What is a Squirrel Cage Rotor? Understanding the Heart of Induction Motors

Have you ever wondered what makes the world go ’round? Well, a lot of the time, it’s an electric motor. And inside most of those motors is a simple, powerful part called a squirrel cage rotor. It sounds funny, but it’s the unsung hero that powers everything from your kitchen blender to giant factory machines. This article will show you exactly what it is, how it works in plain English, and why it’s one of the most important inventions in electrical engineering.

Table of Contents

- Why is it Called a “Squirrel Cage”?

- What Are the Parts of a Squirrel Cage Rotor?

- How Does a Squirrel Cage Rotor Actually Work?

- What is Motor “Slip” and Why Does it Matter?

- What Makes Squirrel Cage Motors So Great?

- Are There Any Downsides to These Motors?

- Where Do We Use Squirrel Cage Motors?

- How is it Different From a Wound Rotor?

- How Do We Take Care of These Rotors?

- The Unsung Workhorse of Our World

Why is it Called a “Squirrel Cage”?

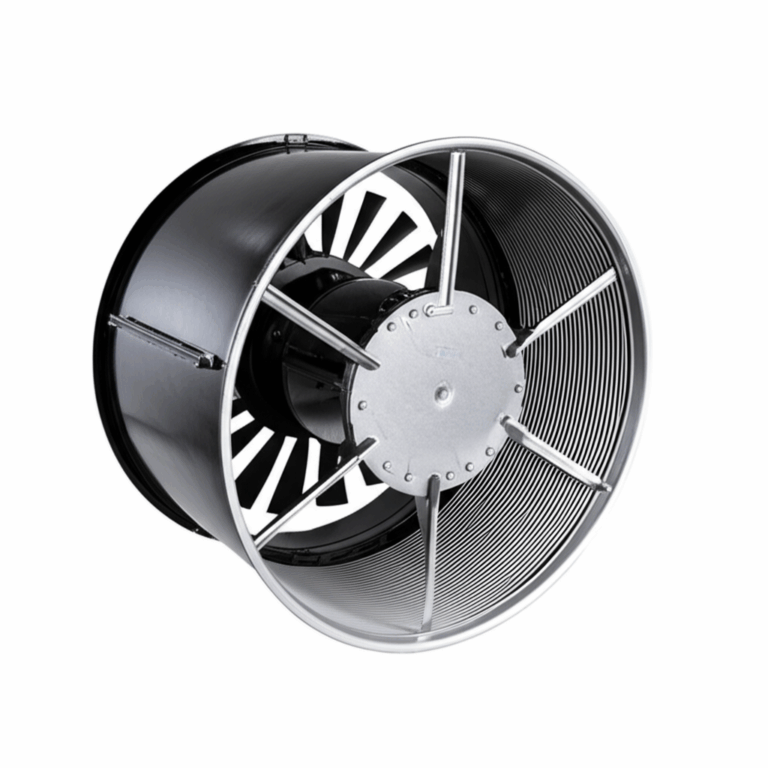

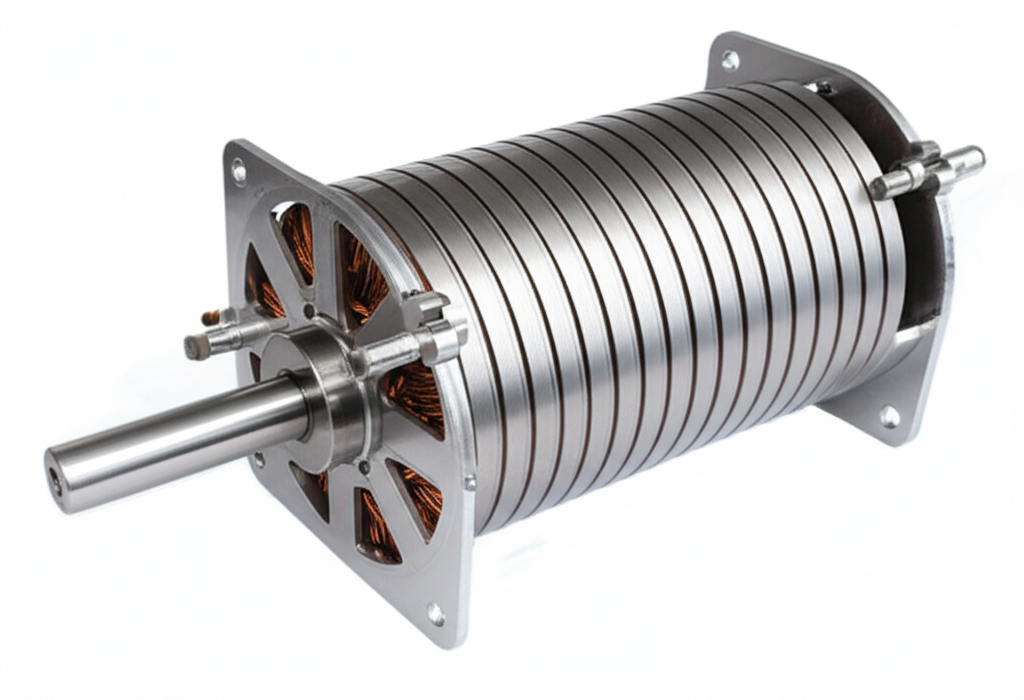

Let’s get this question out of the way first because it’s the most fun part. The name comes from its shape. If you were to take the main part of the rotor out of the motor, it looks a lot like the old-fashioned exercise wheels people used to have for pet squirrels or hamsters. It has two rings at the end connected by a bunch of bars, forming a shape just like a cage.

This simple design is pure genius. There are no complicated wires or connections on the spinning part itself. This is what makes it so tough and reliable. The squirrel cage principle is all about simplicity, and that’s why I find it so fascinating. It’s a perfect example of smart thinking in electromechanical energy conversion.

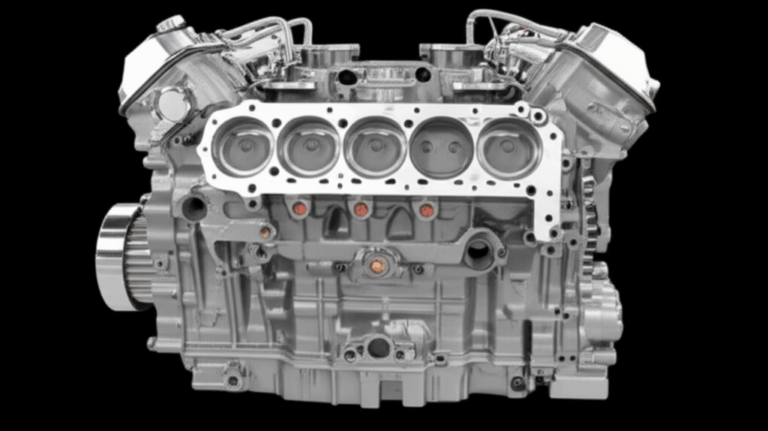

What Are the Parts of a Squirrel Cage Rotor?

Even though it’s simple, the rotor has a few key parts that work together. Imagine you are building one. To understand the asynchronous motor construction, you first need to know about the two main parts: the stator and rotor. The stator stays still and the rotor is the part that spins.

Here’s what makes up the squirrel cage rotor:

- Rotor Core: This is the body of the rotor. It’s not a solid chunk of metal. Instead, it’s made of many thin slices of silicon steel stacked together. This stacked design, a process that creates the rotor core lamination, is super important because it helps reduce wasted energy called core losses.

- Rotor Bars (Conductors): These are solid bars of metal, usually aluminum rotor bars or copper rotor bars. They are slid into slots that run along the length of the rotor core. These bars are the pathways for electricity.

- End Rings: At each end of the rotor, there are two heavy rings. The end rings purpose is to connect all the rotor bars together. This creates a complete, closed electrical path, which is why we sometimes call it a short-circuited rotor.

- Shaft: This is the strong metal rod that runs through the center of the rotor. It sticks out of the motor housing and connects to whatever the motor needs to turn, like a fan blade or a pump.

How Does a Squirrel Cage Rotor Actually Work?

Okay, here comes the magic. How does this simple cage spin without any wires connected to it? It all happens because of a cool science trick called electromagnetic induction. You’ve probably seen this without knowing it!

The problem is, motors seem complex. They hum and spin, and it feels like you need an advanced degree to understand them. You might worry that trying to learn how they work will just leave you more confused, especially with scary words like “magnetic flux path” and “Faraday’s law of induction.”

But what if you could understand it with a simple story? Imagine a dance. The outside part of the motor, the stator, is the dance floor. When you plug the motor in, the stator creates a powerful, invisible, spinning force. We call this the rotating magnetic field (RMF). Think of it as a spinning magnetic dance partner. The RMF spins at a set speed, which we call the synchronous speed.

Now, the rotor is on the dance floor, but it’s standing still at first. As the magnetic dance partner spins past the rotor bars, it “invites” them to dance. This invitation is an electric current that gets created inside the rotor bars. This is Faraday’s Law in action. This new electric current then creates its own smaller magnetic field around each bar. This is Lenz’s Law, which says the rotor’s new field will try to fight the change that created it.

So, you have the stator’s big spinning magnetic field and the rotor’s new small magnetic fields. What happens? The big field pulls the small fields along with it! This pulling creates a powerful twisting force, which we call torque generation. This torque is what makes the rotor—and the shaft attached to it—start to spin. And that’s how an induction motor works! The whole thing is a clever dance of invisible forces.

What is Motor “Slip” and Why Does it Matter?

Here’s a tricky but important idea: for the motor to work, the rotor must always spin a little bit slower than the rotating magnetic field. The rotor can never catch up to its magnetic dance partner.

Think about it. If the rotor did catch up and spun at the exact same synchronous speed, there would be no difference in speed between the magnetic field and the rotor bars. The magnetic field would no longer be “cutting across” the bars. Without that cutting motion, no electric current would be created in the rotor. No current means no rotor magnetic field, and no rotor magnetic field means no torque. The motor would stop pulling.

This difference in speed is called motor slip. Slip is what allows the magic of induction to keep happening, creating continuous torque. So, a little bit of slip is not just normal; it’s absolutely necessary for the motor to run and do its job.

What Makes Squirrel Cage Motors So Great?

There’s a reason over 90% of motors used in industry are the squirrel cage type. Companies from General Electric to Siemens and ABB build millions of them. The advantages of squirrel cage motors are huge.

- They are simple and tough: With no brushes or complex windings on the rotor, there are very few parts that can break. Their solid construction makes them incredibly robust.

- They need almost no maintenance: One of the biggest headaches with other motors is replacing worn-out brushes. A squirrel cage motor maintenance plan is much simpler, usually just checking the bearings every now and then.

- They are cheap to build: The simple design, especially with die-cast aluminum rotors, makes the motor manufacturing process fast and affordable. This low cost is a huge reason they are everywhere.

- They are very reliable: These motors can run for years, even in dirty, dusty, or harsh places. Their Mean Time Between Failures (MTBF) can be 20 years or more! The overall quality of the motor core laminations is key to a motor’s long life.

Are There Any Downsides to These Motors?

Of course, nothing is perfect. The disadvantages of squirrel cage motors are important to know. A major issue is that they can be energy hogs when they first start up.

The biggest problem is the high starting current. When you first turn on a squirrel cage motor, it can draw 5 to 7 times its normal running electricity. This can cause lights to dim in a house or put a big strain on a factory’s electrical system. This is why for bigger motors, we use special starters like a soft starter or a star delta starting system to ease them into action.

Another issue is that they are not great at starting with very heavy loads. Their starting torque, or twisting power, can be low compared to other motor types. They also run at a mostly fixed speed that depends on the power supply. To change the speed, you need a special electronic device called a variable frequency drive (VFD).

Where Do We Use Squirrel Cage Motors?

The list of applications of squirrel cage motors is nearly endless. Because they are so reliable and cheap, you can find them almost anywhere you look. They are the true workhorses behind the scenes.

In industry, they power pumps, fans, compressors, and conveyor belts. They run the machines that make the products we use every day. In your home, they are in your refrigerator, washing machine, and air conditioner. You’ll also find them in agricultural machinery and even some electric vehicle designs. They are the invisible force that makes modern life possible.

How is it Different From a Wound Rotor?

The main alternative to a squirrel cage rotor is called a wound rotor. While both are used in induction motors, they are built very differently, leading to a big comparison: wound rotor vs squirrel cage rotor.

A wound rotor doesn’t have simple bars. Instead, it has actual coils of wire wrapped around it, much like the stator. These wires are connected to slip rings and brushes on the motor shaft, which allow you to connect external parts to the spinning rotor.

Here’s a quick comparison:

| Feature | Squirrel Cage Rotor | Wound Rotor |

|---|---|---|

| Construction | Simple bars and end rings | Complex coils of wire |

| Cost | Lower | Higher |

| Maintenance | Very low (no brushes) | Higher (brushes wear out) |

| Starting Current | High | Lower (can be controlled) |

| Starting Torque | Lower (fixed) | Higher (can be adjusted) |

| Speed Control | Needs a VFD | Can be controlled with resistors |

The choice between them depends on the job. For most simple, fixed-speed tasks, the squirrel cage wins every time because of its cost and reliability. But for things like giant cranes that need to start slowly with a heavy load, the wound rotor is a better choice.

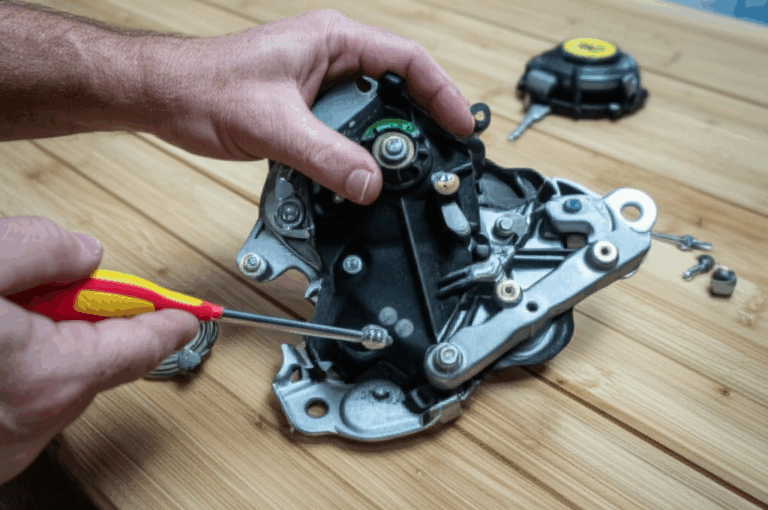

How Do We Take Care of These Rotors?

Even though they are tough, things can still go wrong. A common problem is broken rotor bars. This can happen from stress over time and can cause the motor to vibrate and lose power. If you ignore it, you risk a total motor failure, which can shut down a whole production line. This is a huge risk for any business.

The key is to catch problems early. Modern factories use tools like motor vibration analysis and other condition monitoring techniques. These tools listen to the motor and can tell if a rotor bar is cracked long before it fails completely. This is part of a predictive maintenance plan.

The most common failure point on the whole motor isn’t the rotor itself but the motor bearings that let it spin freely. Proper lubrication and keeping the motor clean and cool are the best ways to ensure a long life. The quality of the stator core lamination and other components also plays a huge role in preventing overheating that can lead to failure.

The Unsung Workhorse of Our World

So, the next time you hear the hum of a fan or the rumble of a machine, you can smile. You know the secret inside: a simple, clever cage of metal spinning around, powered by the invisible dance of magnetism. The squirrel cage rotor isn’t fancy, but its brilliant design is what keeps our world running smoothly and efficiently. It’s a true engineering masterpiece.

Key Takeaways to Remember:

- A squirrel cage rotor is named for its shape, which looks like an exercise wheel for a squirrel.

- It works by electromagnetic induction, where a rotating magnetic field from the stator creates a current in the rotor, causing it to spin.

- The main parts are the rotor core, rotor bars, and end rings.

- Its biggest advantages are its simple, tough design, low cost, and very low maintenance needs.

- Its main downsides are high starting current and a fixed running speed without special controls.

- These motors are used in over 90% of industrial applications, plus countless home appliances.