What is an Eddy Current Sensor? A Simple Guide to Seeing Through Metal!

Have you ever wondered how a factory can build a car engine so perfectly? Or how an airplane can fly for thousands of hours safely? A big part of the magic is a special tool called an eddy current sensor. It’s a small but powerful device that can see things our eyes can’t, like tiny cracks in metal or the exact position of a spinning machine part, all without ever touching it!

This guide will unlock the secrets of how these amazing sensors work. We’ll explore:

- The simple science behind them.

- All the cool jobs they do in the world.

- Why they are a superhero in the world of measurement.

- How they help keep machines running smoothly and safely.

Get ready to learn about a technology that’s shaping our world in ways you never imagined!

Table of Contents

- What Exactly Is an Eddy Current Sensor?

- How Do These Magical Sensors Actually Work?

- What Makes Eddy Current Sensors So Special?

- Where Do People Use These Awesome Gadgets?

- Are There Any Downsides?

- Eddy Current vs. Other Sensors: What’s the Difference?

- How Do You Pick the Right Eddy Current Sensor?

- Can It Find Hidden Flaws in Metal? A Look at NDT

- What’s Inside an Eddy Current Sensor?

- The Future is Smart! What’s Next for These Sensors?

- Key Takeaways

What Exactly Is an Eddy Current Sensor?

Imagine you have a magic wand that can measure the distance to a metal object without touching it. That’s pretty much what an eddy current sensor is! It’s a special type of non-contact displacement sensor. This means it can tell you exactly how far away a metal part is, or if it’s wiggling or vibrating, all from a short distance.

Think of it like a super-powered metal detector. A metal detector at the beach just beeps when it finds something. But an eddy current sensor is much smarter. It can tell you the exact distance to that metal. It is a type of transducer, which is a fancy word for a device that turns one kind of energy into another. In this case, it turns magnetic energy into an electrical signal that we can read. These signals can be an analog output or a digital output.

These sensors are a key part of position sensing technology. They are used in all sorts of machines to make sure everything is lined up perfectly. This is called precision displacement measurement. Because they don’t touch the object, they never wear out from rubbing against it. This makes them super reliable for tough jobs in factories and power plants.

How Do These Magical Sensors Actually Work?

Okay, let’s get into the cool science. It sounds complicated, but it’s like skipping a stone on a pond. The eddy current sensor working principle is all about electricity and magnets, which is called electromagnetism.

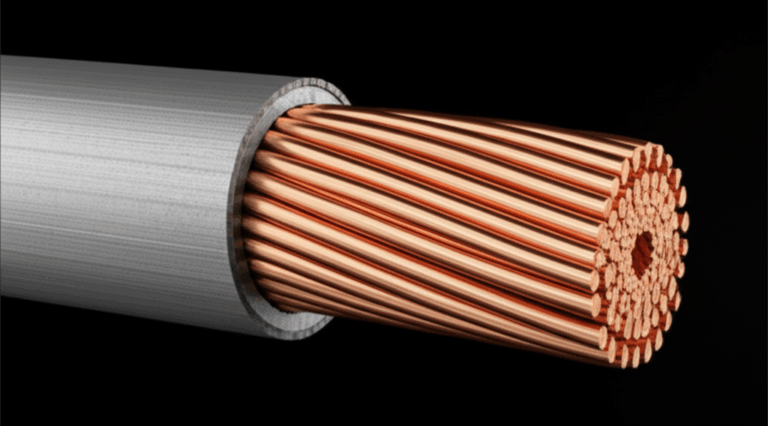

Inside every eddy current sensor is a coil of wire. The sensor’s electronics, sometimes called a sensor driver circuit, send a special kind of electricity, a high-frequency AC excitation, through this coil. This creates an invisible bubble of energy around the sensor’s tip called a magnetic field. It’s kind of like the invisible force you feel when you try to push two magnets together. This whole process is based on a rule of science called Faraday’s Law.

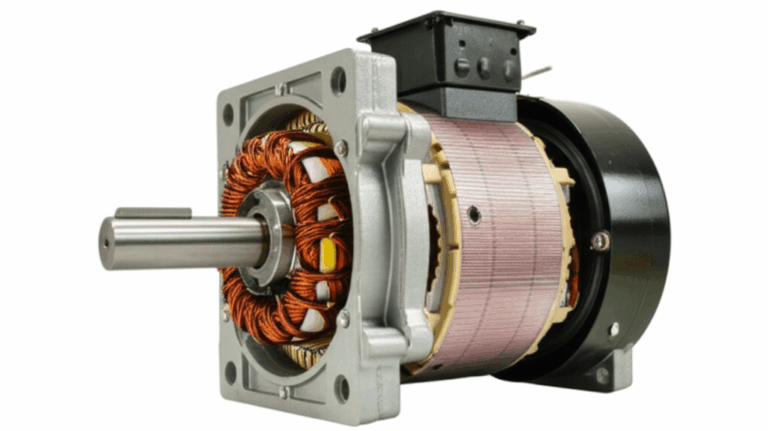

Now, when you bring a metal object (we call this the target material) close to the sensor, something amazing happens. The sensor’s magnetic field creates tiny, swirling electric currents inside the metal object. These are called eddy currents. They are like tiny whirlpools of electricity. You can’t see them, but they are there! This is a core part of the motor principle that powers so many of the devices we use every day. These eddy currents then create their own tiny magnetic field, which pushes back against the sensor’s field, as explained by Lenz’s Law. This interaction causes an impedance change in the sensor coil. The sensor’s brain, or its demodulation circuit, measures this change. The closer the metal object gets, the stronger the eddy currents are, and the bigger the change in impedance. The sensor electronics then turn this change into a number that tells you the exact distance, or gap, between the sensor and the target.

What Makes Eddy Current Sensors So Special?

You might be wondering, “Why not just use a ruler?” Well, in the world of super-fast, super-precise machines, a ruler just won’t cut it. Eddy current proximity sensor technology has some real superpowers that make it a favorite for engineers.

The biggest advantage is that it’s a non-contact measurement tool. It can measure without ever touching the target. Think about trying to measure a spinning fan blade. You can’t touch it, or it will break! An eddy current sensor can do it safely from a distance. This also means no wear and tear, giving these robust industrial sensors a very long lifespan with little need for maintenance of an eddy current sensor.

Another superpower is their toughness. These sensors are unaffected by dirt and oil. If you have a greasy, messy environment inside a car engine or a factory machine, a camera or laser sensor might get dirty and stop working. But an eddy current sensor doesn’t care about oil, water, dust, or grime. As long as it can see the metal target, it works perfectly. This environmental resilience is a huge win for many industries. They also have a fast response time, which means they can keep up with incredibly fast-moving parts.

Advantages of Eddy Current Sensors:

- High Precision & Resolution: They can measure tiny movements, even smaller than a human hair. A high resolution displacement sensor can achieve sub-micrometer accuracy.

- High Speed: They can take thousands of measurements per second, perfect for vibration monitoring.

- Durability: No moving parts to break. They have a high MTBF (Mean Time Between Failures).

- Versatility: They can work in extreme heat or cold, with some high temperature eddy current sensor models working in places as hot as an oven.

Where Do People Use These Awesome Gadgets?

The applications of eddy current sensors are almost endless, especially in places that need precise and reliable measurements. You can find them in everything from making your smartphone to keeping a giant power plant running.

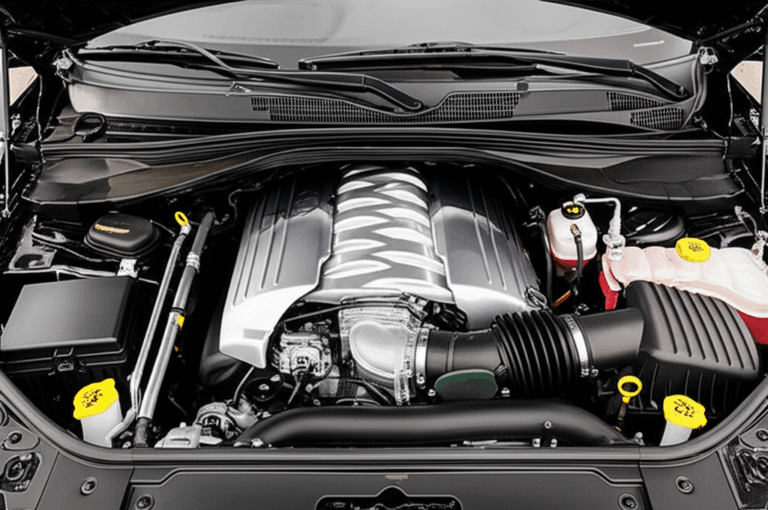

In the automotive industry, they are used on assembly lines for automotive eddy current applications like checking the gap between car doors and the body to make sure they fit perfectly. Inside the engine, they measure how a crankshaft spins to make sure it’s balanced. This is a form of shaft runout measurement. They are also vital for bearing clearance measurement to prevent engine failure.

In aerospace, safety is number one. Aerospace NDT eddy current techniques are used to inspect plane parts like wings and turbine blades for tiny cracks you can’t see. This non-destructive testing, or NDT, helps find problems before they become dangerous. It’s also used for amazing things like turbine blade tip timing.

Here’s a quick look at where else they are used:

- Power Generation: In power plants, they monitor the huge spinning shafts in turbines. This is a critical part of condition monitoring to prevent blackouts.

- Semiconductor Manufacturing: To make computer chips, you need to be incredibly precise. Tiny miniature eddy current sensors help position silicon wafers with amazing accuracy.

- Machine Tools: They make sure cutting tools on big machines are in the exact right spot to make perfect parts.

- Oil and Gas Industry: They are used in tough environments to check pipes and machinery for wear and tear.

Are There Any Downsides?

Like any superhero, eddy current sensors have a weakness or two. It’s important to know their limits so you can use them for the right job. These are the main disadvantages of eddy current sensors.

First and foremost, they only work with conductive materials. This means they can only see metals. If you try to measure the distance to a piece of plastic, wood, or glass, the sensor won’t see anything at all. The non-conductive material measurement impact is that it simply doesn’t work. This is their biggest limitation.

Second, they have a limited range. Most standard sensors are designed for linear measurement range work over very short distances, usually just a few millimeters. This is perfect for measuring a tiny gap, but not for measuring the distance across a room. They are masters of close-up, precision work.

Finally, they can be sensitive to the type of metal you are measuring. A sensor set up for aluminum will give a different reading for steel at the same distance. This is because of the metal’s conductivity and permeability. This means you need to perform a calibration of eddy current sensor for the specific target material you are working with. Also, big changes in temperature can sometimes affect the reading, which is known as sensor drift, although many high-end systems have temperature compensation to fix this.

Eddy Current vs. Other Sensors: What’s the Difference?

There are many ways to measure things, and engineers have a whole toolbox of different sensors. So why choose an eddy current sensor over another type? Let’s compare a few.

Eddy Current Sensor vs. Inductive Sensor: This is a common comparison. A basic inductive proximity sensor is like a simpler cousin. It can tell you if a metal object is there or not (a “yes” or “no” answer), making it a great proximity switch. An eddy current sensor is much more advanced. It gives you a precise measurement of the distance, not just a yes/no signal. So, for simple metal detection, an inductive sensor is fine. For high-precision gap measurement, you need an eddy current sensor.

Eddy Current vs. Capacitive Sensors: Capacitive sensors work with almost any material, not just metal. That’s a big plus! However, they are very sensitive to things like dirt, dust, and humidity, which can mess up their readings. An eddy current sensor, as we learned, works perfectly even when it’s dirty or oily.

Eddy Current vs. Laser Sensors: Laser sensors can measure from much farther away. But they can have trouble if the surface is too shiny or too dull, or if there is smoke or fog in the air. The benefits of non-contact measurement with an eddy current sensor include its immunity to these surface and air conditions.

Here’s a simple table to help:

| Sensor Type | Works With | Best For… | Weakness |

|---|---|---|---|

| Eddy Current | Metals Only | High precision, dirty environments | Short range, needs calibration |

| Inductive Proximity | Metals Only | Simple “on/off” detection | Not for precise measurement |

| Capacitive | Most Materials | Measuring non-metals | Sensitive to dust & moisture |

| Laser | Most Surfaces | Long-range measurement | Sensitive to surface color & light |

| LVDT | Physical Contact | Very high accuracy | Must touch the target, can wear out |

How Do You Pick the Right Eddy Current Sensor?

Choosing the right tool for the job is always important. When picking an eddy current sensor, an engineer thinks about a few key things to make sure it will work perfectly. It’s not just about the cost of eddy current sensor, but about getting the right performance.

First, they look at the measurement range. How far away will the sensor be from the target? If you only need to measure a tiny 1 mm gap, you’ll need a different sensor than if you need to measure a 10 mm gap. The sensor’s size and coil design often determine its range.

Next is the target material. Is it aluminum, steel, copper, or something else? Since the sensor’s output depends on the material, you need to pick one that is designed or can be calibrated for your specific metal. This affects the sensor’s linearity (how straight the measurement line is) and repeatability (getting the same answer every time).

The environment also matters. Will it be super hot or cold? Is there a lot of electrical noise from other machines? For hot places, you’d need a high temperature eddy current sensor. For noisy places, you might need a sensor with good EMI/RFI shielding or a differential eddy current sensor configuration, which uses two coils to cancel out noise. You also think about the shape and size. A miniature eddy current sensor can fit in tight spaces, while a larger one might be needed for a bigger range.

Can It Find Hidden Flaws in Metal? A Look at NDT

One of the most amazing uses for this technology is finding problems in metal that you can’t see with your own eyes. This is called Non-Destructive Testing (NDT), or sometimes Non-Destructive Evaluation (NDE). It means you can inspect something without having to cut it open or break it.

Eddy current testing (ECT) is a powerful NDT method. Imagine an airplane wing. Over time, tiny cracks can start to form from stress. These cracks are dangerous, but they might be too small to see. To find them, a technician uses a special eddy current transducer probe. They slide the probe over the surface of the wing. Remember how eddy currents are like little whirlpools of electricity? When these swirling currents hit a crack, they have to go around it. This changes the flow, like a rock in a stream.

The sensor instantly detects this change in the flow of eddy currents. The signal conditioning electronics in the testing unit show a blip on a screen, telling the technician, “Hey, there’s something here!” This way, they can find cracks or even areas of corrosion hiding under the paint. This technology is crucial for safety in the aerospace industry and also for checking things like the integrity of a transformer lamination core, which is vital for our power grid. It’s a key part of modern material property characterization.

What’s Inside an Eddy Current Sensor?

An eddy current sensor system seems like magic, but it’s actually made of a few key parts working together. Understanding these components of an eddy current sensor helps you see why it’s so reliable.

The first part is the probe or sensor head. This is the part that you point at the metal target. Inside its protective sensor housing, you’ll find the most important piece: the coil. This is a finely wound wire that creates the magnetic field. The size and shape of this coil are carefully designed to control the measurement range and precision. You might have a simple through-coil eddy current sensor or a more complex absolute eddy current sensor design.

The probe is connected by a cable to the “brains” of the system, which is often called the sensor driver or electronics unit. This box contains all the smart circuits. It has the parts that create the high-frequency signal, measure the impedance change, and convert that change into a useful output. The output could be a simple voltage output, like 0-10 volts, or a current loop output, like 4-20mA, which is common in factories. This unit is what makes the whole system work and provides the final, stable measurement. Simple installation of an eddy current sensor is key for its wide adoption.

The Future is Smart! What’s Next for These Sensors?

Technology is always moving forward, and eddy current sensors are no exception. The future is all about making them smarter, smaller, and easier to use. This is part of a huge trend in manufacturing called Industry 4.0, where machines all talk to each other.

We’re seeing more smart eddy current sensors that have tiny computers built right into them. These sensors can do their own health checks and even calibrate themselves. Some are becoming wireless eddy current sensors, getting rid of clumsy cables and making them easier to install anywhere. This allows for better data acquisition across a whole factory floor.

Engineers are also developing sensors that can work in even tougher conditions, like inside a running jet engine or in a deep-sea oil rig. There are even sensors with advanced digital outputs like EthernetIP eddy current sensor systems that can connect directly to a factory’s computer network. As we build more robots and automated systems, the need for precise, tough, and reliable sensors like these will only grow. They are a key building block for the factories of the future, helping to make products better, faster, and safer for everyone. The use of advanced materials like electrical steel laminations in both sensors and the machines they monitor, such as those with a complex stator and rotor, will continue to push performance boundaries.

Key Takeaways

- What It Is: An eddy current sensor is a tool that uses a magnetic field to measure the distance to a metal object without touching it.

- How It Works: It creates tiny electrical whirlpools (eddy currents) in the metal. By measuring how these currents affect its magnetic field, it knows how far away the object is.

- Main Superpowers: It’s incredibly precise, very fast, and works perfectly in dirty, oily, or wet environments where other sensors would fail.

- Key Limitation: It can only be used to measure or detect conductive materials, like metals.

- Where It’s Used: You can find them everywhere, from checking car parts and airplane wings to making sure the components inside your phone are assembled perfectly.