What is Electro Steel? Understanding Electric Arc Furnace (EAF) Steel

Have you ever wondered what the super-strong, high-quality metal in race cars, airplanes, or even a doctor’s tools is made of? Often, it’s a special kind of steel called electro steel. It’s not magic, but it’s made in a really cool way that’s different from old-school steelmaking. In this guide, I’ll walk you through everything you need to know about it. We’ll uncover how it’s made, why it’s so important for modern life, and how it’s helping our planet. You’ll see that electro steel is a true hero in the world of materials.

Table of Contents

- What Does “Electro Steel” Actually Mean?

- How is Electro Steel Made? The Amazing Electric Arc Furnace (EAF) Process

- What Makes Electro Steel So Special?

- Why is Making Electro Steel a Smart Idea?

- Where Can You Find Electro Steel in Your Daily Life?

- Electro Steel vs. Old-School Steel: What’s the Difference?

- What’s Next for Electro Steel? A Look into the Future

- Conclusion: Why Electro Steel is a Modern-Day Hero

What Does “Electro Steel” Actually Mean?

Let’s start with the basics. Electro steel is just another name for steel made using electricity. Think of it like cooking on an electric stove instead of a wood fire. The official name for the process is Electric Arc Furnace (EAF) steelmaking. It’s a modern method that’s great at recycling and making very specific types of steel.

The main problem with older methods is that they often start with raw iron ore dug from the ground and use a giant, hot, and dirty machine called a blast furnace. This creates a lot of pollution and isn’t very flexible. Imagine having to bake a huge batch of 1,000 cookies when you only need a dozen special ones. It’s wasteful and inefficient. This lack of flexibility makes it hard to create the specialty steel needed for high-tech gadgets and strong, lightweight cars.

This is where electro steel comes in as the solution. It doesn’t rely on a giant blast furnace. Instead, it uses a powerful electric furnace to melt down old steel, like junk cars and old washing machines, turning them into brand-new, high-quality steel. This makes it a key part of the circular economy in steel, where we reuse materials again and again. It’s like being a super-recycler for one of the world’s most important materials.

How is Electro Steel Made? The Amazing Electric Arc Furnace (EAF) Process

So, how does this electric magic happen? It all takes place inside an Electric Arc Furnace, or EAF. It’s a giant, pot-shaped furnace with a lid that can be lifted off. Let me break down the process step-by-step. It’s a lot like making a cake, but with thunderously hot metal!

Step 1: Gathering the Ingredients

First, you need your raw materials. The main ingredient is scrap metal. This is all the old steel that gets recycled. It can be anything from old beams from a building to shredded cars. Sometimes, they also add something called Direct Reduced Iron (DRI) or Hot Briquetted Iron (HBI), which is iron made without a blast furnace. These are the “flour” and “sugar” of our steel recipe.

Step 2: Melting It All Down

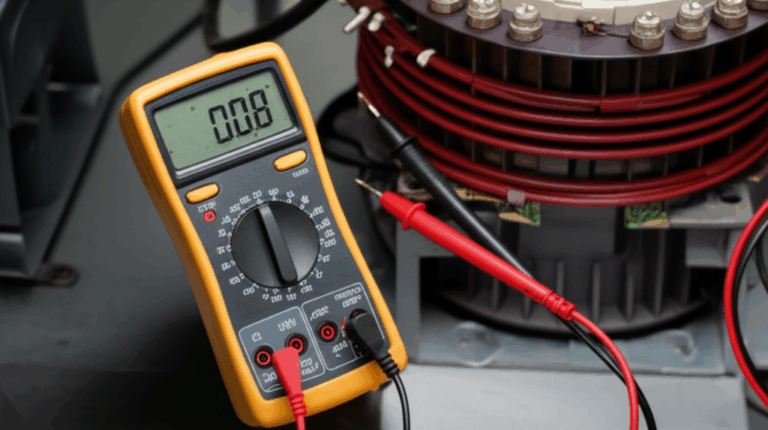

The scrap metal is loaded into the EAF. Then, giant rods called graphite electrodes are lowered into the furnace. When the power is turned on, a massive bolt of electricity jumps from the electrodes to the metal. This is the “electric arc,” and it’s hotter than the surface of the sun! This incredible heat melts the scrap steel into a glowing, liquid pool. This steel scrap melting process is at the heart of EAF technology.

Step 3: Cleaning and Refining the Steel

Once the steel is melted, it’s time to clean it up. The steel might have things in it that we don’t want, like too much carbon or other impurities. To get rid of them, workers use oxygen blowing, shooting pure oxygen into the liquid steel. The oxygen burns away the unwanted bits. These impurities float to the top and form a layer of gunk called slag. The slag is scraped off, leaving behind cleaner, purer steel. This stage is called secondary metallurgy and it’s where the real quality control happens.

Step 4: Adding the Final Touches and Casting

Now the steel is clean, but it might not be the exact type we need. In a separate container called a ladle furnace, workers can add alloying elements. These are other metals like chromium, nickel, or molybdenum that give the steel special powers, like making it rust-proof (stainless steel) or extra tough (tool steel). Once the chemical composition is perfect, the liquid steel is poured into a machine for continuous casting. This shapes the steel into long bars, beams, or slabs, ready to be used.

What Makes Electro Steel So Special?

You might be thinking, “Steel is steel, right?” Not quite. The way electro steel is made gives it some amazing properties that are hard to get with older methods. This is why it’s so popular for high-performance jobs.

One of the biggest deals is purity. The EAF process gives steelmakers amazing control. They can remove tiny, unwanted bits called non-metallic inclusions. Fewer of these “dirt” particles mean the final steel is stronger and more reliable. It’s like baking with carefully sifted flour instead of flour with lumps and bits in it. This results in clean steel technology that you can trust.

This purity leads to fantastic mechanical properties. Depending on the recipe, electro steel can have incredible high strength, toughness, and fatigue strength. This means it can bend without breaking and last a long time even when it’s under a lot of stress. That’s why it’s a top choice for making precision steel components that have to perform perfectly every single time.

Finally, the process is incredibly versatile. Steelmakers can create hundreds of different types of steel, from alloy steel for engine parts to bearing steel for things that spin. They can make high-strength low-alloy (HSLA) steel for cars or stainless steel for medical implants. This ability to create so many different grades makes EAF the go-to for advanced materials that power our modern world.

Why is Making Electro Steel a Smart Idea?

Making electro steel isn’t just cool; it’s also a very smart choice for several reasons. The advantages go way beyond just making good steel.

The most important benefit is for our planet. The environmental impact of EAF steel is much lower than traditional methods. Because it mainly uses recycled scrap metal, it saves tons of natural resources. We don’t have to dig as much iron ore and coal out of the ground. Plus, the carbon footprint of EAF steel is way smaller. An EAF can release about 75% less CO2 than a blast furnace to make the same amount of steel. This makes it a cornerstone of green steel and the decarbonization of the steel industry.

Another big plus is flexibility. An EAF can be turned on and off much more quickly than a giant blast furnace, which has to run 24/7. This means a steel mill can make smaller batches of specialty steel when needed. They can change the recipe or “grade” of steel from one batch to the next. This is perfect for today’s world, where companies need custom materials fast.

Finally, it can be more cost-effective. Building a brand-new steel mill with a blast furnace costs billions of dollars. An EAF plant, or “mini-mill,” is smaller and cheaper to build. And since its main fuel is electricity, it can take advantage of cheaper power at night. Its high energy efficiency makes it a smart business choice, especially in regions with lots of scrap and reliable electricity.

Where Can You Find Electro Steel in Your Daily Life?

You might be surprised by how much electro steel is all around you. Its unique properties make it perfect for a huge range of applications.

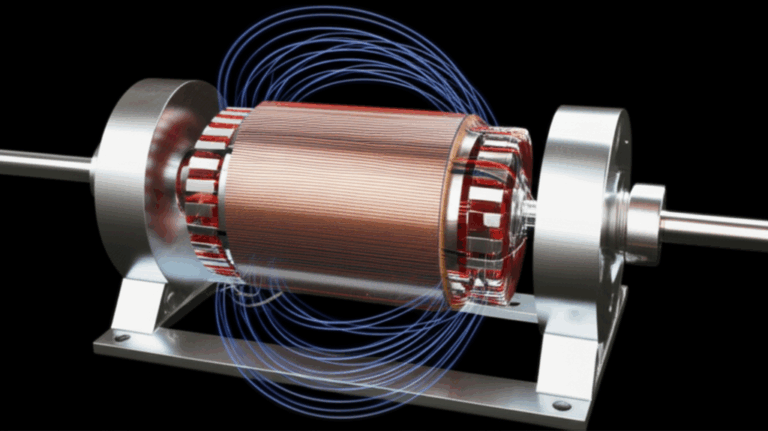

Let’s look at the automotive industry. Cars today need to be both safe and light to save fuel. Makers of advanced high-strength steels (AHSS) use EAFs to create strong steel for car frames, keeping you safe without weighing the car down. This high-purity steel is also critical for manufacturing high-performance electric motors, where the quality of the motor core laminations directly impacts efficiency and power.

In the aerospace industry, there’s no room for error. Parts for airplanes and rockets must be incredibly strong and reliable. Electro steel is used for landing gear, engine parts, and other critical components that have to withstand extreme forces. Its thermal stability makes it perfect for these high-heat jobs.

Even in medicine, electro steel plays a life-saving role. Surgical tools and medical implants, like artificial hips, are often made from special grades of EAF stainless steel. Its excellent corrosion resistance means it won’t rust inside the human body, and its high purity ensures it’s safe.

Here’s a quick list of other places you’ll find it:

- Energy Sector: In parts for power plants and oil and gas drilling equipment.

- Tools and Dies: For the super-hard tool steel used to cut and shape other metals.

- Construction: In special types of rebar and structural beams for buildings and bridges.

- Consumer Goods: In high-quality knives, appliances, and other household items.

From cars to scalpels, the versatility and quality of electric steel make modern life possible.

Electro Steel vs. Old-School Steel: What’s the Difference?

To really understand electro steel, it helps to compare it to the traditional way of making steel, which uses a Basic Oxygen Furnace (BOF). They both make great steel, but they are very different tools for different jobs. Imagine one is a nimble race car and the other is a giant freight train.

The biggest difference is the raw materials. A BOF acts like a freight train, using mostly brand-new iron made from iron ore in a blast furnace. An EAF is more like a recycling truck, using mostly old, recycled scrap steel. This is the main reason for their different environmental impacts.

Another key difference is what they are best at making. The BOF process is great for making huge amounts of simple, common steels, like the kind used for car bodies or building materials. It’s a powerhouse for commodity steels. The EAF process, however, is a master of specialty steels. Its precise control over temperature and chemistry makes it perfect for creating complex alloy and stainless steels.

Let’s put it in a simple table.

| Feature | Electro Steel (EAF) | Traditional Steel (BOF) |

|---|---|---|

| Main Ingredient | Recycled Steel Scrap | New Iron from Iron Ore |

| Energy Source | Electricity | Coal and Coke |

| CO2 Emissions | Lower | Higher |

| Best For | Specialty & High-Quality Steel | Large Amounts of Common Steel |

| Flexibility | High (Small batches, quick changes) | Low (Large batches, runs 24/7) |

| Common Name | Mini-Mill | Integrated Steel Mill |

Both methods are important, but as we look for more sustainable and high-tech solutions, the EAF’s global market share continues to grow.

What’s Next for Electro Steel? A Look into the Future

The future for electro steel is incredibly bright. As the world pushes for a cleaner environment and more advanced technology, the EAF process is set to become even more important.

One of the most exciting trends is the move toward even “greener” steel. Researchers are working on powering EAFs with renewable energy, like solar and wind. Another huge innovation is using hydrogen instead of natural gas to make Direct Reduced Iron (DRI). When you combine hydrogen-made DRI with a renewable-powered EAF, you can make steel with almost zero CO2 emissions! This is the future of sustainable steelmaking.

Technology is also making the furnaces smarter. Automation in EAF operations, along with data analytics, is helping steelmakers fine-tune the process. They can predict when equipment might need repairs (predictive maintenance) and control the steel’s chemistry with incredible precision. This means even better quality and less waste. Companies are focused on creating excellent electrical steel laminations which are essential for everything from power grids to electric vehicles.

The demand for high-performance steel isn’t slowing down. From electric cars to wind turbines, almost every part of our future relies on the kind of advanced, specialty steels that EAFs excel at making. The ability to produce ultra-low carbon EAF steel and control elements like nitrogen will continue to drive innovation. In short, electro steel isn’t just part of the present; it’s building a cleaner, stronger future. This is particularly important for devices like transformers, where a high-quality transformer lamination core is needed for efficiency. The relationship between the stator and rotor in a motor is also highly dependent on the quality of the steel used.

Conclusion: Why Electro Steel is a Modern-Day Hero

So, what is electro steel? It’s more than just metal. It’s a smarter, cleaner, and more flexible way to make one of the most useful materials on Earth. By using electricity to recycle old steel into new, high-performance products, the Electric Arc Furnace process solves many of the problems of traditional steelmaking.

It gives us the strong, pure, and specialized steel needed for everything from life-saving medical devices to the spaceships that explore our universe. It helps us build a more sustainable world by reducing pollution and saving natural resources. It’s a perfect example of how innovation can help both industry and the environment at the same time.

The next time you see a sleek electric car, a giant wind turbine, or a shiny new building, take a moment to think about the amazing journey of the steel inside it. Chances are, it began its new life as electro steel, melted by lightning in a giant furnace, ready to build our modern world.

Key Things to Remember

- Electro steel is made in an Electric Arc Furnace (EAF) using electricity.

- Its main ingredient is recycled scrap metal, which is great for the environment.

- The EAF process produces high-purity, high-quality steel with excellent properties.

- It’s very flexible, allowing steelmakers to create many different types of specialty steel.

- Electro steel has a much lower carbon footprint than steel made in a traditional blast furnace.

- You can find it in cars, airplanes, medical tools, and many other modern products.