What is a Single Phase Motor? Understanding Its Types, Working, and Applications

Have you ever wondered what makes your washing machine spin or your refrigerator hum? It’s not magic. It’s a small but powerful hero called a single phase motor. These little engines are everywhere in our homes and small businesses. But understanding them can feel like trying to solve a puzzle. This guide will make it easy. I’ll show you exactly how they work, what they’re made of, and why they are so important in our daily lives.

Table of Contents

- What Exactly is a Single Phase Motor?

- How Does a Single Phase Motor Actually Work?

- What Are the Main Parts of a Single Phase Motor?

- Can You Explain the Different Types of Single Phase Motors?

- What Are the Biggest Advantages of Using Single Phase Motors?

- Are There Any Downsides to Single Phase Motors?

- Where Do We See Single Phase Motors in Everyday Life?

- How is a Single Phase Motor Different from a Three Phase Motor?

- What Should I Do If My Single Phase Motor Has a Problem?

- Why is This Little Motor So Important?

What Exactly is a Single Phase Motor?

Have you ever plugged something into a wall outlet at home? Of course you have. The power that comes out of that outlet is called single-phase power. And a single phase motor is a special type of electric motor designed to run on that exact kind of power. It’s an AC motor, which means it uses Alternating Current, the type of electricity that flows back and forth.

The real problem is that you can’t just buy any motor and plug it in. Big, heavy-duty motors used in giant factories need a different kind of power called three-phase power. It’s like trying to run a car on apple juice instead of gasoline. It just won’t work. This can be frustrating if you need a motor for a home project or a small workshop but don’t have access to industrial power.

That’s where the single phase motor comes in. It’s the perfect solution because it’s built specifically for the power supply in our homes and small businesses. This is why they are in over 90% of the appliances we use every day. From your refrigerator motor to your garage door opener, this little workhorse is everywhere. It’s the engine that makes modern life possible.

How Does a Single Phase Motor Actually Work?

Here is the one big secret about single phase motors: they are not self-starting. Imagine trying to spin a top. If you just set it down, it won’t do anything. You have to give it a good twist to get it going. A single phase motor is just like that top. Its power source creates a magnetic field that just pulses back and forth. It doesn’t spin. This pulsating field can keep the motor running but can’t get it started from a dead stop.

So, how do we solve this? Engineers came up with a clever trick. They added a second set of wires inside the motor called the auxiliary winding or starting winding. This second winding gets a little “kick” of electricity that is out of step with the main power. This creates a second magnetic field that gives the motor the “twist” it needs to start spinning. It’s a simple but brilliant part of the overall motor principle.

Once the motor gets up to about 75% of its full speed, a little device called a centrifugal switch clicks open. This switch turns off the starting winding because its job is done. Now, the main winding (also called the running winding) takes over completely to keep the motor spinning smoothly. This whole process happens in the blink of an eye every time you turn on a fan or start your washing machine.

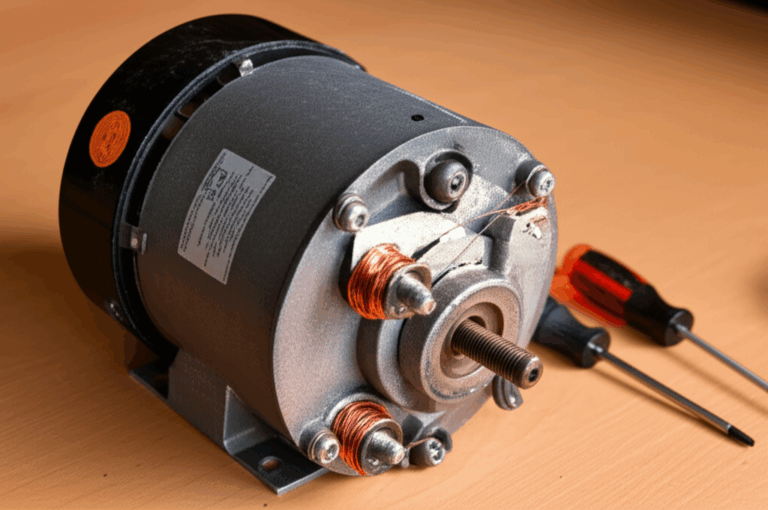

What Are the Main Parts of a Single Phase Motor?

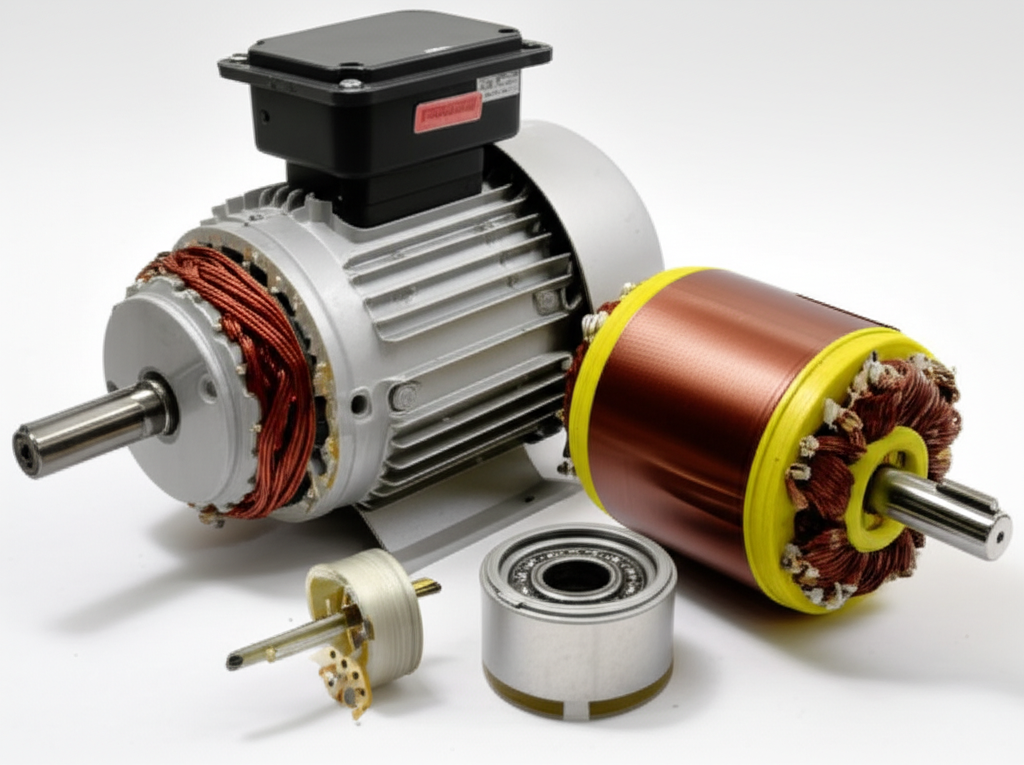

If you were to open up a single phase motor, it might look complicated. But it’s really just a few key parts working together. Let’s look at the main single phase motor components.

The two most important pieces are the stator and rotor. The stator is the stationary outside part. It’s a hollow cylinder with slots cut into it. Copper wires are wound through these slots to create the main and starting windings. The quality of the stator core lamination is very important for the motor’s efficiency. The rotor is the part that spins. In most single phase motors, it’s a squirrel cage rotor, which looks like a small cage for a hamster. It’s made of metal bars connected at each end. There are no wire connections to the rotor; it spins because of the magnetic field created by the stator.

Here are the other key parts:

- Windings: As we discussed, there are two. The main running winding is made of thicker wire and does the work. The auxiliary starting winding is made of thinner wire and just helps it start.

- Capacitor: Many types of single phase motors use a capacitor. Think of it as a small battery that gives the starting winding an extra jolt of energy. This creates a much stronger starting torque, which is the twisting force that gets heavy loads moving.

- Centrifugal Switch: This is the automatic on/off switch for the starting winding. It uses the spinning force of the motor to operate.

- Frame: This is the outer shell that holds everything together and protects the motor’s guts from dust and water.

Can You Explain the Different Types of Single Phase Motors?

Not all single phase motors are the same. Different jobs need different tools and different motors. I’ve worked with many of them over the years. Let me break down the most common types of single phase motors for you.

- Split-Phase Motors: This is the simplest type. It uses a starting winding but has no capacitor. It has low starting torque, so it’s best for things that are easy to start, like small fans or grinders. They are cheap but not very efficient.

- Capacitor-Start Motors: This motor adds a starting capacitor to the mix. That capacitor gives it a huge boost, providing very high starting torque. This makes it perfect for things that are hard to get moving, like an air compressor or a large pump. Once it’s running, the capacitor is switched off.

- Permanent Split Capacitor (PSC) Motors: A PSC motor uses a run capacitor that stays on the whole time. It doesn’t have a centrifugal switch, which makes it quieter and more reliable. It has lower starting torque than a capacitor-start motor but is very efficient while running. You’ll find these in HVAC systems and fans all the time.

- Capacitor-Start, Capacitor-Run Motors: This is the king of single phase motors. It has two capacitors! It uses a big starting capacitor for massive starting torque and a smaller run capacitor for excellent running efficiency. It gives you the best of both worlds but is also the most expensive.

- Shaded-Pole Motors: This is the simplest and cheapest motor of all. It has very low torque and isn’t efficient. But for tiny jobs, like a bathroom fan or a small toy, it’s perfect.

- Universal Motors: This one is special. It can run on either AC power (from your wall) or DC power (from a battery). It runs at very high speeds and is what you’ll find in power drills and blenders.

Here is a simple table to compare them:

| Motor Type | Starting Torque | Efficiency | Common Use |

|---|---|---|---|

| Split-Phase | Low | Low | Small fans, pumps |

| Capacitor-Start | High | Medium | Compressors, large tools |

| PSC Motor | Low-Medium | High | HVAC fans, blowers |

| Shaded-Pole | Very Low | Very Low | Small appliances, toys |

| Universal Motor | High | Medium | Power tools, blenders |

What Are the Biggest Advantages of Using Single Phase Motors?

There’s a reason these motors are so popular. They have some great benefits, especially for home and light commercial use.

First, they are simple and cost-effective. Because they are made in huge numbers and have a simpler design than their three-phase cousins, they don’t cost as much. For a company making washing machines, saving a few dollars on every motor adds up to millions. That saving gets passed on to you.

Second is the availability of single-phase power. Think about it. Every house, apartment, and small shop in the country is wired for single-phase electricity. You can just plug these motors in and go. You don’t need special wiring, which saves a ton of money and hassle.

Finally, they are generally compact and require low maintenance. A PSC motor, for example, has no switch to wear out. The bearings are often sealed for life. This means you can install it and forget about it for years. That reliability is a huge plus for things like refrigerators that need to run 24/7.

Are There Any Downsides to Single Phase Motors?

Of course, no motor is perfect for every job. Single phase motors have some limitations you need to be aware of.

Their biggest disadvantage is lower efficiency compared to three-phase motors. They just can’t turn as much electrical energy into useful work. This means they can use more electricity to do the same job, which can increase your power bill over time, especially for motors that run constantly.

They also have a limited power output. Most single phase motors are made for jobs under 10 or 15 horsepower. When you need to move really heavy stuff, like an industrial elevator or a giant rock crusher, a single phase motor just doesn’t have the muscle. The pulsating power it receives limits its size and strength.

Lastly, as we learned, they require an auxiliary starting mechanism. This adds parts like capacitors and centrifugal switches. These parts can sometimes fail, leading to common single phase motor problems like the motor humming but not starting. More parts mean more potential points of failure.

Where Do We See Single Phase Motors in Everyday Life?

Once you start looking, you’ll see single phase motors everywhere. They are the unsung workhorses of modern life. They power countless devices that we rely on every single day.

In your home, you’ll find them in:

- Appliances: Refrigerators, washing machines, dryers, dishwashers, and vacuum cleaners.

- HVAC Systems: The blower fan in your furnace and the compressor and fan in your air conditioner.

- Pumps: Sump pumps in the basement, well pumps for water, and pool pumps.

- Tools: Bench grinders, small saws, and drill presses in the workshop.

- Other Devices: Ceiling fans, garage door openers, and even electric hand drills.

These motors are chosen for their residential applications because they are reliable, cheap, and work with standard home wiring. The next time you hear that familiar hum of an appliance starting up, you’ll know it’s likely a trusty single phase motor getting to work.

How is a Single Phase Motor Different from a Three Phase Motor?

One of the most common questions I get is about the difference between 1 phase and 3 phase motors. It really comes down to the power supply they use.

Imagine you are pushing a child on a swing. If you are one person pushing (single phase), you give a push, wait for the swing to come back, and then push again. The power comes in pulses. Now imagine three people standing around the swing, each giving a perfectly timed push one after the other (three phase). The swing gets a smooth, constant stream of power.

That’s the main difference. A single phase motor gets one wave of power that goes up and down. A three phase motor gets three waves of power, all overlapping. This makes three-phase motors naturally self-starting, more efficient, and more powerful. However, they require a special three-phase power supply, which is usually only found in large commercial and industrial buildings.

| Feature | Single Phase Motor | Three Phase Motor |

|---|---|---|

| Power Supply | Single wave of AC power | Three overlapping waves of AC power |

| Self-Starting | No, needs help (capacitor/switch) | Yes, naturally self-starting |

| Efficiency | Lower | Higher |

| Cost | Less expensive | More expensive |

| Applications | Home, small business, light tools | Industrial, heavy machinery |

| Power Output | Typically under 15 HP | Can be thousands of HP |

What Should I Do If My Single Phase Motor Has a Problem?

Sooner or later, you might run into a motor that won’t cooperate. Troubleshooting a single phase motor can feel intimidating, but a few common issues account for most problems.

One frequent issue is a failure to start. The motor might just hum or buzz. This is often caused by a bad starting capacitor or a faulty centrifugal switch. The motor wants to run but isn’t getting that initial “push” it needs. Replacing the capacitor is often a simple and cheap fix.

Another problem is overheating. A motor can get too hot for many reasons. It could be overloaded, meaning it’s trying to do more work than it was designed for. The cooling vents might be clogged with dust, or the bearings could be failing. An overheated motor is a sign you need to investigate before it burns out completely. For a deeper dive into what could go wrong, you can explore common causes of a motor problem.

Finally, you might hear excessive noise. A grinding or squealing sound often points to bad bearings. Bearings are small parts that allow the shaft to spin freely. When they wear out, they create friction and noise. A loud electrical hum could also signal a problem with the windings inside the motor.

Why is This Little Motor So Important?

It’s easy to overlook something as common as a single phase motor. It doesn’t have the raw power of a giant industrial motor or the high-tech appeal of a complex servo motor. But its impact on our world is huge.

The single phase induction motor made modern home life possible. Without it, we wouldn’t have automatic washing machines, refrigerators that keep our food fresh, or air conditioners that keep us cool in the summer. It automated countless tasks that were once done by hand.

It democratized power. By running on the same electricity available in every home, it allowed for the creation of small power tools, pumps, and other machines that have empowered small businesses and hobbyists around the world. The global market for these motors is over $18 billion for a reason—they are essential. They are simple, reliable, and get the job done. They are truly the unsung workhorses of our time.

Key Things to Remember

- A single phase motor runs on the standard power you find in your home’s wall outlets.

- It is not self-starting and needs an extra part, like a starting winding or a capacitor, to get spinning.

- The main parts are the stationary stator and the spinning rotor.

- Different types exist for different jobs, like Capacitor-Start for high torque and PSC motors for high efficiency.

- They are perfect for home appliances and small tools but are less powerful and efficient than three-phase motors.

- Common problems often involve the starting capacitor or the centrifugal switch.