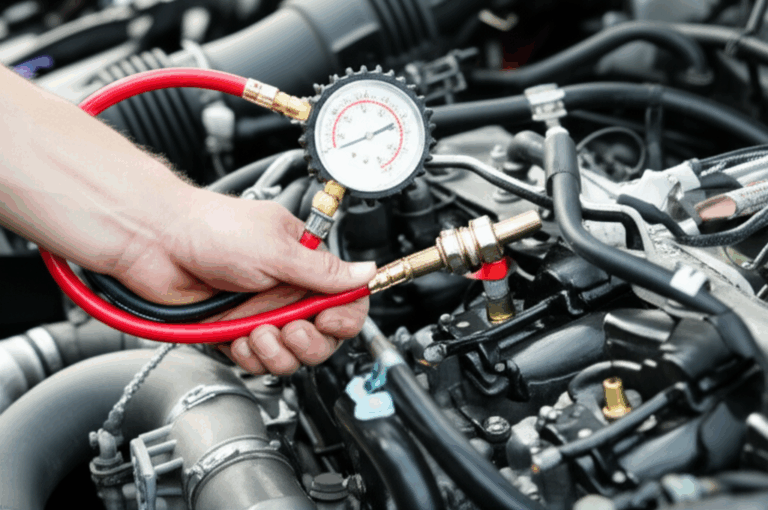

What matters is process control and quality assurance. Ask about:

- Block machining steps: align honing, deck resurfacing, cylinder bore finish, and correctness of main bearing housing geometry

- Crankshaft inspection and processes such as crack detection and grinding

- Bearing clearances and documentation

- Balancing of the rotating assembly

- Piston ring selection and gap strategy for the intended heat load

- Cleanliness controls because grit kills engines

Reputable remanufacturers follow industry best practices and document their engine assembly process. Industry organizations such as SAE International and the Automotive Engine Rebuilders Association (AERA) publish guidance you can use as a reference point. You should review the builder’s test procedures and warranty terms. You should also check whether a core charge applies and how core exchange works for your engine core.

Engine Specifications and Compatibility

Match the short block to your exact vehicle or equipment:

- Make, model, year, and engine code

- Emissions package differences

- Crankshaft reluctor wheel tooth count for the ECU

- Compression ratio requirements for your fuel and calibration

- Cylinder bore and stroke dimensions

- Balance style, flywheel or flexplate fitment, and engine mount fitment

Modern engines are software defined as much as hardware defined. Sensors and timing components must match the ECU expectations. You do not want mismatch errors during startup.

Warranty and Support

A short block warranty is only as strong as the inclusion list. Confirm:

- Coverage period and mileage limits

- What parts are covered and what is excluded

- Requirements for installation, oil choice, and break-in procedures

- Diagnostic process for claims

- Support responsiveness and parts availability during a claim

Good support matters more than a glossy brochure. Ask for references if you are sourcing for a fleet or product line.

Professional Installation vs. DIY

Can you install a short block yourself? Yes if you have strong mechanical skills and the right tools. You also need time, a clean environment, and a trusted engine repair manual for torque specs and assembly sequences.

You should choose a professional mechanic or engine builder if:

- You do not routinely assemble cylinder heads, timing sets, and oiling systems

- You lack specialty tools for tasks like degreeing a cam, checking piston-to-valve clearance, and measuring bearing clearances

- You want warranty protection that requires professional installation

The installation process includes engine removal and engine installation steps, cleaning and assembly of components, and careful timing verification. A disciplined process reduces risk. It also extends engine durability and engine longevity in service.

FAQs About Short Block Motors

- How much does a short block cost?

- Most standard short blocks land between $1,500 and $4,000 for parts. Performance short blocks and specialty engines can cost much more. Final cost depends on engine type, OEM vs aftermarket status, and whether it is new or remanufactured.

- Can I install a short block myself?

- You can if you have the skills and tools. You must transfer the cylinder heads, camshaft and valvetrain, timing chain or belt, oil pan, and all external accessories. You should check component compatibility and follow torque and timing specs exactly.

- What is the typical lifespan of a short block?

- A properly built and installed short block has a service life similar to a complete engine. Longevity depends on oil quality, cooling performance, load cycles, and tune. Performance engines see different duty cycles and thermal loads that change expectations.

- Do short blocks come with a warranty?

- Reputable new and remanufactured suppliers offer warranties. Coverage ranges from 12 months to several years based on application and parts included. Read the terms because warranties cover only the included components and workmanship.

- Is a short block better than rebuilding my old engine?

- If your block needs major machining or you need a faster turnaround a short block often delivers better value. If your block is in excellent shape and you want absolute control you can rebuild with your engine builder. Availability of parts and machine shop load can swing the decision.

- What’s included in a short block that I should verify before ordering?

- Verify the presence of the crankshaft, pistons with rings and pins, connecting rods, main and rod bearings, thrust bearings, and whether cam bearings and oil pump are included. Confirm balance status and cylinder bore size.

- What about engine knocking, blown engine solutions, or engine seizing repair decisions?

- Knock from bearing failure or piston slap often means bottom-end damage. A short block targets that damage. A blown engine with top-end damage might push you toward a long block. A seized engine often demands teardown to see if the block is salvageable.

- How long does short block installation take?

- Installation time varies by engine and vehicle packaging. Expect significantly more labor than a long block because you must assemble and time the top end. For planning purposes many shops quote a range that reflects engine removal, assembly, and installation.

A Note for Electric Motor Teams: Laminations vs Engine Blocks

If you work on electric machines you may have landed here while comparing rotating machinery choices. Think of an internal combustion engine’s short block as the structural and functional foundation of a power unit. Electric motors use a different foundation. They rely on laminated magnetic cores that shape the flux path and minimize core loss. In that world your “bottom end” is the lamination stack.

- The stator core delivers the magnetic circuit that couples with the rotor. If you want a deeper dive on stack quality and performance you can review how stator core lamination choices affect efficiency, noise, and assembly.

- The rotor core sets torque characteristics and mechanical integrity at speed. You can explore typical options and tradeoffs in rotor core lamination designs.

- Material selection is the analog to choosing block material and internals. Electric machines depend on electrical steel laminations with the right thickness, coating, and grade to control hysteresis and eddy current losses.

- If you are scoping a new drive platform you can see how complete motor core laminations stacks and manufacturing processes align with your power density and thermal goals.

Short block decisions revolve around mechanical durability, lubrication, and combustion loads. Lamination decisions revolve around magnetic properties, losses, and manufacturing processes like stamping, laser cutting, bonding, and interlocking. The parallel is simple. In both cases the foundation dictates performance, cost, and long-term reliability. You choose wisely at the core or you fight problems downstream.

Engineering Fundamentals That Influence the Decision

Let’s connect engine fundamentals with practical outcomes.

- Engine block materials:

- Cast iron engine block: Strong, affordable, thermally stable. Heavier than aluminum. Popular for durability and remanufacturing.

- Aluminum block with cast-in iron liners or sleeves: Lighter, helps vehicle dynamics. Needs careful thermal management and can complicate rebuilds.

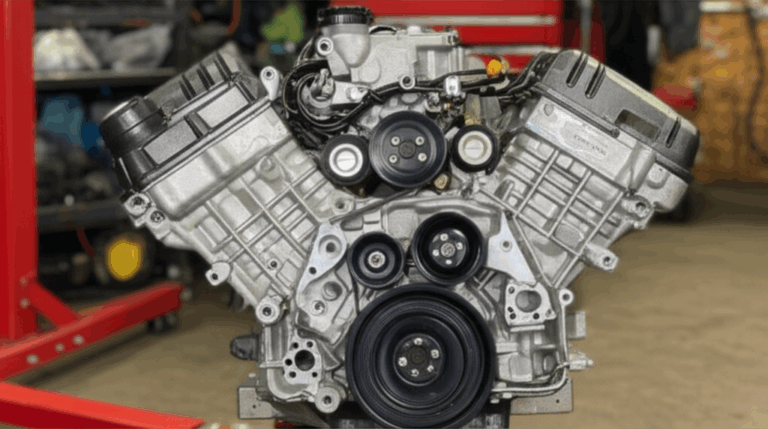

- Rotating assembly:

- Crankshaft: Forged vs cast affects strength and cost. Crankshaft grinding and polishing matter during remanufacturing. The crank couples with main bearings and thrust bearings. Main caps keep alignment under load.

- Connecting rods: Stock powdered metal vs forged rods for performance. Rod bearing clearances are critical.

- Pistons: Cast vs forged. Ring selection and gaps must match load and thermal targets. Piston installation quality sets oil control and engine compression.

- Lubrication:

- Oil pump condition defines bearing life. Pressure and flow must match engine needs. Galleries must be clean. Seals and gaskets must be fresh to avoid pressure loss.

- Machining and assembly:

- Engine block preparation includes cleaning, inspection, boring and honing, and deck resurfacing. Align honing or line boring can be needed to correct main bore geometry.

- Engine balancing reduces vibration which protects bearings and accessories.

- Engine blueprinting sets clearances to spec for durability and repeatability.

When buyers ask about short block reliability the answers come back to these fundamentals. Quality inputs plus disciplined processes result in predictable outputs.

Your Options Explained: A Practical Guide for Buyers

You often must pick between OEM short block, aftermarket short block, or a remanufactured short block from a reputable engine builder.

- OEM short block

- Pros: Known specifications, direct fit, established warranty. Often robust supply for high-volume platforms.

- Cons: Price premium. Limited performance features unless you buy a motorsports variant.

- Aftermarket short block

- Pros: Broad price and performance range. Options from budget short block units to custom short block assemblies. Performance parts integrated from the start.

- Cons: Quality varies widely. Vet the builder. Confirm compatibility with OEM engine management.

- Remanufactured short block

- Pros: Cost effective. Good warranty from established remanufacturers. Sustainability credit by reusing castings responsibly.

- Cons: Requires confidence in the reman process and inspection standards. Core charge and core exchange logistics add steps.

Also consider:

- Short block service life: Dependable if clearances, materials, and lubrication are correct. Abuse or poor assembly shortens life quickly.

- Short block installation time: Budget time for engine removal, top-end assembly, timing setup, and installation. Lead times vary by platform.

If you are the product designer or procurement manager you also care about supplier risk. Ask for process documentation. Ask about SPC data on critical dimensions. Ask how they validate bearing clearances and oiling system flow. It is a parts purchase and a process purchase.

Troubleshooting and Risk Management

Engine failure symptoms push you toward replacement decisions. Spot the red flags early.

- Engine knocking under load and at idle often signals rod bearing or main bearing wear

- Low oil pressure with metallic debris points to bearing and crank damage

- Blue smoke and low compression suggest piston ring or cylinder wear that a short block solves

- Metal in the oil and seized rotation indicate severe bottom-end damage

If cylinder heads show cracks, warpage beyond limits, or valvetrain damage you should compare short block vs long block costs. Do not reuse compromised heads because you will risk a quick repeat failure.

When reusing heads and accessories you should perform:

- Pressure test and resurface heads if needed

- Replace valve stem seals and inspect springs and lifters

- Clean or replace the oil cooler because it can hold debris

- Replace the oil pump if not included

- Replace timing chain or belt, guides, and tensioners

- Use new gaskets and seals throughout

This is your “ounce of prevention” list. It protects the investment and reduces warranty claims.

“Which Application Is This For?” Matching the Solution to Your Use Case

- Daily-driver vehicle with a smoked bottom end and good heads

- Choose a remanufactured short block. Reuse your heads after inspection. Replace timing and oil pump. You will get back on the road quickly at a fair cost.

- Fleet service with uptime as the top KPI

- Consider a long block or complete engine. Shorten downtime and reduce assembly risk. Warranties and standardized processes help your maintenance team.

- Performance build that targets specific horsepower and torque

- Start with a performance short block. Pick forged internals and an appropriate compression ratio. Pair with heads and camshaft that match your airflow and rpm band.

- Older vehicle with an unknown service history

- Long block can be better if the top end shows wear. Confirm costs because you do not want surprises halfway through the job.

- Tight timeline with parts shortages

- Short block availability sometimes beats long block lead times. Check distributor inventory before committing.

Be honest about limitations. A short block saves money and lets you customize the top end. It also demands strong assembly practices and part compatibility checks. If those are not in your team’s wheelhouse you should upgrade to a long block to control risk.

The Business Side: Costs, Warranty, and Core Logistics

Procurement managers care about total landed cost, not just the short block motor price. Build your budget with line items for:

- Short block purchase price

- Core charge and shipping for the core exchange

- Gaskets, seals, timing components, oil pump, fluids, filters

- Machine shop services for heads

- Labor for engine removal, assembly, and installation

- Calibration or ECU relearn if required

Total cost of ownership also includes warranty risk. Long blocks and complete engines often carry longer warranties. Short blocks can still be a great value if you execute assembly correctly.

A Quick Glossary for Clarity

- Engine block / cylinder block: The main structure of the engine that holds cylinders and main bearings

- Rotating assembly: Crankshaft, connecting rods, pistons, and associated bearings

- Main bearings and rod bearings: Bearings that support the crankshaft and connecting rods

- Thrust bearings: Bearings that control crankshaft axial movement

- Cylinder bore: Diameter of the cylinder which defines displacement along with stroke

- Crankshaft main caps: Caps that hold the crankshaft in the block

- Cylinder head: The top-end component that houses valves and combustion chambers

- Valvetrain: Camshaft, valves, lifters, springs, and related parts that open and close the valves

- Timing chain or timing belt: Synchronizes crankshaft and camshaft motion

- Bare block vs short block: Bare block is only the block, short block includes the bottom end internals

- Long block: Short block plus cylinder heads, valvetrain, and timing set

- Crate engine: A complete engine assembly ready to install

- OEM vs aftermarket: Original equipment manufacturer vs non-OEM supplier

- Engine blueprinting: Precision measuring and setting of clearances to specification

- Engine balancing: Matching rotating and reciprocating mass to reduce vibration

Your Engineering Takeaway

You want clarity and a plan. Here it is.

- Choose a short block when the bottom end failed and your top end remains good

- Verify what is included in the short block. Confirm bore, balance status, and whether the oil pump is included

- Inspect and refresh the top end. Replace timing components and oil pump as a rule

- Match the short block to your exact engine code and ECU requirements

- Vet your supplier’s machining and assembly processes. Ask for documentation

- Consider new vs remanufactured based on budget and warranty priorities

- Step up to a long block or crate engine when time is tight or top-end wear is significant

- For electric motor projects think in terms of the magnetic foundation. Stacks and materials define efficiency and heat the way the bottom end defines durability in an engine. See stator core lamination, rotor core lamination, electrical steel laminations, and complete motor core laminations for context on materials and stacks

You can move forward with confidence. If you manage assembly risk and verify compatibility a short block offers a smart balance of cost, performance, and timing for many applications.

Conclusion: Making an Informed Decision

A short block is the practical middle ground in the engine replacement spectrum. It packages the engine core and rotating assembly so you can target bottom-end failures without buying a full long block or complete engine. It keeps budgets lean and design options open.

- Use a short block for cost-effective engine repair when your cylinder heads and valvetrain check out

- Choose a performance short block for custom builds that need stronger internals or new displacement

- Move to a long block or complete engine when you want faster installation or when the top end is compromised

- Protect the investment with clean assembly, fresh gaskets and seals, and a new oil pump

- Align your choice with lead times, warranty requirements, and in-house expertise

If your next step is a purchase decision bring your engine code, vehicle details, and failure symptoms to your supplier. If you run an electric motor program and you landed here for comparison look at your lamination stack decisions the same way. The foundation sets your ceiling on performance and cost. Reach out to a trusted mechanic or engine builder for an estimate. Then get your project moving again with a solution that fits your goals and your timeline.