Why Are Outboard Motors So Expensive? Unpacking the High Cost of Marine Engines

Of course. Here is the article, written according to your detailed instructions.

If you’ve ever shopped for a new boat or considered repowering your current one, you’ve probably had a moment of pure, unadulterated sticker shock. You look at the price tag on a new outboard motor and think, “Wait, for that price, I could buy a pretty decent car… so why is this boat engine so expensive?”

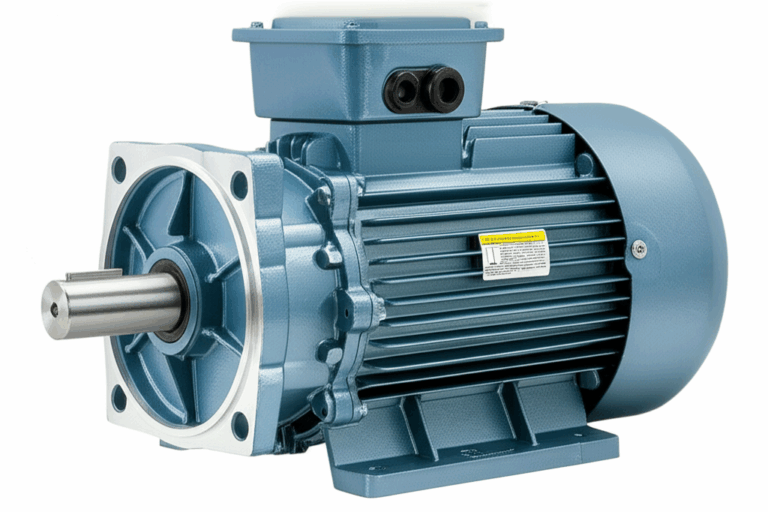

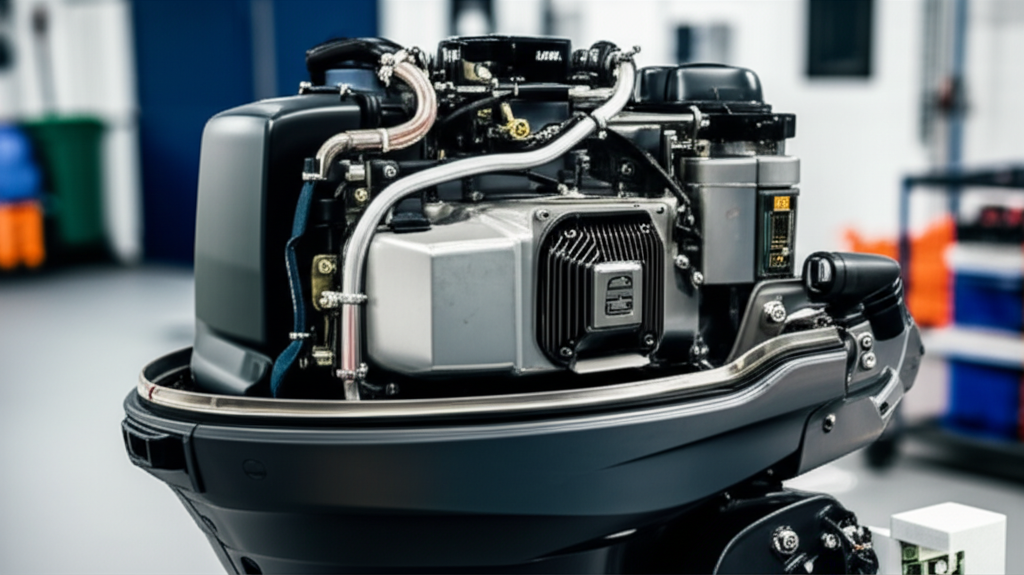

It’s a perfectly valid question, and you’re not alone in asking it. The high cost of outboard motors can seem perplexing, especially when you compare them, horsepower for horsepower, to automotive engines. But the truth is, an outboard motor is far more than just an engine. It’s a highly specialized, self-contained propulsion system engineered to perform flawlessly while surviving one of the harshest environments on Earth: the water.

That hefty price tag isn’t arbitrary. It’s the direct result of intensive research, specialized materials, cutting-edge technology, and the brutal realities of a low-volume, high-stakes market. Let’s pull the cowling off and take a deep dive into what truly drives the high cost of marine engines.

What We’ll Cover

- The Core Engineering & Manufacturing Drivers of Outboard Motor Costs: A look at the intense R&D, specialized materials, and strict regulations that form the foundation of the price.

- Economic & Market Factors Influencing Outboard Motor Pricing: How supply chains, brand reputation, and dealer networks add to the final cost.

- Beyond the Purchase Price: Understanding Long-Term Ownership Costs: An overview of the other expenses that come with owning a marine engine.

- Exploring More Affordable Alternatives & Value Considerations: A guide to used motors, smaller engines, and the emerging electric market.

- Conclusion: The Value Proposition Behind the Price Tag: Summarizing why a modern outboard is an investment in safety, reliability, and performance.

The Core Engineering & Manufacturing Drivers of Outboard Motor Costs

The biggest chunk of an outboard’s cost comes from what it takes to design, build, and test a machine that can reliably push your boat through chop, waves, and corrosive saltwater for thousands of hours without failing. A car engine lives a pampered life in comparison.

Intensive Research & Development (R&D) and Innovation

You don’t just whip up a new outboard motor design on a napkin. Major manufacturers like Yamaha and Mercury Marine invest staggering amounts—often hundreds of millions of dollars annually—into their marine research and development divisions. For instance, Yamaha’s total R&D budget across all its segments in 2022 was around $1.5 billion. A significant slice of that pie goes directly into marine technology.

This investment fuels a constant push for innovation in several key areas:

- Performance & Efficiency: Engineers are in a never-ending race to squeeze more power and better fuel economy out of every drop of gasoline. This leads to complex fuel systems, like multi-stage direct injection and lean-burn technologies, which are costly to develop and perfect.

- Emissions Compliance: Meeting a dizzying array of global emissions standards is a massive engineering challenge that adds significant cost (more on that later). While most outboards are internal combustion, the R&D into different electric motor designs, such as those using a sophisticated bldc stator core, is a major area of future investment.

- User Comfort: Modern boaters expect a quiet, smooth ride. A huge amount of R&D goes into sophisticated sound dampening, engine balancing, and vibration reduction technologies to make your day on the water more pleasant.

- Digital Integration: Outboards are no longer just mechanical brutes. They are sophisticated computers that must seamlessly integrate with GPS, sonar, digital throttles, and advanced joystick piloting systems. Developing the software and hardware for this level of integration is a major expense.

Developing a completely new engine platform from the ground up can easily take five to seven years and cost over $100 million before the first unit is even sold. That massive upfront cost is baked into the price of every motor.

Specialized Materials & Manufacturing for Harsh Environments

Here’s the single biggest difference between a car engine and an outboard: saltwater. Saltwater is relentlessly corrosive; it finds every weakness and attacks it without mercy. To survive, an outboard can’t be made from the same stuff as the engine in your car.

- Corrosion Resistance is Everything: Manufacturers use proprietary, marine-grade aluminum alloys that can cost two to five times more per pound than standard aluminum. Critical components in the gearcase, driveshaft, and powerhead are often made of high-grade stainless steel.

- Proprietary Coatings: It doesn’t stop with the metal itself. Companies have developed their own multi-layer coating and painting processes, like Mercury’s “MercFusion” or Yamaha’s “Ultimate Corrosion Protection System.” These are complex, expensive, multi-step processes involving electro-deposition primers and specialized top coats designed to create an impenetrable barrier against corrosion.

- Precision Manufacturing: An outboard must be completely watertight. This requires incredibly precise engineering and manufacturing tolerances to ensure every seal and gasket holds up under intense pressure, vibration, and thermal cycling. The manufacturing process is therefore more meticulous and less automated than mass-market car engine production. Even the internal electrical components, like starter motors and alternators, require robust designs with high-quality motor core laminations to withstand vibration and temperature extremes.

Stringent Environmental Regulations & Emissions Standards

The days of smoky, sputtering two-stroke outboards are long gone. Today’s engines must comply with incredibly strict emissions standards set by bodies like the U.S. Environmental Protection Agency (EPA) and the California Air Resources Board (CARB), which has some of the toughest rules in the world.

Meeting these standards isn’t cheap. It requires complex engineering solutions like:

- Electronic Fuel Injection (EFI): Precisely controlling the fuel-to-air ratio is key to clean combustion.

- Catalytic Converters: Just like in your car, many modern four-stroke outboards use catalysts in their exhaust systems to scrub harmful pollutants.

- Advanced Engine Management: Sophisticated sensors monitor everything from oxygen levels to engine temperature, allowing the onboard computer to make constant adjustments for optimal efficiency and minimal emissions.

The costs for R&D, specialized components, and the rigorous testing and certification needed to prove compliance can add anywhere from 5% to 15% to the final retail price of a new outboard.

Advanced Technology & Integrated Features

A modern outboard is a technological powerhouse. The list of advanced features that add to the cost is long and growing:

- Digital Throttle and Shift (DTS): Also known as “fly-by-wire,” these systems replace clunky mechanical cables with smooth, responsive electronic controls. This feature alone can add $1,500 to $5,000 per engine.

- Integrated Power Steering: High-horsepower motors require power steering, and modern integrated systems provide effortless control but add significant cost and complexity.

- Joystick Piloting: For boats with multiple engines, joystick systems allow for incredible low-speed maneuverability, like moving sideways or spinning in place. It’s a game-changing feature, but it’s also a costly option, often adding $15,000 to $25,000 to the total package.

- Smart Systems: Modern engines feature built-in diagnostic systems, are compatible with NMEA 2000 networks to share data with your boat’s other electronics, and often have smart features like troll control and automatic trim.

Robust Quality Control & Extensive Durability Testing

When you’re miles offshore, engine failure isn’t an inconvenience; it’s a life-threatening emergency. Manufacturers know this, and their quality control and testing procedures are absolutely brutal for a reason.

Before a new model is released, prototypes are subjected to thousands of hours of torture testing. They’re run at full throttle for days on end in super-salinated water tanks, exposed to extreme temperature swings, and subjected to intense vibration tests. Every component, from the lower unit to the electrical connectors, is tested to ensure it can withstand years of abuse. This rigorous, multi-stage testing is incredibly expensive but essential for building a reputation for reliability—and that cost is passed on to the consumer.

Economic & Market Factors Influencing Outboard Motor Pricing

Beyond the engineering and manufacturing floor, a handful of powerful economic forces also contribute to the high price you see at the dealership.

Complex Global Supply Chains & Raw Material Costs

Outboard motors are globally sourced products. A single engine might have components made in Japan, the United States, and Southeast Asia. This complex supply chain is vulnerable to fluctuations in raw material costs (like the 20-40% spike in aluminum and steel prices from 2020-2022), international shipping expenses (which surged by over 200% during the pandemic), tariffs, and currency exchange rates. Any disruption or cost increase anywhere along that chain ultimately impacts the final price.

Brand Reputation, Market Demand & Limited Competition

The outboard motor market is a consolidated industry dominated by a few key players: Mercury, Yamaha, Suzuki, and Honda. Unlike the automotive world with its dozens of brands, this limited competition allows these established manufacturers to command a premium for their products.

These brands have spent decades building a reputation for reliability and performance. That brand trust is a valuable asset, and it’s reflected in the price. Furthermore, the demand for recreational boating has been consistently high, meaning there’s less pressure on manufacturers to aggressively compete on price.

Distribution Networks, Dealerships & After-Sales Support

You don’t buy a 300HP outboard on Amazon. You buy it from a certified dealer, and that distribution model carries significant costs.

- Dealer Markup: The price you pay includes the dealer’s profit margin, which typically ranges from 15% to 30%. This markup covers their overhead—the showroom, service bays, specialized tools, and sales staff.

- After-Sales Support: The manufacturer has to support a vast network of trained technicians. This involves providing extensive (and expensive) technical training, maintaining massive parts inventories in warehouses around the world, and honoring comprehensive multi-year warranties. These support costs are substantial and account for an estimated 2-5% of an engine’s MSRP.

Low Production Volumes & Lack of Automotive-Scale Economies

This is one of the most critical economic factors. The entire global outboard motor industry produces around 2 to 3 million units per year. In contrast, the automotive industry produces roughly 80 million vehicles annually.

This vast difference means outboard manufacturers simply can’t achieve the same economies of scale. The per-unit cost for everything is higher. The specialized components, from the gearbox gears to the specific electrical steel laminations used in the charging system, can’t be produced with the same cost-saving scale as automotive parts. Tooling, molds, and assembly lines are more specialized and less automated, leading to a higher cost for every single engine that rolls off the line.

Beyond the Purchase Price: Understanding Long-Term Ownership Costs

The initial purchase is just the beginning. It’s important to remember the total cost of ownership, which includes:

- Rigging & Installation: Professional installation is critical for performance and safety, and it can cost several thousand dollars.

- Scheduled Maintenance: Regular service, including oil changes, filter replacements, and impeller inspections, is essential for longevity.

- Fuel & Oil: A powerful outboard can be thirsty, and fuel will be your single biggest ongoing expense.

- Winterization & Storage: Proper seasonal care is crucial in many climates to prevent damage from freezing temperatures.

- Insurance: Insuring your expensive new motor is a necessary and recurring cost.

Exploring More Affordable Alternatives & Value Considerations

If a brand-new, high-horsepower motor is out of reach, don’t despair. You have several options to get on the water more affordably.

- The Used Outboard Market: A well-maintained used motor can be a fantastic value. However, it comes with risks. Always get a thorough mechanical inspection and check the engine’s service history before buying.

- Smaller Horsepower Options: Don’t buy more motor than you need. A smaller, lighter engine will not only be cheaper to purchase but also more fuel-efficient to run. Match the horsepower to your boat and your typical activities.

- The Emerging Electric Outboard Market: Electric outboards are gaining traction. Their upfront cost can be high, comparable to or even exceeding that of a gas motor, but their operational costs are a fraction of the price. With no gas, oil, or complex winterization, the long-term savings can be significant. At the heart of these electric marvels, the design of the stator core lamination is absolutely critical for maximizing range and power from the battery pack.

- Repowering Strategically: If you’re replacing an old engine, talk to your dealer about options. Sometimes a previous-year model or a brand that offers a better value proposition can save you thousands.

Conclusion: The Value Proposition Behind the Price Tag

So, why are outboard motors so expensive?

Because they have to be.

The high price tag is a direct reflection of what it takes to build a machine that can generate immense power while surviving a relentless assault from the elements. It’s a product of hundreds of millions of dollars in research, the use of exotic and costly materials, compliance with tough environmental laws, and the integration of bleeding-edge technology.

When you buy a modern outboard from a reputable brand, you’re not just buying an engine. You’re making an investment in reliability, safety, performance, and peace of mind. You’re buying the confidence that your engine will start every time you turn the key and get you and your family safely back to the dock, season after season. Seen through that lens, the high price starts to make a lot more sense.