What is a Three-Phase Motor? Your Essential Guide to Industrial Powerhouses

If you’ve ever walked through a factory, a large commercial building, or a processing plant, you’ve been surrounded by the quiet, consistent hum of industry’s greatest workhorse: the three-phase motor. These powerful devices are the unsung heroes behind everything from massive conveyor belts and industrial pumps to the HVAC systems that keep skyscrapers comfortable. For any engineer, designer, or manager involved in industrial applications, understanding this technology isn’t just academic—it’s fundamental.

You’re here because you need to know what a three-phase motor is, how it operates, and why it’s the default choice for nearly every serious industrial task. You’re trying to grasp the core principles that make it so efficient, reliable, and powerful. You’re in the right place. This guide will break down the complex principles into clear, understandable concepts, moving from the fundamental science to real-world applications and advantages.

What We’ll Cover

- What Exactly is a Three-Phase Motor? A look at the core definition, the magic of three-phase power, and the essential components.

- How Does a Three-Phase Motor Work? We’ll dive into the science behind the spin, from the rotating magnetic field to the principle of induction.

- Why Three-Phase Motors Dominate Industry: Exploring the key advantages that make these motors the undisputed champions of industrial power.

- Three-Phase vs. Single-Phase Motor: A critical comparison to understand the strengths and weaknesses of each.

- Types of Three-Phase Motors: A breakdown of the most common variations, including induction and synchronous motors.

- Common Applications of Three-Phase Motors: Where you’ll find these powerhouses in the real world.

- Advanced Control & Efficiency: The role of VFDs in modern motor control.

What Exactly is a Three-Phase Motor?

At its core, a three-phase motor is a type of AC (alternating current) motor that runs on a three-phase power supply. That’s the simple definition, but the magic is in what “three-phase” actually means and how the motor uses it to create powerful, efficient rotation.

The Concept of Three-Phase Power

Imagine trying to push a merry-go-round by yourself. You’d have to give it a shove, run around, and shove it again. Your effort would be jerky and inefficient. Now, imagine you have two friends helping you, spaced perfectly around the merry-go-round. Each person pushes in a coordinated sequence, creating a smooth, continuous, and much more powerful rotation.

This is the fundamental difference between single-phase and three-phase power.

- Single-Phase Power: This is what you have in your home. It’s a single wave of alternating current. Like the lone person pushing the merry-go-round, it provides power in pulses, which is perfectly fine for running your lights, toaster, or laptop.

- Three-Phase Power: This system uses three separate AC waves, all delivered on different wires. Crucially, these waves are 120 degrees out of phase with each other. This means their peaks and valleys never align. The result is a constant, uninterrupted stream of power. Instead of a single “push,” the motor receives three perfectly timed “pushes” for every cycle, resulting in a balanced and smooth power delivery. This continuous power flow is why three-phase motors are inherently more efficient and powerful than their single-phase counterparts.

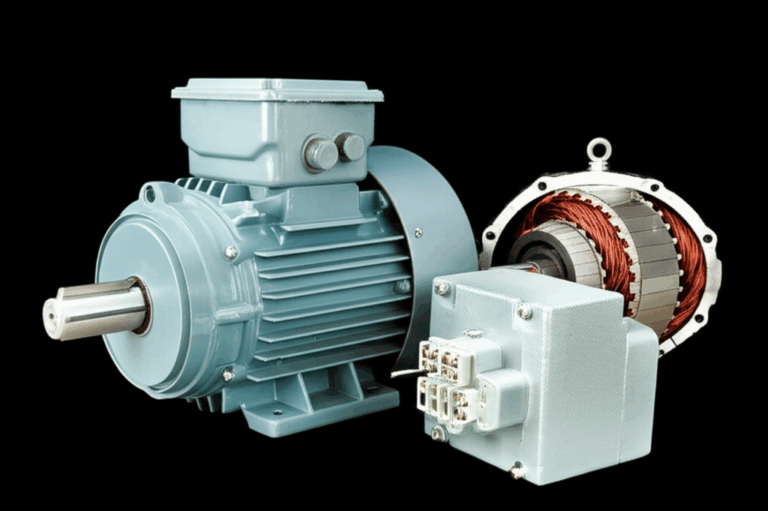

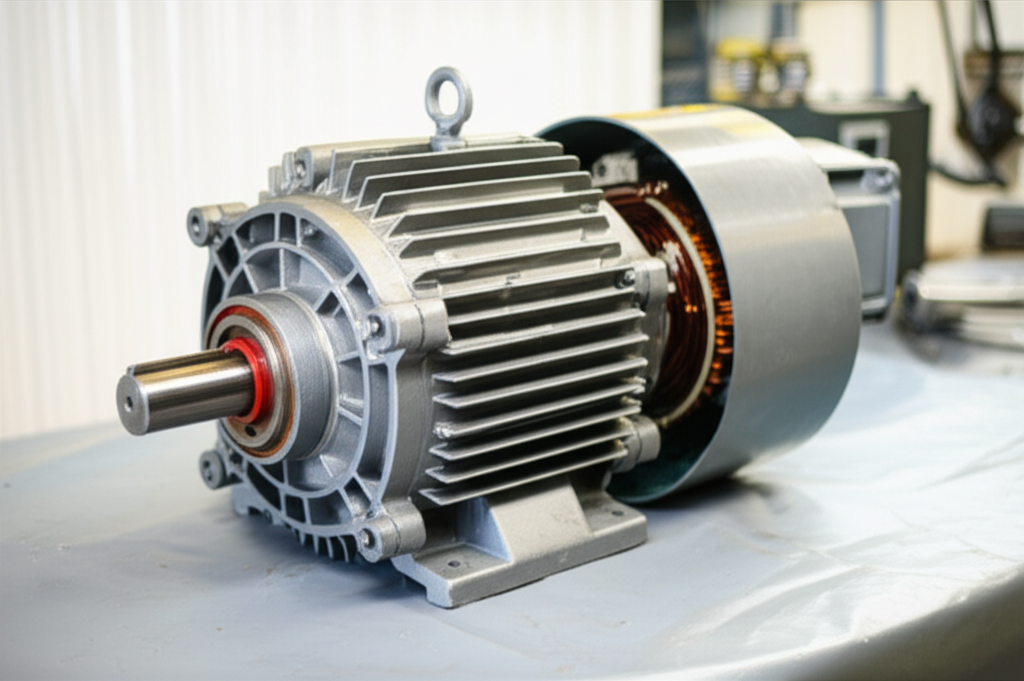

Key Components of a Three-Phase Motor

While there are many variations, nearly all three-phase motors share a few core components. Their elegant simplicity, particularly in the most common types, is a key reason for their incredible durability. The two main parts are the stator and rotor.

- Stator: This is the stationary outer part of the motor. It consists of a laminated steel core wrapped with several sets of insulated copper windings. When the three-phase AC power is connected to these windings, the stator creates the all-important rotating magnetic field. The quality of the motor core laminations used in the stator is critical for minimizing energy loss.

- Rotor: This is the rotating part located inside the stator. It’s connected to the output shaft that drives the mechanical load. Unlike the stator, the rotor isn’t typically connected directly to the power source. Instead, it gets its power through induction (more on that in a moment). The most common type is the “squirrel cage” rotor, a brilliantly simple design made of conductive bars shorted at each end by rings, resembling a hamster’s exercise wheel.

- Frame/Enclosure: This is the motor’s housing, which protects the internal components from the environment (dust, moisture) and helps dissipate heat. Enclosure types are standardized with IP (Ingress Protection) ratings.

- Bearings: Located at each end of the shaft, bearings allow the rotor to spin smoothly within the stator with minimal friction.

- Shaft: The part of the rotor that extends outside the motor to connect to the equipment it’s driving, like a pump, fan, or gearbox.

- Cooling Fan: Most three-phase motors have an external fan mounted on the shaft. As the motor spins, the fan blows air over the finned frame to dissipate the heat generated during operation.

How Does a Three-Phase Motor Work? The Science Behind the Spin

The working principle of a three-phase motor is a beautiful application of electromagnetism, specifically Faraday’s Law of Induction and Lenz’s Law. It sounds complicated, but the concept is surprisingly intuitive. It all boils down to creating a “magnetic chase.”

1. The Rotating Magnetic Field (RMF)

The real genius of three-phase power, a concept largely credited to Nikola Tesla, is its ability to create a rotating magnetic field without any moving parts. Here’s how it works:

When you connect the three-phase power supply to the stator’s windings, each phase energizes its respective set of coils in sequence. Because the AC waves are 120 degrees apart, the magnetic field generated by each set of windings reaches its peak strength at a different instant. The combined effect of these three overlapping and phase-shifted fields is a single, unified magnetic field that rotates around the inside of the stator at a constant speed.

Think of it like three spotlights arranged in a circle, each turning on and off in a rapid, repeating sequence. Your eye would perceive a single spot of light moving smoothly around the circle. That’s exactly what the RMF is—a seamlessly rotating magnetic force. The speed of this field, known as the synchronous speed, is determined by the frequency of the AC power (e.g., 60 Hz in North America, 50 Hz in Europe) and the number of poles in the stator windings.

2. The Principle of Induction

Now that we have a rotating magnetic field in the stator, we need to get the rotor to spin. This is where induction comes in.

According to Faraday’s Law of Induction, if you move a conductor through a magnetic field (or move a magnetic field past a conductor), a voltage (and thus a current) will be induced in that conductor.

The RMF of the stator sweeps across the conductive bars of the squirrel cage rotor. From the rotor’s perspective, it’s experiencing a rapidly changing magnetic field. This change induces a powerful electric current in the rotor bars.

3. Torque Production & Continuous Rotation

We now have a rotor with a strong current flowing through its bars. A fundamental principle of electromagnetism states that any current-carrying conductor placed in a magnetic field will experience a force. This force pushes on the rotor bars.

Crucially, Lenz’s Law dictates that the magnetic field created by the induced current in the rotor will oppose the change that created it. In simple terms, the rotor’s magnetic field will try to “catch up” to the stator’s rotating magnetic field to reduce the relative motion between them.

This creates a constant “chase.” The rotor is always trying to catch the RMF but can never quite reach it. This relentless pursuit generates a powerful twisting force, or torque, that spins the rotor and its connected shaft.

The small difference in speed between the RMF (synchronous speed) and the actual rotor speed is called slip. Slip is essential for an induction motor to produce torque; if the rotor ever reached the same speed as the RMF, there would be no relative motion, no induced current, and therefore no torque. This elegant and straightforward motor principle is what makes the three-phase induction motor so reliable.

Why Three-Phase Motors Dominate Industry: Key Advantages

Engineers and industrial operators choose three-phase motors for a host of compelling reasons. They aren’t just slightly better than single-phase motors for heavy-duty work; they are exponentially superior in almost every metric that matters in an industrial setting.

1. Superior Efficiency & Power Output

Three-phase motors make better use of electricity. Because power is delivered continuously, the motor’s operation is smoother, and less energy is wasted as heat or vibration. The International Energy Agency (IEA) estimates that electric motors account for over 70% of industrial electricity consumption, making efficiency paramount. Modern IE3 (Premium Efficiency) and IE4 (Super Premium Efficiency) three-phase motors boast efficiencies upwards of 95%, translating directly into lower electricity bills and a smaller carbon footprint. They also have a much higher power-to-weight ratio, meaning you get more power from a smaller, lighter motor.

2. Self-Starting Capability

The rotating magnetic field gives three-phase motors a powerful, inherent starting torque. They don’t need any special external components like capacitors or starting windings to get going, which is a common requirement for many single-phase motors. This makes their design simpler, more robust, and less prone to failure. They can start under heavy loads, a critical requirement for applications like compressors, conveyors, and loaded pumps.

3. Smooth Operation & Reduced Vibration

Remember the merry-go-round analogy? The three balanced “pushes” per cycle result in a constant, ripple-free torque. This smooth power delivery means the motor runs with significantly less vibration and noise compared to a single-phase motor. Reduced vibration not only leads to quieter operation but also minimizes mechanical stress on the motor’s bearings and the connected machinery, extending the operational life of the entire system.

4. Robustness & Durability

The squirrel cage induction motor, the most common type of three-phase motor, is a marvel of engineering simplicity. The rotor has no windings, brushes, or commutators to wear out. It’s essentially a solid chunk of laminated steel and conductive bars. This simple, rugged construction means there are very few failure points. With proper maintenance (which is minimal), a well-built three-phase motor can easily provide 15-20 years or more of reliable service in the harshest industrial environments.

5. Cost-Effectiveness

While the initial wiring for a three-phase system can be more complex than for single-phase, the motors themselves are often cheaper to manufacture for equivalent power ratings (above a few horsepower). More importantly, their higher efficiency and reliability lead to a much lower total cost of ownership (TCO) over the motor’s lifespan, thanks to reduced energy consumption and lower maintenance costs.

Three-Phase Motor vs. Single-Phase Motor: A Critical Comparison

To truly appreciate the strengths of a three-phase motor, it helps to compare it directly with its single-phase cousin.

| Feature | Three-Phase Motor | Single-Phase Motor |

|---|---|---|

| Power Supply | Requires a three-phase power supply (3 hot wires, sometimes a neutral). | Runs on a standard single-phase supply (1 hot wire, 1 neutral). |

| Starting Mechanism | Self-starting. The RMF provides powerful starting torque without extra components. | Not self-starting. Requires auxiliary components like start capacitors or shaded poles to initiate rotation. |

| Efficiency & Power | Highly efficient (up to 96%+). Delivers constant, high power output. | Less efficient. Power is delivered in pulses, resulting in lower power output for the same size. |

| Performance | Smooth, quiet operation with very low vibration due to balanced torque. | Noticeably more vibration and noise due to pulsating torque. |

| Cost & Complexity | Simpler motor construction. Wiring installation is more complex. | More complex motor construction (due to starting parts). Wiring is simpler. |

| Typical Applications | Industrial and commercial: pumps, compressors, conveyors, large fans, machine tools, HVAC. | Residential and light commercial: refrigerators, small fans, power tools, home appliances. |

| Reliability | Extremely reliable and low-maintenance due to simple, rugged design (especially squirrel cage). | Less reliable due to failure-prone starting components like capacitors and switches. |

Types of Three-Phase Motors

While all three-phase motors operate on the principle of the RMF, there are two main categories based on how their rotors behave.

1. Three-Phase Induction Motors (Asynchronous)

This is by far the most common type of three-phase motor in the world. They are called “asynchronous” because the rotor always spins slightly slower than the synchronous speed of the magnetic field (the “slip” we discussed earlier).

- Squirrel Cage Induction Motor: The undisputed workhorse of industry. Its rotor is simple, rugged, and requires almost no maintenance. It’s used in over 90% of industrial motor applications.

- Wound Rotor Induction Motor (Slip-Ring Motor): This type has actual windings in its rotor, connected to external resistors via slip rings and brushes. This design allows for control over the motor’s starting torque and speed, making it useful for specialized applications like cranes and hoists that require very high starting torque and variable speed control. However, it’s more expensive and requires more maintenance than a squirrel cage motor.

2. Three-Phase Synchronous Motors

In a synchronous motor, the rotor is designed to lock in with the rotating magnetic field and spin at the exact same speed—the synchronous speed. There is zero slip. This is typically achieved by using a rotor that is either a permanent magnet or an electromagnet energized by a separate DC power source.

Synchronous motors are used in applications that demand precise speed control, regardless of the load. You’ll find them in robotics, machine tools, and high-precision positioning systems. They can also be used for power factor correction in large industrial facilities.

Common Applications of Three-Phase Motors

The next time you’re in an industrial or large commercial environment, look around. The chances are high that nearly every piece of major equipment is powered by a three-phase motor. Their applications are virtually limitless:

- Pumps and Fans: Moving vast quantities of water, air, and other fluids in industrial processes, water treatment plants, and large-scale HVAC systems.

- Conveyor Systems: Powering the belts that move everything from packages in a logistics hub to raw materials in a mine.

- Compressors: Providing compressed air for tools and automation systems in manufacturing plants.

- Machine Tools: Driving lathes, mills, grinders, and other precision machinery in workshops.

- Manufacturing Equipment: Powering mixers, agitators, crushers, and assembly lines.

- Electric Vehicles (EVs): High-performance traction motors in many modern EVs are sophisticated three-phase AC motors.

Advanced Control & Efficiency: The Role of VFDs

One of the most significant advancements in motor technology has been the development of the Variable Frequency Drive (VFD). A VFD is an electronic controller that sits between the power supply and the three-phase motor. It works by converting the incoming AC power to DC and then inverting it back to a simulated three-phase AC output.

The magic of a VFD is that it can vary the frequency of that output. Since a motor’s speed is directly tied to the frequency of the power supply, a VFD gives you precise control over the motor’s speed.

This has massive benefits:

- Energy Savings: For applications like pumps and fans, even a small reduction in speed can lead to enormous energy savings (often 20-50%). Case studies from companies like ABB and Siemens show that the payback period for installing a VFD can be as short as 1-3 years.

- Process Control: VFDs allow for fine-tuning of machine speeds to match production needs, improving product quality and reducing waste.

- Soft Starting: A VFD can ramp up the motor’s speed gradually, reducing the huge inrush of current and mechanical shock associated with starting a large motor directly on the line. This extends the life of both the motor and the machinery.

Conclusion: The Unsung Hero of Modern Infrastructure

The three-phase motor is a testament to brilliant yet simple engineering. It’s a technology that is simultaneously powerful, efficient, and incredibly durable. Its ability to convert electrical energy into smooth, reliable mechanical work is the invisible force that drives our modern world. From the factories that produce our goods to the systems that provide us with clean water and air, this industrial powerhouse is always there, quietly doing the heavy lifting.

Understanding the principles of the three-phase motor empowers you to make better decisions, whether you’re designing a new piece of equipment, managing a facility, or simply appreciating the intricate engineering that underpins our infrastructure. It truly is the unsung hero, spinning reliably behind the scenes of progress.