What is a Synchronous Motor? Understanding its Definition, Working, and Applications

Table of Contents

- What Is a Synchronous Motor?

- How Does a Synchronous Motor Work?

- What Is Synchronous Speed and How Do You Find It?

- What Are the Main Parts of the Motor?

- Why Does Constant Speed Matter in Real Life?

- Can a Synchronous Motor Fix Power Factor?

- What Types of Synchronous Motors Should You Know?

- Why Does a Synchronous Motor Not Self‑Start?

- Where Do We Use These Motors?

- How Does It Compare to an Induction Motor?

- How Do We Control Speed and Torque with Drives?

- What About Design, Materials, Cooling, and Noise?

- What About Reliability, Maintenance, and Cost?

- What Does the Data Say? Real Numbers and Trends

- What Comes Next for These Motors?

- FAQ

- Key Takeaways

Synchronous motors run on AC power. They turn at a constant speed that matches the grid frequency. They also can help fix power factor in your plant. If you want steady speed, strong torque, and fewer energy penalties, this is worth your time.

I have helped teams pick motors for pumps, fans, EVs, and even wind turbines. When we needed tight speed or better power bills, we looked at synchronous motors first. By the end, you will know what they are, how they work, where to use them, and how to choose the right type.

What Is a Synchronous Motor?

A synchronous motor is an AC motor that runs at synchronous speed. That means the rotor turns at the same speed as the rotating magnetic field in the stator. There is no slip in steady state.

Why does this matter? You get constant speed under load. You can also set the power factor to lag, lead, or unity with DC excitation on wound types. That helps with grid stability and voltage regulation in a power system.

Problem. Many plants fight poor power factor, rising energy costs, and speed drift. Agitate. You pay utility penalties, waste power as heat, and fight vibration or noise from motors that slip. Solution. A synchronous motor locks speed with the line and can run at a leading power factor. It can act like a synchronous condenser to improve your system.

How Does a Synchronous Motor Work?

The stator has three‑phase windings. When you feed it AC, the currents create a rotating magnetic field. We call it RMF. The RMF spins around the inner air gap at a speed set by the line frequency and the number of poles.

The rotor carries its own magnetic field. You can make it with DC excitation in a field winding or with a permanent magnet. When the rotor field “locks” with the stator field, both spin together. That is frequency synchronization. Torque forms because the two fields pull into alignment. This is electromechanical conversion at work. Faraday’s Law and Lenz’s Law explain the voltage and the direction of induced currents.

In practice, control systems watch current, voltage, and frequency. In modern drives, a voltage source inverter feeds the motor. Field oriented control (FOC) or direct torque control (DTC) fine tune the torque and magnetic flux. Sensorless control can estimate rotor position, so you don’t need a physical sensor.

What Is Synchronous Speed and How Do You Find It?

You can find the speed with a simple formula. Use:

Ns = (120 × f) / P

where Ns is speed in RPM (Revolutions Per Minute), f is frequency in Hz, and P is the number of poles.

- At 60 Hz with 4 poles, Ns = (120 × 60) / 4 = 1800 RPM.

- At 50 Hz with 6 poles, Ns = (120 × 50) / 6 ≈ 1000 RPM.

The motor runs at this speed with no slip. That is the big difference from an induction motor, which needs slip to make torque.

Sample Synchronous Speeds

| Frequency (Hz) | Poles | Synchronous Speed (RPM) |

|---|---|---|

| 60 | 2 | 3600 |

| 60 | 4 | 1800 |

| 60 | 6 | 1200 |

| 50 | 4 | 1500 |

| 50 | 8 | 750 |

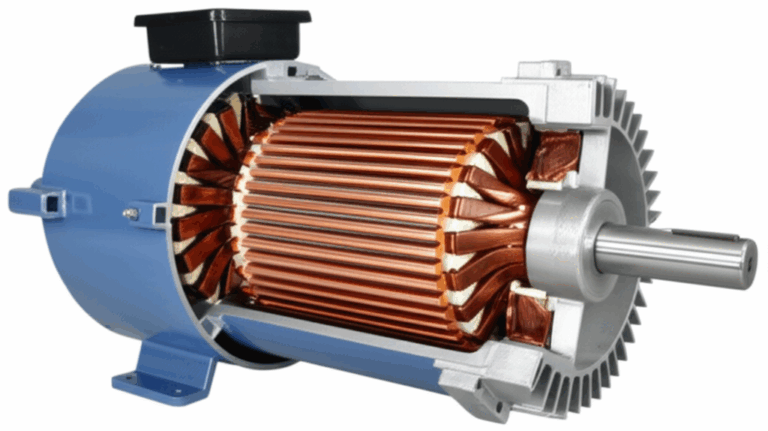

What Are the Main Parts of the Motor?

Every synchronous motor has two main parts, the stator and the rotor. The stator carries the stator winding in a laminated core. The rotor carries the rotor winding or permanent magnets. The thin steel sheets are core laminations that reduce eddy current loss and harmonics.

On a wound rotor, you feed DC excitation into the field winding. You often use slip rings and brushes to bring in DC from a DC exciter or a static rectifier. Many rotors include a damper winding. It helps with starting and damps hunting phenomenon under load changes.

When you source cores, the quality of the stator core lamination matters a lot. Good steel and tight tolerances cut losses and improve motor efficiency. The same is true for rotor core lamination. Better cores give you lower heat, stable magnetic flux, and longer life.

If you want a simple refresher on parts, this quick primer on stator and rotor helps.

Why Does Constant Speed Matter in Real Life?

Constant speed saves your process. Many industrial drives need a set speed no matter the load. Think pumps and compressors, fans and blowers, rolling mills, or mine hoists. If speed drifts, product quality drops, flows shift, or belts slip.

In robotics, servo motors, and high precision control, steady speed and clean torque production are key. You get smoother motion with fewer ripple effects. That means less noise levels and less vibration. In marine propulsion and traction motors, you also want predictable speed and good low‑speed torque.

I once worked with a textile line. It lived and died by speed. We swapped in a synchronous motor with a drive. The fabric weave steadied. Scrap fell. The room got quieter too.

Can a Synchronous Motor Fix Power Factor?

Yes. This is a big win. You can set a wound‑rotor synchronous motor to run at a leading power factor or unity power factor. Plants use this as a synchronous condenser. It cancels lag from other loads. You reduce utility penalties and improve voltage regulation.

Why does this work? The DC field sets how strong the rotor magnet is. That shifts the phase of the stator current. So the motor can power factor correction for the whole bus. On a good day you run at 0.9 leading to unity and keep the grid happy.

In a power systems engineering plan, these motors help with grid stability. You can ride through dips or surges better. Your alternator and generator tie‑ins like wind turbine and hydroelectric plants love that.

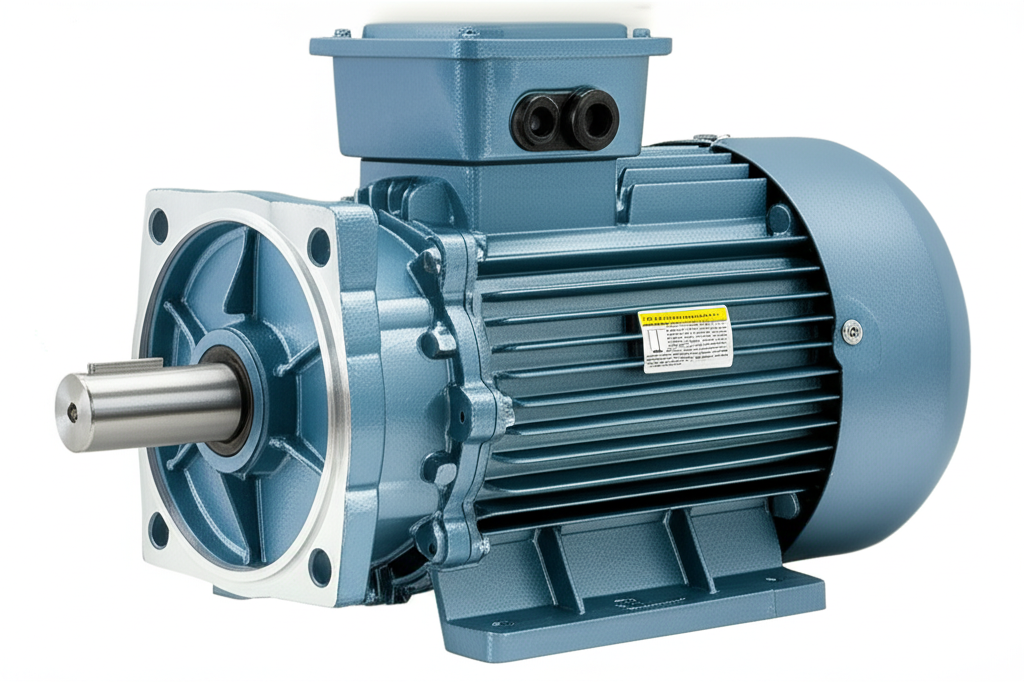

What Types of Synchronous Motors Should You Know?

You will see three main types in the field:

- Wound‑rotor synchronous motor. It uses a field winding on the rotor. You feed it with DC excitation via slip rings. You can set leading or lagging power factor and smooth voltage regulation. You often choose a salient pole rotor for low speed or a cylindrical rotor for high speed.

- Permanent Magnet Synchronous Motor (PMSM). The rotor uses permanent magnet poles. No DC brushes. You get high efficiency, high power density, and great part‑load energy savings. Many Electric Vehicle (EV) makers choose PMSM.

- Reluctance Synchronous Motor (RSM). It uses magnetic reluctance. The rotor has iron sections that line up with the field. It is simple and can be very rugged.

I have seen PMSM shine in tight spaces. I have seen wound machines pay for themselves by cutting power factor charges. RSM can be a sweet spot when you want simple and strong.

Why Does a Synchronous Motor Not Self‑Start?

At standstill the rotor poles see a field that spins. The pull flips each half cycle. Net torque averages to near zero. So classic synchronous motors do not self‑start.

We fix this in a few ways:

- Use a damper winding. It acts like a squirrel cage at start. The motor starts as an asynchronous motor, then you add DC and pull into sync.

- Use an auxiliary motor starting method. A small motor spins the shaft up to near synchronous speed.

- Use a variable frequency drive (VFD). The drive ramps frequency from zero so the rotor never loses lock. Modern VFDs do auto‑synchronization smoothly.

During sudden load steps, the rotor can swing a bit. We call it the hunting phenomenon. The damper bars and good control settings calm it down.

Where Do We Use These Motors?

You will see them across electrical machines in big jobs and small ones.

- Power generation. Large alternators in hydroelectric and wind turbine plants are synchronous machines. Grid code compliance demands tight sync and reactive control.

- Industrial drives. Pumps, compressors, fans, blowers, crushers, rolling mills, and mine hoists all benefit. Steady speed and better power factor save money.

- Electric Vehicles (EVs). Many EVs use PMSM for traction motors. You get regenerative braking, high torque, and wide speed range. Cars from Tesla and Hyundai use versions of this in some trims. Brands like ABB, Siemens, and General Electric (GE) also build solutions for industry.

- Robotics and servo motors. You get high precision control and fast moves.

I also see them in marine propulsion. The steady pull helps propellers avoid cavitation. In industrial automation, tight speed often means better product.

How Does It Compare to an Induction Motor?

An induction motor is tough, cheap, and self‑starting. It runs with slip. That is fine for many jobs. A synchronous motor runs with no slip. That gives you constant speed and control of power factor.

- Speed. Synchronous stays at set speed. Induction speed falls as load rises.

- Power factor. Synchronous can go leading, lagging, or unity. Induction motors run lagging.

- Starting. Induction self‑starts. Synchronous needs help unless a VFD runs it.

- Cost and complexity. Synchronous often has higher initial cost. Wound types add complexity with excitation gear. PMSM needs a good drive and magnets.

If your main goal is steady speed and lower energy risk, the synchronous choice pays off. If you want simple and low price, induction still wins in many light jobs.

How Do We Control Speed and Torque with Drives?

A VFD turns DC into AC with an inverter. The DC comes from a rectifier in the converter front end. A voltage source inverter feeds the motor. We then shape the waves with advanced control algorithms.

- Field oriented control (FOC) sets current in two axes to control torque and magnetic flux.

- Direct torque control (DTC) adjusts voltage vectors to keep torque on point.

- Sensorless control estimates rotor position from back EMF or models. You skip a physical sensor.

- Current control keeps phase currents within safe limits for rated current and avoids short circuit current risk.

With a drive, you can start at zero frequency and zero voltage. You ramp up to speed with no jerk. You can hold rated power, rated voltage, and rated current within specs. That protects your insulation class and extends life.

What About Design, Materials, Cooling, and Noise?

Good design starts with the stator design and rotor design. You choose pole pairs, stack length, and air gap. You pick cooling methods like TEFC, water jacket, or forced air. You match the insulation class to heat rise.

Core steel matters. High grade electrical steel laminations lower loss and cut EMI/EMC considerations. Better steel and tight stacks help fight harmonics. If you need a supplier, look into quality electrical steel laminations. Many also use silicon steel laminations, CRGO lamination core, or CRNGO lamination grades for the best balance of cost and loss. You also see EI core and UI lamination core in transformer lamination core work that ties into motor test setups.

Noise comes from torque ripple and fans. PMSM with good control runs smooth and quiet. Low vibration helps bearing life and keeps staff happy. I listen for bearing hum and whine from harmonics. When we fix harmonics in the drive setup, sound drops.

What About Reliability, Maintenance, and Cost?

With proper care, a synchronous motor can run 20–30+ years. Maintenance requirements are low on PMSM since there are no brushes. Wound‑rotor machines need care on slip rings and brushes. Keep the excitation system healthy. Watch overload capacity and short circuit current clear times to protect windings.

Reliability improves with clean power, tight cores, and good cooling. Use predictive maintenance with IoT integration. You can track heat, current, voltage, and vibration. Smart motors feed data into digital twins. You can plan work before a fault. That reduces lifecycle cost and total cost of ownership.

Yes the initial cost can be 10–25% higher than a basic induction motor. You get that back in energy savings, better power factor, and longer life. In heavy duty jobs with long run hours, the math often works in your favor.

What Does the Data Say? Real Numbers and Trends

Here are key data points I share with clients. They show why so many teams choose synchronous motors and generators.

| Category | Data/Statistic | Source/Context |

|---|---|---|

| Efficiency | Up to 98.5% efficiency for Permanent Magnet Synchronous Motors (PMSM). | Often 1–3% higher than equivalent induction motors at part load. Saves energy over time. |

| Power Factor | Can run leading, lagging, or unity. Plants often aim for 0.9 leading to unity. | Cuts utility penalties. Improves overall plant electrical efficiency. |

| Market Growth (PMSM) | Global PMSM market projected to grow at a CAGR of 7–9% from 2023–2028. | Driven by EVs, renewable energy, and industrial automation. |

| Application – EVs | About 70–80% of current EV traction motors are PMSM. | High power density, great efficiency across wide speeds, compact size. Examples include Tesla and many Hyundai/Kia models. |

| Application – Industrial | Energy savings of 5–15% reported in large pump and compressor upgrades. | Case studies in oil and gas and mining report lower operating cost and better PF. |

| Longevity | Lifespan typically 20–30+ years with proper maintenance. | Robust design and fewer wearing parts than DC motors. |

| Cost Comparison | 10–25% higher initial cost for wound‑rotor synchronous vs standard induction. | Offset by PF improvement and efficiency over long duty cycles. |

| Noise Levels | Quieter than induction motors at high speeds and changing loads. | Smoother torque and zero slip reduce acoustic noise. |

| Renewable Energy | Dominant generator type for large wind and hydro plants. | Precise synchronization and reactive control help grid performance. |

These numbers align with what I see in the field. They also match vendor guides from big names like Siemens, ABB, and GE.

What Comes Next for These Motors?

The future looks bright. Renewable energy applications keep growing. Green energy solutions need solid grid code compliance and voltage regulation. Synchronous machines do this well in power generation.

In EVs, next‑gen PMSM and RSM keep getting better. Advanced control algorithms and clever sensorless control boost range and regenerative braking. In plants, smart motors with IoT integration, predictive maintenance, and digital twins cut downtime. We will see more next‑generation motors and the future of electric motors will lean on tight control and data.

I also see more VFD‑based starts. That means easier startup methods and clean auto‑synchronization. Software will keep harmonics and EMI/EMC considerations in check. The tools get better each year.

FAQ

Q: Is a synchronous motor the same as a generator?

A: The alternator principle says the same machine can act as a generator or a motor. In a plant, big synchronous machines often do both in different roles.

Q: Can I use a synchronous motor for variable speed?

A: Yes with a VFD. The drive sets frequency. You keep steady torque with FOC or DTC. You can even do sensorless control in many cases.

Q: What rotor type should I choose?

A: Use a salient pole rotor for low speed and high poles. Use a cylindrical rotor for high speed. Choose PMSM for high efficiency and compact size. Choose RSM if you want simple, rugged, and magnet‑free.

Q: What materials matter most?

A: Core laminations and control gear. Good electrical steel laminations lower loss. Tighter stator core lamination and rotor core lamination stacks improve stability and cut heat.

Q: Where can I learn motor basics fast?

A: This friendly guide on stator and rotor is a quick start. It ties the big ideas together.

Key Takeaways

- A synchronous motor is an AC motor that runs at constant speed with no slip.

- It can improve power factor with DC excitation and act like a synchronous condenser.

- Core parts include stator winding, rotor winding, slip rings, brushes, and damper winding.

- The synchronous speed formula is Ns = (120 × f) / P with frequency and poles.

- Main types are wound‑rotor, PMSM, and RSM.

- Start with a damper winding, an auxiliary motor, or a VFD with auto‑synchronization.

- Use them in industrial drives, power generation, EVs, robotics, servo systems, and marine propulsion.

- Drives with FOC or DTC deliver tight torque production and smooth speed control.

- Good motor design, solid stator design and rotor design, and quality electrical steel cut losses and harmonics.

- Plan for maintenance, match insulation class, and watch rated power, rated voltage, rated current, overload capacity, and short circuit current.

- You get lower lifecycle cost and total cost of ownership with higher efficiency, energy savings, and great reliability.

References:

- Chapman, S. J. Electric Machinery Fundamentals, McGraw‑Hill.

- Krause, P. C., Wasynczuk, O., and Sudhoff, S. D. Analysis of Electric Machinery and Drive Systems, Wiley‑IEEE.

- ABB. Synchronous Motors Technical Guide and Product Brochures.

- Siemens. Synchronous Machines Catalogs and Application Notes.

- U.S. Department of Energy (energy.gov). Motor Systems and VFD Best Practices.