What is Permanent Magnetism? Understanding the Science Behind Lasting Magnetic Force

Of course, here is the SEO-optimized article based on your instructions.

Table of Contents

- The Enduring Pull of Permanent Magnetism

- The Science Behind the Static Field: How Permanent Magnetism Works

- Atomic Origins: The Tiny Engine of Magnetism

- Ferromagnetism: The Special Ingredient

- Magnetic Domains: Getting Everyone Pointing the Same Way

- The Hysteresis Loop: A Magnet’s “Memory”

- Key Properties Defining Permanent Magnets

- Remanence (Br): The Strength It Holds

- Coercivity (Hcj): The Resistance to Forgetting

- Energy Product ((BH)max): The All-Around Powerhouse Metric

- Curie Temperature: The Magnet’s Breaking Point

- Magnetic Anisotropy: A Preferred Direction

- Types of Permanent Magnets: Material Matters

- Neodymium Magnets (NdFeB): The Powerhouses

- Ferrite (Ceramic) Magnets: The Workhorses

- Samarium-Cobalt (SmCo) Magnets: The High-Temp Heroes

- Alnico Magnets: The Classic Performers

- A Quick Look at How Magnets Are Made

- Permanent vs. Temporary Magnetism vs. Electromagnetism

- The Incredible World of Permanent Magnet Applications

- In Your Daily Life

- Driving the Future in Automotive

- Powering a Greener World

- Innovations in Medicine

- The Backbone of Industry

- Weighing the Good with the Bad: Advantages and Limitations

- Conclusion: The Indispensable Nature of Permanent Magnets

The Enduring Pull of Permanent Magnetism

Have you ever stopped to think about that simple magnet holding a grocery list to your fridge? Or the satisfying snap when your earbuds click into their charging case? These little moments of invisible force are powered by one of the most fascinating phenomena in physics: permanent magnetism.

I’ve spent years working with and studying magnetic materials, and I still get a kick out of it. At its heart, permanent magnetism is a material’s built-in ability to create its own persistent magnetic field without any outside help, like an electrical current. It’s not magic; it’s a property locked deep within the material’s atomic structure. Unlike an electromagnet, which needs electricity to work, a permanent magnet just is magnetic, all on its own.

And why does this matter? Because this silent, steady force is a cornerstone of modern technology. From the motors in electric vehicles to the generators in massive wind turbines, permanent magnets are the unsung heroes doing the heavy lifting. In this guide, I want to walk you through what I’ve learned, breaking down what permanent magnetism is, how it works, and why it’s so incredibly important.

The Science Behind the Static Field: How Permanent Magnetism Works

To really get what’s going on, we have to zoom in—way in. I mean, down to the atomic level. The “magic” of a permanent magnet isn’t one single thing but a team effort happening inside the material.

Atomic Origins: The Tiny Engine of Magnetism

Every atom has electrons, and these electrons are constantly spinning. Think of each spinning electron as a minuscule magnet with its own north and south pole. This is called its “magnetic dipole moment.” In most materials, these electron spins are completely random. For every electron spinning one way, there’s another spinning the opposite way, and their magnetic fields cancel each other out. It’s like a room full of people all shouting at once—it just becomes noise. The material as a whole isn’t magnetic.

Ferromagnetism: The Special Ingredient

This is where certain materials, which we call ferromagnetic materials, come into play. Think of elements like iron, nickel, and cobalt, as well as rare-earth elements like neodymium. What makes them special is a quantum mechanical effect that encourages the electron spins of neighboring atoms to align in the same direction. It’s a bit like peer pressure at the atomic level. Instead of canceling each other out, they start to work together.

Magnetic Domains: Getting Everyone Pointing the Same Way

Even in an unmagnetized piece of iron, this alignment is already happening, but in tiny, localized neighborhoods called magnetic domains. Imagine a large field filled with thousands of small groups of people. Within each group, everyone is facing the same direction (say, north). But each group is facing a different, random direction. One group faces north, another faces southwest, another east, and so on.

From a distance, the overall effect is zero. There’s no single preferred direction. This is what an unmagnetized piece of ferromagnetic material looks like. The magnetic domains are all there, but their random orientation means the material as a whole doesn’t have a magnetic field.

So, how do we create a permanent magnet? We have to get all those domains to face the same way. We do this by exposing the material to a very strong external magnetic field. When I’ve worked in manufacturing settings, this is often done using a powerful electromagnet called a magnetizer. This external field acts like a drill sergeant, yelling at all the little magnetic domains to snap to attention and align in the same direction.

The amazing part is what happens next. For hard magnetic materials (the stuff permanent magnets are made of), once we turn off that external field, a large majority of those domains stay aligned. The material’s internal structure essentially locks them in place. Now, with billions and billions of tiny atomic magnets all pointing in the same direction, their forces add up, creating a strong, persistent, and macroscopic magnetic field. That’s a permanent magnet.

The Hysteresis Loop: A Magnet’s “Memory”

There’s a concept in magnetism called a magnetic hysteresis loop, which sounds complicated, but it’s really just a graph that shows how “stubborn” a magnetic material is. It tells the story of how a material responds to being magnetized and then having that magnetic field reversed. For permanent magnets, this loop is wide, which signifies that once you magnetize it, it takes a lot of effort (a strong opposing magnetic field) to demagnetize it. This “memory” or resistance to change is exactly what makes a permanent magnet, well, permanent.

Key Properties Defining Permanent Magnets

When you’re choosing a magnet for a job, you can’t just say you want a “strong” one. I’ve learned that you need to be specific, and that means understanding a few key properties. These are the stats on the magnet’s trading card.

Remanence (Br): The Strength It Holds

Remanence is the measure of the magnetic flux density remaining in a material after the external magnetic field is removed. In simpler terms, it’s how strong the magnet is on its own. It’s usually measured in units like Tesla (T) or Gauss (G). A higher Remanence means a stronger magnetic field.

Coercivity (Hcj): The Resistance to Forgetting

If Remanence is strength, Coercivity is toughness. It’s a measure of the material’s ability to resist being demagnetized by an external magnetic field. A magnet with high coercivity is very “stubborn” and won’t easily lose its magnetism, even if it’s exposed to opposing magnetic fields or physical shock. This is crucial for applications like electric motors, where the magnet is constantly operating in a dynamic magnetic environment.

Energy Product ((BH)max): The All-Around Powerhouse Metric

The Maximum Energy Product, or (BH)max, is often considered the single best figure for a magnet’s overall performance. It’s a measure of the magnetic energy density stored within the magnet, calculated from its Remanence and Coercivity. It’s given in units like KiloJoules per cubic meter (kJ/m³). The higher the (BH)max, the more magnetic power you can get from a smaller magnet. This is why Neodymium magnets, with their incredibly high energy products, are so valuable in compact devices.

Curie Temperature: The Magnet’s Breaking Point

Every permanent magnet has an Achilles’ heel: heat. The Curie Temperature is the specific temperature at which a material loses its permanent magnetic properties. At this point, the thermal energy becomes so great that it shakes the atoms violently, breaking the alignment of the magnetic domains and turning them random again. I once saw an intern ruin a very expensive magnet by using a heat gun on it, not realizing that once you cross that Curie temperature, the magic is gone for good (though it can sometimes be re-magnetized).

Magnetic Anisotropy: A Preferred Direction

Some magnets are anisotropic, which means they have a preferred direction of magnetization. During manufacturing, their crystalline structure is aligned in a specific way, so they can only be magnetized along that one axis. The payoff? They become much stronger in that direction. Isotropic magnets, on the other hand, have no preferred direction and can be magnetized any which way, but they are generally weaker. Most high-performance magnets you’ll find today are anisotropic.

Types of Permanent Magnets: Material Matters

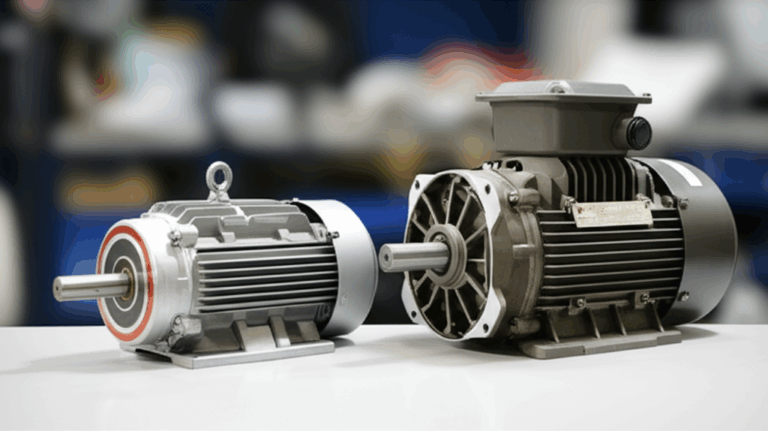

Not all permanent magnets are created equal. The material they’re made from dictates their strength, cost, and how they behave under different conditions. Based on market data, Neodymium and Ferrite magnets dominate the industry, but each type has its place.

Neodymium Magnets (NdFeB): The Powerhouses

These are the strongest commercially available permanent magnets, part of the rare-earth magnet family. They are a composition of Neodymium, Iron, and Boron (NdFeB).

- Properties: They have an incredibly high Remanence and Energy Product. Seriously, the force you can get from a tiny Neodymium magnet is astounding. However, they have a lower Curie temperature compared to other types and are prone to corrosion, which is why they are almost always coated (usually in nickel-copper-nickel).

- Common Uses: Their strength-to-size ratio makes them perfect for applications where space and weight are critical. You’ll find them in high-performance electric vehicle (EV) motors, hard disk drives, headphones, and modern wind turbine generators. The push for EV efficiency, for instance, has seen gains of up to 10-15% partly thanks to these powerful magnets.

Ferrite (Ceramic) Magnets: The Workhorses

Made from strontium carbonate and iron oxide, these are the familiar, dark gray, brittle magnets.

- Properties: They aren’t nearly as strong as Neodymium magnets, but they are much cheaper and have excellent resistance to corrosion and high temperatures.

- Common Uses: Their low cost makes them the go-to for a huge range of applications. I’ve seen them everywhere: refrigerator magnets, loudspeakers, small DC motors, and in industrial magnetic separation systems where cost is a major factor.

Samarium-Cobalt (SmCo) Magnets: The High-Temp Heroes

Another type of rare-earth magnet, SmCo magnets were the strongest available before Neodymium magnets were developed.

- Properties: Their main claim to fame is their exceptional performance at high temperatures. They can operate at temperatures that would permanently damage a Neodymium magnet. They are also highly resistant to corrosion.

- Common Uses: Because of their temperature stability and strength, they are often used in demanding applications like aerospace, military hardware, and high-performance motors that run very hot.

Alnico Magnets: The Classic Performers

Made from Aluminum, Nickel, Cobalt, and Iron, Alnico magnets have been around since the 1930s.

- Properties: They have excellent temperature stability and a reasonably high Remanence, but their Coercivity is quite low, meaning they can be demagnetized more easily than other types.

- Common Uses: You’ll find them in applications that need a stable field over a wide temperature range, like electric guitar pickups, sensors, and various types of laboratory equipment.

A Quick Look at How Magnets Are Made

I’ve had the chance to see parts of the magnet manufacturing process, and it’s quite a feat of engineering. Generally, it involves a few key steps:

Permanent vs. Temporary Magnetism vs. Electromagnetism

It’s easy to get these terms mixed up, so here’s a quick breakdown from my perspective:

- Permanent Magnetism: As we’ve discussed, this is the ability of “hard” magnetic materials to retain their magnetism indefinitely after being magnetized. The field is always on and requires no power.

- Temporary Magnetism: This happens in “soft” magnetic materials, like soft iron. They become strongly magnetic when placed in a magnetic field, but they lose almost all of that magnetism the moment the field is removed. This property is vital in things like transformers and the cores of electromagnets. For example, a transformer lamination core is designed to channel a magnetic field efficiently but not stay permanently magnetized.

- Electromagnetism: This is magnetism created by an electric current flowing through a wire (usually wrapped into a coil). The key difference is control. You can turn an electromagnet on and off, and you can change its strength by adjusting the current. This is the fundamental motor principle that drives much of our world.

The Incredible World of Permanent Magnet Applications

The applications are truly endless. I’m constantly amazed at the clever ways engineers use these invisible forces. Here are just a few places you’ll find them.

In Your Daily Life

- Refrigerator Magnets: The classic example.

- Speakers and Headphones: A permanent magnet interacts with an electromagnet (the voice coil) to create vibrations, which produce sound.

- Sensors: The magnetic sensors in your home security system that detect when a door or window is opened.

- Hard Disk Drives (HDDs): A powerful magnet on the actuator arm moves the read/write heads across the magnetic platters at incredible speeds.

Driving the Future in Automotive

- Electric Vehicle (EV) Motors: High-strength Neodymium magnets are essential for creating the powerful, efficient, and compact motors that drive EVs. The interaction between the permanent magnets on the rotor and the electromagnets in the stator is what creates motion. Understanding the relationship between the stator and rotor is key to understanding modern motors.

- Sensors: They’re everywhere in a modern car—in ABS wheel speed sensors, power steering systems, and throttle position sensors.

Powering a Greener World

- Wind Turbine Generators: Over half of new offshore wind turbines use permanent magnet direct-drive generators. They are more efficient and require less maintenance than traditional gearbox-based systems, which is a huge advantage when you have to service them out at sea.

- Energy Harvesting: Small magnets are used in devices that convert kinetic energy (like vibrations) into small amounts of electrical energy.

Innovations in Medicine

- Magnetic Resonance Imaging (MRI): MRI machines use massive, incredibly powerful superconducting magnets, but permanent magnets are also used in smaller, open MRI systems and various medical devices and sensors.

- Medical Implants: Used in things like hearing aids and magnetic dentures.

The Backbone of Industry

- Magnetic Separators: Powerful magnets are used in recycling plants and mining operations to separate ferrous metals from other materials. I’ve seen systems that can achieve over 99% purity in iron ore processing.

- Lifting Magnets: Huge permanent magnets (or electromagnets) are used in scrapyards and steel mills to lift and move tons of metal.

- Automation: They are critical components in countless actuators, sensors, and robotic systems. The motors that power these systems often rely on a precisely crafted bldc stator core to function efficiently.

Weighing the Good with the Bad: Advantages and Limitations

From my experience, it’s important to know both sides of the coin.

Advantages:

- No Power Required: They provide a constant magnetic field without needing any electricity. This makes them highly efficient.

- Compact and Powerful: Especially with rare-earth magnets, you can get a lot of magnetic force from a very small package.

- Reliability: With no moving parts or power source to fail, they are very reliable.

Limitations:

- Fixed Strength: You can’t change the strength of a permanent magnet. It is what it is.

- Temperature Sensitivity: As we saw with the Curie temperature, heat can be a killer.

- Fragility: Many high-performance magnetic materials (like Neodymium and Ferrite) are brittle like ceramics and can chip or break if dropped.

- Cost and Supply Chain: The raw materials for rare-earth magnets can be expensive, and their prices can fluctuate wildly based on geopolitics and supply chain issues.

Conclusion: The Indispensable Nature of Permanent Magnets

So, that little fridge magnet is part of a much bigger story. It’s a story of quantum physics, material science, and engineering coming together to create an invisible force that we’ve harnessed to build our modern world. From the tiniest sensor to the largest generator, permanent magnetism is a fundamental property that we rely on every single day.

What I find most exciting is that the innovation hasn’t stopped. Researchers are constantly working on new magnetic materials that are stronger, more resistant to heat, and use fewer critical raw materials. As we push for more efficient electronics, cleaner energy, and smarter technology, the role of the humble permanent magnet will only continue to grow. It’s a field that, in my opinion, will never lose its attraction.