What is a Split Phase Motor? A Comprehensive Guide to Its Working, Components & Uses

Short summary: A split phase motor is a simple single-phase AC motor that uses two windings and a switch to start. It is low cost and common in small tools and home gear. In this guide I show you how it works, where it fits, and how to pick and care for one. Read on if you want plain talk and clear steps without the fluff.

Table of Contents

- Introduction: What is a split phase motor?

- How does single-phase power start a motor?

- How do two windings make a phase difference?

- What does the centrifugal switch do?

- What are the key parts inside the motor?

- How does a split phase motor perform?

- Pros and cons: Is it right for your job?

- Where will you use a split phase motor?

- How does it compare to other motor types?

- How do I pick the right size and frame?

- Can I control speed with a VFD or other methods?

- How do I maintain and troubleshoot it?

- What do common nameplate terms mean?

- Two short case studies you can picture

- Cost, energy use, and market trends

- FAQ

- Key takeaways

Introduction: What is a split phase motor?

I like to start with a clear picture. A split phase motor is a type of single-phase induction motor. It runs on Alternating Current (AC) and uses two stator winding sets to get going. We call them the main (run) winding and the auxiliary (start) winding. A centrifugal switch cuts the start winding out after the motor speeds up.

Why do we call it “split phase”? The motor makes a small phase difference between currents in the two windings. That phase shift fakes a rotating magnetic field at start. The motor grabs torque and turns. It sounds like a magic trick. It is not. It is electromagnetism in action.

Problem: You need a small motor for a fan or a pump. You do not want a complex drive or high cost.

Agitate: The load will not budge at start. The lights dim. The tool hums and gets hot.

Solution: Use a split phase induction motor for light loads with low to moderate starting torque needs. It is simple. It is cheap. It works.

How does single-phase power start a motor?

A single-phase line by itself does not make a rotating field. It makes a pulsating field. That field does not know which way to turn at standstill. The rotor sits and buzzes. That is a problem for any single phase induction motor.

So we cheat a little. We add a second path for current with a different time angle. When two currents are out of step, their fields add in a way that looks like rotation. That helps the rotor pick a direction. The motor starts to spin toward synchronous speed then it settles at a speed with some slip.

Want the physics? Faraday’s Law of Induction says a changing magnetic field makes a voltage. Lenz’s Law says the induced current will oppose the change. The squirrel cage rotor has bars that carry these induced currents. The rotor then makes torque because the field tries to drag it along. Eddy current losses show up too. Good design keeps those low.

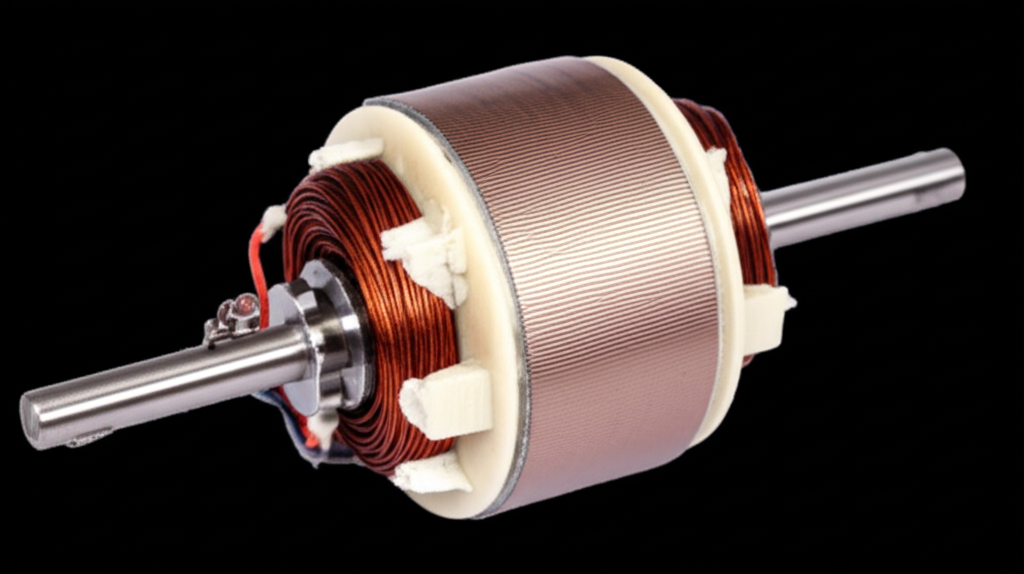

How do two windings make a phase difference?

The trick is simple. Build the main winding with higher inductance and lower resistance. Build the auxiliary winding with higher resistance and lower inductance. Place the two windings in the stator at a physical angle. The current in the start coil then leads or lags the main coil by a small angle. This creates the needed phase difference.

- The main winding is also called the run winding.

- The auxiliary winding is the start winding.

- The little phase shift creates a weak rotating field. It is enough to start many loads.

If you add a capacitor in series with the start winding, you get a capacitor-start motor. That raises the phase shift and gives more starting torque. Some motors use a Permanent Split Capacitor (PSC) and keep the capacitor in the circuit. Those are quiet and smooth.

For deeper theory on the rotating field and phase shift see the motor basics in this guide and explore a simple overview of the motor principle.

What does the centrifugal switch do?

A centrifugal switch is a small speed switch mounted on the shaft or end bell. It closes at rest to feed the start winding. As the rotor speed rises to about 70% to 80% of synchronous speed, the switch opens. It takes the start winding out. The motor then runs only on the main winding.

This switch matters. If the start winding stayed in, it would overheat. The motor would waste power. The switch cuts that risk. It also boosts motor efficiency in run and helps power factor a bit.

Problem: The motor starts slow or not at all.

Agitate: It hums, it smells hot, and the breaker pops.

Solution: Check the centrifugal switch for wear or arcing. Clean or replace it. This is a common motor troubleshooting fix in split phase units.

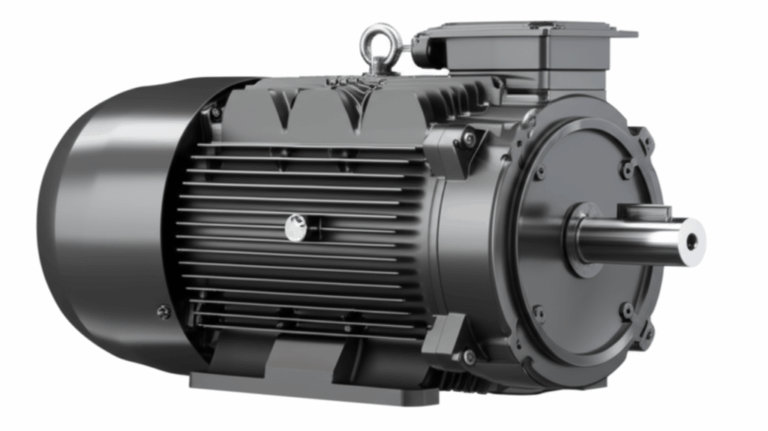

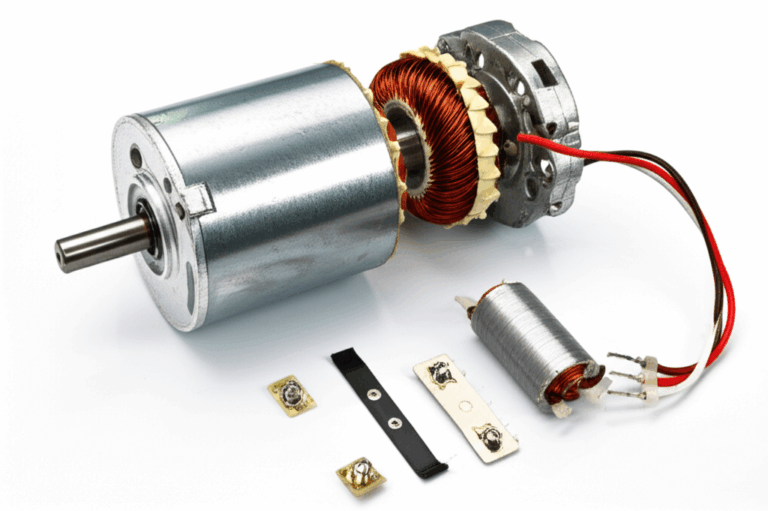

What are the key parts inside the motor?

Let’s name the parts you will see.

- Stator: The fixed part. It holds the main winding and the auxiliary winding. The iron core is made from thin sheets called laminations. Good stator core lamination reduces loss and heat.

- Rotor: The spinning part. Most are squirrel cage rotors. The cage sits in a laminated iron core. Quality rotor core lamination helps cut eddy currents and noise. Learn how these two parts work together here: stator and rotor basics.

- Centrifugal switch: We covered it. It opens at speed.

- End bells and bearings: They support the rotor and keep it straight. Different bearing types change life and noise.

- Frame and enclosure: These protect the motor. They also help with heat.

- Thermal overload protection: Many units include it to guard the windings.

Note on materials. The core stack uses electrical steel laminations to guide magnetic flux. Better steel means lower loss. See a quick overview of modern electrical steel laminations. Makers also offer full motor core laminations for custom builds.

How does a split phase motor perform?

Here is a quick look at characteristics and performance. Use this as a handy guide.

- Starting torque: Low to moderate. About 100% to 120% of full-load torque.

- Starting current: High. Often 5 to 7 times full-load current.

- Efficiency: Moderate. Often 55% to 65% at run.

- Power factor: Moderate to low. Often 0.55 to 0.70 in run.

- Torque-speed curve: Smooth start then a gentle drop in torque as speed climbs close to load.

Here is a simple table with the numbers and a comparison:

| Feature/Metric | Split Phase Motor Characteristics | Industry Context / Comparison |

|---|---|---|

| Typical HP Range | 1/20 HP to 1/3 HP | Small fractional horsepower (FHP) jobs |

| Starting Torque | 100% to 120% of FLT | Lower than capacitor-start (200% to 400%) |

| Starting Current | 5 to 7 x FLA | Can cause voltage dips |

| Efficiency (Run) | 55% to 65% | Lower than PSC and capacitor-start |

| Power Factor (Run) | 0.55 to 0.70 | More reactive power drawn |

| Cost | Low | Simple build, no capacitor |

| Common Failure Point | Centrifugal switch | Mechanical wear and arcing |

| Best Applications | Fans, blowers, small pumps | Low inertia loads work best |

You should also know the basic terms of speed. At no load the speed sits just under synchronous speed. At load it drops a bit more. That drop is slip. Slip makes torque. No slip means no torque.

Pros and cons: Is it right for your job?

Let’s get honest.

Advantages:

- Simplicity of construction

- Economical price

- Good reliability if used within limits

- Good for constant speed tasks

Disadvantages:

- Low starting torque

- High starting current

- Lower efficiency than capacitor motors

- Centrifugal switch can fail

- Not ideal for frequent starts

Problem: You have heavy loads that need strong starts.

Agitate: The machine stalls. The line sags. Bearings run hot.

Solution: Use a capacitor-start motor or a Permanent Split Capacitor (PSC) motor. Or step up to a three-phase motor if power is there.

Where will you use a split phase motor?

You see them in many places with light starts and steady runs.

- Fans and blowers

- Small pumps and air compressors with easy starts

- Older washing machines and some agitators

- Light-duty grinders and grinding machine tasks

- Drill press and small woodworking tools

- Office machinery and small conveyor belt jobs

You also find them in residential motors, some commercial motors, and a few agricultural motors. They show up in industrial motors for light benches or test rigs. They fit when you want low price and simple manual motor starter circuits.

How does it compare to other motor types?

You have many choices. Let’s compare.

- Split phase vs capacitor-start motor: Capacitor-start gives more phase shift and higher starting torque. Use it for heavier loads.

- Split phase vs PSC motor: PSC runs smooth with better power factor and efficiency. PSC is better for quiet fans.

- Split phase vs shaded pole motor: Shaded pole is even simpler with very low torque and very low efficiency. Use it only for tiny fans.

- Split phase vs universal motor: A universal motor has brushes. It can run on AC or DC. It spins fast with high torque. It is noisy and needs more care.

- Split phase vs three-phase motor: Three-phase is king for power and efficiency. Use it when three-phase supply is ready.

- Split phase vs DC motor: DC motors can give great control and torque. They need a DC drive. That adds cost.

You may also hear about capacitor run motor, permanent split capacitor motor, and single phase induction motor types. These names tell you how the start or run circuit uses the capacitor. Some gear sets also pair motors with gearboxes. Gear motor types and brake motor types are common in conveyors and lifts. Split phase is not the first pick for brake jobs.

How do I pick the right size and frame?

Use a simple motor selection guide approach.

- Define horsepower (HP) and torque needs.

- Check voltage (V), amperage (A), and Hertz (Hz) on your line.

- Look at duty cycle: continuous duty or intermittent duty.

- Choose NEMA frame sizes that match your mounts.

- Decide enclosure: open, TEFC, or special.

- If needed, pick explosion proof motors for hazardous location motors. Split phase is not common in those zones.

- Think about motor speed control needs.

- Plan motor protection devices: fuses, breakers, and thermal overload protection.

Read the motor nameplate. It lists RPM, efficiency, power factor, service factor, and sometimes a torque speed characteristic note. If noise is a worry, check motor noise specs and balance.

Problem: You buy on price only.

Agitate: The motor trips on start. Bearings fail early. The motor lifespan drops.

Solution: Size for load. Match the torque-speed characteristics to the job. Use the right NEMA frame. Build with good materials like high grade laminations.

If you make or repair motors, you may need full stacks. Some suppliers offer ready motor core laminations for custom frames and ratings.

Can I control speed with a VFD or other methods?

Speed control on split phase motors is limited. The best choice for wide range speed is a three-phase motor with a Variable Frequency Drive (VFD). You can run a single-phase motor on a special VFD for single phase, yet results vary. Some VFD for single phase options can run PSC motors better than split phase. Cooling can also suffer at low speeds.

For small changes, you can use belts, pulleys, or gear sets. Some loads use dampers and valves. These methods waste less energy than just choking a duct or line.

If you need smooth control, think about PSC, BLDC, or three-phase with VFD. BLDC designs use a bldc stator core and electronics. They get high efficiency and low noise. Many new fans and washers use BLDC.

How do I maintain and troubleshoot it?

Basic care goes a long way.

- Keep vents clean.

- Check and, if needed, add motor lubrication to bearings.

- Inspect the centrifugal switch for dust, pitting, and wear.

- Test winding insulation with a megohmmeter.

- Check for open circuit winding or motor winding short circuit.

- Look at motor vibration and do simple motor balancing if needed.

- Replace worn bearings and seals.

In a motor troubleshooting guide, common faults include switch failure, bearing noise, poor power factor, and low motor efficiency due to heat. Watch starting current spikes. They can trip breakers and cause voltage dips.

If a winding fails, you can send it to motor re-winding services. You can also replace the split phase motor with a PSC or capacitor-start unit. When in doubt, call a tech. Use safe motor control circuits and lockout.

If you want a quick tour of frequent issues, skim this plain list of common motor problem.

What do common nameplate terms mean?

Here is a short table that maps terms you will see. It helps when you read specs and plan work.

| Term | What it means | Why it matters |

|---|---|---|

| HP and FHP | Horsepower and Fractional horsepower | Size and load fit |

| RPM | Revolutions Per Minute | Speed for your tool |

| V / A / Hz | Voltage, Amperage, Hertz | Must match power supply |

| Efficiency | Output power / input power | Lower loss means less heat |

| Power factor | Real power / apparent power | Low PF draws more reactive power |

| Synchronous speed | Theoretical field speed | Sets top speed target |

| Slip | Difference between sync speed and rotor speed | Needed for torque |

| Duty | Continuous or intermittent | Heat and rest cycles |

| Frame | NEMA frame sizes | Bolt and shaft fit |

| Enclosure | Open, TEFC, or special | Dust and water limits |

| Protection | Thermal, overload, fuses | Motor safety |

| Nameplate amps | Full-load current | Sizing wire and starters |

You also may see service factor, insulation class, and bearing type. For harsh sites you will see explosion proof or hazardous location marks. Check IEEE and NEMA guides if you need deep specs.

Two short case studies you can picture

Scenario 1: Bench grinder

A small grinding wheel motor in a home shop uses a split phase design. The wheel is light. The motor starts fast. The centrifugal switch opens. The grinder runs steady at constant speed. This is a good fit. Cost stays low.

Scenario 2: Washing machine agitator

An older washing machine motor for the agitator uses a split phase start. The load is not too heavy. The motor starts and runs well in one direction. Newer washers often use PSC or BLDC for better energy efficiency rating and flexible cycles.

Cost, energy use, and market trends

A split phase motor wins on cost. It is one of the least expensive single phase induction motor options. That is why you still see them in budget gear and legacy tools.

Energy wise, the power consumption is higher than PSC or capacitor-start for the same job. Efficiency in the 55% to 65% range is not great. The power factor is also modest.

Market share is sliding in new high-efficiency appliance designs. Many makers go with PSC, BLDC, or three-phase with drives. Still, split phase motors hold a spot in low price, light load, and intermittent duty jobs. They are easy to repair. They work in many residential and commercial tools.

Problem: You fight high energy bills and hot motors.

Agitate: Insulation cooks. Bearings dry out. The motor dies early.

Solution: Pick better materials and cores. Use good laminations and smart cooling. If you build or buy, look for high grade silicon steel laminations and tight stack tolerances. Suppliers who specialize in core stacks can help if you need custom designs.

If you need raw materials or custom stacks, explore quality motor laminations and cores. Strong material choices help cut eddy current and keep magnetic flux where you want it. That pays off as lower heat and longer life.

PAS in practice: Where product quality solves the root problem

Problem: Your motor runs hot and noisy. It pulls high current and trips often.

Agitate: Downtime hurts your shop. Work stops. You lose time and money.

Solution: Upgrade the core materials and stack build. Better laminations reduce loss and hum. They also boost stability. If you want to see what good looks like, review modern stator core lamination options and matched rotor core lamination. For a broader view of materials and stacks see this overview of electrical steel laminations.

These links show how the core impacts motor efficiency, power factor, motor vibration, and motor noise. The right core means smoother starts and cooler runs.

References

- IEEE (Institute of Electrical and Electronics Engineers) resources on induction motors

- NEMA (National Electrical Manufacturers Association) frame and motor standards

- Electric Machinery Fundamentals by Stephen J. Chapman

- Principles of Electromechanics texts covering Faraday’s Law and Lenz’s Law

FAQ

Q: What is the main difference between a split phase motor and a capacitor-start motor?

A: The capacitor-start motor uses a capacitor to make a larger phase shift. That gives higher starting torque. It starts heavy loads better.

Q: Can I use a split phase motor with a VFD?

A: It is not ideal. Some drives can run PSC motors better than split phase. For wide range speed, go with a three-phase motor and a VFD.

Q: Why does my split phase motor hum and not start?

A: The centrifugal switch may be stuck. The start winding could be open. Power supply issues and stuck loads also cause this.

Q: What loads are best for split phase motors?

A: Fans, blowers, light pumps, small grinders, and simple woodworking tools with low inertia.

Q: How do I extend motor life?

A: Keep it clean and cool. Lubricate bearings. Check the switch. Use the right frame and duty rating. Do not overload it.

Key takeaways

- A split phase motor is a single-phase induction motor that uses a start winding and centrifugal switch to begin turning.

- It offers low cost, simple build, and fair reliability for light loads and constant speed work.

- Expect low to moderate starting torque, high starting current, and modest efficiency and power factor.

- Use it for fans, blowers, small pumps, grinders, and older washing machines.

- For heavy starts, consider capacitor-start, PSC, BLDC, or three-phase options.

- Choose the right NEMA frame, duty, enclosure, and overload protection.

- Good stator and rotor cores with high grade laminations can cut loss and noise.

- Maintain bearings, clean the motor, test insulation, and check the centrifugal switch.

- Read the motor nameplate for HP, RPM, V, A, Hz, efficiency, and power factor.

- Pick the motor that fits the job and the power supply so your shop runs smooth.

For deeper study, review field basics on stator and rotor and materials like electrical steel laminations that shape real-world performance.