What is IE3 Motor Efficiency? A Comprehensive Guide to Premium Efficiency Motors

I’ve spent over two decades working in and around industrial facilities, from bustling manufacturing floors to the quiet hum of commercial HVAC rooms. If there’s one thing I’ve learned, it’s that the invisible workhorses of our world are electric motors. They power everything. But for years, we treated them like simple commodities. We’d burn one out, and we’d just buy the cheapest replacement. That mindset, I can tell you from experience, is a costly mistake.

The game changed when I first started digging into motor efficiency standards, specifically IE3. It wasn’t just another piece of jargon; it was a fundamental shift in how we should think about energy, cost, and reliability. In this guide, I want to walk you through everything I’ve learned about IE3 motor efficiency. We’ll break it down in simple terms, look at why it’s so important, and figure out how it impacts your bottom line.

Table of Contents

- Introduction: The Drive for Efficiency – What is IE3 Motor Efficiency?

- Decoding IE3: Understanding the Premium Efficiency Standard

- The IE Efficiency Spectrum: IE1, IE2, IE3, IE4 & Beyond (A Quick Comparison)

- Why IE3 Matters: Tangible Benefits of Premium Efficiency Motors

- IE3 Regulations and Global Adoption: What You Need to Know

- Key Applications Benefiting from IE3 Motors

- Making the Switch: Considerations for Upgrading to IE3 Motors

- Conclusion: IE3 – A Foundation for Sustainable Industrial Operations

Introduction: The Drive for Efficiency – What is IE3 Motor Efficiency?

Let’s start with a staggering fact. According to the International Energy Agency (IEA), electric motors are responsible for a massive chunk of global electricity consumption—somewhere around 45-50%. In the industrial sector, that number jumps to a whopping 70%. When you realize that, the efficiency of these motors stops being a minor detail and starts becoming a major global issue.

So, what is IE3 motor efficiency?

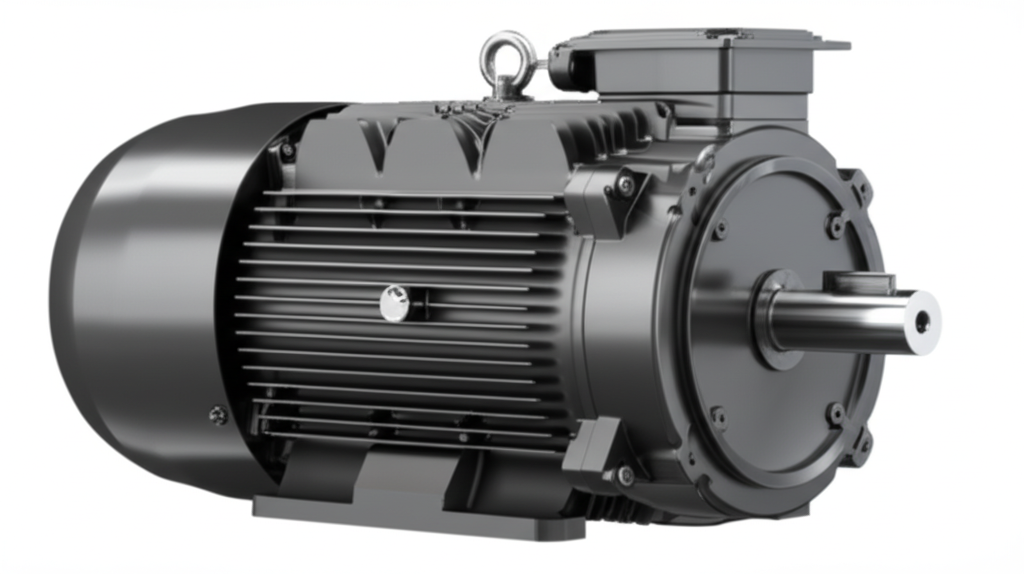

Simply put, IE3 is an international standard that defines “Premium Efficiency” for electric motors. It’s part of a larger classification system designed to help us easily identify how much energy a motor converts into useful work versus how much it wastes as heat. An IE3 motor is significantly more efficient than older motors, meaning it uses less electricity to do the same job. Think of it like the miles-per-gallon rating on a car. An IE3 motor is the fuel-efficient sedan, while an older IE1 motor is the gas-guzzling SUV from the 90s. Both will get you there, but one will cost you a lot less at the pump.

Decoding IE3: Understanding the Premium Efficiency Standard

The world of motor standards can feel like alphabet soup, but it’s actually quite logical once you break it down. Let’s decode what “IE3” really means.

The “IE” Classification System

The “IE” stands for International Efficiency. It’s a classification system established by the International Electrotechnical Commission (IEC) in their standard IEC 60034-30-1. Before this standard, different regions and manufacturers had their own ways of defining efficiency, which made comparing motors a real headache. I remember trying to spec out motors for a multinational project and having to cross-reference NEMA standards from the US with CEMEP standards in Europe. It was confusing.

The IEC created the IE code to harmonize these standards globally, giving us a single, clear language for motor efficiency.

What Does the “3” Signify?

The number in the IE code tells you the efficiency level. It’s a simple scale: the higher the number, the better the efficiency.

- IE1 is “Standard Efficiency.” These are the older, less efficient motors that were common for decades.

- IE2 is “High Efficiency.” This was a good step up from IE1.

- IE3 is “Premium Efficiency.” This is the current benchmark in most developed countries for new motor installations.

- IE4 is “Super Premium Efficiency.” This class represents the next generation of motor technology.

- IE5 is “Ultra Premium Efficiency,” pushing the very limits of what’s possible with current designs.

So, when you see “IE3,” you know you’re looking at a motor designed to have significantly lower energy losses than an IE1 or IE2 model.

How is Efficiency Measured?

At its core, motor efficiency is a simple ratio: (Mechanical Output Power / Electrical Input Power) x 100%.

Imagine you put 100 kilowatts (kW) of electrical energy into a motor. If the motor delivers 92 kW of rotational power to its shaft, its efficiency is 92%. The missing 8 kW didn’t just disappear; it was lost, primarily as heat, due to things like electrical resistance in the windings and friction in the bearings.

An IE3 motor is designed to minimize these losses. Manufacturers like Siemens, ABB, and WEG achieve this through better design and materials. This includes using more high-quality copper in the windings, employing better electrical steel laminations in the core, designing a smaller air gap between the stationary and rotating parts, and installing higher-quality bearings. It’s a combination of small improvements that add up to a big difference in performance.

The IE Efficiency Spectrum: IE1, IE2, IE3, IE4 & Beyond (A Quick Comparison)

To really understand the value of IE3, you need to see it in context. Let’s compare the different efficiency classes. The difference between them might seem small in percentage points, but over thousands of hours of operation, those small percentages translate into massive energy and cost savings.

Here’s a quick look at the typical efficiency for a common 11 kW (15 HP), 4-pole motor:

| Efficiency Class | Designation | Typical Efficiency (11 kW motor) | Notes |

|---|---|---|---|

| IE1 | Standard Efficiency | ~88.6% | Now phased out in many countries for new installations. |

| IE2 | High Efficiency | ~90.4% | A good improvement, but now superseded by IE3 in many regions. |

| IE3 | Premium Efficiency | ~91.8% | The current mandatory standard in the EU and US. |

| IE4 | Super Premium Efficiency | ~93.2% | The next frontier, often required for specific power ranges. |

| IE5 | Ultra Premium Efficiency | >94-95% | Emerging technology, often using different motor designs. |

That 1.4% jump from IE2 to IE3 doesn’t sound like much, does it? But let’s do some quick math. For that 11 kW motor running 6,000 hours a year (a common scenario for a factory), that small efficiency gain saves over 900 kWh of electricity annually. At an average industrial electricity rate, that’s real money back in your pocket from just one motor. Now multiply that across dozens or hundreds of motors in a facility. It adds up fast.

Why IE3 Matters: Tangible Benefits of Premium Efficiency Motors

When I first started advocating for upgrading to IE3 motors, the main pushback was always the higher upfront cost. And it’s true, an IE3 motor costs more than an IE2 model. But I quickly learned to reframe the conversation around the Total Cost of Ownership (TCO), because that’s where the real story is.

A motor’s purchase price is a tiny fraction of its lifetime cost. The European Copper Institute estimates that for an industrial motor, the initial price is only about 1-3% of its TCO. The other 97% is the cost of the electricity it consumes over its life.

Let that sink in.

Once you understand that, choosing a more efficient motor becomes a no-brainer. Here are the key benefits I’ve seen firsthand.

1. Significant Energy Savings

This is the most obvious benefit. By reducing energy losses, IE3 motors directly cut your electricity bills. As we saw in the example above, even a small percentage improvement leads to substantial savings year after year. For energy-intensive applications like pumps, fans, and compressors that run 24/7, the payback period on the extra investment for an IE3 motor can be surprisingly short—often between one and three years.

2. Lower Total Cost of Ownership (TCO)

Because energy is the biggest cost component, anything that reduces consumption drastically lowers the TCO. The higher purchase price is an investment that pays for itself many times over. When I run the numbers for a potential upgrade project, the TCO chart always tells a powerful story. The IE3 motor starts out more expensive, but its total cost line rises much more slowly than the cheaper, less efficient motor.

3. Environmental Responsibility

Reducing energy consumption isn’t just about money; it’s about sustainability. Less electricity used means less demand on power generation, which translates directly to a lower carbon footprint. Replacing just one old 15 kW IE1 motor with an IE3 equivalent can reduce annual CO2 emissions by around 3.5 tonnes. That’s like taking a car off the road. For companies with sustainability goals, upgrading their motor fleet is one of the most impactful changes they can make.

4. Enhanced Reliability and Longevity

This is a benefit that often gets overlooked. Wasted energy in a motor doesn’t just vanish—it becomes heat. An IE3 motor runs cooler than an IE1 or IE2 motor because it’s more efficient. This has a huge impact on reliability.

- Longer Winding Life: Heat is the number one enemy of motor winding insulation. For every 10°C increase in operating temperature, the insulation life is cut in half. A cooler-running IE3 motor’s windings will last significantly longer.

- Longer Bearing Life: Heat also degrades bearing grease, leading to premature failure. I’ve seen countless motor failures that started with a bad bearing. A cooler motor means happier, longer-lasting bearings.

- Less Downtime: A more reliable motor means less unscheduled downtime, which in a production environment is worth its weight in gold. Solving a common motor problem before it starts is a massive win.

5. Regulatory Compliance

In many parts of the world, you don’t have a choice anymore. Governments have recognized the huge potential for energy savings and have made IE3 efficiency mandatory for most new motors. Staying compliant avoids potential fines and ensures your facility is up to modern standards.

IE3 Regulations and Global Adoption: What You Need to Know

The push for IE3 isn’t just a good idea; it’s the law in many places. Understanding the regulatory landscape is crucial.

- In the European Union (EU): The Ecodesign Directive has been a major driver. Since July 2021, most new 3-phase motors between 0.75 kW and 1000 kW must meet IE3 standards. They’ve even started pushing for IE4 in certain power ranges as of July 2023.

- In the United States (US): The Department of Energy (DOE) has similar rules. Since 2016, most general-purpose motors sold in the US must meet NEMA Premium® efficiency levels, which are harmonized with and equivalent to IE3. NEMA (National Electrical Manufacturers Association) is the key standards body in North America.

- Other Regions: Countries like Canada, China, Australia, and India have also implemented or are phasing in their own mandatory efficiency standards that align closely with the IE3 level.

There are some exemptions for special-purpose motors (like those designed for explosive atmospheres or intermittent duty), but for the vast majority of industrial applications, IE3 is the baseline.

Key Applications Benefiting from IE3 Motors

While any motor can be upgraded to IE3, the benefits are most dramatic in applications with long operating hours and consistent loads. Based on my experience, these are the prime candidates for an IE3 upgrade:

- Pumps, Fans, and Compressors: These are the big three. They often run continuously and represent a huge portion of a facility’s energy use. Upgrading the motors on your HVAC systems, compressed air systems, or water pumps will almost always provide a fantastic return on investment.

- Conveyors and Material Handling Systems: In factories and distribution centers, conveyor belts can run for entire shifts without stopping. These are perfect applications for IE3 motors.

- General Industrial Machinery: Any machine that runs for more than a few thousand hours per year, like mixers, grinders, or machine tools, will benefit from a more efficient motor.

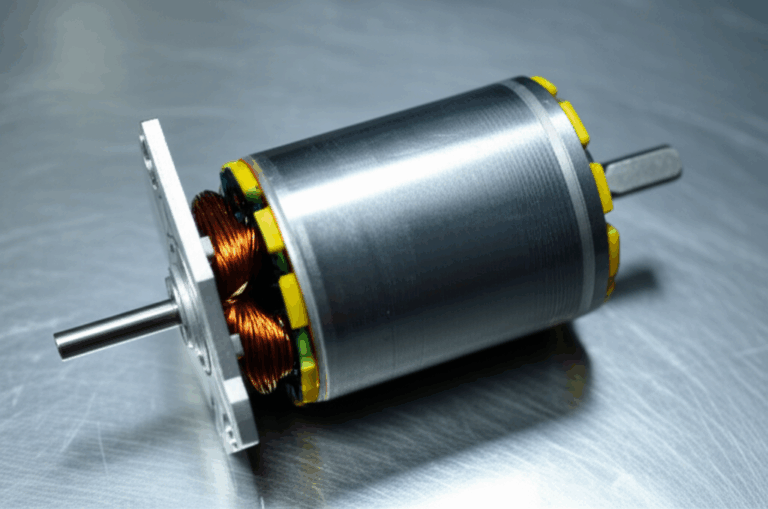

The basic motor principle is to convert electrical energy into mechanical motion. The less energy wasted in that conversion, the better, especially when the motor is running all day long.

Making the Switch: Considerations for Upgrading to IE3 Motors

So, you’re convinced that IE3 is the way to go. What’s next? Here are a few practical steps I always recommend before starting a motor upgrade project.

1. Conduct an Energy Audit

You can’t manage what you don’t measure. The first step is to audit your current motor fleet. Identify your oldest, least efficient (likely IE1 or older) motors, especially those in high-use applications. This will give you a clear “hit list” of the best candidates for replacement, where you’ll get the most bang for your buck.

2. Calculate the ROI

Don’t just look at the price tag. Calculate the payback period. The formula is simple: (Cost of New IE3 Motor – Cost of Standard Motor) / Annual Energy Savings. Your motor supplier or a good energy consultant can help you run these numbers. When you present this to management, you’re not asking for an expense; you’re proposing an investment with a clear, predictable return.

3. Consider VFD Compatibility

Variable Frequency Drives (VFDs) are devices that control a motor’s speed, offering massive energy savings in variable-load applications (like a fan that doesn’t always need to run at full blast). IE3 motors work beautifully with VFDs. In fact, combining a premium efficiency motor with a VFD is the gold standard for energy optimization in many systems. Many modern IE3 motors are even “inverter-ready,” with enhanced insulation on the windings to handle the stresses from a VFD.

The synergy between the two main components, the stator and rotor, is optimized in IE3 designs, making them robust partners for modern drive systems.

4. Debunk the Myths

The biggest myth is that the higher upfront cost isn’t worth it. As we’ve seen with the TCO analysis, this is completely false for most applications. The savings on your energy bill will dwarf the initial price difference. Arm yourself with the data and be ready to explain the long-term financial benefits.

Conclusion: IE3 – A Foundation for Sustainable Industrial Operations

Looking back, the shift to IE3 premium efficiency motors has been one of the most significant and positive changes I’ve witnessed in the industry. It forced us all to look beyond the initial purchase price and consider the full lifecycle cost of our equipment.

IE3 isn’t just a technical standard or a regulation to comply with. It’s a smarter way of doing business. It’s a practical tool for reducing operational costs, improving the reliability of your machinery, and meeting corporate sustainability goals. It represents a fundamental understanding that the cheapest motor to buy is rarely the cheapest motor to own.

And the journey doesn’t stop here. As technology advances, standards will continue to evolve towards IE4 and IE5. But for today, embracing IE3 is the essential foundation for any modern, efficient, and responsible industrial operation. It’s an investment in your bottom line and in a more sustainable future.