What is the Purpose of a Squirrel Cage Induction Motor? The Workhorse of Industry

Have you ever wondered what makes the world go round? I’m not talking about gravity. I mean, what makes the fans spin, the factory belts move, and the water pumps work? You might be surprised to learn that a simple, tough, and brilliant machine is behind it all. It’s called a squirrel cage induction motor and its purpose is simple: to turn electrical energy into useful mechanical motion. This article will show you how this amazing device, the workhorse of industry, powers nearly everything around you. You’ll learn what it is, how it works, and why it’s the most popular motor on the planet.

Table of Contents

- How Does a Squirrel Cage Motor Actually Work?

- What are the Main Parts of this Motor?

- Why is it Called a “Squirrel Cage”?

- What is the “Magic” Called Electromagnetic Induction?

- What Makes Squirrel Cage Motors So Popular?

- Where Can You Find These Motors in Action?

- Are There Different Kinds of Squirrel Cage Motors?

- How Do We Control the Speed of These Motors?

- What Problems Can These Motors Have?

- Why is Motor Efficiency So Important Today?

How Does a Squirrel Cage Motor Actually Work?

Imagine you have a compass. If you move a magnet around the outside of the compass, what happens? The needle spins to follow the magnet, right? A squirrel cage motor works on a very similar idea but without a real needle or a hand-held magnet. Instead of a hand, it uses electricity to create a spinning magnetic field.

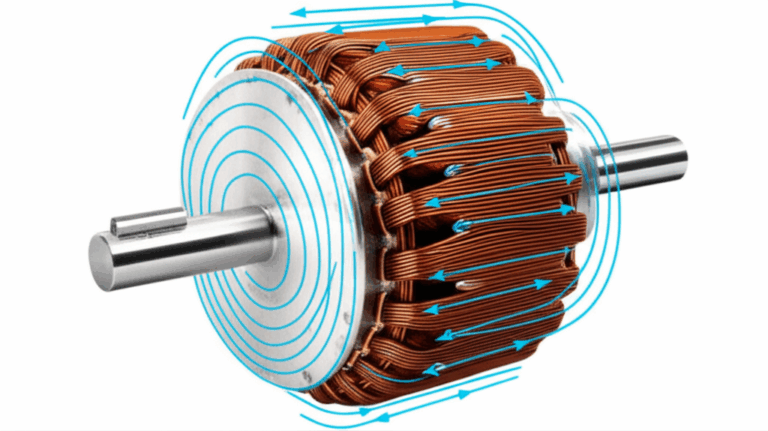

This spinning magnetic field is invisible but very powerful. It’s created in the outer part of the motor. Inside this spinning field is the “squirrel cage” part, which is a special kind of rotor. The invisible magnetic field “pulls” the rotor along with it, causing it to spin. This spinning motion is the mechanical energy we use to power machines. It’s a clever trick of physics, a perfect example of power conversion from electrical to mechanical.

The whole process is called electromagnetic induction. A genius inventor named Nikola Tesla came up with this idea a long time ago. He figured out how to use alternating current (AC) to create a rotating magnetic field generation without any touching parts. This makes the AC motor incredibly reliable. The basic motor principle is elegant and has barely changed in over a hundred years.

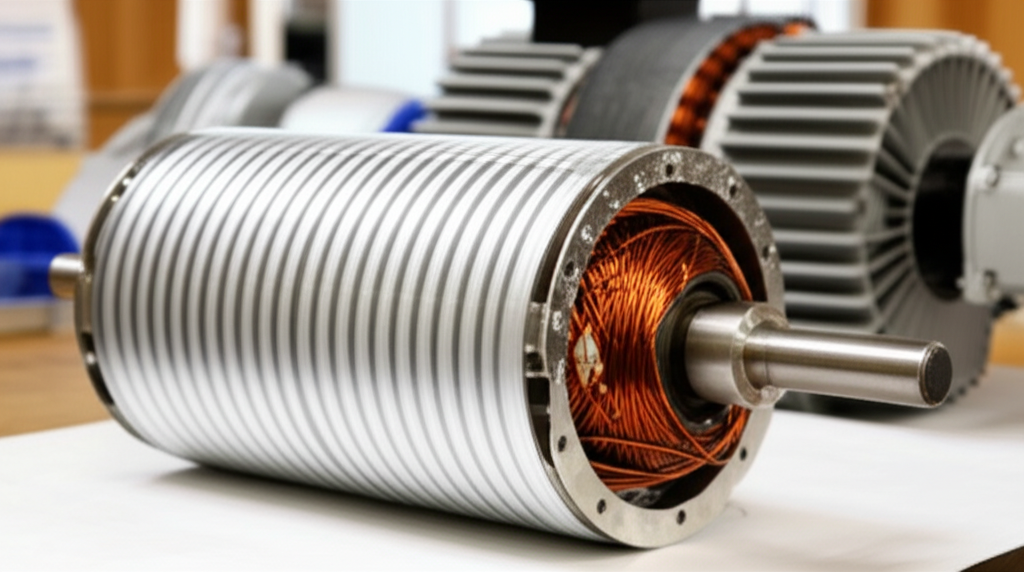

What are the Main Parts of this Motor?

To understand its purpose, you need to know its two main parts. Think of it like a can of soup. You have the can itself and the soup inside. A motor has an outer part and an inner part.

The outer, stationary part is called the stator. It’s like the can. The stator has coils of copper wire, called motor windings, wrapped around a core. When you feed electricity into these windings, the stator creates the powerful rotating magnetic field I mentioned. The quality of its construction, especially the stator winding types and connections, is key to a motor’s performance. High-quality stator core lamination helps focus the magnetic energy and reduce waste.

The inner, spinning part is called the rotor. This is the soup! In our case, this is the “squirrel cage.” It’s not connected by wires to the power source. It just sits inside the stator, separated by a tiny air gap. The rotor’s job is to be “grabbed” by the magnetic field and spin. This spin is transferred to a shaft, which sticks out of the motor housing and connects to whatever we want to move, like a fan blade or a pump.

Why is it Called a “Squirrel Cage”?

Now for the fun part. Why the funny name? If you were to take the rotor out of the motor and remove its outer metal layers, you would see its core structure. It’s made of thick metal bars running lengthwise, all connected by end rings at both ends.

It looks almost exactly like a hamster or squirrel exercise wheel! That’s it. That’s the whole reason for the name. The inventor who first saw this design thought, “Hey, that looks like a squirrel cage.” The name stuck. So, when you hear why is it called a squirrel cage, you know it’s because the rotor in an induction motor looks just like one. This simple, strong squirrel cage rotor design is one of the biggest reasons for the motor’s success.

What is the “Magic” Called Electromagnetic Induction?

So how does the stator’s field make the rotor spin without touching it? This is where the magic of physics comes in. The process is called electromagnetic induction motor principle.

First, the stator creates a magnetic field that is constantly spinning. As this magnetic field sweeps past the bars of the squirrel cage rotor, it “induces” or creates an electric current in those bars. It’s like magic—creating electricity in a piece of metal just by moving a magnet near it. This is based on a rule in physics called Faraday’s Law.

Now, another rule of physics (Lenz’s Law) says that this new current in the rotor bars will create its own magnetic field. This new rotor magnetic field naturally pushes and pulls against the stator’s spinning field. The rotor’s field tries to “catch up” to the stator’s field, but it can never quite get there. This chase is what produces torque, or the twisting force that makes the rotor spin.

There is always a small difference in speed between the spinning field and the rotor. This is called slip in induction motor. If there were no slip, the rotor bars wouldn’t see a changing magnetic field, no current would be created, and there would be no torque. So, slip is absolutely necessary for the motor to work!

What Makes Squirrel Cage Motors So Popular?

Imagine you own a factory. Your biggest Problem is keeping everything running smoothly. If a machine breaks down, you lose time and money. It’s a huge headache.

Now, let’s Agitate that problem. What if you used motors that were complicated, with lots of little parts that wear out? You’d have constant breakdowns. Your conveyor belts would stop, your compressors would fail, and your whole operation would grind to a halt. You’d be spending a fortune on repairs and replacements. This is a nightmare for any business owner.

Here’s the Solution: the squirrel cage induction motor (SCIM). This motor is the answer to your problems. The advantages of squirrel cage motor are huge.

- It’s Tough: Its construction is simple and strong. There are no brushes or other delicate parts that wear out easily. This robust motor design can handle dusty, dirty, and tough environments.

- It’s a Low Maintenance Motor: Because it has so few wearing parts, it can run for years with just a little care, like checking the motor bearings and lubrication. This high squirrel cage motor reliability means you can count on it.

- It’s a Cost Effective Electric Motor: They are simple to build, which makes them cheaper to buy than other types of motors. Their long life and low repair needs save you even more money over time.

- It’s Efficient: Modern motors are very good at turning electricity into work, which saves on your energy bills. This efficiency of induction motor is constantly getting better.

These benefits make it the perfect choice for almost any job that needs a constant speed motor. It’s the definition of an asynchronous motor that you can set and forget.

Where Can You Find These Motors in Action?

Once you know what to look for, you’ll see the applications of squirrel cage motor everywhere. They are the true workhorses of our modern world. In fact, over 80% of all industrial motors are squirrel cage induction motors.

Here are just a few places they fulfill their purpose:

| Application Area | Examples of Use | Why It’s a Good Fit |

|---|---|---|

| Industrial Machinery | Pumps: Moving water for cities or chemicals in a plant. | Reliability is key; pumps must run for a long time. |

| Fans & Blowers: In your home’s HVAC or huge factory vents. | Simple, constant speed is perfect for moving air. | |

| Compressors: Powering air tools or refrigeration units. | Needs a strong, steady torque to work correctly. | |

| Conveyor Systems: Moving boxes at Amazon or rocks in a mine. | A tough motor is needed for heavy, continuous work. | |

| Machine Tools: Spinning lathes and drills in a workshop. | Delivers smooth, consistent power for precise cuts. | |

| Commercial Use | Elevators, escalators, commercial washing machines. | Quiet operation and high reliability are important. |

| Home Appliances | Refrigerators, washing machines, garage door openers. | Small, cheap, and long-lasting motors are ideal. |

From a tiny fan motor applications to large industrial motors that are bigger than a car, the squirrel cage design is scalable and versatile. It is the go-to pump drive motor and conveyor belt motor across the globe.

Are There Different Kinds of Squirrel Cage Motors?

Yes, they come in two main flavors, depending on the type of electrical power they use. The core operating principle of AC motors is the same, but the power supply is different.

A single phase squirrel cage motor is what you’ll find in most homes. It runs on the standard electrical supply you have in your wall outlets. These are great for smaller jobs, like in your washing machine or a small workshop compressor. They need a little extra help to get started, often using a special capacitor or starting winding.

A three phase squirrel cage motor is the king of the industrial world. It runs on a more powerful and balanced three-phase electrical supply, which is common in factories, large buildings, and industrial plants. These motors are more efficient, don’t need a special starting mechanism, and can be built to enormous sizes, delivering huge amounts of horsepower (hp). Many big names like Siemens, ABB, and General Electric (GE) specialize in these industrial electric motors.

How Do We Control the Speed of These Motors?

One of the few disadvantages of squirrel cage motor is that it naturally wants to run at a constant speed, which is tied to the frequency of the electrical power supply. For a long time, this was a “take it or leave it” situation.

But what if you need to slow down a fan or speed up a pump? Today, we have a brilliant solution: the Variable Frequency Drive (VFD). A VFD is an electronic controller that takes the incoming electricity and changes its frequency. By changing the frequency, you can change the speed of the motor’s rotating magnetic field. This gives you precise speed control of induction motor.

Using a VFD for SCIM not only gives you control but also saves a huge amount of energy. Instead of running a pump at full speed all the time, a VFD can slow it down when demand is low. This technology has made the already great squirrel cage motor even more adaptable and efficient. For starting, methods like Direct on line (DOL) starting, star delta starting, or soft starters for induction motors are used to manage the high starting current.

What Problems Can These Motors Have?

Even though they are incredibly tough, these motors aren’t invincible. Like any machine, they can have problems. Knowing the common issues helps in troubleshooting squirrel cage motor. Studies show that the top reasons for motor failure are:

The heart of the motor’s durability lies in its core components. Poorly made laminations in the stator or rotor can lead to more heat, vibration, and wasted energy, causing a shorter lifespan. That’s why high-quality motor core laminations are essential for a reliable and efficient motor. They form the backbone of the motor’s magnetic circuit.

Why is Motor Efficiency So Important Today?

Think about this staggering fact: electric motors, mostly squirrel cage induction types, use about 45% of all the electricity in the world! That’s a huge amount of power. This massive energy consumption electric motors has a big impact on both company budgets and the environment.

Because of this, governments and organizations like NEMA and IEC have created motor efficiency standards. You may see motors labeled with ratings like IE1, IE2, IE3 (Premium Efficiency), or IE4 (Super Premium Efficiency). Each step up represents a significant drop in energy waste. Moving from an old, inefficient motor to a new IE3 or IE4 model can save thousands of dollars in electricity costs over its life.

Improving motor efficiency is one of the easiest ways to reduce our environmental impact of electric motors. It lowers the demand for electricity, which reduces the carbon footprint from power plants. So, the purpose of a modern squirrel cage motor isn’t just to spin a shaft—it’s to do it as efficiently as possible, saving money and helping the planet.

In Summary: The Unsung Hero

The squirrel cage induction motor is truly one of the most important inventions in history. Its purpose is elegant and essential.

Here’s what to remember:

- Its Main Goal: To convert electrical energy into powerful, useful rotational motion.

- How It Works: It uses a spinning magnetic field in the stator to “induce” a current and a magnetic field in the rotor, causing it to spin without any physical contact.

- Why It’s Called That: The rotor looks just like a squirrel’s exercise wheel.

- Its Key Strengths: It’s incredibly robust, reliable, low-maintenance, and cost-effective.

- Where It’s Found: Everywhere! From your kitchen refrigerator to the largest industrial factories, powering pumps, fans, compressors, and conveyors.

The next time you see a fan spinning or hear the hum of a large machine, you can bet that a simple, powerful squirrel cage motor is inside, quietly doing the work that keeps our world moving.