What is a Squirrel Cage Blower Used For? Essential Applications & Benefits

As an engineer or product designer, you’re constantly making critical decisions about components. You need parts that are reliable, efficient, and perfectly suited for your application. When it comes to moving air, few devices are as ubiquitous yet as frequently misunderstood as the squirrel cage blower. You’ve probably seen them—those cylindrical, hamster-wheel-like fans humming away inside furnaces, air conditioners, and industrial machinery.

If you’ve ever found yourself asking, “Is this the right type of fan for my system?” or “Why is this specific design so common?”, you’re asking the right questions. Choosing the correct air movement device isn’t just about airflow; it’s about managing pressure, noise, energy consumption, and spatial constraints. Understanding what a squirrel cage blower is used for—and why it excels in those roles—is fundamental to designing a successful system.

This guide will demystify the squirrel cage blower. We’ll break down how it works, explore its vast range of applications, and explain the key advantages that make it a versatile workhorse across dozens of industries.

What We’ll Cover

- How a Squirrel Cage Blower Works: The simple physics behind its power.

- Primary Applications: From your home HVAC to massive industrial systems.

- Key Advantages: Why this design is chosen over others.

- Differentiating from Other Fan Types: A quick comparison to axial fans.

- Factors to Consider When Selecting a Blower: An engineer’s checklist for making the right choice.

How a Squirrel Cage Blower Works

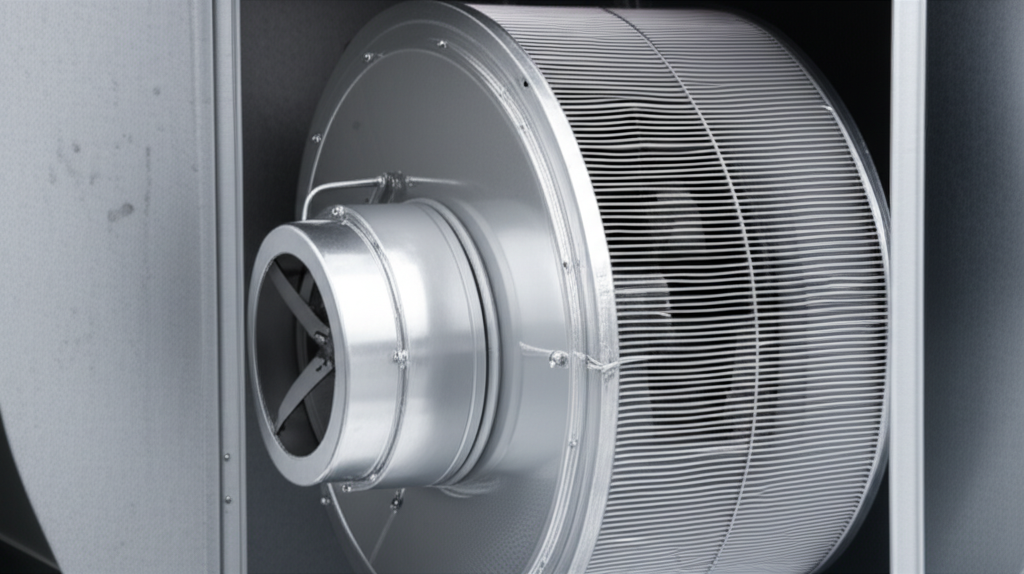

At its heart, a squirrel cage blower is a type of centrifugal fan. Its operation is a beautiful example of basic physics put to practical use. Instead of pushing air straight through like a propeller (an axial fan), it slings air outwards using centrifugal force.

Imagine you’re on a playground merry-go-round. As it spins faster, you feel a force pushing you away from the center. A squirrel cage blower does the exact same thing to air molecules.

This process creates a pressure difference that pulls more air into the center of the wheel, establishing a continuous, powerful airflow. It’s a simple yet incredibly effective mechanism.

Key Components

Two main parts work in tandem to make this happen:

This ability to generate significant static pressure is the squirrel cage blower’s superpower. It’s what allows it to effectively push air through long, complex paths filled with resistance, like the ductwork in a building, dense filter media, or the heat exchange coils in an air conditioner.

Primary Applications of Squirrel Cage Blowers

The reason you see squirrel cage blowers everywhere is their incredible versatility. They are the unsung heroes of air movement, operating tirelessly in applications ranging from home comfort to critical industrial processes.

HVAC Systems (Heating, Ventilation, Air Conditioning)

This is, without a doubt, the most common application. If you have a forced-air furnace or central air conditioning, you have a squirrel cage blower.

- Furnaces and Air Handlers: In a residential furnace, the blower is responsible for pushing the heated or cooled air from the unit through the ductwork and into every room of your house. A typical 3-ton residential furnace blower can move 1200-1600 CFM (Cubic Feet per Minute) of air against the static pressure of the ducts and filters, which is usually around 0.5 to 1.0 inches of water column (iwc).

- Central Air Conditioning Units: The blower works in tandem with the evaporator coils, pushing indoor air across them to be cooled before circulating it throughout the home.

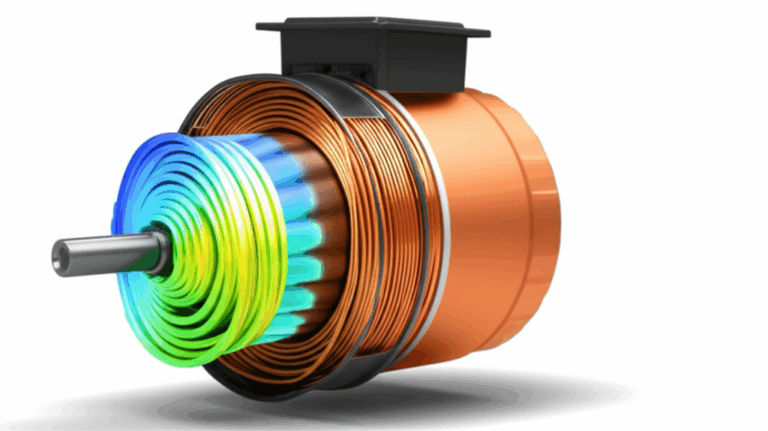

- Commercial HVAC Systems: Scaled-up versions of these blowers are the heart of large commercial HVAC units found in office buildings, malls, and hospitals. They provide the necessary power to move conditioned air across vast spaces and multiple floors. The performance of these systems is heavily influenced by the motor’s core components, where the interaction between the stator and rotor dictates efficiency and reliability.

Industrial Ventilation and Exhaust

In industrial settings, controlling air quality isn’t just about comfort—it’s about safety, compliance, and process integrity.

- Dust Collection Systems: In woodworking shops, metal fabrication facilities, and agricultural processing plants, squirrel cage blowers provide the suction needed to pull sawdust, metal shavings, and other particulate matter into a collection system, keeping the air clean and safe for workers.

- Fume Extraction: These blowers are critical for removing hazardous fumes, vapors, and gases from environments like welding stations, chemical processing plants, and laboratories. A case study of a welding facility that installed a new fume extraction system using high-volume squirrel cage blowers showed a 60% reduction in airborne particulate matter, dramatically improving worker safety and ensuring OSHA compliance.

- Drying and Curing Processes: Industries from food processing to printing rely on blowers to provide a consistent, controlled flow of heated air for drying products, curing coatings, and setting inks.

- Material Conveying: In some applications, these blowers can be used to move lightweight granular materials, such as plastic pellets or wood chips, through pipes from one part of a plant to another.

Automotive & Transportation

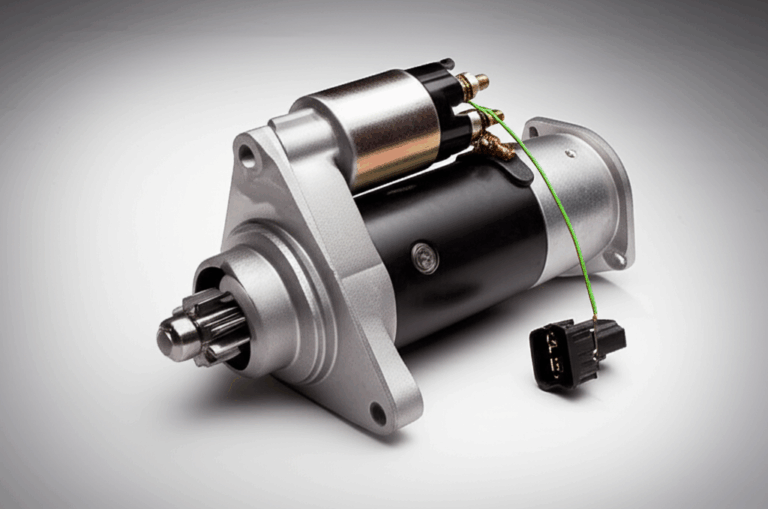

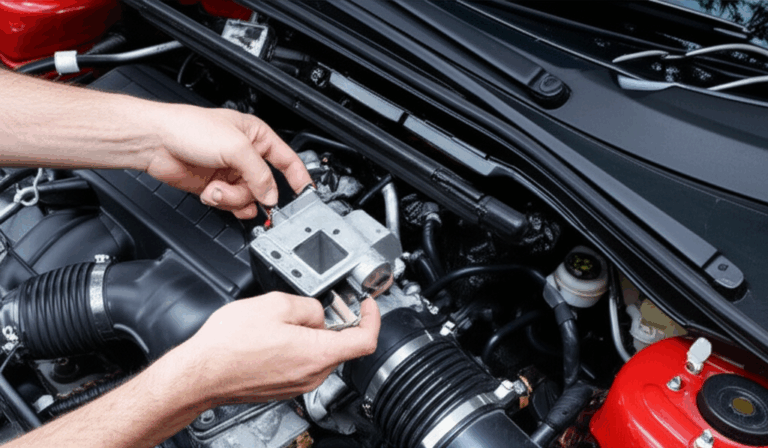

Your vehicle’s climate control system relies on a compact, powerful squirrel cage blower motor to function.

- Vehicle Climate Control: Tucked away under the dashboard of nearly every car, truck, and bus is a blower that pushes air through the heater core or evaporator to provide warm or cool air to the cabin. It’s also the fan that provides the airflow for defrosting your windshield.

- Recreational Vehicles (RVs): Onboard HVAC systems in RVs use these blowers to provide heating and cooling in a compact, efficient package.

Electronics Cooling & Data Centers

As electronics have become more powerful and compact, managing heat has become a paramount engineering challenge.

- Server Racks and Data Centers: These facilities generate immense amounts of heat. Large squirrel cage blowers inside Computer Room Air Conditioner (CRAC) units are essential for maintaining a controlled environment and preventing catastrophic hardware failure. Upgrading to optimized blowers in data centers can reduce fan-related power consumption by 15-25%, which has a direct positive impact on the facility’s Power Usage Effectiveness (PUE).

- Medical and Telecom Equipment: High-power medical devices like MRI and CT scanners, as well as critical telecommunications equipment, use integrated blowers to cool sensitive components and ensure reliable operation.

Commercial Kitchens and Specialty Uses

The applications don’t stop there. You’ll find squirrel cage blowers in a wide array of specialized roles:

- Commercial Kitchen Exhaust Hoods: They provide the powerful suction needed to pull smoke, grease, and heat away from cooking surfaces.

- Cleanrooms and Laboratories: Here, they are used in filtration systems to provide a steady stream of highly filtered air, maintaining a sterile environment.

- Inflatable Structures: Large blowers are used to inflate everything from bouncy castles for kids to temporary industrial structures.

- Air Curtains: At the entrance of stores and warehouses, a row of blowers creates a high-velocity “curtain” of air that keeps conditioned air in and unconditioned air, dust, and insects out.

Key Advantages: Why Choose a Squirrel Cage Blower?

Engineers and designers repeatedly turn to the squirrel cage blower because it offers a compelling mix of performance characteristics that are ideal for a huge range of applications.

1. High Airflow at Moderate Static Pressure

This is the blower’s signature strength. While an axial fan is great at moving a large volume of air in an open space (low pressure), it struggles mightily when it encounters resistance. A squirrel cage blower, on the other hand, is specifically designed to overcome this resistance, making it the perfect choice for any system involving ductwork, filters, dampers, or heat exchangers.

2. Relatively Quiet Operation

For a given airflow, the design of a squirrel cage blower with its numerous small blades tends to be quieter than an axial fan with a few large blades. The blades slice through the air more smoothly, resulting in less turbulence and a lower, less intrusive noise frequency. Residential units are often designed to operate in the 40-60 decibel range, which is crucial for homeowner comfort.

3. Energy Efficiency

Efficiency is a primary concern in any modern design. The performance of a blower is directly tied to its electric motor. Modern squirrel cage blowers are often paired with Electronically Commutated (EC) motors, which are a type of brushless DC motor. The efficiency of these motors relies heavily on the quality of their magnetic components, such as the bldc stator core.

- EC Motors vs. PSC Motors: An EC motor can reach efficiencies of up to 80%, a massive improvement over older Permanent Split Capacitor (PSC) motors, which hover around 40-60% efficiency. According to the US Department of Energy, this upgrade can lead to a 30-50% reduction in fan energy consumption, translating to significant operational cost savings over the equipment’s lifespan.

4. Compact and Durable Design

A squirrel cage blower can move a substantial amount of air from a relatively small package. The impeller itself is robust, and when housed in a sturdy steel casing, the entire assembly is durable and reliable, capable of running for thousands of hours with minimal maintenance.

Differentiating from Other Fan Types (Briefly)

To truly appreciate why a squirrel cage blower is used, it helps to compare it to its main alternative.

- Squirrel Cage Blower vs. Axial Fan:

- Think of it this way: An axial fan is like a big paddle—it’s great for moving a lot of water across the surface of a lake (high volume, low pressure). A squirrel cage blower is more like a water pump—it’s designed to push that water through a long, winding garden hose (moderate volume, high pressure).

- Use an axial fan for general ventilation, room cooling, or cooling electronics in an open chassis.

- Use a squirrel cage blower when you need to push or pull air through a restrictive path like ductwork, a filter bank, or an automotive dashboard.

Factors to Consider When Selecting a Blower

As an engineer or procurement manager, choosing the right blower involves more than just picking one off a shelf. You need to match the component to the system’s demands. This is where you empower your design.

electrical steel laminations, is foundational to achieving this efficiency.motor core laminations are essential for preventing premature failure from heat and electrical stress.Conclusion: The Versatile Workhorse of Air Movement

The squirrel cage blower is far more than just a simple fan. It is a precisely engineered solution to a fundamental problem: moving air efficiently against resistance. Its unique design, which leverages centrifugal force to generate substantial static pressure, has made it an indispensable component across countless applications.

From ensuring your comfort at home and in your car to guaranteeing safety and productivity in complex industrial environments, this humble device is a true workhorse. By understanding how it operates, where it excels, and what factors to consider in its selection, you can confidently specify the right blower for your next project, ensuring your system performs reliably, quietly, and efficiently for years to come.