What Is Motor FLA? Your Essential Guide to Full Load Amperage in Electric Motors

Every engineer has asked a version of this question. What is Motor FLA and why does it matter so much in real-world design and procurement? Maybe a breaker keeps tripping on a compressor. Maybe your PLC flags overcurrent on a fan drive. Or you are sizing a generator for a pump skid and you need confidence in your motor current numbers. FLA sits at the center of those decisions. It informs safety. It drives efficiency. It shapes wiring, protection, and upstream power. It even connects to your motor core laminations and how much heat you have to manage. Let’s break it down in clear, practical terms.

In This Article

- The Engineering Problem: What FLA Is and Why It Drives Your Design Decisions

- Full Load Amperage (FLA) Explained in Plain Language

- Why FLA Matters: Safety, Efficiency, and System Design

- Where to Find FLA and How to Determine It

- What Really Drives FLA: The Physics and the Role of Laminations

- Turn FLA Into Design Choices: Protection, Wiring, and Power Systems

- FLA vs RLA vs LRA vs Service Factor

- Troubleshooting With FLA: Maintenance, Testing, and Reliability

- Which Application Is This For? Matching FLA and Components to Your Industry

- Material and Process Guide: Laminations That Lower Current and Heat

- Quick Reference: Typical FLA Values and Code Touchpoints

- Your Engineering Takeaway and Next Steps

The Engineering Problem: What FLA Is and Why It Drives Your Design Decisions

You need to make a safe choice. You also want a cost-effective one. FLA or Full Load Amperage gives you the current a motor draws when it delivers its rated horsepower at its rated voltage. That one number underpins a lot. Overcurrent protection sizing. Wire gauge and conduit fill. Motor starter selection. VFD sizing. Transformer and generator sizing. Overload relay settings. Even a maintenance tech’s clamp meter reading. Get FLA wrong and you risk nuisance trips or worse. Get it right and you protect the machine while you keep energy bills on a leash.

This guide speaks to electricians, technicians, product designers, and procurement managers. You’ll see the standards that matter. You’ll see what to trust on the motor nameplate and when to run a calculation. You’ll learn how efficiency, power factor, and core design shift operating current. You’ll leave with clear next steps.

Full Load Amperage (FLA) Explained in Plain Language

- Definition: FLA is the current an electric motor draws when it operates at its full rated mechanical load at its rated voltage and frequency. It’s a nameplate rating from the manufacturer. You’ll often see it on the Motor Nameplate as “FLA” or “Full Load Amps.”

- FLA vs operating current: Real operating current can sit below FLA if your load is light. It can run near FLA when the load matches the rated horsepower. If you see current exceed FLA under steady state then something’s off. You might have overload, low voltage, a mechanical fault, or a control issue.

- Why “nameplate rating” matters: Manufacturers test or model their motors. They factor in Efficiency and Power Factor at the rated point. They publish FLA so you can design a safe branch circuit that meets National Electrical Code (NEC) rules and aligns with NEMA naming conventions.

A quick analogy: Think of FLA like a vehicle’s rated towing current. It’s the current at full tow. You can drive lighter and draw less. Hitch more than the rating and you stress the system.

Why FLA Matters: Safety, Efficiency, and System Design

You use FLA across design and maintenance tasks. Here’s where it pays the bills.

- Overcurrent protection sizing

- FLA drives the selection of Circuit Breakers and Fuses. NEC Article 430.52 gives maximum settings for branch-circuit short-circuit and ground-fault protection. The setting varies with device type. You aim to ride through Locked Rotor Amperage (LRA) at startup without nuisance trips while you protect against faults.

- Thermal Overload Relay settings use FLA as the baseline. NEC Article 430.32 sets overload protection at no more than 125% of motor FLA if the Service Factor is 1.15 or higher. At 1.0 SF you size at 115% of FLA.

- Wire and conductor sizing

- Conductor ampacity must be at least 125% of the motor’s FLA for continuous duty per NEC Article 430.22. You choose a wire gauge from ampacity tables like NEC Table 310.15(B)(16). This prevents overheating.

- Good wiring practices reduce voltage drop. Lower drop improves motor torque and reduces current draw for a given load.

- Motor performance and energy consumption

- Motors tend to run most efficient near their rated load. Operating far below FLA can reduce Efficiency and Power Factor. That leads to higher energy consumption per unit of work. The impact varies but a motor at 70% of rated FLA can run a few percent less efficient than the same motor near 90 to 100% FLA.

- System design and component selection

- FLA influences Motor Starter contact ratings. It also shapes MCC bus capacity and VFD sizing. It informs Transformer and Generator sizing. You want enough headroom to handle inrush and overload without overspending.

- Maintenance and troubleshooting

- A clamp meter reading near or over FLA under steady load is a red flag. You might have poor bearings, misalignment, a jammed pump, or low voltage. FLA gives technicians a reference point that shortcuts guesswork.

Where to Find FLA and How to Determine It

You have four practical paths. Use them in this order.

1) The Motor Nameplate

- Primary source: The motor nameplate lists Horsepower, Voltage, Frequency, FLA, Efficiency, Power Factor, Service Factor, and often Insulation Class. It may show dual voltage like 230/460 V for AC motors. FLA doubles when voltage halves given the same mechanical load.

- Dual-voltage note: A 10 HP motor might show 28 A at 230 V and 14 A at 460 V. That inverse relationship comes from Watt’s Law and Power Factor realities.

2) Manufacturer data sheets and manuals

- If the nameplate is missing or unreadable then go to the manufacturer’s catalog. Look up the exact model number. You’ll usually get full motor electrical specifications and performance curves.

3) Calculation formulas for estimates

- For single-phase AC motors:

- FLA ≈ (HP × 746) / (V × Efficiency × Power Factor)

- Example: 2 HP at 230 V with 85% Efficiency and 0.90 PF → (2 × 746) / (230 × 0.85 × 0.90) ≈ 1,492 / 176.55 ≈ 8.45 A

- For three-phase AC motors:

- FLA ≈ (HP × 746) / (√3 × V × Efficiency × Power Factor)

- Example: 10 HP at 460 V with 92% Efficiency and 0.85 PF → numerator = 7,460. Denominator = 1.732 × 460 × 0.92 × 0.85 ≈ 623.9. FLA ≈ 7,460 / 623.9 ≈ 11.95 A

- Approximations and tables:

- NEC and NEMA publish typical current values by horsepower and voltage for design use. Designers often reference these when early in a project.

4) Measure with a clamp meter

- Verify actual operating current on each phase for three-phase motors and record the highest. Compare the reading to the nameplate FLA. You want steady-state values for continuous duty.

- Safety matters. Follow lockout-tagout. Use CAT-rated meters. Keep clear of rotating parts. Wear proper PPE. This is not a casual measurement.

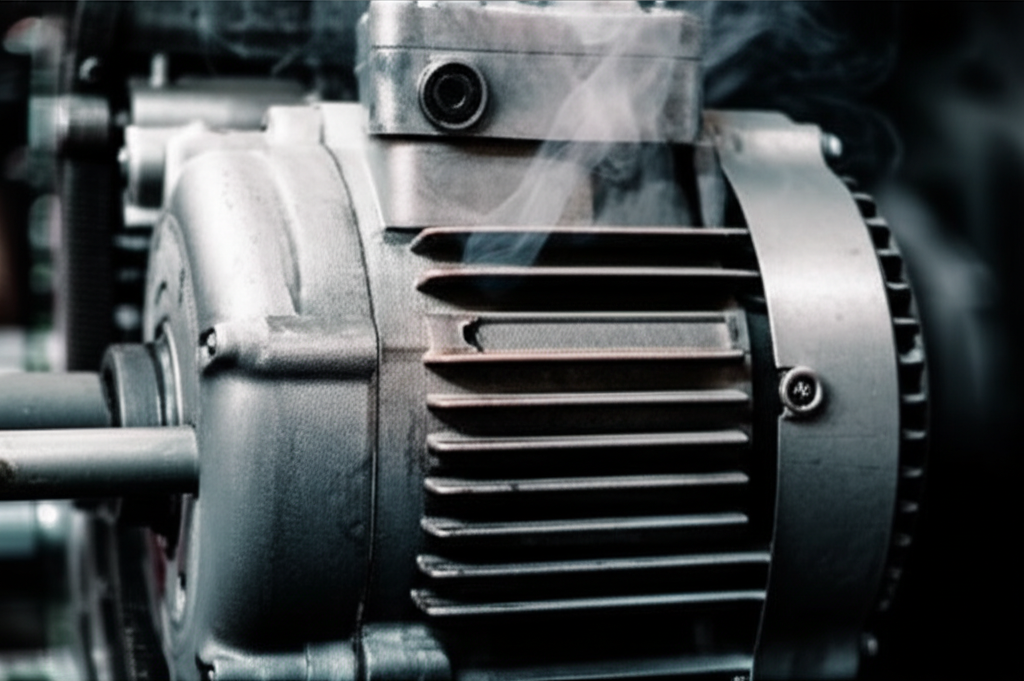

What Really Drives FLA: The Physics and the Role of Laminations

Why do two motors with the same HP and voltage show different FLA? Because Efficiency and Power Factor differ. The magnetic design matters. The quality of the steel matters. The stack geometry matters.

- Efficiency

- Higher efficiency motors convert more electrical power into mechanical work with less loss. That lowers input current for the same output HP. Efficiency depends on winding design, stator and rotor geometry, and core loss.

- Power factor

- Power Factor shows how effectively the motor converts supplied volts and amps into real work. Induction motors draw magnetizing current that does not produce torque. Better design and control improve PF. VFDs can also help by managing reactive power at the drive input.

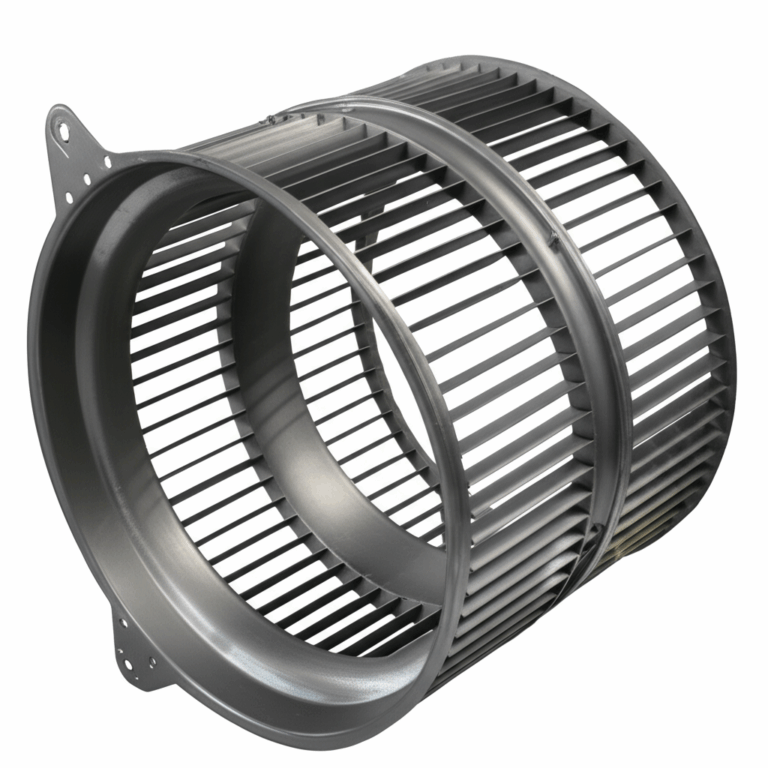

- Magnetic core losses and laminations

- Two loss types dominate in the core: hysteresis and eddy currents. Think of eddy currents like tiny whirlpools in a river. A changing magnetic field induces circulating currents in the steel. Those currents cause heat and waste energy. Thinner, insulated laminations break up the whirlpools. That cuts eddy currents and trims losses. Hysteresis loss comes from flipping the steel’s magnetic domains back and forth every cycle. Materials with lower coercivity reduce that loss.

- Better lamination material and thickness lower core loss which improves Efficiency. Higher Efficiency lowers FLA for the same HP. This connection links motor electrical specifications with the physical motor core and the quality of its motor core laminations.

- Winding temperature and insulation class

- As winding temperature rises so does resistance. Higher resistance can nudge current and losses upward. Poor airflow or blocked ducts lead to higher operating temperature. That shortens motor life. Every 10°C increase above the insulation class limit can halve insulation life. Proper FLA-based protection helps prevent that.

You can summarize the physics with two buckets. Copper loss from winding resistance and magnetic loss from the core. The lamination stack design directly affects the second bucket. This is why a premium lamination stack often pays back through lower Heat, better efficiency at rated load, and lower FLA for the same mechanical output.

Turn FLA Into Design Choices: Protection, Wiring, and Power Systems

Let’s turn numbers into hardware. This is where your drawings and bills of materials come to life.

- Overcurrent protection sizing

- Use FLA as the reference for branch-circuit short-circuit and ground-fault protection per NEC 430.52. Device type matters. Non-time-delay fuses can be sized up to a higher percentage of FLA than some circuit breakers because they behave differently during inrush. You size to avoid nuisance trips during LRA without compromising safety.

- Overload protection

- Size overload relays per NEC 430.32. With a Service Factor (SF) of 1.15 or higher, overload protection must not exceed 125% of FLA. With SF below 1.15, use 115% of FLA. This keeps the motor safe under sustained overload. You set thermal overload relay dials to those values. Verify the class of trip curve that fits your start profile.

- Wire gauge and conductor ampacity

- Size conductors at least 125% of FLA for continuous duty motors per NEC 430.22. Select from ampacity tables like 310.15(B)(16). Account for ambient temperature, conduit fill, and insulation temperature rating. Aluminum conductors need larger gauge than copper for the same ampacity.

- Starters, contactors, and control components

- Select the Motor Starter class and contact rating based on FLA and duty cycle. Consider the Rated Load Amperage (RLA) if the manufacturer provides it for the intended load. For motors with frequent starts or reversing, choose components with appropriate AC-3 or AC-4 duty per IEC or NEMA designations.

- Variable Frequency Drives (VFDs)

- Size a VFD for the motor’s FLA with headroom for overload. Match the drive’s continuous current rating to the motor FLA and check the overload current limit. Use the drive’s motor parameter setup to match nameplate data. This improves torque control and reduces energy consumption under variable load conditions.

- Transformers, generators, and UPS

- Use FLA to estimate steady-state current demand on a transformer or generator. Account for starting current or use a soft start. Critical systems like data centers or medical equipment sometimes include UPS systems upstream of VFDs. Check UPS compatibility with non-linear loads. Confirm harmonic mitigation if needed.

- Voltage quality and balance

- Three-phase motors hate voltage imbalance. A small imbalance in voltage can cause a large imbalance in current. That raises heat. Keep voltage within nameplate tolerance. Use proper tap settings on transformers. Monitor with IoT motor monitoring systems when uptime matters.

FLA vs RLA vs LRA vs Service Factor

These terms often collide in conversations. Clear them up.

- FLA (Full Load Amperage)

- Nameplate current at rated HP, voltage, and frequency.

- RLA (Rated Load Amperage)

- Often used interchangeably with FLA in HVAC. Some manufacturers publish RLA as a practical rating for controllers or overloads. Treat the nameplate as your source.

- LRA (Locked Rotor Amperage)

- Inrush current at startup when the rotor is stopped. It can be 5 to 7 times FLA for many NEMA Design B induction motors. You use LRA to check breaker or fuse sizing. You ensure the feeder and source can handle starting current without excessive voltage sag.

- Service Factor (SF)

- A multiplier that indicates how much overload the motor can carry for short periods. An SF of 1.15 means the motor can deliver 115% of rated HP without immediate damage under specified conditions. Use SF to set overload protection per NEC 430.32 and to judge if intermittent overloads are acceptable. High SF can mask misapplied motors so use it with care.

Troubleshooting With FLA: Maintenance, Testing, and Reliability

Your clamp meter tells a story. FLA helps you read it.

- Overcurrent under load

- If the measured current exceeds FLA under steady conditions then look for overload. Check mechanical drag from bearings. Inspect for misalignment. Verify that a pump or fan is not over-trimmed. Confirm voltage is within rated range. Low voltage increases current for a given torque.

- Current below FLA but high heat

- Underload operation reduces airflow in TEFC motors. That can raise winding temperature. Check operating point on the motor performance curves. Sometimes a motor runs cool when underloaded. Sometimes not. The details matter.

- Imbalance and harmonics

- Measure all three phases. A 2% voltage imbalance can produce a 6% or more current imbalance. That heats one phase. VFDs introduce harmonics at the line side. Use line reactors or filters if needed. Follow IEEE recommendations for harmonic limits when sensitive equipment shares the bus.

- Thermal protection and trip events

- Check the Thermal Overload Relay settings against the nameplate FLA and SF. Verify the overload class suits the start profile. Frequent restarts might need a different time class. If a breaker trips immediately then you may have a short circuit or ground fault. Inspect insulation with a megohmmeter. Respect insulation class and UL, CSA, or IEC test procedures.

- Preventive and predictive maintenance

- Measure operating current as part of your PM route. Track trends. Add vibration analysis and bearing lubrication plans. Use temperature sensors or IoT motor monitoring solutions for early warning of electrical or mechanical issues. Predictive maintenance reduces surprise failures and energy waste.

Which Application Is This For? Matching FLA and Components to Your Industry

Different industries push motors in different ways. FLA helps you tailor the system.

- HVAC systems

- Fan and pump motors run continuous duty. Wire and protect at 125% of FLA. Many VFD-driven fans run well below FLA at part load which saves energy. Watch RLA vs FLA on packaged equipment. Follow manufacturer instructions for Overcurrent Protection Devices.

- Pumps and compressors

- Positive displacement compressors can spike torque at start. Centrifugal pumps have steep horsepower curves with flow. Match motor HP and FLA to curve data. Verify the breaker will ride through LRA. Consider soft starters or VFDs when supply is limited.

- Industrial machinery and automation

- Mixers, conveyors, and robotics use precise torque control. Three-phase motors with VFDs shine here. BLDC motors have different electrical characteristics. Their controller current ratings play the same role that FLA plays for AC induction.

- Data center cooling and building management systems

- Reliability is king. Motors run for years. Use proper Overcurrent Protection Devices, wire sizing, and overload settings. Keep voltage stable. Monitor PF and harmonics. Maintain Efficient operation near FLA to minimize wasted energy.

- Medical equipment, food processing, agriculture, marine, aviation, mining, oil and gas, and wastewater treatment

- Environments vary. Safety standards tighten. Consult UL, CSA, ISO, NEMA, and IEEE guidance. Check corrosion protection and enclosure ratings. Address ground fault protection where needed. In harsh duty or hazardous locations, protection and wiring decisions become even more critical.

Material and Process Guide: Laminations That Lower Current and Heat

You might ask why a guide about FLA talks about lamination stacks. Because the core material and construction change Efficiency and Power Factor. That changes the FLA needed to deliver a set horsepower. You do not buy FLA directly from a steel catalog yet the lamination choice echoes through current draw, losses, and thermal design.

Material considerations

- Silicon steels (non-oriented CRNGO and oriented CRGO)

- For general-purpose motors, non-oriented electrical steels with silicon improve resistivity which reduces eddy currents. Lower core loss improves Efficiency. Better Efficiency lowers input amperage at rated load. Grades vary in thickness and grain structure. Thinner gauge reduces eddy current loss at higher frequencies which helps high-speed designs.

- Cobalt alloys

- High magnetic saturation and low loss at elevated frequencies. Aerospace and high-power-density applications pay a premium for performance. You can hit high torque density and reduce motor size. That often trims copper and core losses at rated load. The result can be lower FLA for the same output when the system runs at the intended operating point.

- Amorphous and nanocrystalline materials

- Exceptional loss performance for transformer cores. Motors also benefit at certain frequencies. These materials can be expensive and hard to process. You weigh peak performance against cost and manufacturability.

Manufacturing and assembly processes

- Stamping vs laser cutting

- Stamping both sides of the argument. For high volume and stable geometry, stamping produces consistent parts with tight tolerances and low cost per piece. Laser cutting excels in prototyping and low-volume complex designs. Laser can introduce more heat-affected zones that slightly raise core loss if not managed. Stamping dies require upfront capital but win on long runs.

- Insulation coatings and bonding

- Each lamination gets an insulating coating to block eddy currents between plates. The coating type and thickness change interlaminar resistance. Bonding methods like interlocking, welding, riveting, or resin bonding affect stack integrity. Interlocking works like LEGO bricks and avoids heat that could degrade magnetic properties. Welding can add structural strength, yet it risks localized loss increases if heavy.

- Stack geometry and fill factor

- Higher slot fill can lower copper loss yet it complicates manufacturing. Optimized tooth shapes and magnetics reduce harmonics and acoustic noise. Better design lowers core loss and supports a higher Power Factor at the operating point. That helps FLA.

Where laminations meet your design intent

- If you pursue lower current draw at rated load, focus on core loss. Specify materials with proven hysteresis and eddy-current performance at your frequency. Ask suppliers for B-H curves, core loss charts, and thickness options. Test with your stack height and winding method. Validate real FLA at the shaft load you care about.

For deeper context on the building blocks, see these resources:

- Learn how a stator core lamination shapes magnetic flux and slot geometry.

- Understand how a rotor core lamination influences torque production and losses.

- Review the role of electrical steel laminations in reducing eddy currents with the right coating and thickness.

- See how complete motor core laminations come together as stacks ready for slot insulation, winding, and assembly.

Honest fit guidance

- Laser cutting offers precision and fast iteration for prototypes or intricate geometries. It shines in low to medium volumes. For large runs with stable designs, stamping provides lower unit cost and consistent edge quality.

- Bonding improves structural integrity and vibration behavior. Interlocking avoids thermal damage to the steel. Welding offers robustness if applied with care. Resin bonding can damp vibration and noise. No single method wins every time. Pick based on your duty cycle, manufacturing scale, and acoustic targets.

Quick Reference: Typical FLA Values and Code Touchpoints

When you need ballpark values fast, these help you sanity-check a design.

Typical FLA for common three-phase motors at 460 V

- 1 HP: about 1.6 A

- 5 HP: about 7.6 A

- 10 HP: about 12.2 A

- 20 HP: about 24.5 A

- 50 HP: about 62 A

These are typical. Always check the nameplate or the manufacturer’s catalog for exact values. Varying Efficiency and Power Factor shift the numbers.

NEC touchpoints that use FLA directly

- NEC 430.22: Conductor ampacity for continuous duty motors must be at least 125% of FLA.

- NEC 430.32(A)(1): Overload protection must not exceed 125% of FLA for motors with SF ≥ 1.15. Use 115% for SF < 1.15.

- NEC 430.52(C)(1): Maximum branch-circuit short-circuit and ground-fault protective device percentages are based on FLA and device type.

- Ampacity tables like 310.15(B)(16): Use FLA to select wire size. Apply adjustment factors for ambient and bundling as required.

Standards and trust signals

- NEMA sets common motor standards. You’ll rely on NEMA design letters and nameplate conventions.

- UL, CSA, and IEC approvals indicate compliance with safety standards.

- IEEE publishes guidance on power quality and harmonics.

- ESFI promotes safe installation practices. Their guidance works well for apprentices, technicians, and engineers alike.

Engineering Fundamentals That Link Back to FLA

A few core ideas tie all this together.

- Ohm’s Law and Watt’s Law

- Voltage, current, and resistance interact in simple ways. Real systems add Power Factor. You can estimate current from power after you include Efficiency and PF.

- Single-phase vs three-phase

- Three-phase motors run smoother and usually more efficient at higher HP. They draw lower current for the same HP compared to single-phase equivalents at the same voltage because three-phase delivers power more evenly.

- Continuous duty vs intermittent duty

- Motors are often rated continuous duty. Intermittent duty cycles allow temporary overloads and cool-down intervals. This affects overload setting and thermal behavior. Respect duty cycle when you compare measured current to FLA.

- Underload vs overload operation

- Underload operation can lower Efficiency and PF which raises the cost per unit work. Overload pushes current above FLA. That drives heat. Heat shortens insulation life. Balance your motor size to keep operation near FLA for the expected duty.

Practical Scenarios: Applying FLA in the Field

HVAC motor FLA

- You size VFDs and Overcurrent Protection Devices around FLA. Account for LRA on direct-on-line starters. Many fans run at partial speed with VFDs which cuts current. Verify minimum cooling airflow at low speed.

Pump motor FLA

- Hydraulic changes alter power draw. A small change in impeller diameter can shift required horsepower. Match FLA with the pump curve at the target flow and head. Use overload protection to catch dead-head or run-out events that spike current.

Compressor motor FLA

- Refrigeration and air compressors have distinct LRA and RLA conventions. Follow the manufacturer’s guidance. Hard starts, voltage drop, and high head pressure all escalate current.

Industrial motor applications

- Conveyor lines, mixers, grinders, and mills stress motors differently. Track starting frequency and load inertia. Overcurrent protection must ride through expected starts while still protecting for faults.

Electric vehicle and robotics motors

- BLDC and synchronous motors present current differently than induction motors. Their controllers define continuous and peak current ratings. The concept mirrors FLA and LRA, yet the numbers come from drive settings and thermal limits rather than NEMA tables. Align controller current to the motor’s thermal envelope.

Procurement Notes: What to Ask Your Motor or Lamination Supplier

You can save time and cost if you ask the right questions up front.

- Request motor nameplate data with Efficiency, Power Factor, FLA, and Service Factor at the intended voltage and frequency.

- Ask for performance curves. You want current vs torque or load. That helps you place your operating point near the efficient region.

- For lamination stacks, request core loss curves at your frequency and flux density. Ask for B-H curves and coating type. Verify lamination thickness and tolerances.

- Discuss manufacturing process. Stamping vs laser. Interlocking vs welding vs bonding. Ask for evidence of how the process controls heat-affected zones and preserves magnetic properties.

- Confirm standards and certifications. UL, CSA, ISO quality systems, and NEMA compliance build confidence.

Your Engineering Takeaway and Next Steps

If you remember only a handful of points, remember these.

- FLA is the motor’s expected current at rated load and voltage. It’s your anchor for protection sizing, wiring, and component selection.

- Efficiency and Power Factor shift FLA. Better laminations and smart magnetic design lower core loss which lowers current for the same HP.

- Use the nameplate first. Back it up with manufacturer data or calculations. Verify with a clamp meter under steady-state load.

- Size conductors at 125% of FLA for continuous duty per NEC 430.22. Set overloads using FLA and Service Factor per NEC 430.32. Choose short-circuit and ground-fault protection per NEC 430.52.

- Match the motor and controls to the load and duty cycle. Avoid chronic underload or overload. That protects your budget and your equipment.

Actionable next steps

- Pull the motor nameplate and capture FLA, voltage, frequency, Efficiency, Power Factor, and Service Factor.

- Check your one-line and panel schedules. Validate OCPD and wire sizes against FLA and NEC rules.

- If you’re designing a new product, discuss lamination material and process with your supplier. Confirm how the core choice affects Efficiency and current at your operating point.

- If a system trips, log clamp meter readings on each phase at steady load. Compare to FLA. Use those numbers to guide troubleshooting.

- When in doubt, schedule a technical consultation. Bring your load profile, starting method, and environmental conditions. Ask the hard questions and expect clear answers.

You build safe and efficient systems when you treat FLA as a design driver rather than a footnote. That one number connects the electrical math to the metal in the core. Use it well.

Glossary of key terms at a glance

- Full Load Amperage (FLA): Current at rated load and voltage.

- Locked Rotor Amperage (LRA): Inrush at startup.

- Rated Load Amperage (RLA): Often used interchangeably with FLA in HVAC contexts. Check the nameplate or manual.

- Service Factor (SF): Allowable overload multiplier.

- Power Factor: How effectively current does useful work.

- Efficiency: Ratio of mechanical output power to electrical input power.

- Overcurrent Protection Device (OCPD): Circuit Breaker or Fuse sized using FLA and NEC rules.

- Thermal Overload Relay: Protects the motor from sustained overload.

- Motor Control Center (MCC): Centralized assembly for motor feeders and controls.

- Variable Frequency Drive (VFD): Controls motor speed and torque while improving efficiency at partial loads.

- NEMA: Standards body for motors and industrial equipment. Their designs and nameplate norms are widely used.

- NEC: National Electrical Code for safe installation and protection.

- Ohm’s Law and Watt’s Law: Basic electrical relationships that inform current calculations.

If you want to reduce current draw and heat at your rated duty, look first at your load and control strategy. Then look inside the motor at the lamination stack. Smarter materials and processes make your electrical job easier. They also improve the motor’s efficiency, reliability, and lifetime.