What Motors Power Monster Trucks? The Roaring Heart of the Beasts Explained

When you’re in a stadium and the ground starts to shake, you know what’s coming. A 12,000-pound beast of engineering, like Grave Digger or Maximum Destruction, screams into the arena, its engine roaring like a thunderclap. You see it leap 30 feet into the air, crush a row of cars like they’re aluminum cans, and perform gravity-defying stunts. It’s pure spectacle.

But have you ever stopped to wonder what’s really going on under that fiberglass body? What kind of motor does it take to create that much raw, earth-shaking power? If you’ve ever found yourself marveling at these machines and asking, “What motors are in monster trucks?” you’re in the right place. The answer isn’t just a simple engine model; it’s a deep dive into a world of custom-built, high-performance engineering designed for one purpose: maximum destruction.

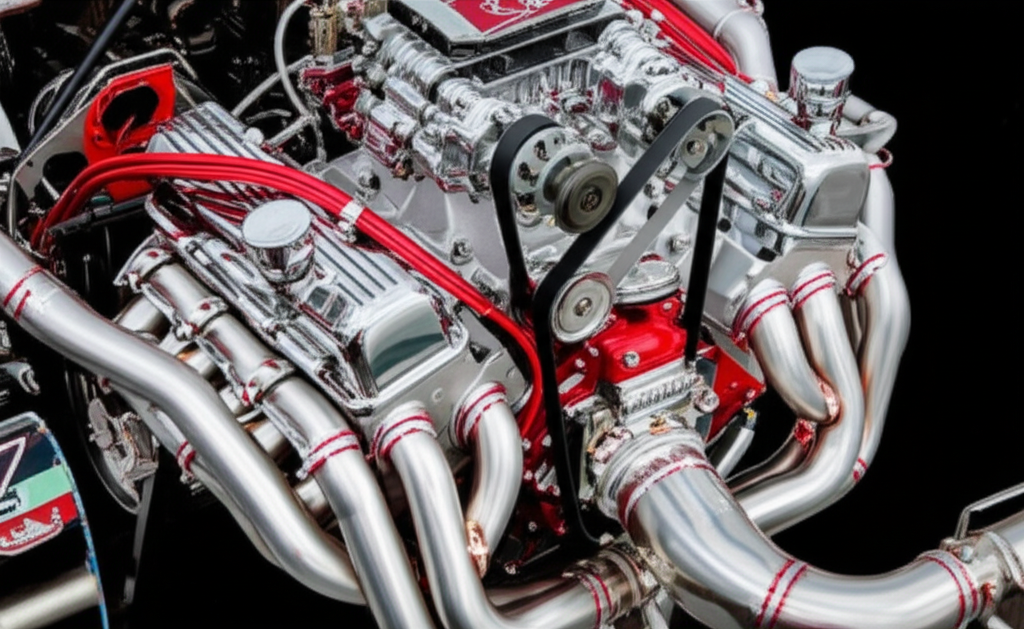

These aren’t engines you can just pull from a production pickup truck. They are purpose-built marvels, a symphony of specialized components working together to achieve something truly extraordinary. Let’s lift the hood and explore the roaring heart of these mechanical monsters.

What We’ll Cover

- The Dominant Force: Monster Truck Engine Types

- Unpacking the Power: Key Performance Metrics

- Beyond the Engine: Supporting Systems for Extreme Power

- The Evolution and Future of Monster Truck Engines

- A Look Inside: Common Engine Components & Their Roles

The Dominant Force: Monster Truck Engine Types

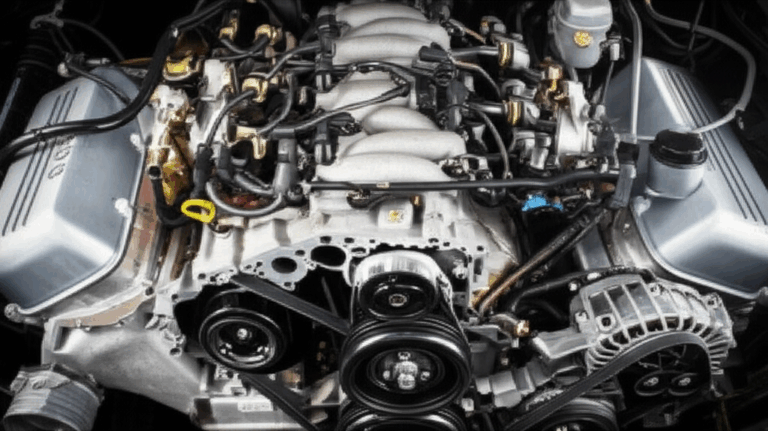

At the core of nearly every competitive monster truck in circuits like Monster Jam is a trifecta of power: a massive big-block V8 engine, a screaming supercharger, and a thirst for methanol fuel. This combination is the undisputed king of the arena, providing the explosive power needed for both racing and freestyle events.

The Reign of the Big Block V8

Why a V8? The answer lies in its inherent strength, relatively simple design, and its massive potential for generating the two things a monster truck needs most: horsepower and torque. But these aren’t your grandpa’s V8s.

The typical monster truck engine is a custom-built, big-block V8 with a staggering displacement, usually ranging from 540 to over 632 cubic inches (that’s 8.8 to 10.4 liters!). For perspective, a high-performance Ford F-150 Raptor has an engine about half that size. This massive volume allows the engine to gulp down enormous quantities of air and fuel, which is the first step in making colossal power.

You won’t find these engine blocks on a standard assembly line. Teams start with ultra-strong, aftermarket cast-iron or billet aluminum blocks from specialized manufacturers like Merlin or Dart Machinery. While the architecture is often based on a Chevrolet big-block design, nearly every component is forged, reinforced, and built to withstand forces that would shatter a normal engine. This focus on a robust foundation is why these powerplants can handle the incredible stresses of a two-minute freestyle run.

The Supercharger Advantage: Forced-Air Fury

A big engine is a great start, but to get to the 1,500+ horsepower range, you need to force-feed it. That’s where the supercharger, or “blower,” comes in. That massive, polished piece of machinery sitting on top of the engine isn’t just for looks; it’s the key to unlocking insane power.

Think of a supercharger like an industrial-strength air pump. Driven by a belt connected directly to the engine’s crankshaft, it spins at incredible speeds and crams air and fuel into the engine’s cylinders under immense pressure. This process, known as forced induction, allows the engine to burn way more fuel than it normally could, resulting in a dramatic increase in horsepower and torque.

Most monster trucks use one of two types of superchargers:

- Roots-type Blower: The traditional, iconic design. It’s great for making huge torque right from idle.

- Screw-type Blower: A more modern and efficient design from companies like PSI Superchargers. These are incredibly popular in Monster Jam because they build boost very consistently and efficiently across the engine’s RPM range.

How much pressure are we talking about? A typical monster truck supercharger generates 25 to 40+ PSI of boost. A turbocharged sports car might run on half that. This constant, high-pressure charge is what gives monster trucks their explosive acceleration and the ability to spin those 66-inch tires with ease.

The Fuel of Champions: Why Methanol?

You might assume these trucks run on high-octane racing gasoline, but you’d be mistaken. The fuel of choice in the monster truck world is methanol, a type of alcohol. There are several critical reasons for this.

First and foremost, methanol makes more power. It has a much higher octane rating than gasoline, which means it’s far more resistant to engine knock or detonation—a destructive force in high-pressure, supercharged engines. This allows engine builders to run higher compression ratios and more boost, squeezing every last drop of power out of the motor.

Second, it has a cooling effect. Methanol absorbs a tremendous amount of heat when it vaporizes in the intake manifold. This “chemical intercooling” results in a cooler, denser air-fuel charge, which again translates to more power and helps keep the engine from overheating during a demanding run.

Finally, there’s a safety component. While highly flammable, a methanol fire burns with a clear or light blue flame and can be extinguished with water, unlike a gasoline fire. This provides a crucial safety advantage for drivers in the event of a fuel line rupture.

Of course, using methanol isn’t without its challenges. These engines are incredibly thirsty, consuming about 10 gallons of methanol for a single race or freestyle run—that’s about 2.5 gallons per minute! This requires a specialized fuel delivery system, often from brands like Enderle or Kinsler, capable of pumping massive volumes of this corrosive fuel to the engine.

Unpacking the Power: Key Performance Metrics

So, we have a giant V8, a massive blower, and potent fuel. What does that all add up to? The performance numbers are just as mind-boggling as the trucks themselves.

Horsepower: The Top-End Thrust

A modern monster truck engine produces anywhere from 1,300 to over 2,000 horsepower. Let that sink in. A brand-new Ferrari supercar has around 700-800 horsepower. A monster truck has more than double that. This immense horsepower is what allows the truck to build incredible wheel speed for soaring through the air and hitting massive ramps at full throttle.

Torque: The Crushing Force

While horsepower is impressive, torque is arguably more important for a monster truck. Torque is the rotational force—the raw, twisting power that gets the truck moving. It’s what allows a driver to launch a 12,000-pound machine off the line, climb near-vertical obstacles, and flatten a car without breaking a sweat.

These engines generate a staggering 1,200 to over 1,500 lb-ft of torque. That’s more than three times the torque of a heavy-duty diesel pickup truck. This instant, ground-shredding force is available almost immediately, giving drivers the on-demand power they need to maneuver and perform spectacular stunts.

RPMs and Durability: A Short, Violent Life

Monster truck engines are built to scream, often revving to 7,000 RPM or higher during a run. This combination of high RPMs, immense cylinder pressure from the supercharger, and the shock loads from massive jumps puts an incredible strain on every internal component.

Because of this, engine longevity is measured in runs, not miles. Teams perform an engine rebuild after every 15-20 hours of run time, meticulously inspecting and replacing parts like pistons, connecting rods, and bearings. A complete race engine can cost anywhere from $40,000 to over $100,000, so maintenance is a critical and expensive part of the sport.

Beyond the Engine: Supporting Systems for Extreme Power

Making 1,500 horsepower is one thing; getting it to the ground and keeping the engine from self-destructing is another. The engine is just one piece of a complex puzzle.

Heavy-Duty Drivetrain

All that power is useless if you can’t transmit it to the wheels. Monster trucks use incredibly robust drivetrain components to handle the abuse.

- Transmissions: Most trucks use a highly modified 2- or 3-speed automatic transmission, like a Powerglide or a custom unit from SCS Gearbox. These are built for strength and reliability, not for smooth shifting or fuel economy.

- Axles and Drivelines: The drivelines and planetary axles (often from military vehicles) are massive and reinforced to withstand the violent shock of landing a 30-foot jump under full power.

Specialized Cooling & Lubrication

Generating that much power also generates an immense amount of heat. To keep things from melting down, monster trucks use large aluminum radiators, often mounted in the rear, along with powerful auxiliary fans to pull air through them.

Just as critical is the lubrication system. These trucks use a dry sump oil system. Unlike a conventional car where oil sits in a pan at the bottom of the engine, a dry sump system uses an external tank and a multi-stage pump. This ensures the engine receives a constant supply of oil at stable pressure, even when the truck is flying through the air upside down or tilted at an extreme angle. It completely prevents oil starvation, which would instantly destroy the engine.

Ignition Systems

Lighting the fire in the cylinders requires a powerful and reliable spark. Monster trucks use a magneto ignition system, often from brands like MSD or Mallory. A magneto is like a self-contained mini-generator that creates its own high-voltage electricity. It doesn’t rely on the truck’s battery, and it produces an incredibly hot, consistent spark, which is essential for igniting a dense, pressurized methanol fuel mixture at high RPMs.

The Evolution and Future of Monster Truck Engines

The engines powering today’s trucks are a world away from where they started. In the early days, pioneers like Bob Chandler of Bigfoot used modified, factory-based V8s from production trucks. As the sport grew, the demand for more power led to the custom-built, supercharged, methanol-fueled monsters we see today. But what does the future hold?

The Rise of Electric Monster Trucks

While the methanol-burning V8 remains the king, electric technology is starting to make its presence felt. In 2019, the Bigfoot team debuted Bigfoot #21, the first all-electric monster truck. Powered by a series of electric motors and a massive battery pack, it proved that electric powertrains could deliver the instant torque and impressive performance required for monster truck competition.

The engineering behind these trucks is fascinating. Instead of a single engine, they use multiple compact, high-power electric motors. The core motor principle of converting electrical energy into rotational force is the same as in any EV, but scaled up to an incredible degree. Each motor is essentially comprised of a stationary part and a rotating part, known as the stator and rotor, which interact through magnetic fields to generate torque. The precision-engineered rotor core lamination is a critical component in maximizing the efficiency and power output of these advanced motors.

Electric monster trucks offer several advantages, including incredible instant torque, quieter operation (a pro or con, depending on your perspective!), and zero emissions. However, they also face challenges like battery weight, charging infrastructure at venues, and the high cost of development. For now, they remain a niche, but they point toward an exciting possible future for the sport.

A Look Inside: Common Engine Components & Their Roles

To truly appreciate these engines, it helps to know the key players inside the block. Here’s a quick rundown of the main components:

- Engine Block: The foundation of the engine, typically made of cast iron or aluminum. It houses the cylinders and all other components.

- Cylinder Heads: Sit on top of the block and contain the valves, spark plugs, and passages for air/fuel intake and exhaust.

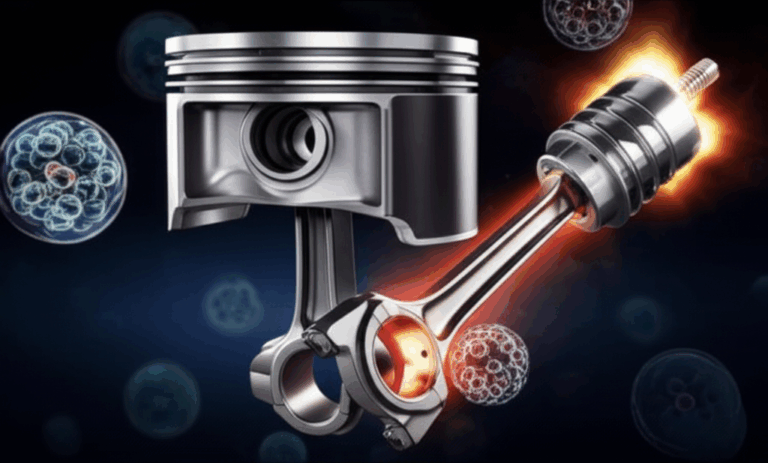

- Crankshaft: The backbone of the engine. It converts the up-and-down motion of the pistons into the rotational force that drives the truck.

- Pistons & Connecting Rods: The pistons are forced down by combustion, pushing on the connecting rods, which in turn spin the crankshaft. In a monster truck, these are forged from high-strength alloys.

- Camshaft: A rotating shaft with lobes that open and close the intake and exhaust valves at precisely the right time. The “cam” profile is critical for engine performance.

- Intake Manifold: Sits between the supercharger and the cylinder heads, directing the air and fuel mixture into each cylinder.

- Exhaust Headers: A set of tuned pipes that carry the burnt gases out of the engine. They are designed to scavenge exhaust efficiently, which helps the engine breathe better and make more power.

Conclusion: The Engineering Marvels of Monster Trucks

The roar of a monster truck engine is more than just noise; it’s the sound of extreme engineering. It’s the result of a purpose-built, supercharged big-block V8 designed to survive in one of the most brutal motorsports on the planet. This symphony of power is a carefully orchestrated combination of massive displacement, high-pressure forced induction, potent methanol fuel, and a host of heavy-duty supporting systems.

From the custom-forged internals to the sophisticated fuel and ignition systems, every single part is chosen for maximum power, performance, and durability. These engines are the heart and soul of the show, providing the raw, untamed power that allows these 12,000-pound giants to defy gravity and captivate millions. The next time you see a monster truck fly, you’ll know that it’s not magic—it’s the incredible power of a true mechanical beast.