What is Electro Galvanized Steel? Understanding the Process, Benefits, and Applications

As an engineer or designer, you’re constantly making critical choices about materials. You’re balancing durability, cost, performance, and aesthetics. When your project demands corrosion resistance but also needs a flawless surface finish for painting or a visible application, you’ve likely come across a specific material: electro galvanized steel. But what exactly is it? And how do you know if it’s the right choice over its more common cousin, hot-dip galvanized steel?

If you’ve ever wrestled with specifying a coated steel that can be stamped into a complex shape without the coating flaking off, or one that provides a perfect canvas for a Class-A finish, you’re in the right place. This guide will break down the entire world of electro galvanized steel, from the science behind its creation to its practical applications, empowering you to make a more confident and informed decision for your next project.

In This Article

- Defining Electro Galvanized Steel

- The Electro-Galvanizing Process: How It’s Made

- Key Characteristics and Properties

- Advantages of Electro Galvanized Steel

- Disadvantages and Limitations

- Electro Galvanizing vs. Hot-Dip Galvanizing: A Key Comparison

- Common Applications of Electro Galvanized Steel

- Standards and Specifications

- The Role of Electro Galvanized Steel in Modern Manufacturing

Introduction: Defining Electro Galvanized Steel

At its core, electro galvanized (EG) steel is a type of carbon steel sheet coated with a thin, uniform layer of pure zinc. The magic happens through an electrochemical process called electroplating. Think of it less like dipping something in a vat of paint and more like a highly controlled, electrically-charged process that bonds zinc to steel one ion at a time.

The primary purpose of this zinc layer is to provide corrosion resistance. Zinc is more reactive than steel, so it acts as a “sacrificial anode.” This means when exposed to corrosive elements like moisture, the zinc coating will corrode first, sacrificing itself to protect the underlying steel from rust. However, what sets electro-galvanizing apart is the quality and precision of that coating. It delivers a smooth, bright, and aesthetically pleasing surface finish that is unmatched by other galvanizing methods.

The Electro-Galvanizing Process: How It’s Made

Creating electro galvanized steel isn’t just a simple dip; it’s a sophisticated, multi-stage process that happens on a continuous galvanizing line. A coil of steel is unwound at one end and systematically transformed, step-by-step, before being recoiled at the other end.

Step 1: Substrate Preparation

You can’t apply a perfect coating to a dirty surface. The first and most critical step is preparing the cold-rolled steel substrate. The steel coil is passed through a series of stations designed to make it impeccably clean.

- Degreasing: Alkaline cleaning baths remove any oil, grease, or dirt from the steel’s surface.

- Pickling: The steel then moves through a mild acid bath (a process called pickling) to remove any surface oxides or mill scale.

- Rinsing: Thorough rinsing between each stage ensures no residual chemicals contaminate the next step.

A perfectly clean surface is essential for strong adhesion of the zinc coating. Any imperfection here will compromise the final product.

Step 2: Electrolytic Coating

This is the heart of the electro-galvanizing process. The prepared steel strip enters an electrolytic cell filled with an electrolyte solution, which is typically a salt solution containing zinc ions (like zinc sulfate).

Here’s how the electrochemical reaction works:

- The steel strip is connected to the negative terminal of a power source, making it the cathode.

- Large zinc slabs (or insoluble anodes, with zinc constantly replenished in the solution) are connected to the positive terminal, becoming the anode.

- When a direct electric current is applied, a circuit is completed through the electrolyte. This causes the positively charged zinc ions in the solution to migrate and deposit evenly onto the negatively charged surface of the steel strip.

Think of it like using a magnet to precisely arrange iron filings. The electric current provides the “magnetic” force that pulls the zinc ions out of the solution and bonds them atom-by-atom to the steel. The amount of zinc deposited is controlled with incredible precision by adjusting the electric current density and the speed of the steel strip moving through the cell.

Step 3: Post-Treatment

Once coated, the steel isn’t quite finished. It undergoes a few final steps to enhance its properties and prepare it for its end-use.

- Rinsing and Drying: The strip is rinsed again to remove any remaining electrolyte solution and then thoroughly dried.

- Passivation: A crucial step for many applications is the application of a passivation layer, often a chromate conversion coating or a more modern, environmentally friendly chromate-free alternative. This thin chemical layer does two things: it significantly boosts the corrosion resistance of the zinc, preventing the formation of “white rust” (zinc oxide), and it primes the surface for excellent paint adhesion.

- Oiling: A light protective oil film may be applied to provide further protection during transportation and storage.

Step 4: Quality Control

Throughout the entire process, sensors and technicians monitor key variables. They meticulously check the coating thickness, uniformity, adhesion strength, and surface finish to ensure the final product meets strict material specifications and customer requirements.

Key Characteristics and Properties

The unique manufacturing process of electro galvanized steel gives it a distinct set of properties that make it the ideal choice for specific applications.

- Superior Surface Finish: This is arguably its biggest advantage. The electroplating process results in a smooth, bright, and spangle-free surface. It’s uniform and highly aesthetic, making it perfect for products where appearance is critical.

- Precise Coating Thickness: Unlike hot-dip galvanizing, which builds up a thick and somewhat variable layer, electro-galvanizing allows for precise control over the zinc layer’s thickness. Coatings are typically much thinner, often ranging from 1 to 10 micrometers (µm). This precision is vital for components with tight tolerances.

- Excellent Formability and Weldability: Because the zinc coating is thin, uniform, and strongly bonded to the steel substrate, it demonstrates exceptional ductility. This means the steel can be bent, stamped into complex shapes, or deep-drawn without the zinc layer cracking or flaking off. It also maintains good weldability.

- Corrosion Resistance: The sacrificial zinc layer provides reliable protection against red rust formation in mild to moderate environments. While not as robust as the thick coatings from hot-dipping for harsh outdoor use, it’s more than sufficient for indoor applications or as a base for further painting.

- Good Paint Adhesion: The combination of a uniform surface and a passivation post-treatment makes EG steel an excellent substrate for painting, e-coating, and powder coating. The paint adheres strongly, resulting in a durable and high-quality finish.

Advantages of Electro Galvanized Steel

When you’re deciding on a material, it helps to see the pros laid out clearly. Here’s where EG steel truly shines:

Disadvantages and Limitations

Of course, no material is perfect for every situation. It’s just as important to understand the limitations of electro galvanized steel.

Electro Galvanizing vs. Hot-Dip Galvanizing: A Key Comparison

Understanding the difference between electro-galvanizing (EG) and hot-dip galvanizing (HDG) is critical for any engineer or designer. They are fundamentally different processes that yield products suited for very different applications.

| Feature | Electro Galvanizing (EG) | Hot-Dip Galvanizing (HDG) |

|---|---|---|

| Process | Electrochemical deposition of zinc in an electrolyte solution. | Immersing steel in a bath of molten zinc (~450°C / 842°F). |

| Coating Thickness | Thin & Precise: Typically 1-10 µm. Excellent control. | Thick & Robust: Typically 45-100 µm or more. Less precise control. |

| Surface Quality | Smooth, bright, uniform, spangle-free. Ideal for painting. | Rougher, can have a crystalline “spangle” pattern. Less aesthetic. |

| Corrosion Protection | Good. Suited for indoor or mild environments. Perfect as a paint base. | Excellent. Suited for harsh outdoor, industrial, and marine environments. |

| Formability | Excellent. Thin, ductile coating adheres during severe bending and stamping. | Good to Fair. Thicker, more brittle alloy layers can crack or flake during severe forming. |

| Cost | Higher initial material cost but can reduce finishing costs. | Lower initial material cost but may require more surface prep for painting. |

| Typical Use Case | Automotive body panels, appliance casings, electronics enclosures. | Structural steel, guardrails, outdoor fasteners, utility poles. |

In short, you choose EG for finish and formability and HDG for brute-force corrosion protection.

Common Applications of Electro Galvanized Steel

Given its unique properties, it’s no surprise that electro galvanized steel is a go-to material in industries where precision and appearance are paramount.

Automotive Industry

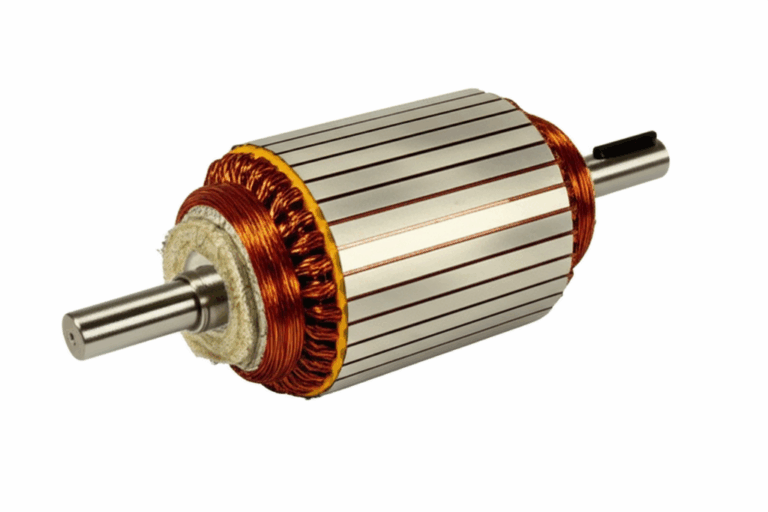

This is a huge market for EG steel. Its superior formability and paintability make it the perfect choice for visible parts like outer body panels, doors, hoods, and fenders. It allows automakers to create complex, aerodynamic shapes and achieve a flawless, durable paint finish. It’s also used for internal components and fuel tanks. While the body panels are EG steel, it is fascinating to note that the powertrains of modern electric vehicles rely on completely different materials, such as specialized electrical steel laminations which are essential for motor efficiency.

Appliance Manufacturing

Take a look at your refrigerator, washing machine, or microwave. The smooth, painted casings are very likely made from electro galvanized steel. The material can be easily formed into the required shapes and provides a perfect, clean surface for the durable enamel or powder coatings that define “white goods.”

Electronics

The case of your desktop computer, the rack holding servers in a data center, or the electrical switchbox in your wall—all of these enclosures are common applications. EG steel provides the necessary structural integrity, corrosion resistance for indoor use, and a clean finish. More critically, while the casing provides protection, the performance of the electronics inside often depends on components like a transformer lamination core to manage power effectively.

Construction (Interior/Light Duty)

While heavy structural components rely on hot-dip galvanizing, EG steel finds its place in interior applications. This includes HVAC ductwork, interior wall paneling, ceiling grids, lighting fixtures, and metal studs. Its clean surface and formability are key advantages here. The internal mechanics of building systems, such as elevator motors, again require different specialized parts like a stator core lamination to function.

Other Uses

The versatility of EG steel extends to countless other products, including office furniture components, retail shelving, signage, and metal doors.

Standards and Specifications

When you’re sourcing electro galvanized steel, it’s crucial to refer to industry standards to ensure you’re getting the right product. These standards define everything from the chemical composition of the steel to the required coating weight and mechanical properties.

Some of the most common standards include:

- ASTM A879/A879M: The standard specification for steel sheet, zinc coated (electrogalvanized) for applications requiring designation of coating mass on each surface.

- JIS G3313: A widely used Japanese Industrial Standard for electrogalvanized steel sheets and coils.

These documents specify coating weight designations (e.g., A60, G60) that tell you how much zinc is on the surface. Working with your supplier to specify the correct standard and coating weight for your application is a critical step in the procurement process.

Conclusion: The Role of Electro Galvanized Steel in Modern Manufacturing

Electro galvanized steel isn’t just another coated metal; it’s a high-performance material that solves a specific set of engineering challenges. It bridges the gap where you need reliable corrosion protection but simply cannot compromise on surface quality or formability. Its value isn’t just in the raw material itself but in the downstream benefits it provides—less prep work for painting, flawless aesthetic finishes, and the ability to create complex, precisely engineered parts.

Your Engineering Takeaway

To wrap it all up, here are the key points to remember when considering electro galvanized steel:

- Process is Key: It’s made by electroplating, a precise process that yields a thin, uniform, and smooth zinc coating.

- Think Finish and Form: Its primary advantages are a superior surface finish ideal for painting and excellent ductility for stamping and forming.

- Know Its Limits: It offers good corrosion protection for mild environments but is not a substitute for heavy hot-dip coatings in harsh outdoor conditions.

- Choose by Application: It’s the go-to material for automotive bodies, appliances, electronics enclosures, and other applications where aesthetics and precision matter. Just as you’d select EG for a casing, you’d rely on precisely engineered motor core laminations for the powertrain inside.

By understanding the unique balance of properties that electro galvanized steel offers, you are now better equipped to specify the right material, have more productive conversations with suppliers, and design products that are both durable and beautifully finished.