What is Motor Service Factor? Understanding Its Importance for Motor Life & Performance

- Table of Contents

- What is Motor Service Factor? Understanding Its Importance for Motor Life & Performance

- Article Outline

- What is a service factor for an electric motor?

- Where do I find it on the motor nameplate, and how do I read it?

- How do I use service factor without hurting the motor?

- What does service factor 1.15 or 1.25 mean in real life?

- NEMA vs IEC: Why do standards talk about SF in different ways?

- When should I use SF, and when should I not?

- How does SF affect efficiency, power factor, and energy cost?

- What about VFDs, harmonics, and voltage imbalance?

- How do environment and enclosure type change what SF can do?

- How do I size motors for pumps, fans, and compressors with SF in mind?

- What protection, testing, and maintenance keep SF safe?

- Common myths about service factor

- Quick reference tables

- FAQ

- Summary: Key points to remember

- References

Here is the big idea. A motor can handle a little extra load for a short time. That “extra” is the motor’s service factor. Use it right, and you save your day. Use it wrong, and you shorten motor life. In this guide, I show you how to read it, when to use it, and how to protect your electric motor from heat, stress, and surprise overloads.

I use simple words. I share stories from the field. You get a clear plan to size, run, and protect your motor. You also see how this affects efficiency, power factor, bearing life, and your total cost of ownership.

Article Outline

- What is a motor service factor definition and meaning

- Reading the motor nameplate and doing the service factor calculation

- Why SF matters for motor life, insulation class, and temperature rise

- What does SF 1.15 or SF 1.25 allow in real work

- NEMA service factor vs IEC service factor

- When to use SF for continuous duty, intermittent duty, and peak loads

- How SF changes efficiency of electric motors, power factor motor, and energy cost

- SF with VFDs, harmonic distortion motor effects, and voltage imbalance motor effects

- SF with ambient temperature motor, altitude, cooling methods for electric motors, and motor enclosure type

- SF with motor sizing for pumps, fans, and compressors

- Motor protection devices, overload relay setting, motor thermal protection, motor testing procedures

- Myths and clear rules for motor operating conditions and motor reliability engineering

What is a service factor for an electric motor?

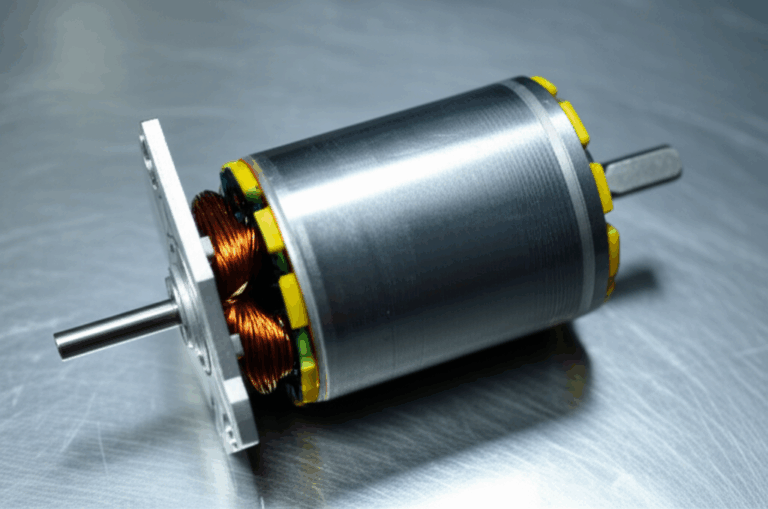

Here is a simple motor service factor definition. Service factor (SF) is a number on the motor nameplate that tells you how much extra load the motor can handle for short times. You will see common values like 1.0, 1.15, or 1.25. The motor service factor meaning is simple. A motor with SF 1.15 can handle 15% more than the rated output motor load, for a limited time, under the right conditions.

Why is this helpful? Life does not run at a flat line. Loads spike. Pump pressure jumps. A conveyor jams. A fan sees a dirty filter. You need a little wiggle room. That is what SF gives you. Think of it as a spare tire, not a second engine.

You may also hear people say “mechanical service factor” or “safety factor motors.” Those words point to the same idea. A margin. A buffer. A short overload capacity that helps you ride out bumps without breaking the machine.

Where do I find it on the motor nameplate, and how do I read it?

Look at the motor nameplate interpretation. You will see Horsepower (HP) or Kilowatt (kW), Rated Voltage, Rated Current, Synchronous Speed, Slip, Efficiency, and Power Factor. You also see Insulation Class like Class B, F, or H. You should see Service Factor too, like 1.15. That is the service factor motor rating.

The service factor calculation is easy. Take the motor horsepower rating and multiply by SF. Example. A 10 HP motor with SF 1.15 can deliver up to 11.5 HP for short periods. That is all service factor calculation means. Keep in mind the motor duty cycle and the continuous rated motor rating. You cannot run at SF all day.

If the plate says SF 1.0, the motor has no extra margin by design. Many IEC service factor motors list SF 1.0. Some NEMA service factor motors list SF 1.15 as standard for 1 HP and up. Always read the plate. Always check the motor operation manual and the motor design standards.

How do I use service factor without hurting the motor?

Problem. People hear “extra” and they push the motor hard. That feels fine at first. Then the motor runs hot. It fails early. You face motor repair vs replacement. You lose time. You pay more on power. You push bearings past their limit. You risk motor winding insulation breakdown.

Agitate. Heat is the enemy. A high temperature rise electric motor kills motor insulation life expectancy. Each 10°C rise can cut motor lifetime in half. You get more vibration in electric motors. You raise noise levels electric motors. You speed up wear on bearings and the shaft. You can hurt gearbox couplings too.

Solution. Use SF for short intermittent duty motor overloads. Handle a temporary process upset. Ride out a quick peak. Watch ambient temperature motor levels. Watch voltage variation and frequency variation. Use motor protection devices and set the thermal overload relay right. Plan your motor maintenance best practices and your maintenance schedule. That is how you prevent motor failure and get extended motor operation.

What does service factor 1.15 or 1.25 mean in real life?

You may ask, “what does service factor 1.15 mean?” It means you can pull 115% of rated HP for short periods. You may also ask, “what does service factor 1.25 mean?” It means you can pull 125% of rated HP for short periods. That is it. No magic.

Here is a key point. Impact of service factor on motor life is real. If you run at SF all day, you raise winding temperature. You raise hotspot temperature. You push motor winding temperature limits. You shorten life. It can cut your insulation life by a big chunk. You may also lower the efficiency of electric motors in that range. You can lower power factor motor too.

I like to say this. “Use SF like a raincoat. Wear it in storms. Do not wear it all summer.”

NEMA vs IEC: Why do standards talk about SF in different ways?

In North America, we see NEMA (National Electrical Manufacturers Association) rules in NEMA MG 1. Many NEMA motors list SF 1.15. In much of the world, IEC (International Electrotechnical Commission) rules in IEC 60034. Many IEC motors list SF 1.0 and focus more on duty cycle, thermal class, and temperature rise.

To keep it straight. NEMA service factor talks about a built-in overload margin. IEC service factor tends to use duty types and thermal limits to define what the motor can take. Both care about heat, load, and life. Both protect electrical motor performance and equipment reliability.

So use the right playbook for your market. Use motor selection guidelines from your motor application engineering team. Follow the motor procurement specifications for the site. Good specs save you pain.

When should I use SF, and when should I not?

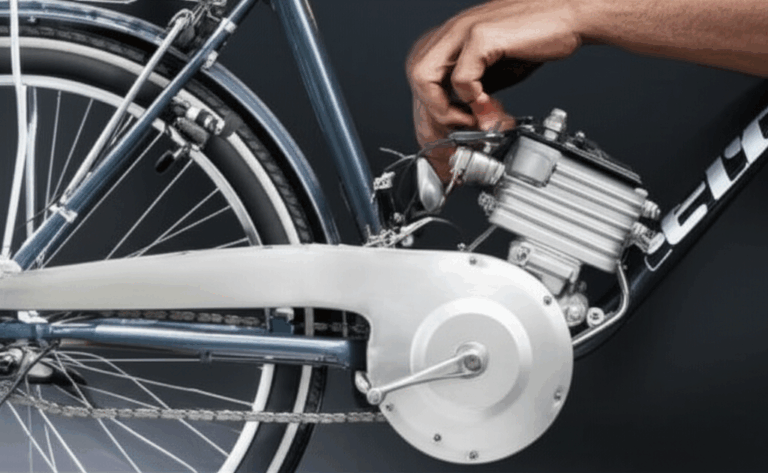

Use service factor in appropriate scenarios. Handle infrequent, short-duration peak loads. Smooth out a temporary process upset. Use a small design safety margin when you know the load bumps now and then. That helps with motor and load matching and motor and drive system optimization.

Do not use SF in inappropriate scenarios. Do not run continuous operation above nameplate HP. Do not compensate for an undersized motor. Do not use SF at high ambient temperatures or altitude without de-rating. Do not assume variable frequency drive service factor applies in the same way. Many standard motors lose SF when run on a VFD (Variable Frequency Drive). Check the maker. Use Inverter Duty if needed.

If you push SF all the time, you risk reduced bearing life and higher heat. That hurts motor bearing life, lubrication life, and seals. It also raises mechanical stress on couplings and belts.

How does SF affect efficiency, power factor, and energy cost?

When you run at SF load, you move away from the peak motor performance curves. You may see lower efficiency. You may see lower power factor. You raise motor power consumption for the same job. That hits your energy cost and your total cost of ownership motor.

You can avoid that. Pick premium efficiency motors with the right size. Balance torque and horsepower relation to the motor load characteristics. Keep voltage imbalance low. Use clean power. Choose the right motor control systems. Use a soft start motor if you hammer the motor with high inrush. Or use a direct online motor starter if the system needs simple and fast starts with proper protection.

I watch the numbers. I check motor efficiency ratings IE1 IE2 IE3 IE4. I look at the rated output motor and the continuous rated motor. I set the motor to run between 75% and 100% load most of the time. That is the sweet spot.

What about VFDs, harmonics, and voltage imbalance?

Harmonic distortion motor effects can raise heat. A VFD uses PWM waves. That is not a pure sine wave. It can add loss in the stator and rotor. That can lower the real service factor. Many motor makers say SF does not apply on a VFD unless the motor is designed for it. You need Inverter Duty with the right insulation class and winding temperature design. Check NEMA MG 1 Part 31 for guidance.

Watch voltage imbalance motor effects. A small imbalance causes big current imbalance. Heat jumps. The motor thermal protection might trip late if set wrong. Always test power quality. Fix loose lugs. Keep cables tight. Lower harmonics with filters if needed. Use a line reactor when the drive needs one.

Want a solid primer on how motors work at the core level? See this clear guide on the motor principle to ground your team.

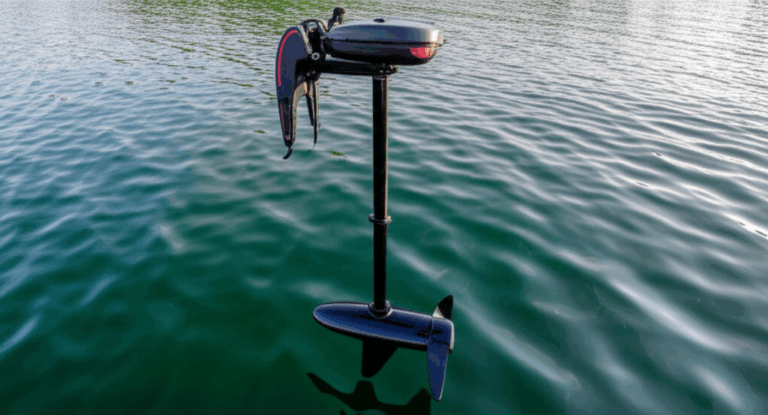

How do environment and enclosure type change what SF can do?

Heat is the boss. The rest of the world follows. Most motors are rated for 40°C ambient temperature and sea level air. At high altitude, air is thin. Cooling drops. You need de-rating. Your motor service factor and altitude may fall from 1.15 to 1.0 or less. The same is true for hot rooms. High ambient temperature motor cuts your margin. That hits motor service factor and cooling hard.

Motor enclosure type matters too. A TEFC motor cools one way. An ODP motor cools another way. Cooling methods for electric motors vary by size and design. A dirty cooling fan hurts heat flow. A blocked vent raises temperature rise. Clean the motor. Keep air paths open. Match the frame, enclosure, and cooling to the job.

This is also where build quality pays off. Low loss electrical steel laminations keep core heat down. If you want a quick explainer with build options, check these high-grade electrical steel laminations. Better steel can mean cooler windings and a longer life under stress.

How do I size motors for pumps, fans, and compressors with SF in mind?

Start with the motor applications heavy duty profile. Study the motor load characteristics. A pump load often tracks the square of speed. A fan does too. A compressor can be tougher. Get the motor performance curves for the load. Use motor sizing for pumps, motor sizing for fans, and motor sizing for compressors rules. Match the motor frame size, torque, and rated HP to the job.

Use motor selection guidelines to pick the right types of electric motors. Think about motor and gearbox selection. Check motor and coupling alignment. Read the motor commissioning plan. If you expect short peaks, you can plan to use SF for those. Do not use SF as a way to cheat on motor procurement specifications. Get the right motor. Use SF as a cushion, not a crutch.

Tie this all back to your motor asset management plan. Look at energy efficiency motor standards and premium efficiency motors. A small step up in efficiency can save you a lot over years. That is how you protect equipment reliability and your budget.

What protection, testing, and maintenance keep SF safe?

You need the right overload protection. Set the Thermal Overload Relay right. For a motor with SF 1.15, your motor service factor vs overload relay setting matters. Many NEC (NFPA 70) rules and NEMA guides say set at 115% to 125% of FLA when SF is 1.15. Follow local code. Follow the maker. Do not guess.

Build a simple motor troubleshooting guide. Check voltage variation and frequency variation. Use vibration analysis to spot mechanical stress and balance issues. Track motor bearing life and lubrication cycles. Watch noise levels electric motors. Review motor testing procedures each year. Keep a clean maintenance schedule.

If you need to rewind, think before you act. Motor rewind impact on service factor and motor remanufacturing service factor can change the motor’s thermal profile. A poor rewind can raise core loss and heat. That cuts life. Work with a shop that understands reliability engineering.

You can also raise reliability by selecting better core parts. The quality of the stator core lamination affects magnetic loss. The fit of the rotor core lamination affects heat and torque. Good laminations help lower loss and heat which supports safe SF use.

Common myths about service factor

Myth 1. “SF means I can run at 115% forever.” No. Motor service factor vs continuous rating says no. SF is not for steady overload.

Myth 2. “VFDs make SF bigger.” No. Motor service factor and harmonics cut margin on many motors. Check the maker.

Myth 3. “SF fixes bad power.” No. Motor service factor and voltage variation will not fix imbalance or sag. Fix the power. Then plan the load.

Myth 4. “Bigger SF always saves money.” Not always. Motor service factor and energy cost can go up if you run hot and inefficient. Look at the whole total cost of ownership.

Quick reference tables

Typical SF and what it means

| Item | Typical Values | What it Means |

|---|---|---|

| Service Factor (SF) | 1.0, 1.15, 1.25 | Overload margin for short times |

| Ambient Temp Rating | 40°C | Above this, you may need de-rating |

| Altitude Rating | ≤ 1000 m | Above this, cooling drops, de-rate SF |

| Insulation Class | B, F, H | Higher class allows higher temperature rise |

| Nameplate HP | Varies | Base for SF calculation: HP × SF = max short-term HP |

SF do’s and don’ts

| Do | Don’t |

|---|---|

| Use SF for short peaks | Run above nameplate HP all day |

| Check NEMA MG 1 and IEC 60034 | Assume SF is the same on a VFD |

| Set OLR per code and maker | Ignore overload relay setting |

| Watch ambient temperature and altitude | Forget to de-rate when it is hot or high |

| Keep laminations and airflow clean | Block vents and fans |

FAQ

Q: Why is service factor important?

A: It gives safe overload capacity for short times. It helps you avoid trips during peaks. It protects you from premature failure when you face bumps in the load. That is why why is service factor important matters for planners and techs.

Q: How do I use motor service factor on a VFD?

A: Treat it with care. Many motors have no variable frequency drive service factor. Harmonics add heat. You often need Inverter Duty designs. Ask the maker.

Q: Does SF change my protection settings?

A: Yes. Motor service factor vs overload relay setting is a big deal. Check the NEC, NEMA, and the motor sheet.

Q: What if my motor runs too hot in SF?

A: Lower the load. Improve cooling. Check voltage imbalance. Consider a larger motor. Review motor failure analysis data before you restart.

Q: Can better materials help?

A: Yes. High grade laminations reduce core loss. That lowers heat under overload. Explore premium electrical steel laminations and quality stacks for better heat control.

Summary: Key points to remember

- Service factor is short-term overload capacity, not a new base rating.

- Read the motor nameplate and know Insulation Class, efficiency, and power factor.

- Use SF for peaks. Do not use it for continuous duty.

- Heat kills. Watch temperature rise, ambient temperature, and altitude.

- VFDs change the game. Many motors lose SF with drives.

- Set thermal overload relays right per NEC and NEMA.

- Keep bearings healthy. Watch lubrication, vibration, and noise.

- Size motors right for pumps, fans, and compressors.

- Clean airflow. Choose quality laminations and core parts. See stator core lamination and rotor core lamination.

- Learn the basics. Review the motor principle to train your team.

References

- NEMA MG 1: Motors and Generators. National Electrical Manufacturers Association.

- IEC 60034 Series: Rotating Electrical Machines. International Electrotechnical Commission.

- IEEE Std 841: Petroleum and Chemical Industry — Severe Duty Motors. Institute of Electrical and Electronics Engineers.

- U.S. Department of Energy. Energy Efficiency and Electric Motors guidance.

- NFPA 70: National Electrical Code (NEC). National Fire Protection Association.

- EASA (Electrical Apparatus Service Association). Good Practice Guides on rewinds and reliability.

Full Guide Sections with Details

How do I use service factor calculation with a nameplate example?

Let’s walk a quick example. You have a continuous duty 10 HP motor. The nameplate says SF 1.15. The math is 10 × 1.15 = 11.5 HP. You have a short peak to 11.2 HP on a conveyor restart. You can ride that peak with the SF margin. You do not stay there. You drop back to 9.5 HP once the belt clears. That is safe use.

If your ambient temperature is 50°C, you cannot count on the same SF. The motor service factor and ambient temperature relationship says de-rate. If the site is at 2000 m, the motor service factor and altitude rule also says de-rate. Heat rules the roost.

One more check. If the motor starts direct-on-line with high inrush, consider a soft start motor to lower stress. Or use a direct online motor starter if the system design expects it and protection is tuned.

What other factors affect motor life when using service factor?

Many factors affecting motor life play a role. Voltage imbalance creates uneven phase currents. That heats the stator. Harmonic distortion adds extra loss. Poor cooling methods for electric motors like blocked vents raise temperature rise. Bad motor and coupling alignment adds mechanical stress. Poor lubrication hurts bearing life.

Good news. You can fix most of these. Set a motor maintenance best practices plan. Use vibration analysis every quarter. Grease per the maintenance schedule. Keep air paths clean. Log motor testing procedures like insulation resistance and winding resistance. Review motor failure analysis reports with your team.

How do materials and design affect service factor and heat?

The core of every motor is a stack of thin steel sheets. These are called laminations. They cut eddy current loss. Good laminations keep heat low. That helps with SF. The same is true for BLDC stator core designs or induction cores. The right steel and stack reduce core loss.

If you want a quick tour of build choices, look at motor core laminations and how different grades behave under load. The quality of the sheet, the coating, and the stack pressure all change heat. Precision stacks help you run cooler at the same load. Cooler windings last longer. That is simple and true.

I also look at frame, enclosure, and cooling fan design. These change airflow. They change hotspot temps. They change how safe it is to use SF during peaks.

How do I tie SF to codes, standards, and buying specs?

Tie it back to the rules. NEMA MG 1 gives SF guidance for North America. IEC focuses on duty cycle and thermal definitions. IEEE gives test methods. NEC (NFPA 70) covers wiring and protection. Your motor procurement specifications should point to the right standard, the motor testing procedures, and the site operating conditions.

Ask vendors for motor performance curves, power factor, and efficiency at multiple loads. Ask how SF changes at high ambient or altitude. Ask for motor commissioning steps. Ask for a motor troubleshooting guide. Smart buying saves money for years.

How do I make the case for better cores and upgrades?

If you run close to the edge, a cooler motor gives you more safety. That can come from better steel, tighter stacks, and better airflow. I like to show the team the link between laminations and heat. Lower loss cores mean lower heat at the same torque. You get more headroom for those bumps that SF covers.

If you want to see real products that support this, explore the portfolio of electrical steel laminations. You can also review specific stator and rotor build options to match your application engineering plan. Better cores can be part of your motor asset management playbook.

By the way, if you want a deeper dive into the inside of the machine, the motor principle article is a solid primer. It shows how stator and rotor parts work together to make torque which helps you connect SF use to the physics under the hood.