What Motor Did the 1985 Harley-Davidson FXR Come With? (The Iconic Evolution Engine)

If you searched for what motor the 1985 Harley-Davidson FXR came with you probably want a straight answer first, then the context. You might also be an engineer or procurement lead who wants more than trivia. You want to understand how that engine worked, why it mattered, and how this kind of manufacturing evolution parallels modern decisions you make about motor core laminations. You’re in the right place.

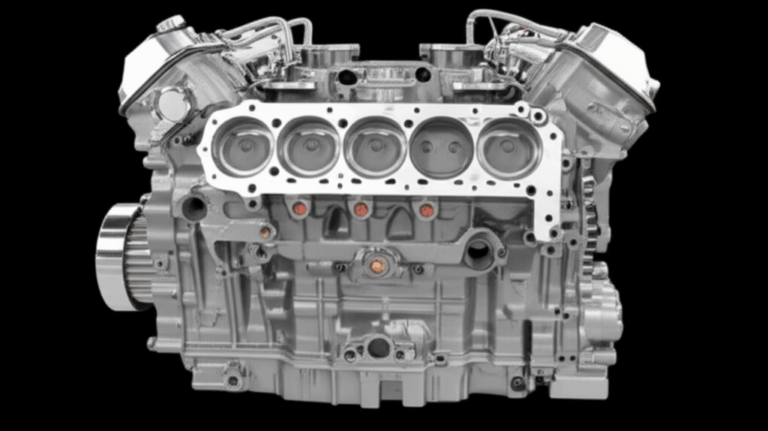

Direct answer: The 1985 FXR came with Harley-Davidson’s 80 cubic inch (1340 cc) Evolution V-twin engine, commonly called the Evo or the “Blockhead.” It’s a 45-degree, air-cooled, overhead-valve Big Twin with aluminum heads, a carburetor, and electronic ignition. This motor helped rebuild Harley-Davidson’s reputation after the AMF era, and it remains a benchmark for reliability and longevity among classic Harleys.

Now let’s unpack the details engineers care about, connect the dots to performance and reliability, and then pivot into a practical engineering guide on electric motor laminations that you can use today.

In This Article

- The Legendary Evolution Engine: Powering the 1985 FXR

- A New Era for Harley-Davidson: Why the Evolution Engine Mattered

- The FXR Chassis: The Perfect Mate for the Evolution Motor

- Evolution Engine Performance and Longevity

- Identifying an Evolution Engine on a 1985 FXR

- The Enduring Legacy of the 1985 FXR and its Evolution Motor

- Frequently Asked Questions About the 1985 FXR Engine

- Engineering Sidebar: What This Means for Electric Motor Laminations

- Your Engineering Takeaway

The Legendary Evolution Engine: Powering the 1985 FXR

Let’s start with the essentials. Engineers live on clear specs.

- Engine family and nickname: Evolution (Evo) Big Twin, often called the “Blockhead”

- Displacement: 80 cubic inches, or 1340 cc

- Configuration: 45-degree V-Twin, overhead valve (OHV), pushrod valvetrain

- Cooling: Air-cooled

- Fuel system: Carbureted, typically Keihin butterfly type in the mid-1980s with manual choke; many later upgrades moved to CV carburetors

- Ignition: Electronic ignition, a notable reliability improvement over points systems

- Mounting: Rubber-mounted in the FXR chassis to reduce vibration

- Approximate output: About 60–65 horsepower at the crank with roughly 70–75 ft-lb of torque at the crank, depending on tune and exhaust

- Materials and design cues: Aluminum cylinder heads and cylinders with distinctive squared-off rocker boxes and “square-ish” fin geometry that distinguish it from earlier Shovelhead engines

You can think of this engine as Harley’s first truly modern Big Twin. Riders loved the stronger oil sealing, better materials, and increased robustness. Engineers appreciated its manufacturability and serviceability.

The Direct Answer: 80 Cubic Inches of “Blockhead” Power

Harley replaced the Shovelhead with the Big Twin Evolution starting with 1984 models. By 1985, the FXR line was fully into the Evo era. The 1985 FXR came from the factory with the 80 cu in (1340 cc) Evo motor. Harley-Davidson enthusiasts and service manuals often refer to it as the “motor that saved Harley.” That’s not hype. It’s history.

Key Specifications: Displacement, Configuration, and Cooling

- Displacement and geometry: 1340 cc in a 45-degree V-twin layout produces the torque-rich, low-speed grunt that defines Big Twins

- Cooling and combustion: Air-cooling simplifies the system and preserves the classic look and sound while the OHV pushrod valvetrain keeps the package compact

- Materials: Aluminum heads improved heat transfer, cut weight, and allowed better head gasket sealing compared to cast iron predecessors

- Ignition and fueling: Electronic ignition improved spark consistency, and the carburetor suited the tuning and manufacturing realities of the day

A New Era for Harley-Davidson: Why the Evolution Engine Mattered

The Evolution engine represented a turning point for Harley-Davidson. The company bought itself back from AMF in 1981 and needed a reliable, modern Big Twin to restore confidence. The Evo engine did that job.

- Transition from the Shovelhead: The Shovelhead delivered character but suffered from oil leaks and inconsistent quality in late years

- Reliability improvements: Better oil sealing, improved metallurgy, and tighter machining tolerances delivered stronger longevity

- Aluminum heads and cylinders: These reduced weight and improved heat management

- Valve train refinement: The pushrod OHV layout remained, yet the engine benefited from better casting, improved gaskets, and more reliable lifter and rocker box sealing

- Manufacturing discipline: Harley raised quality after the AMF era and re-centered manufacturing in Milwaukee and Wisconsin with renewed focus on process control

Harley’s leadership, including Willie G. Davidson, understood that product credibility would win back riders. The Evo earned that trust, and it set the stage for future motors like the Twin Cam and later the Milwaukee-Eight.

The FXR Chassis: The Perfect Mate for the Evolution Motor

Ask anyone who has ridden an Evo-powered FXR at pace. The frame stands out. Engineers designed the FXR chassis for stiffness, stability, and reduced rider fatigue.

- Rubber mount engine: The FXR used rubber mounts for the Evo engine that cut down on vibration transmitted through the frame and into the rider

- Chassis geometry: The frame delivered better handling than many contemporaries which is why some riders called the FXR “the Cadillac of Harleys”

- FXR variants: The 1985 lineup included models such as FXRS Low Rider, FXRT Sport Glide or Touring, and FXRP Police. Variants differed in suspension tuning, luggage, fairing, and ergonomics

The combination of a tighter, more modern engine and a better chassis gave the 1985 FXR real road manners. Long days felt easier. Cornering felt lighter and more stable for a Big Twin.

Evolution Engine Performance and Longevity

You want numbers and practical guidance. Let’s set expectations.

- Horsepower and torque: About 60–65 hp and 70–75 ft-lb at the crank depending on factory tune and emissions setup. The focus sat squarely on low-end and midrange torque rather than peak horsepower

- Transmission and primary drive: The FXR used a 5-speed gearbox with a belt final drive in many trims, and a chain primary drive. This setup complemented the Evo’s torque characteristics

- Maintenance: Regular oil changes, valve train checks, carb tuning, and ignition timing verification kept the Evo happy. The switch to electronic ignition cut maintenance overhead

- Reliability profile: The Evo Big Twin gained a reputation for durability. With proper maintenance, many examples ran long distances without major issues

- Aftermarket support: S&S Cycle, Mikuni, Vance & Hines, Dynatek, and Harley’s Screamin’ Eagle catalog offered abundant performance and reliability upgrades

Common Upgrades and Their Trade-Offs

- Carburetors: Many owners swapped the stock Keihin butterfly for a Mikuni or an S&S Super E for sharper throttle response. A later CV carb from Keihin improved rideability across conditions

- Cams: Mild cam upgrades bumped torque and moved usable power slightly up the rev range. Aggressive cams demanded compression, exhaust, and jetting changes to reap full benefits

- Ignition: Aftermarket electronic ignitions from makers like Dynatek improved spark control and allowed custom curves

- Exhaust: 2-into-1 systems often improved midrange torque while classic duals kept the look and sound many riders wanted

- Drivetrain: Upgraded clutch packs and primary components helped if you pursued big torque bumps

As with any engine, no free lunch exists. More power can stress crankcases, primary chains, and clutches. Many riders kept the Evo near stock and enjoyed rock-solid longevity.

Identifying an Evolution Engine on a 1985 FXR

Visual cues make this easy. You don’t need to be a concours judge.

- Rocker boxes: The Evo’s rocker boxes have a squarer, blockier look than the Shovelhead’s. This gave rise to the “Blockhead” nickname

- Fins and materials: Aluminum heads with regular, square-ish fin stacks stand out compared to earlier designs

- Cases and external hardware: Cleaner casting lines and improved gasket surfaces signal the Evo era

- Engine numbers: Harley’s engine numbers can identify year and model fitment. If you plan a purchase or restoration, verify the engine number format and cross-check with factory documentation or reputable references. Avoid tampered numbers and ask for provenance when possible

The Enduring Legacy of the 1985 FXR and its Evolution Motor

The Evo-powered FXR carved a unique place in Harley history.

- Collector status: Clean, original 1985 FXR examples draw interest because they represent an early pairing of the Evo Big Twin with the famously capable FXR chassis

- Influence on later models: The Dyna line echoed some of the FXR’s virtues. Later Big Twins like the Twin Cam and Milwaukee-Eight stood on the Evo’s reputation for reliability and better oil control

- Community and culture: FXR clubs and online forums celebrate the chassis’ handling, the Evo’s reliability, and the ease of customization

- Service and documentation: Clymer and Haynes manuals, along with Harley factory service manuals, still guide maintenance and rebuilds

Frequently Asked Questions About the 1985 FXR Engine

Q: Is the 1985 FXR a Shovelhead?

A: No. By 1985, the FXR shipped with the 80-inch Evolution Big Twin. Some early 1984 models paired the FXR with a Shovelhead during the transition, but 1985 FXRs used the Evo.

Q: What is the “Blockhead” engine?

A: It’s the nickname for the Evolution Big Twin. The squared-off rocker box covers led to the name, echoing nicknames for earlier engines like Knucklehead, Panhead, and Shovelhead.

Q: How many cc is an 80 cubic inch Harley engine?

A: 80 cubic inches equals 1340 cubic centimeters.

Q: Are FXRs reliable?

A: Yes. The Evo engine and the FXR chassis earned reputations for durability if maintained well. Many consider the Evo one of Harley’s most reliable engines, especially in near-stock trim.

Q: What replaced the Evolution engine?

A: The Twin Cam Big Twin arrived for 1999 in most Big Twin models. The Milwaukee-Eight followed later and serves as Harley’s current Big Twin architecture.

Q: How does the Evo Big Twin differ from the Sportster Evolution engine?

A: The Sportster Evolution engine is a separate family with different displacement options and a different architecture. People often call the Big Twin Evolution the “Big Twin Evo” and the Sportster’s as the “Sportster Evo” to avoid confusion.

Engineering Sidebar: What This Means for Electric Motor Laminations

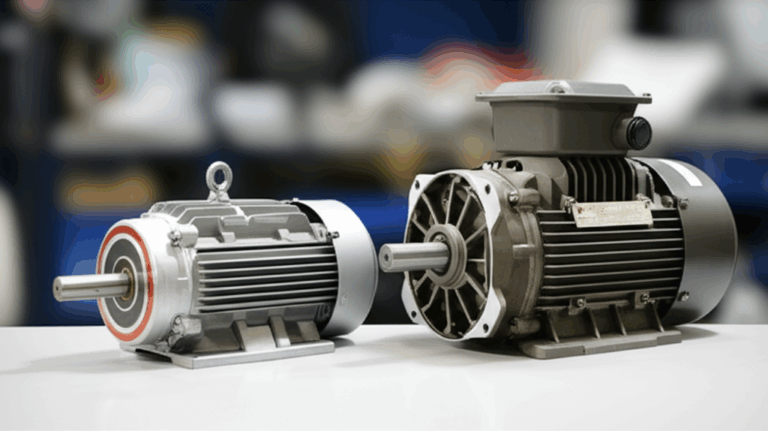

Now let’s bridge from classic motorcycle engine design to your world. You navigate design trade-offs, material choices, and manufacturing processes every day. The Evo engine shows how a disciplined redesign can rescue a brand. Electric motor laminations deserve the same rigor because they influence efficiency, heat rise, and lifetime cost in your motors. If you design or buy stator and rotor stacks, this section is for you.

What’s Really Going On? Eddy Currents and Hysteresis in Plain Terms

An AC machine or an inverter-driven motor constantly swings its magnetic field. That changing field creates two core loss mechanisms in the iron.

- Eddy currents: Picture a river with big swirling whirlpools. Those are eddy currents, but in metal. Changing magnetic fields induce circulating currents inside the core. Those currents waste energy as heat

- Hysteresis: Think of this as magnetic friction inside the material. Every time you cycle the field, the material resists changing its magnetization. The B-H curve captures this behavior. Coercivity tells you how hard it is to demagnetize the material

How do laminations help? Thinner, electrically insulated laminations act like barriers that break large eddy currents into small ones. Smaller loops mean less heat. That’s why you don’t use a solid steel core for an AC motor. You stack thin sheets with insulation coatings to reduce eddy current loss while balancing cost and manufacturability.

Magnetic permeability describes how easily a material carries magnetic flux. If permeability is like water flow then high permeability is a wide pipe for flux. It lowers magnetizing current and reduces copper losses in many designs.

The Guide: Materials and Manufacturing You Can Trust

You have two big levers: the electrical steel itself and how you cut and assemble it. Let’s take a balanced look at both.

Material Considerations

- Non-oriented silicon steels (NOES, M-grades): These are the workhorses for rotating machines. They offer good performance across different directions of flux. ASTM A677 covers many NOES grades. You’ll see M19, M27, M36, etc. The number often correlates with thickness in mils, though the naming convention varies by supplier

- Pros: Widely available, proven, cost-effective for general-purpose motors

- Cons: Not optimal for extreme frequencies or the highest power densities

- Grain-oriented silicon steels (GOES, CRGO): Engineered for one preferred magnetic direction, and used primarily in transformers

- Pros: Very low losses in the rolling direction

- Cons: Poor for rotating machines since flux rotates. Save it for transformer cores

- Cobalt-iron alloys: When you need very high saturation and low loss at elevated frequencies, cobalt alloys shine

- Pros: High power density and lower core loss at high flux densities

- Cons: Very expensive and harder to source

- Amorphous and nanocrystalline materials: These can deliver exceptional low core loss for high-frequency applications

- Pros: Outstanding loss performance

- Cons: Mechanical handling can be tricky and the cost can bite if volumes are high

Thickness matters. Thinner laminations reduce eddy currents at higher frequency. They cost more and require more sheets for the same stack height. Optimize thickness against mechanical constraints, loss targets, and cost.

Insulation coatings matter too. You need a dielectric layer that survives your stamping and stacking process while maintaining stack factor. Ensure the coating class and cure schedule match your process.

For a deeper overview of available plate materials and their role in motor builds, see this practical primer on electrical steel laminations.

Manufacturing and Assembly Processes

- Stamping: The go-to for high-volume production. Hard tooling costs more up front yet gives the lowest per-piece cost and tight repeatability

- Pros: High throughput, consistent burr control with good tool maintenance

- Cons: Tooling lead time and cost. Edge burr and work hardening can raise local loss if not controlled

- Laser cutting: Perfect for prototypes and short runs, plus intricate shapes without tooling

- Pros: Fast iteration with no tooling investment

- Cons: Heat-affected zones can increase local losses. Post-process stress relief or coating repair may be needed

- Wire EDM and waterjet: Useful for specific tolerances or materials. Usually slower and costlier per piece

- Stack assembly choices:

- Interlocking: Tabs lock layers together like LEGO bricks and yield strong stacks without welding. They keep heat low and preserve magnetic properties

- Welding: Strong joints but heat can raise local core loss. Use targeted welds and consider post-weld stress relief

- Bonding and adhesive lamination: Excellent for minimizing vibration and noise, and it can improve fill factor and stiffness. Validate adhesive outgassing and thermal behavior at operating temperatures

- Riveting or cleating: Traditional and easy to inspect. Can add local stress points

If you’re evaluating prototype to production paths, your progression might look like laser cut samples, then pilot stamping tools, then production tooling. Keep a close eye on burr height, lamination flatness, and stack factor at each stage. You protect your performance targets when you police those details early.

For context on subassemblies and the interplay between stator and rotor geometry, you can reference practical overviews of stator core lamination and rotor core lamination. If you want a full-stack view of how core stacks come together in motors of many sizes, a higher-level summary of motor core laminations is also handy during early concept reviews.

Which Application Is This For? Match Choices to Real Use Cases

You make better decisions when you tie materials and processes to the duty cycle.

- General-purpose industrial motors at 50/60 Hz: NOES silicon steels in common M-grades strike a reliable balance. Thickness in the 0.35–0.65 mm range is typical depending on size, efficiency targets, and cost

- Inverter-fed high-speed machines: Consider thinner NOES grades, premium low-loss alloys, or cobalt blends if saturation limits your design. Pay attention to burr and edge quality since higher frequency magnifies eddy-current hotspots

- BLDC and PMSM for traction or robotics: Rotor topology and magnet placement dictate your lamination shape and tolerances. Bonded stacks can cut noise and improve structural integrity at speed

- Transformers and inductors: Use grain-oriented silicon steel or amorphous materials. This is a different design space than rotating machines, so match the material to flux direction and frequency

As you define fit, ground your specs in standards and best practices. IEC 60404 defines magnetic property tests. ASTM A677 defines many non-oriented electrical steel grades. Align your supplier’s test methods to your target standard so you compare apples to apples.

Procurement Notes Engineers Appreciate

Small details separate good suppliers from great ones. Ask about:

- Lamination thickness tolerance and flatness across lots

- Burr height control and deburring processes

- Coating class, cure schedule, and dielectric breakdown strength

- Stack factor and target lamination factor by process

- Core loss test methods and frequency points

- Tool steel choice and scheduled maintenance plans for stamping dies

- Heat input limits for welding or brazing and any stress-relief steps

- Traceability, PPAP or equivalent documentation, ISO 9001 system maturity

- RoHS and REACH compliance and MSDS for adhesives or coatings

- Packaging that preserves flatness and prevents corrosion in transit

If your team lives or dies by losses at a given operating frequency and flux density, insist on consistent sampling and third-party data verification during PPAP or first article inspection.

For material selection references and sourcing basics, many teams consult primers on silicon steel laminations when they need to align M-grades, coating types, and stock availability early in a program.

A Quick Analogy Engineers Like to Share

The Evo engine’s success came from better sealing, better materials, and a smarter chassis integration. That’s exactly how you should think about motor laminations. Better coatings and smarter cutting methods stop performance from leaking out as heat. Thinner, cleaner laminations act like replacing sloppy gaskets with well-machined faces and modern seals. The motor runs cooler, lasts longer, and quietly does its job. It’s not flashy. It’s just good engineering.

Your Engineering Takeaway

Key points at a glance:

- The 1985 FXR came with Harley’s 80 cu in (1340 cc) Evolution Big Twin, known as the “Blockhead”

- The Evo represented a major step up in reliability and oil control after the Shovelhead. It used aluminum heads, a better valvetrain, improved gaskets, and electronic ignition

- The FXR chassis and rubber mounts made a great platform. It handled well, rode comfortably, and still feels sorted today

- Output sat around 60–65 hp and 70–75 ft-lb at the crank depending on tune. The design centered on usable torque and longevity

- Aftermarket support is massive. Upgrades like carbs, cams, ignition, and exhaust can transform throttle response and midrange, though every change comes with trade-offs

- For electric motor designers and buyers: lamination choices drive efficiency, heat rise, and cost. Select material grade, thickness, and assembly method to match your frequency and duty cycle

- Prioritize burr control, insulation integrity, and repeatable stacking. Align tests to standards like IEC 60404 and ASTM A677. Validate with PPAP and consistent sampling

If you’re speccing motor laminations now and want a grounded second opinion, line up your duty cycle, frequency, peak flux density, and target losses. Then start a focused discussion with your supplier about thickness, coating, and cut process. A 30-minute technical review can save weeks of iteration and thousands in retesting.

And if you’re here for the Harley answer only, here it is once more in one clean line: The 1985 Harley-Davidson FXR came with the 80 cu in (1340 cc) Evolution “Blockhead” V-twin. Simple as that.

Additional context and entities referenced for clarity and completeness:

- Harley-Davidson engine lineage: Knucklehead, Panhead, Shovelhead, Evolution, Twin Cam, Milwaukee-Eight

- FXR model family and variants: FXRS Low Rider, FXRT Sport Glide or Touring, FXRP Police, FXRD Grand Touring, FXLR Low Rider Custom in later years

- Big Twin Evolution versus Sportster Evolution engines. Big Twin covers 1340 cc Evo used in FXR, Softail, Dyna, and touring families during the 1984–1999 window. Sportster used a different Evolution engine family

- Aftermarket names: S&S Cycle, Mikuni, Dynatek, Screamin’ Eagle, Vance & Hines

- Supporting resources often used by restorers and mechanics: Clymer Manuals, Haynes Manuals, Harley-Davidson factory service manuals, and community knowledge hubs like FXR owners groups and H-D forums

- Standards context for motor materials and testing: IEC 60404 family for magnetic properties and ASTM A677 for non-oriented electrical steels. SAE J1349 provides an engine power rating standard if you’re comparing crank versus wheel numbers on internal combustion engines

Note on model year nuances:

- The Evolution Big Twin entered production in 1984, and the FXR line moved to the Evo early. When confirming originality on a specific 1984 or 1985 bike, always check engine numbers, frame tags, and documented service history

Finally, if your day job revolves around designing, buying, or validating lamination stacks, keep this truth handy. You don’t win efficiency in one big leap. You win it by shaving loss at every seam, every edge, and every sheet. That’s how good engineering pays off ride after ride and run after run.