What is a Three Phase Motor? Understanding How They Power Industry

Every design engineer wrestles with the same balancing act. You want high efficiency, solid starting torque, low noise, and dependable uptime. You also need a motor that fits the budget and the footprint. If you are evaluating three phase motors for pumps, compressors, conveyors, HVAC, or robotics you are asking the right question. What exactly is a three phase motor and why does it dominate industrial power? More important for your project, how do choices like electrical steel grade, lamination thickness, and stack assembly affect performance, heat, and lifetime cost?

You are in the right place. We will explain the fundamentals in plain language then go deeper into the motor’s magnetic heart: the laminations. We will lay out options and trade-offs so you can move forward with clarity and confidence.

In This Article

- The Core Concept: What Defines a Three Phase Motor?

- How a Three Phase Motor Works: The Rotating Magnetic Field

- Key Advantages: Why Three Phase Motors Dominate Industry

- Common Types of Three Phase Motors

- Applications of Three Phase Motors: Powering the World

- Three Phase vs. Single Phase Motors: A Crucial Comparison

- Essential Considerations for Three Phase Motors

- The Lamination Lens: Core Losses and Materials

- Your Options Explained: Materials and Manufacturing for Laminations

- Which Application Is This For? Best-Fit Guidance

- Data and Specs That Matter

- The Future of Three Phase Motors: Efficiency and Smart Integration

- Your Engineering Takeaway

The Core Concept: What Defines a Three Phase Motor?

A three phase motor is an AC motor powered by three separate alternating currents that are phase-shifted by 120 electrical degrees. Those three currents feed three sets of stator windings. The result is a smooth, continuously rotating magnetic field that sweeps around the stator bore. The rotor sits inside that field and turns because the rotating field induces currents and torque in it.

That is the gist. Under the hood you are dealing with polyphase power. In a three phase system each phase reaches its peak at a different time. That staggering of peaks is the secret sauce. It creates constant power delivery and a rotating field with no dead spots.

Three key traits define a three phase motor:

- AC power input rather than DC.

- Three stator windings placed 120 electrical degrees apart.

- A rotor designed to chase the rotating magnetic field.

You will often see these motors connected in either delta or wye (star). Delta connection three phase motor wiring links the three windings in a triangle. Wye connection ties one end of each winding together at a common point. Both deliver the same basic operation with different line currents and voltages at the terminals.

How a Three Phase Motor Works: The Rotating Magnetic Field

The physics feels abstract at first so let’s break it down step by step.

Basic Components

- Stator: The stationary outer part of the motor that holds the three sets of windings. The stator core is a stack of insulated steel laminations that guides magnetic flux. The quality of the stator core lamination directly affects losses, heat, and efficiency.

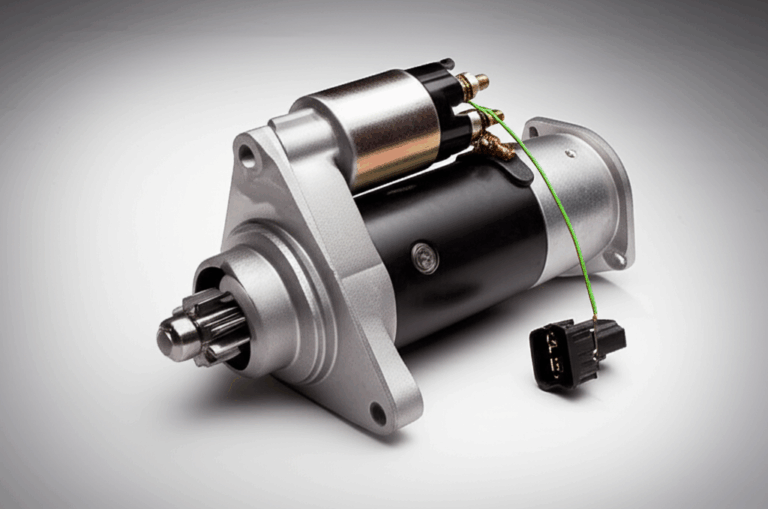

- Rotor: The rotating inner part. In most industrial motors it is a squirrel cage rotor made of conductive bars shorted by end rings and embedded in a laminated steel core. Wound rotor designs replace the cage with a three phase winding connected via slip rings for special control needs. The magnetic path and loss profile depend on the rotor core lamination.

The Magic of Three Phases

Feed the stator with three sinusoidal currents that are 120 degrees out of phase and you generate a rotating magnetic field. Imagine three people pushing a carousel. If they push in sequence not in unison the carousel spins steadily and it never stalls between pushes. The three phase currents do that for the rotor.

In an induction motor the rotating field induces currents in the rotor bars. Those currents create their own magnetic field which tries to align with the stator field. The rotor chases the rotating field and torque appears at the shaft. No brushes. No commutator. Just electromagnetic coupling through air.

Slip Explained

The rotating stator field spins at the synchronous speed which depends on the supply frequency and the number of stator poles. The rotor in an induction motor always lags that synchronous speed by a small fraction called slip. Slip is essential. Without it no relative motion exists between the field and the rotor conductors and no induced currents or torque can arise. In a synchronous motor the rotor locks to the rotating field and runs at exact synchronous speed with zero slip once synchronized.

Key Advantages: Why Three Phase Motors Dominate Industry

Three phase motors became the industrial workhorse for a reason. Several reasons in fact.

- High efficiency: The motor sees constant power delivery rather than pulsating power. Modern IE3 and IE4 motors often hit 85% to 96% efficiency at rated load depending on frame size. You waste less energy as heat which means lower operating costs.

- Superior starting torque: A three phase motor typically delivers 200% to 300% of full-load torque at start-up. High inertia loads like compressors and conveyors come up to speed without auxiliary windings or start caps.

- Smooth, constant power: The rotating magnetic field delivers steady torque. Vibration and electrical hum drop. Noise levels can improve as a result.

- Robustness and reliability: Squirrel cage induction motors use a simple, rugged design with few wearing parts. Bearings do most of the work which keeps maintenance limited and predictable.

- Cost-effectiveness: On a per-horsepower basis these motors bring a favorable cost profile and a long service life. Simpler construction can translate to faster repairs and better uptime.

- Power output at scale: Three phase motors scale from fractional horsepower into the megawatt class. You can match power range to any industrial task.

Common Types of Three Phase Motors

Three Phase Induction Motors (Asynchronous)

- Squirrel cage induction motor: The most common across industry. Simple and rugged. Fixed-speed operation with across-the-line power. Variable speed with a VFD.

- Wound rotor induction motor: The rotor uses windings connected to slip rings. You can add external resistance during start for high starting torque or use special control systems for speed control.

Three Phase Synchronous Motors

- Definition: The rotor spins exactly at synchronous speed. You drive the rotor field with DC excitation or use permanent magnets. No slip in steady state.

- Applications: Precision speed control. Large power factor correction for plants that want to offset reactive power. High efficiency in constant speed loads.

Applications of Three Phase Motors: Powering the World

Three phase motors show up anywhere you need reliable, efficient mechanical power at scale.

- Industrial machinery: Pumps, compressors, conveyors, fans, grinders, mixers. You see them on production lines, in milling machines, in material handling, and in process plants.

- HVAC systems: Large air handling units, chillers, and cooling tower fans. Variable frequency drives help match airflow and pressure to demand.

- Manufacturing and production lines: Robotics, assembly, packaging, and processing equipment. Motion control systems rely on precise torque and speed delivery.

- Transportation and vertical movement: Electric trains, elevators, escalators. Smooth torque and robust duty cycles fit the brief.

- Commercial buildings: Large refrigeration units, water pumps, and central plant equipment.

Three Phase vs. Single Phase Motors: A Crucial Comparison

- Power supply: Three phase power is standard in industrial parks and commercial sites. Residential sites often have single phase service. Infrastructure availability drives feasibility more than any other single factor.

- Starting mechanism: Three phase induction motors are self-starting. Single phase induction motors need auxiliary windings or start capacitors since a single phase cannot generate a rotating field on its own.

- Efficiency and performance: Three phase motors generally deliver higher efficiency, better power factor, and higher power density at a given frame size. You get more torque with fewer parts.

- Size and application: Three phase for heavy duty and continuous duty. Single phase for light duty or small appliances where three phase lines are not available.

Essential Considerations for Three Phase Motors

You know the basics. Now let’s focus on the engineering details that drive real-world results.

- Voltage and current: Standard industrial voltages include 208 V, 230 V, 460 V, 480 V, 575 V, and 600 V in North America. Europe and much of Asia use 380 V, 400 V, 415 V, and 690 V. Confirm utility and facility specs early in the design.

- Frequency: 50 Hz or 60 Hz depending on region. Synchronous speed depends on frequency and number of poles. The same motor can behave differently on 50 Hz versus 60 Hz.

- Motor control and VFDs: A variable frequency drive adjusts frequency and voltage to control speed and torque. VFDs can cut energy use by 30% to 50% on variable torque loads like pumps and fans. They also add soft-start and better process control.

- Protection and safety: Overload relays, circuit breakers, and appropriate contactors belong in every motor control circuit. Standards like NEMA MG 1 and IEC 60947 guide selection. Good protection prevents nuisance trips and saves motors from damage.

- Wiring configurations: Delta and wye options change line current and line-to-line voltage. Some motors are dual rated. The right connection depends on supply voltage and desired performance.

- Power factor: Three phase motors often run 0.80 to 0.90 at full load. Power factor correction capacitors or synchronous condensers can improve it. That reduces reactive power and potential utility penalties.

- Starters: Across-the-line starters, soft starters, and VFDs each have a place. Consider starting current limits, mechanical stress, and utility rules.

- Harmonics and power quality: VFDs can introduce harmonics. Line reactors and filters help. Keep an eye on voltage imbalance and total harmonic distortion since both raise losses and heat.

- Phase sequence and rotation: Confirm phase sequence during installation. Wrong sequence flips rotation which can damage pumps or compressors.

- Enclosures and environment: Choose TEFC, TENV, TEAO, or explosion-proof enclosures based on dust, moisture, and hazardous area classification. IP ratings help match ingress protection to the environment.

- Cooling and ambient conditions: Ambient temperature and altitude affect cooling. De-rate motors at high altitude where air density drops. Verify insulation class and temperature rise against the duty cycle.

The Lamination Lens: Core Losses and Materials

Now we turn to the motor’s magnetic backbone. Laminations are thin sheets of electrical steel stacked to form the stator and rotor cores. They carry the magnetic flux that makes torque possible. They also govern how much heat the core generates at a given frequency and flux density. That heat is core loss. Lower core loss means higher efficiency and lower operating temperature.

Two main types of core loss matter here:

- Eddy current loss: Think of eddy currents like tiny whirlpools forming in a river after a hard rain. A changing magnetic field induces circulating currents in any conductive path. Those loops waste energy as heat in the core. Thin laminations with an insulating coating break up the whirlpools. Each lamination becomes a barrier that cuts the size of the eddy loops which slashes this loss.

- Hysteresis loss: Magnetic domains in the steel flip back and forth as the AC field reverses. Each flip takes energy. Materials with lower coercivity lose less energy per cycle. The B-H curve describes this behavior. Narrow loops in that curve indicate lower hysteresis loss.

Other losses matter too:

- Copper losses: I2R losses in the stator windings and rotor cage.

- Mechanical losses: Bearings, windage, and friction.

- Stray load losses: Small but real. Caused by leakage flux and non-idealities.

You reduce eddy current loss with thinner laminations and better coatings. You reduce hysteresis loss with improved electrical steel grades that have lower core loss at the operating flux density and frequency. You protect those gains with manufacturing techniques that do not damage the steel’s grain structure or insulation.

Your Options Explained: Materials and Manufacturing for Laminations

You have two big decision buckets. Material selection and manufacturing processes. Let’s walk both in a balanced way so you can pick what fits your design and business constraints.

Material Considerations

- Nonoriented silicon steels (CRNGO): The most common choice for rotating machines. CRNGO stands for cold-rolled non-grain-oriented steel. It offers isotropic magnetic properties in-plane which suits motors that rotate through all angles. You will see grades specified by thickness and core loss at standardized test conditions.

- Grain-oriented silicon steels (CRGO): Excellent for transformers along the rolling direction where flux follows the grain. Less common for motors because motor flux rotates through many angles not just along the rolling direction. CRGO shines in EI and UI transformer cores.

- Higher silicon content alloys: These cut eddy current and hysteresis losses further but can be more brittle and harder to stamp. Balance magnetic gains with manufacturability and scrap rate risk.

- Cobalt-iron alloys: Premium materials for high power density and high flux operation. You pay for performance here. Aerospace and specialty motors may justify it.

- Amorphous and nanocrystalline metals: Exceptional core loss performance at higher frequencies. Great for certain transformers and specialty high-frequency machines. Not a mainstream choice for general industrial three phase motors today because of cost and manufacturing complexity.

- Coatings and insulation systems: Each lamination carries a thin inorganic coating to keep sheets electrically insulated. Coating class affects interlaminar resistance, punching performance, and bonding adhesion. Insulation class for the windings (like Class F or H) is a separate topic yet it ties into temperature rise and life.

If you are new to material selection, start with nonoriented electrical steel laminations then benchmark performance and cost against your targets. Tighten from there.

Manufacturing and Assembly Processes

How you turn sheets into a precision core matters. Bad processing can hand back the losses you fought to win.

- Stamping (progressive die): The gold standard for high-volume production. Excellent repeatability and speed. Lowest unit cost at scale. Die design and maintenance become critical. Burr control and die clearance protect interlaminar insulation.

- Laser cutting: Ideal for prototypes and low-volume or complex shapes. No tooling costs. HAZ (heat-affected zone) must be controlled since it can increase local losses. Proper fiber lasers and cutting parameters reduce that risk.

- Wire EDM: High precision. Slow cycle times. You will see it in specialty cores and test laminations.

- Waterjet: No heat input. Edge quality and taper control need attention.

- Mechanical stacking: Hand stacking with interleave patterns and step-lap techniques where applicable. Good for prototypes and small runs.

- Interlocking: Tabs and slots on laminations snap together like LEGO bricks to create rigid stacks without welding. Fast and clean. Great for stator stacks that need mechanical integrity with minimal added loss.

- Bonding and adhesive stacking: Thin bonding layers or full-surface bonding create very rigid stacks with low noise and vibration. Adhesives must be compatible with the lamination coating and curing process.

- Welding and cleating: Traditional methods for rotor stacks or special assemblies. Control heat to avoid damaging the magnetic properties.

- Skewing: Introduces a slight axial twist to rotor bars or stator slots. Reduces cogging, torque ripple, and acoustic noise. Important for applications that demand smooth operation.

- Post-processing: Stress relief annealing in some cases, particularly after laser cutting or welding. Careful temperature control maintains magnetic properties.

You can source fully built motor core laminations or procure stacks along with stator winding and rotor assembly services. The right path depends on volume, complexity, and whether you want to centralize supply.

Which Application Is This For? Best-Fit Guidance

Let’s connect choices to applications. You will move faster when you align materials and processes with the job to be done.

- General-purpose industrial motors (pumps, fans, conveyors): CRNGO silicon steel with thicknesses around 0.35 mm to 0.50 mm is a proven choice at 50/60 Hz. Progressive die stamping for volume. Interlocking or bonding for stack rigidity. Use a VFD for variable-torque loads and you unlock big energy savings.

- High power density or aerospace: Consider thinner steel (0.27 mm or below) and possibly cobalt-iron for elevated flux density. Bonded stacks reduce vibration and noise. Tight tolerances and skewing help smoothness and EMI performance.

- Precision speed applications: Synchronous motors or permanent magnet synchronous motors (PMSM) deliver exact synchronous speed. Laminations need low loss and precise slot geometry. Pay attention to rotor construction and magnet placement.

- High-frequency or specialized machines: If you are running well above 60 Hz, push toward thinner laminations and premium steels. Validate with core loss data at your operating frequency not just at standard test points.

- Prototyping and low volume: Laser cutting avoids tooling cost and gets you parts fast. Manage HAZ with proper parameters and consider a stress relief step if your loss budget is tight.

Remember the stator and rotor share the magnetic workload. Match the stator core lamination quality and the rotor core lamination approach to your target torque ripple, noise, and efficiency. Consistency across both pays off.

Data and Specs That Matter

When you size or specify motors and laminations these figures drive decisions.

- Efficiency: Industrial three phase motors often land between 85% and 96% at rated load depending on frame and design. IE3 and IE4 levels represent premium and super-premium efficiency. Higher efficiency trims heat and energy cost.

- Power range: Off-the-shelf three phase motors span from 1/4 HP to several thousand HP. The 1 HP to 500 HP band covers a huge chunk of industrial duty.

- Starting torque: Expect 200% to 300% of full-load torque for induction motors started across the line. Wound rotor designs can exceed this with external resistance at start.

- Power factor: Typically 0.80 to 0.90 at full load for induction machines. Synchronous designs can overexcite to correct plant power factor.

- Lifespan and reliability: With proper maintenance many motors run 15 to 20 years. Bearings set the schedule. Keep them lubricated. Monitor vibration and temperature.

- Energy consumption impact: Electric motors consume roughly half of the world’s electricity and more than 70% of industrial electricity. Energy efficiency projects that upgrade to IE3/IE4 motors and add VFDs deliver significant savings.

- VFD energy savings: On pumps and fans VFDs commonly cut energy use by 30% to 50% by matching speed to process demand. Soft start reduces mechanical stress which lowers maintenance.

- Electrical ratings: Confirm full-load current, no-load current, locked-rotor current, and service factor against your starters and breakers. Make sure the upstream electrical distribution can handle inrush and harmonics.

- Mechanical and thermal: Watch breakdown torque, pull-out torque, and speed-torque characteristics. Validate enclosure type, IP rating, and cooling method against duty cycle and ambient.

If you want a simple sanity check for three phase selection, start with voltage availability, load type, duty cycle, and control needs. Then verify with motor performance curves and stack up the total cost of ownership over the service life.

The Future of Three Phase Motors: Efficiency and Smart Integration

Three trends shape your next specification.

- Efficiency standards: IE3 and IE4 efficiency requirements continue to expand across regions. NEMA Premium in North America maps to similar performance expectations. Better steels and tighter manufacturing tolerances keep pushing the curve.

- Smart control and IoT: VFDs now bundle condition monitoring and networked diagnostics. Sensors watch vibration, temperature, and harmonics. Predictive maintenance reduces downtime and extends service life.

- Electrification and sustainability: Plants are chasing energy and carbon reductions. Upgrading to high efficiency motors with optimized laminations cuts CO2 emissions. The physics stays the same yet the impact at scale grows.

Suppliers including ABB, Siemens, and many others publish application notes and efficiency case studies. You can lean on their data to fine-tune your selections. Standards like IEC 60034 and NEMA MG 1 remain the rulebook for ratings and test methods.

Your Engineering Takeaway

Here is the short version you can clip to a spec sheet.

- A three phase motor uses three AC currents 120 degrees apart to create a rotating magnetic field. The rotor follows that field and delivers smooth torque.

- The stator and rotor cores are built from thin, insulated steel sheets called laminations. These laminations guide flux and control core losses which set heat and efficiency.

- Lower core loss comes from thinner laminations, better electrical steel grades, and gentle manufacturing that preserves magnetic properties.

- Induction motors are rugged and self-starting. Synchronous motors lock at exact speed and can improve power factor.

- VFDs unlock variable speed, soft start, and big energy savings on variable torque loads.

- Choose materials and processes based on frequency, flux density, volume, complexity, and cost targets. Use stamping for scale. Use laser cutting for speed and flexibility. Pick interlocking or bonding for rigid, low-noise stacks.

Action steps:

1) Define your operating frequency, voltage, load type, and duty cycle. Add any environmental constraints like altitude, ambient temperature, and hazardous location requirements.

2) Set performance targets for efficiency, temperature rise, and acoustic noise.

3) Select a baseline steel grade and lamination thickness then model core loss at your flux density and frequency.

4) Choose a manufacturing route that hits cost and quality targets. Validate with sample stacks and core loss testing.

5) Collaborate early with your lamination supplier. Share drawings, coatings, stacking instructions, and quality checkpoints. Expect better outcomes when you treat them like a design partner.

If you need a quick primer on the building blocks themselves, review options for complete motor core laminations and the material fundamentals behind modern electrical steel laminations. The match between your stator and rotor stacks matters as much as the windings and the drive.

Appendix: Deeper Dives for Practitioners

Because engineers love details, here are concise notes on several common topics that often come up during design reviews and procurement.

- Polyphase power vs. single phase: Three phase power supplies constant power to the motor and the grid. Single phase delivers pulsating power. That difference shows up as smoother torque and lower vibration.

- Power quality: Unbalanced three phase supply increases copper loss and heat. Keep phase voltages within a few percent of each other. Harmonics from VFDs can raise temperatures. Use filters and follow drive manufacturer guidance.

- Motor starters revisited: Across-the-line starters are simple and inexpensive. Soft starters cut inrush and mechanical shock. VFDs replace both with more control and better energy performance.

- Speed control: VFDs shine for induction motors. Synchronous motors track frequency exactly which makes them great for constant speed applications. Servo motor three phase systems deliver precise motion with feedback loops. Stepper motor three phase configurations move in discrete steps and are common in positioning. BLDC and PMSM use three phase drives even though the waveforms can differ from pure sine AC.

- Protection and codes: Overload relays protect against thermal overcurrent. Short-circuit devices protect against faults. Decide on Class 10, 20, or 30 trip curves based on load inertia and start profile.

- Temperature, altitude, and life: Every 10°C increase in winding temperature roughly