What is Electrical Steel? Understanding This Essential Material for Modern Electrification

Every engineer, designer, and procurement manager involved with electrical machinery faces a common challenge: maximizing performance and efficiency while keeping a close eye on costs and manufacturability. Whether you’re designing a high-performance electric vehicle motor, a massive power grid transformer, or a compact household appliance, the materials you choose are foundational to success. If you’ve ever found yourself deep in datasheets, weighing the trade-offs between magnetic properties, core losses, and material costs, you’re in the right place. The unsung hero at the heart of this entire electrical ecosystem is a specialized material: electrical steel.

Unlike the structural steel that forms our buildings and bridges, electrical steel is an engineered marvel with a single, critical purpose: to guide and concentrate magnetic fields with minimal energy loss. Getting this choice right means creating a more efficient, cooler-running, and cost-effective product. Getting it wrong can lead to wasted energy, overheating, and subpar performance.

This guide will demystify electrical steel. We’ll break down what it is, why it’s so crucial, how it works its magic, and how to choose the right type for your application. Think of this as your engineering partner’s guide to making smarter, more informed decisions about one of the most important materials in modern technology.

What We’ll Cover in This Guide

- What Exactly is Electrical Steel? A look at its core definition and unique composition.

- The Science Behind Electrical Steel: How it masters magnetic fields and minimizes energy-wasting core losses.

- Types of Electrical Steel: A breakdown of Grain-Oriented (GOES) vs. Non-Grain-Oriented (NGOES) steels.

- How Electrical Steel is Manufactured: The meticulous process that creates its unique properties.

- Key Applications of Electrical Steel: From massive transformers to the motor in your electric car.

- The Impact and Future of Electrical Steel: Why this material is critical for global energy efficiency and technological advancement.

- Your Engineering Takeaway: Key points to remember for your next project.

What Exactly is Electrical Steel? (Definition & Composition)

At its heart, electrical steel—often called silicon steel, lamination steel, or transformer steel—is a specialty alloy designed specifically for its magnetic properties. It’s a type of soft magnetic material, which means it can be easily magnetized and demagnetized without retaining significant magnetism. This is the exact opposite of a “hard” magnetic material, like the neodymium magnets you might find holding things to your fridge, which are designed to stay permanently magnetized.

The magic of electrical steel lies in its unique recipe.

Core Composition: The primary ingredient is, of course, iron. But the secret sauce is the addition of a small, precisely controlled amount of silicon, typically ranging from 0.5% to 6.5% by weight.

The Crucial Role of Silicon: So, why add silicon to steel? The answer is all about fighting an invisible enemy: eddy currents. Adding silicon to the iron alloy significantly increases its electrical resistivity. Think of resistivity as electrical friction. A material with high resistivity, like rubber, makes it very difficult for electricity to flow. A material with low resistivity, like copper, lets it flow easily. By increasing the steel’s resistivity, we make it harder for wasteful eddy currents to form and circulate within the core, which we’ll explore in more detail shortly. This simple addition is one of the most effective ways to reduce energy loss.

Keeping Carbon Out: Just as important as what’s added is what’s removed. The manufacturing process for electrical steel involves reducing the carbon content to extremely low levels (often below 0.005%). Carbon impurities can interfere with the movement of magnetic domains—tiny magnetic regions within the material—and increase a type of energy loss known as hysteresis loss. By keeping the steel pure, we ensure the magnetic field can flip back and forth with minimal resistance.

In short, electrical steel is not just steel. It’s a high-purity iron-silicon alloy, meticulously engineered and processed to serve as an efficient pathway for magnetic flux in alternating current (AC) applications.

The Science Behind Electrical Steel: Mastering Magnetic Properties

To truly appreciate why electrical steel is so essential, we need to understand the forces at play inside every motor, generator, and transformer. When an electric current alternates—as it does in most power systems—it creates a constantly changing magnetic field. The job of the steel core is to contain and direct this magnetic field, but this process isn’t perfectly efficient. Some energy is always lost, primarily as heat. This energy loss is called core loss or iron loss.

Core loss is the arch-nemesis of electrical efficiency, and it comes from two main sources: hysteresis loss and eddy current loss. Electrical steel is engineered specifically to minimize both.

1. Hysteresis Loss: The Cost of Flipping Polarity

Imagine you have a vast collection of tiny compass needles inside a material. These are the magnetic domains. When you apply an external magnetic field, these tiny domains align themselves with it, magnetizing the material. When the AC current reverses direction, the magnetic field flips, and all those tiny domains have to flip around to realign.

This constant reorientation isn’t frictionless. It takes energy to overcome the material’s internal “stickiness,” and this energy is released as heat. This is hysteresis loss.

A material’s resistance to changes in its magnetic state is called coercivity. Materials with low coercivity are easy to magnetize and demagnetize, minimizing this internal friction. The B-H curve, a graph that plots magnetic flux density (B) against magnetic field strength (H), visually represents this. A “thin” hysteresis loop on this graph indicates low coercivity and low hysteresis loss—a hallmark of high-quality electrical steel. The careful alloying and annealing process of silicon steel is designed to create a crystal structure that allows these domains to flip easily, slashing hysteresis losses.

2. Eddy Current Loss: The Unwanted Electrical Whirlpools

This is where silicon’s role becomes crystal clear. According to Faraday’s law of induction, a changing magnetic field will induce an electrical current in any nearby conductor. Since the steel core is itself a conductor, the fluctuating magnetic field creates small, swirling loops of electrical current within it. These are called eddy currents.

Think of eddy currents like tiny, unwanted whirlpools in a river. They do no useful work. Instead, they just spin around, generating heat (due to the material’s resistance) and wasting a tremendous amount of energy.

Electrical steel fights eddy currents in two brilliant ways:

By tackling both hysteresis and eddy current losses, electrical steel allows devices to run cooler, consume less power, and operate far more efficiently than they could with standard carbon steel.

Types of Electrical Steel: Tailored for Specific Applications

Not all electrical applications are the same. The magnetic field in a large power transformer behaves very differently from the field in a high-speed electric motor. To meet these varied demands, electrical steel is produced in two primary forms: Grain-Oriented (GOES) and Non-Grain-Oriented (NGOES).

Grain-Oriented Electrical Steel (GOES)

Imagine a plank of wood. It’s incredibly strong and easy to split along the grain but much weaker if you try to snap it across the grain. Grain-Oriented Electrical Steel works on a similar principle, but for magnetism.

Through a complex process of rolling and annealing, the microscopic crystal grains within the steel are aligned in a uniform direction, known as the “Goss texture.” This alignment creates a path of least resistance for the magnetic flux.

- Characteristics: GOES is anisotropic, meaning its magnetic properties are direction-dependent. It has exceptionally high magnetic permeability (the ability to support the formation of a magnetic field) and extremely low core loss, but only when the magnetic flux travels parallel to the grain direction.

- Benefits: Unmatched efficiency in predictable, unidirectional magnetic fields.

- Primary Applications: This makes GOES the undisputed material of choice for power and distribution transformers. In a transformer, the magnetic flux flows in a well-defined loop through the core, allowing designers to align the steel’s grain direction perfectly with the flux path. You’ll find it in the transformer lamination core of nearly every transformer connected to the power grid.

Non-Grain-Oriented Electrical Steel (NGOES)

If GOES is like a plank of wood, Non-Grain-Oriented Electrical Steel is like a block of high-quality particleboard. Its properties are the same no matter which direction you test it.

In NGOES, the crystal grains are randomly oriented. This means it doesn’t have a single “easy” direction for magnetism. Instead, it offers good, consistent magnetic properties in all directions within the plane of the sheet.

- Characteristics: NGOES is isotropic. While its peak magnetic properties aren’t as high as GOES in its optimal direction, it provides reliable and uniform performance regardless of how the magnetic field is applied.

- Benefits: Consistent performance in applications with rotating or multi-directional magnetic fields.

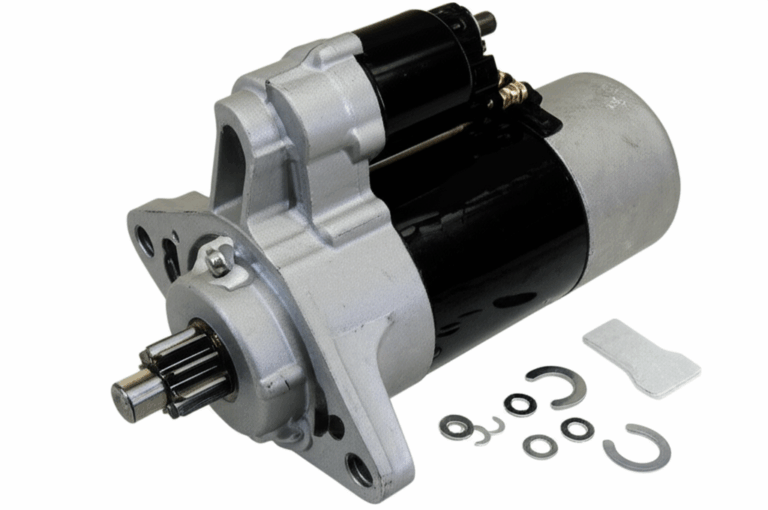

- Primary Applications: NGOES is the workhorse material for all types of rotating electrical machinery. This includes the cores for electric motors, generators, and alternators. In a motor, the magnetic field is constantly rotating, so a material that performs equally well in all directions is essential. From the massive generators in hydroelectric dams to the traction motor in an electric vehicle, NGOES provides the performance needed. It is the fundamental material used in motor core laminations worldwide.

Advanced and Emerging Alternatives

While GOES and NGOES dominate the market, research is always pushing forward. For high-frequency applications like those found in advanced power electronics and some specialty motors, even thinner materials with lower losses are required. This has led to the development of:

- Amorphous Metals: These have a non-crystalline, glass-like structure that eliminates grain boundaries, resulting in extremely low hysteresis losses. They are often used in high-efficiency distribution transformers.

- Nanocrystalline Materials: These materials start as amorphous ribbons and are then heat-treated to form ultra-fine grains, offering excellent high-frequency performance.

How Electrical Steel is Manufactured: From Ore to Lamination

Creating a material with such precise magnetic properties is a far more involved process than making simple structural steel. Each step is carefully controlled to build the desired microstructure and chemistry.

From this carefully produced steel coil, individual laminations are then stamped or laser-cut into the precise shapes needed for a motor’s stator and rotor or a transformer’s core before being stacked and assembled.

Key Applications of Electrical Steel: Powering Modern Life

Electrical steel is so pervasive in our energy infrastructure that it’s easy to overlook. Yet, without it, the modern world would grind to a halt. Its applications are foundational to how we generate, transport, and use electricity.

- Transformers: This is the largest single market for electrical steel, particularly GOES. Transformers are essential for stepping voltage up for efficient long-distance transmission and then stepping it down for safe use in homes and businesses. The efficiency of the entire power grid is heavily dependent on the low core losses of the electrical steel used in these devices.

- Electric Motors & Generators: From the fractional horsepower motors in your kitchen blender to the multi-megawatt generators in a power plant, NGOES is the core material of choice. It enables the efficient conversion of electrical energy into mechanical motion (motors) and vice-versa (generators). Its use is critical in industrial machinery, HVAC systems, pumps, and countless other applications.

- Electric Vehicles (EVs): The rise of electrification has created a massive new demand for high-performance NGOES. The traction motor is the heart of an EV, and its efficiency directly impacts the vehicle’s range and performance. Automakers are constantly pushing for advanced electrical steel grades that offer lower losses at the high frequencies and operating temperatures found in modern EV powertrains.

- Power Electronics and Inductors: Inverters, power supplies, and other electronic devices use magnetic components like inductors and chokes to store and filter energy. Electrical steel, often in very thin gauges or as a powdered core, is used to make these components compact and efficient.

- Renewable Energy Systems: Electrical steel is a cornerstone of the green energy transition. It’s essential for the large generators inside wind turbines and plays a vital role in the inverters and transformers needed to connect solar farms and other renewable sources to the smart grid.

The Impact and Future of Electrical Steel

The global impact of this specialized material is difficult to overstate. It’s estimated that core losses in electrical devices account for several percent of all electricity generated worldwide. Every incremental improvement in the quality of electrical steel translates into enormous energy savings, lower electricity bills for consumers, and a significant reduction in greenhouse gas emissions from power generation.

The industry is not standing still. Research and development continue to push the boundaries of performance:

- Ultra-Low Loss Materials: Manufacturers like Nippon Steel, POSCO, and ThyssenKrupp are constantly refining their processes to produce GOES and NGOES grades with ever-lower core losses.

- High-Frequency Steels: As power electronics and motors operate at higher switching speeds to become smaller and more efficient, the demand for thin-gauge electrical steel that performs well at higher frequencies is skyrocketing.

- Improved Processing and Sustainability: Innovation is also focused on making the production of electrical steel more environmentally friendly and developing new coatings and processing techniques that improve the final performance of the assembled core.

Your Engineering Takeaway: The Indispensable Foundation

Electrical steel is far more than just “steel.” It is a highly engineered material that forms the invisible backbone of our electrical world. Understanding its fundamental properties and the differences between its main types is no longer optional—it’s essential for any engineer or designer working on electrical applications.

Here are the key points to remember:

- Purpose-Built for Magnetics: Electrical steel is an iron-silicon alloy specifically designed to be a “soft” magnetic material, making it easy to magnetize and demagnetize with minimal energy loss.

- Core Loss is the Enemy: Its primary job is to reduce core losses, which come from two sources: hysteresis (internal magnetic friction) and eddy currents (wasteful electrical whirlpools).

- Silicon and Laminations are Key: Silicon increases electrical resistivity to fight eddy currents, while stacking thin, insulated laminations breaks up their path.

- GOES vs. NGOES: Choose Grain-Oriented (GOES) for static applications with a predictable, one-way magnetic path, like transformers. Choose Non-Grain-Oriented (NGOES) for rotating machines like motors and generators, where the magnetic field is constantly changing direction.

- Application Drives Selection: The right grade of electrical steel depends entirely on your application’s operating frequency, required flux density, efficiency targets, and cost constraints.

By grasping these concepts, you are better equipped to analyze material datasheets, understand performance trade-offs, and have more productive conversations with your material suppliers and manufacturing partners. This knowledge empowers you to make design choices that lead to more efficient, reliable, and innovative electrical products, helping to build a more sustainable and electrified future.