What is Single Phasing a 3 Phase Motor? Causes, Effects, & Essential Protection

Of course. Here is the article, written according to all your instructions.

I’ve been working with industrial machinery for over 15 years, and if there’s one silent killer for a three-phase motor, it’s single phasing. I’ve seen it turn a brand-new, high-horsepower motor into a smoking piece of scrap metal in minutes. It’s a frustrating, costly, and often preventable problem. If you’re here, you’ve probably either heard the term and want to know what it means, or you’re staring at a motor that’s humming angrily instead of running smoothly.

Let’s break down what single phasing is, what it does to your equipment, and most importantly, how you can stop it from happening.

Table of Contents

- Understanding Single Phasing: The Definition

- How Single Phasing Affects 3-Phase Motor Operation

- Primary Causes of Single Phasing in 3-Phase Systems

- Recognizable Symptoms of a Single Phased Motor

- Catastrophic Effects: Damage & Downtime from Single Phasing

- Essential Protection Methods for 3-Phase Motors Against Single Phasing

- Prevention and Best Practices for System Reliability

- Conclusion: Safeguarding Your 3-Phase Motor Investment

Understanding Single Phasing: The Definition

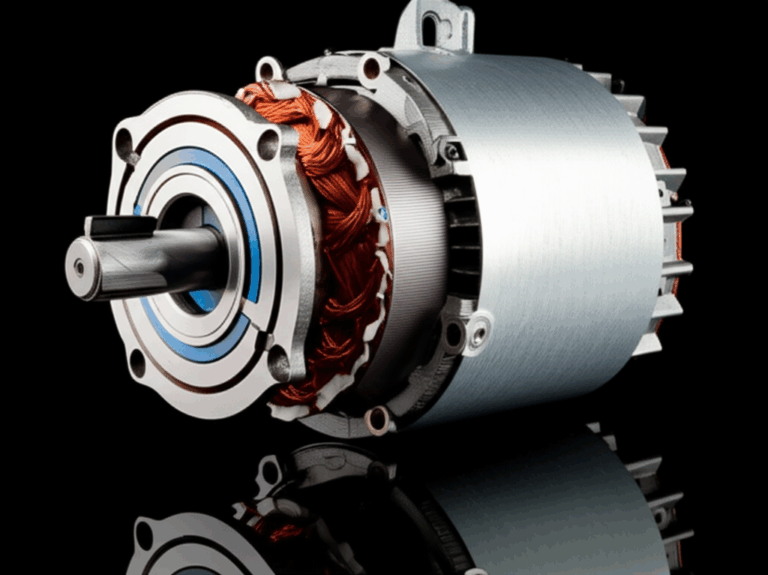

First things first, let’s get on the same page. A standard three-phase electrical system is like a perfectly balanced three-lane highway. You have three separate alternating currents (AC), or “phases,” that are all 120 degrees out of sync with each other. A three-phase motor is designed to use this balanced power. It creates a smooth, rotating magnetic field inside the motor that pulls the rotor around, generating consistent torque and power. It’s an elegant and efficient design.

Single phasing is what happens when one of those three lanes on your electrical highway suddenly closes.

You lose one of the three phases. The motor, which was expecting three balanced power sources, is now trying to run on just two. It’s like trying to run a V8 engine on only five or six cylinders—it might still turn, but it’s going to struggle, shake, and eventually destroy itself. This condition is also known as “phase loss,” and it’s one of the most common causes of motor failure I see in the field.

How Single Phasing Affects 3-Phase Motor Operation

When a motor is designed for three phases, its entire internal physics depends on that balanced supply. The moment you lose a phase, a cascade of bad things starts happening inside that motor housing.

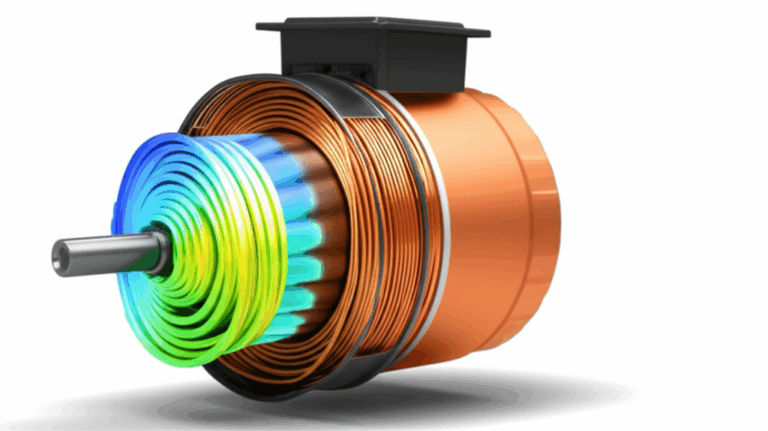

Loss of the Symmetrical Magnetic Field

The real magic behind a three-phase motor is the creation of a perfectly smooth, rotating magnetic field within the stator. Each of the three phases contributes to this field, handing off the magnetic pull seamlessly from one winding to the next. It’s this smooth rotation that makes three-phase motors so efficient and powerful.

When you lose a phase, that beautiful rotating field collapses. What you’re left with is a pulsating, elliptical magnetic field. Instead of pulling the rotor around smoothly, it just kind of jerks it back and forth. If the motor is already running, it might have enough inertia to keep spinning, but it will be weak, noisy, and incredibly inefficient. If it’s trying to start, it likely won’t have enough torque to even get going. This is known as a locked rotor condition, and it’s a death sentence for a motor. Understanding the fundamental motor principle is key to grasping why this balanced field is so critical.

Increased Current in Remaining Phases

This is where the real damage starts. The motor is still trying to do the same amount of work, but now it only has two phases to draw power from instead of three. To compensate for the missing power, the current in the remaining two windings skyrockets. I’ve seen current levels jump to 173% or even 200% of the motor’s full load amp (FLA) rating. This is far beyond what the windings are designed to handle.

Think of it like three people trying to lift a heavy box. If one person suddenly lets go, the other two have to strain much harder to hold it up. That’s exactly what’s happening inside your motor windings. They are under immense electrical strain.

Negative Sequence Currents

This is a more technical concept, but it’s crucial. In a balanced three-phase system, you only have “positive sequence” currents, which produce the forward-rotating magnetic field. When you have a phase loss or even just a voltage imbalance, you create “negative sequence” currents. These currents try to create a magnetic field that rotates in the opposite direction of the rotor.

This is like hitting the brakes while you’re still pressing the accelerator. This opposing force creates immense heat and vibration, contributing significantly to the rapid destruction of the motor.

Primary Causes of Single Phasing in 3-Phase Systems

So, what causes a motor to lose one of its phases? It can happen anywhere between the power utility and the motor itself. I’ve troubleshooted hundreds of these cases, and the cause usually falls into one of two categories.

External Supply Issues

Sometimes, the problem isn’t in your facility at all. The fault can be upstream in the power distribution network.

- Blown Fuse: This is probably the most common culprit I see. A fuse on just one of the three incoming lines blows, but the other two remain intact. This can happen due to a temporary surge or a fault somewhere else in the building.

- Tripped Circuit Breaker: Similar to a fuse, a single pole of a three-pole circuit breaker can sometimes trip without the others, or you might have three separate single-pole breakers where only one trips.

- Utility Line Problems: It’s not rare for a fault to occur on the utility’s side. A tree branch falling on a power line, a failed insulator, or a lightning strike can take out one phase before it ever reaches your building.

- Transformer Failure: The transformers that step down the voltage for your facility can also fail. A problem in one of the primary or secondary windings of the transformer can lead to a single-phasing condition downstream.

Internal System Faults

More often than not, the problem is closer to home. These are the issues within your own electrical system.

- Loose Connections: This is a big one. Vibration, heat cycles (expansion and contraction), and improper tightening can cause a connection to come loose over time. I’ve found them everywhere: at the main panel, in the motor starter, or right inside the motor’s terminal box (the peckerhead). A loose wire is an open circuit, and an open circuit on one phase is single phasing.

- Faulty Contactor or Starter: Motor starters and contactors are mechanical devices with moving parts. The contacts inside can become pitted, corroded, or just plain wear out. If one contact in a three-pole contactor fails to close properly, that phase is lost.

- Broken Wire: A wire can break inside a conduit due to excessive vibration or repeated flexing. It’s less common but definitely happens, especially in mobile equipment or high-vibration environments.

- Internal Motor Fault: While it’s rare for this to be the initial cause, it’s possible for a winding inside the motor to fail and create an open circuit. However, it’s far more likely that single phasing causes a winding to fail, not the other way around.

Recognizable Symptoms of a Single Phased Motor

A motor suffering from single phasing isn’t quiet about it. If you know what to look and listen for, you can often catch the problem before it turns into a catastrophic failure.

- Audible Indicators: The most immediate sign is a loud, angry humming or growling noise. A healthy three-phase motor has a smooth, consistent whir. A single-phasing motor sounds like it’s struggling and in pain. It’s a deep, low-frequency hum that you can often feel as much as hear.

- Thermal Indicators: The motor will get hot, fast. The excessive current drawn by the remaining windings generates a tremendous amount of heat. If you can safely get near the motor, you’ll often feel the heat radiating from the housing. In severe cases, you might even see smoke or smell burning insulation. That’s the smell of money burning, as it means the winding insulation is failing.

- Performance Degradation: If the motor was already running when the phase was lost, it will lose a significant amount of power. You’ll notice a drop in speed and torque. It might not be able to handle its normal load anymore. If the motor is stopped, it will likely fail to start at all. It will just sit there and hum loudly.

- Excessive Vibration: The unbalanced magnetic field creates uneven forces on the rotor, causing the entire motor to vibrate abnormally. This can damage bearings and couplings in addition to the motor itself.

- Electrical Readings: The definitive way to diagnose single phasing is with a clamp-on ammeter. In a healthy motor, the current draw on all three phases (L1, L2, L3) should be very close to equal. In a single-phasing motor, you’ll see zero amps on one phase and abnormally high amps on the other two. This is a clear-cut sign of a serious motor problem that needs immediate attention.

Catastrophic Effects: Damage & Downtime from Single Phasing

I want to be very clear here: single phasing is not a minor inconvenience. It’s an emergency for your motor. The consequences are severe, swift, and expensive.

- Severe Overheating: As I mentioned, the current in the remaining two windings can increase by 73% or more. This leads to a rapid and destructive rise in temperature. Motor windings are coated with a thin layer of enamel insulation, and this insulation has a specific temperature rating. Single phasing can push the winding temperature past its limit in a matter of minutes.

- Winding Insulation Breakdown: Once the insulation gets too hot, it melts, cracks, and burns off. This is the “motor burnout” people talk about. When the insulation is gone, the copper wires of the windings can touch each other (a phase-to-phase short) or touch the motor’s metal frame (a phase-to-ground short). At this point, the motor has failed. The delicate balance between the stator and rotor is compromised, and the entire assembly is often damaged beyond repair.

- Motor Burnout and Failure: The end result is a dead motor. In my experience, a motor running under a heavy load can be destroyed by single phasing in less than a minute. Even under a light load, it’s usually only a matter of a few minutes before permanent damage occurs.

- Reduced Motor Lifespan: Let’s say you catch it quickly and shut it down before it completely fries. Even a brief period of single phasing can cook the insulation, making it brittle and weak. This drastically shortens the motor’s expected life. It might work for a while longer, but it’s now a ticking time bomb, much more susceptible to future failures from heat, vibration, or voltage spikes.

- Production Losses & Costly Downtime: The cost of the motor itself is often just the tip of the iceberg. What about the production line that just came to a screeching halt? Or the critical HVAC system that’s no longer cooling your server room? The cost of unplanned downtime and lost production can easily be ten or even a hundred times the cost of the motor itself.

- Safety Hazards: An overheating motor is a fire hazard. The burning insulation can ignite, and if there are any flammable materials nearby, you could have a much bigger disaster on your hands. There’s also the risk of arc flash when components fail catastrophically.

Essential Protection Methods for 3-Phase Motors Against Single Phasing

The good news is that you don’t have to just sit and wait for disaster to strike. We have excellent technology designed specifically to prevent this kind of failure. Investing in proper motor protection is one of the smartest financial decisions you can make.

- Phase Loss Relays (Phase Failure Relays): This is the gold standard for preventing single-phasing damage. A phase loss relay is a smart device that constantly monitors the voltage or current of all three phases. The instant it detects that one phase is gone (or even if the voltage just drops too low, indicating a brownout or severe imbalance), it sends a signal to trip the motor starter’s contactor, shutting down the motor before it has time to self-destruct. They are relatively inexpensive and can save you thousands in replacement and downtime costs. I consider them essential on any critical three-phase motor.

- Advanced Motor Protection Relays (MPRs): These are the next level up. MPRs are microprocessor-based and offer comprehensive protection. They don’t just look for phase loss; they can monitor for phase imbalance, overcurrent, undercurrent, locked rotor conditions, ground faults, and more. They are highly programmable, allowing you to tailor the protection to the specific needs of your motor and application. For large, expensive, or mission-critical motors, an MPR is a must-have.

- Thermal Overload Relays: Nearly every motor starter has some form of thermal overload protection. These devices work by using bimetallic strips that bend when they heat up, eventually tripping a contact if the current remains too high for too long. While they can sometimes protect against single phasing, they are often too slow. The current surge from a phase loss can destroy the winding insulation before the overload relay has a chance to heat up and trip, especially if the motor is not fully loaded. They are a good backup but should not be your only line of defense.

- Fuses & Circuit Breakers: These are designed for overcurrent and short-circuit protection, not for detecting phase imbalances. A fuse will only blow if the current in that phase exceeds its rating. In a single-phasing scenario, the current in the two remaining phases will be very high, but the current in the lost phase is zero. So, the fuse on the lost phase won’t blow, and the fuses on the other two phases might not blow either if the current, while high, doesn’t quite reach their trip threshold fast enough. They are essential for safety but are not reliable for preventing motor burnout from single phasing.

Prevention and Best Practices for System Reliability

Protection is crucial, but prevention is even better. Good maintenance practices can significantly reduce the chances of a single-phasing event occurring in the first place.

- Regular Inspections & Maintenance: This is the most important thing you can do. Regularly (at least annually) open up your motor control panels, disconnect switches, and motor terminal boxes. Check for any signs of overheating, like discolored wires or melted plastic. Most importantly, check and tighten every single electrical connection. A loose connection is an accident waiting to happen.

- Infrared Thermography: A fantastic preventative tool is an infrared camera. Scanning your electrical panels and motors while they are under load can instantly reveal hot spots caused by loose connections or failing components. It’s a non-invasive way to find a problem before it finds you.

- Routine Testing: Don’t just assume your circuit breakers and fuses are working. They should be part of a regular testing and maintenance schedule to ensure they will operate correctly when needed.

- Quality Components: When installing or replacing parts like contactors, relays, and breakers, don’t skimp. Using high-quality components from reputable manufacturers pays for itself in reliability and longevity. The internal parts of a motor, like the motor core laminations, are built to last, but the external controls are often the weakest link.

- Proper Installation: Ensure that all wiring is correctly sized for the load and that all connections are made securely from the very beginning. A little extra care during installation can prevent a lot of headaches down the road.

Conclusion: Safeguarding Your 3-Phase Motor Investment

Single phasing isn’t just a technical term; it’s a direct threat to your equipment, your productivity, and your bottom line. It transforms a reliable workhorse into a ticking time bomb, where excessive current and heat conspire to destroy the motor’s windings from the inside out.

I’ve learned from experience that being reactive is always more expensive than being proactive. The cost of a good phase loss relay is a tiny fraction of the cost of a new motor, not to mention the lost production while you wait for a replacement. By understanding the causes, recognizing the symptoms, and investing in proper protection and maintenance, you can effectively eliminate this threat from your facility. Don’t wait for the smell of burning insulation to tell you something is wrong. Check your connections, invest in protection, and keep your operations running smoothly.