Why Copper is the Preferred Choice for Electrical Wiring and Motors

Every engineer, designer, and procurement manager eventually faces a fundamental question about materials: why do we stick with what works? In the world of electrical systems, from the simple wiring in your walls to the high-performance windings of an industrial motor, one material has reigned supreme for over a century: copper. While alternatives exist and new alloys are constantly being developed, copper remains the undisputed benchmark.

If you’ve ever found yourself weighing the trade-offs of material choice, wondering if there’s a more cost-effective or modern alternative, you’re asking the right questions. The decision to use copper isn’t just based on tradition; it’s a calculated engineering choice rooted in a unique combination of electrical, physical, and economic advantages that no other commercially viable material has been able to match. This article explores the core reasons why copper dominates, providing the clarity you need to make confident design and purchasing decisions.

In This Article

- The Unrivaled Electrical Conductivity of Copper

- Exceptional Physical Properties for Durability and Performance

- Resistance to Corrosion and Oxidation for Long-Term Reliability

- Safety and Reliability in Electrical Systems

- Cost-Effectiveness and Lifecycle Benefits

- Copper’s Crucial Role in Electrical Motors

- Why Not Alternatives? Copper vs. Aluminum and Others

- The Future of Copper in Advanced Electrical Applications

The Unrivaled Electrical Conductivity of Copper

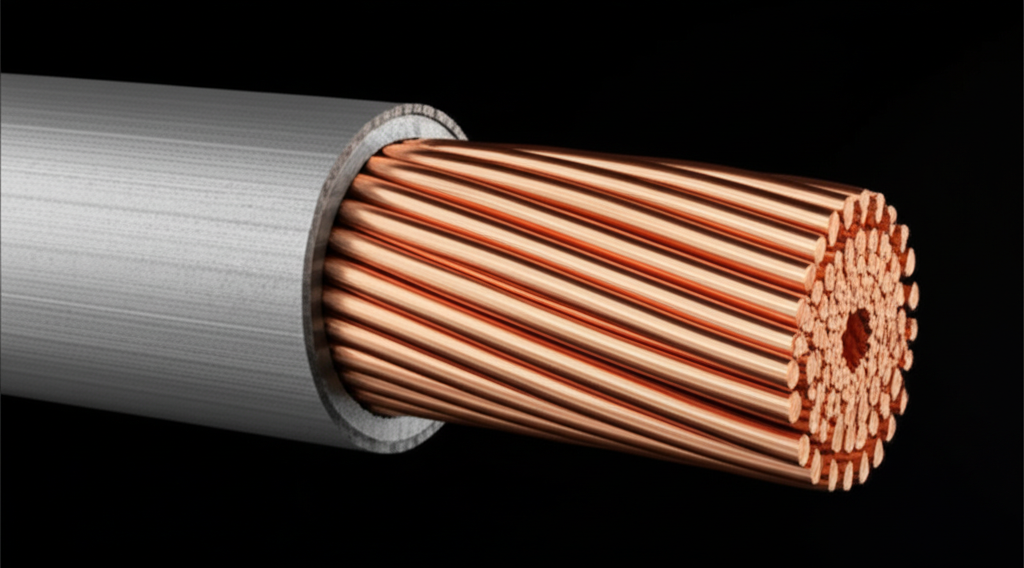

At the heart of any electrical system is the flow of electrons. The primary job of a conductor is to allow this flow with as little resistance as possible. This is where copper first begins to pull away from the competition.

Low Resistivity, High Efficiency

Electrical conductivity is the measure of how easily a current can pass through a material. It’s the inverse of resistivity, which is the material’s inherent opposition to that current. Among all non-precious metals, pure copper has the lowest electrical resistivity.

Think of it like a water pipe. A high-conductivity material like copper is a wide, smooth, clean pipe that allows water (current) to flow freely with minimal pressure loss (voltage drop). A higher-resistivity material, like aluminum or steel, is a narrower, rougher pipe that requires more pressure to move the same amount of water, wasting energy in the process.

This low resistance is not just an academic talking point; it has profound real-world consequences. Every bit of resistance in a wire or motor winding converts precious electrical energy into wasted heat through a process called Joule heating. By minimizing this resistance, copper wiring directly translates to:

- Higher Energy Efficiency: Less energy is lost as heat, meaning more of the power you put in gets to where it’s needed. In large industrial motors or across the vast electrical grid, this translates to massive energy savings and lower operating costs.

- Reduced Power Loss: In power transmission and distribution, minimizing loss ensures that the voltage at the end of the line is stable and reliable.

The International Annealed Copper Standard (IACS), established in 1913, sets the benchmark for conductivity, with pure annealed copper rated at 100% IACS. This remains the standard by which we judge all other conductors.

Ampacity Advantage

A conductor’s ability to carry current safely is known as its ampacity. This is largely determined by how hot the wire gets under load, as excessive heat can melt the insulation and create a serious fire hazard. Because copper is such an efficient conductor, it generates less heat for a given amount of current compared to other materials.

This superior performance means that for the same current load, you can use a smaller diameter copper wire compared to an aluminum one. To achieve the same ampacity, an aluminum conductor typically needs to be one or two gauge sizes larger than its copper counterpart. This has several practical benefits:

- Space Savings: In complex machinery, control panels, or conduits packed with wires, space is at a premium. Smaller copper wires allow for more compact and less cluttered designs.

- Flexibility: A smaller wire is a more flexible wire, making it easier for electricians to pull through conduits and around tight corners during installation.

Exceptional Physical Properties for Durability and Performance

While high electrical conductivity is copper’s headline feature, its mechanical properties are what make it a truly practical and reliable material for real-world applications.

Ductility and Malleability: The Ease of Formation

- Ductility is the ability of a material to be stretched or drawn into a wire without breaking. Copper is exceptionally ductile, second only to gold and silver. This property is what allows manufacturers to draw it down to very fine diameters, creating everything from heavy-gauge power cables to the hair-thin magnet wire used in stator core lamination windings. This ease of manufacturing is a key reason for its widespread availability.

- Malleability is the ability to be shaped or hammered without shattering. This, combined with ductility, makes copper forgiving during installation. It can be bent, twisted, and pulled into place without fracturing, reducing material waste and installation time.

Superior Tensile Strength: Built to Last

Tensile strength measures a material’s resistance to being pulled apart. Copper wire has nearly double the tensile strength of aluminum wire. This is critically important for a few reasons:

- Installation Durability: During installation, wires are pulled through long runs of conduit, subjecting them to significant stress. Copper’s strength ensures it doesn’t stretch, thin out (a condition called “necking”), or break.

- Connection Integrity: Strong, stable connections are essential for safety. Copper’s strength prevents it from deforming or breaking at termination points, such as screws, lugs, or connectors.

- Vibration Resistance: In applications like motors, transformers, and vehicles, constant vibration can fatigue weaker materials. Copper’s inherent strength helps it withstand these mechanical stresses over a long service life.

Excellent Thermal Conductivity: Keeping Things Cool

Beyond its electrical properties, copper is also an excellent thermal conductor. Its ability to dissipate heat is a crucial, often overlooked, safety and performance feature.

As we mentioned, all conductors generate heat due to electrical resistance. Copper’s ability to quickly move this heat away from potential “hot spots” and dissipate it into the surrounding environment is vital.

- In Motor Windings: This is paramount. Efficient heat dissipation prevents the enamel insulation on the magnet wire from breaking down, which would lead to short circuits and catastrophic motor failure. Better thermal management allows motors to run cooler, which directly contributes to higher efficiency and a longer operational life.

- In High-Current Wiring: For heavy loads in industrial settings or power distribution, copper’s thermal conductivity helps manage the significant heat generated, preventing insulation degradation and maintaining the safety of the entire system.

Let’s compare the numbers. Copper’s thermal conductivity is around 401 W/m·K, while aluminum’s is only about 205 W/m·K. This means copper is nearly twice as effective at getting rid of performance-killing heat.

Resistance to Corrosion and Oxidation for Long-Term Reliability

Electricity and chemistry are deeply intertwined. A material’s chemical stability, especially at connection points, is just as important as its conductivity.

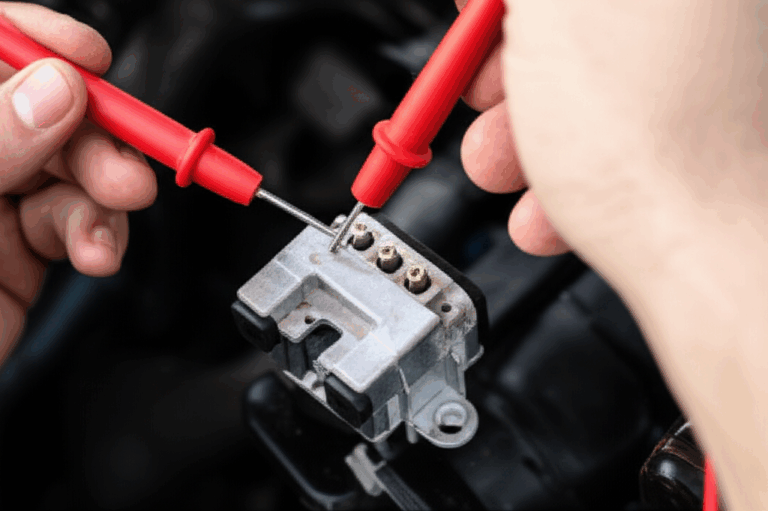

Stable Connections

When copper is exposed to air, it forms a thin, hard layer of copper oxide on its surface. While this might sound like a bad thing, this patina is actually conductive and protects the underlying metal from further, more aggressive corrosion. This means that even over decades, a properly made copper connection remains electrically sound and stable.

This property is a stark contrast to aluminum. When aluminum is exposed to air, it forms a layer of aluminum oxide. This layer is hard, brittle, and—most importantly—is an excellent electrical insulator. If this oxide layer forms at a connection point, it can dramatically increase resistance, leading to heat buildup, arcing, and a potential fire hazard.

Preventing Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte (like moisture). Copper is relatively noble, meaning it’s less reactive than many other metals. This makes it compatible with a wide range of common connector materials, such as brass and bronze (which are themselves copper alloys), minimizing the risk of corrosive degradation at critical junctions.

Safety and Reliability in Electrical Systems

The physical and chemical properties of copper combine to make it the safest and most reliable choice for electrical conductors, a fact recognized by regulatory bodies worldwide.

Minimizing Fire Hazards

The history of residential wiring provides a powerful case study. In the 1960s and 70s, due to high copper prices, aluminum wiring was used in some homes. This led to a notable increase in electrical fires. The primary culprits were the properties of aluminum that we’ve discussed:

- Oxidation: The insulating oxide layer at connections caused overheating.

- Cold Flow (Creep): Under pressure and thermal cycling, aluminum tends to slowly “flow” or deform, causing connections to loosen over time.

- Higher Thermal Expansion: Aluminum expands and contracts more than copper with temperature changes. This cycling can also work connections loose.

Loose connections are a recipe for disaster, creating tiny gaps that cause arcing—sparks of electricity jumping across the gap. This arcing can reach incredibly high temperatures, easily igniting nearby materials. The significantly lower incidence of these failure modes in copper systems is a major reason it’s the standard.

Code Compliance and Industry Standards

Because of its proven track record of safety and reliability, copper is the material mandated or overwhelmingly preferred by electrical codes and standards bodies around the globe. Organizations like the National Electrical Code (NEC) in the United States, the International Electrotechnical Commission (IEC), and Underwriters Laboratories (UL) have developed stringent standards for electrical wiring and components. These codes are based on decades of real-world data and overwhelmingly favor copper for its predictable and safe performance in residential, commercial, and industrial applications. When you choose copper, you’re choosing a material that has been tested and proven to meet the highest safety benchmarks.

Cost-Effectiveness and Lifecycle Benefits

While the initial purchase price of copper wire can be higher than aluminum, a simple cost-per-pound comparison is misleading. A true assessment must consider the total lifecycle cost, where copper often emerges as the more economical choice.

Initial Investment vs. Long-Term Value

The higher conductivity and strength of copper mean you can use less of it to do the same job. Smaller wire sizes, less conduit space, and easier installation can offset some of the initial material cost.

However, the real value lies in long-term reliability. A copper installation is a “fit and forget” solution. Its resistance to corrosion, creep, and fatigue means fewer failures, less maintenance, and minimal downtime. In an industrial setting, where a single motor failure can shut down an entire production line, the cost of an unreliable electrical system can be astronomical. The premium paid for copper is an investment in operational continuity and peace of mind.

Recyclability and Sustainability

Copper is a champion of the circular economy. It is 100% recyclable and can be recycled over and over again with absolutely no loss of its inherent properties. Recycled copper is indistinguishable from primary-produced copper.

This has two major benefits:

Copper’s Crucial Role in Electrical Motors

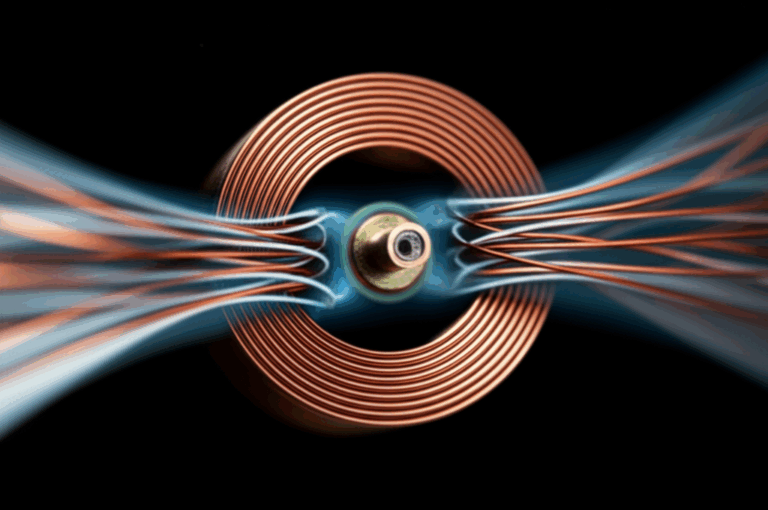

Nowhere are the combined advantages of copper more apparent than inside an electrical motor. The intricate relationship between the stator and rotor demands materials that can perform under immense electrical and mechanical stress.

High-Efficiency Windings

The heart of a motor is its windings—coils of wire that generate the magnetic fields that create motion. The efficiency of a motor is directly tied to the conductivity of these windings. Because copper has such low resistivity, it minimizes the energy lost to heat (known as I²R losses) within the windings.

According to a study by the Copper Development Association (CDA), increasing the amount of copper in motor windings can directly boost efficiency by 1-2 percentage points. While that might not sound like much, for a large industrial motor running 24/7, that small percentage translates into thousands of dollars in electricity savings over its lifespan. This is why standards like NEMA Premium® efficiency often necessitate the use of high-quality copper windings in conjunction with properly designed electrical steel laminations.

Compact Designs

Copper’s superior conductivity allows motor designers to achieve a target power output with smaller and lighter windings compared to alternatives. This leads to more compact, power-dense motors. A smaller motor requires less material for its housing and core, fits into tighter spaces, and has lower inertia, which can be critical in applications requiring rapid acceleration and deceleration, such as robotics and electric vehicles.

Why Not Alternatives? Copper vs. Aluminum and Others

To fully appreciate copper’s dominance, it helps to understand the limitations of its main competitors.

| Property/Metric | Copper (ETP – C11000) | Aluminum (AA 1350) | Silver (Pure) | Notes & Relevance to Electrical Use |

|---|---|---|---|---|

| Electrical Conductivity (% IACS) | 100% | ~61% | ~106% | Copper sets the standard. Aluminum requires larger conductors for the same ampacity. Silver is slightly better but prohibitively expensive for bulk use. |

| Tensile Strength (MPa) | ~220-250 | ~80-120 | ~150 | Copper is significantly stronger and more resistant to installation stress, stretching, and breaking at connection points. |

| Thermal Conductivity (W/m·K) | ~401 | ~205 | ~429 | Copper dissipates heat almost twice as effectively as aluminum, crucial for preventing overheating in motors and high-load circuits. |

| Corrosion Resistance | Excellent (forms a stable, conductive oxide layer) | Poor (forms a resistive oxide layer leading to connection failure) | Excellent | Copper’s stable surface ensures long-term connection integrity, a major safety advantage over aluminum. |

| Creep (Cold Flow) | Very Low | High | Very Low | Copper resists deforming under pressure, preventing connections from loosening over time, unlike aluminum which is prone to this failure mode. |

| Relative Cost | Medium | Low | Very High | While aluminum is cheaper per pound, its technical drawbacks often lead to higher lifecycle costs and safety risks. Silver’s cost makes it impractical for general wiring. |

The Aluminum Challenge

As the table shows, aluminum’s primary advantage is its lower weight and cost. However, its technical disadvantages—lower conductivity, lower strength, high thermal expansion, and a propensity for oxidation and creep—make it a challenging material for general wiring. It requires larger conductor sizes, specialized installation procedures, and specific connectors designed to mitigate the risks of connection failure. While it finds use in high-voltage overhead transmission lines where weight is a primary concern, for most other applications, the safety and reliability of copper are paramount.

Silver and Gold: The Precious Metals

Silver is actually a slightly better conductor than copper. So why don’t we use it? The answer is simple: cost. It is far too expensive for widespread use as a bulk conductor. It does, however, find niche applications in high-performance coatings and specialty contacts where every fraction of a percent of conductivity matters.

Gold, while less conductive than copper, is exceptionally resistant to corrosion. This makes it the ideal material for plating critical electrical connectors, contacts, and pins in low-voltage, low-current electronics to ensure a perfectly reliable connection for decades.

The Future of Copper in Advanced Electrical Applications

Far from being a legacy material, copper is more critical than ever as the world transitions to a more electrified and sustainable future.

- Electric Vehicles (EVs) and Charging Infrastructure: The shift to electric mobility is driving a massive increase in copper demand. An average internal combustion engine car contains about 20-25 kg of copper. A battery electric vehicle (BEV) can contain four times that amount, up to 85 kg or more, used in the motor windings, battery pack, inverters, and extensive wiring harnesses. The charging stations themselves also rely on heavy-gauge copper cabling.

- Renewable Energy Systems: Wind turbines and solar farms are copper-intensive. A large wind turbine can contain several tons of copper in its generator windings, cables, and transformers. Solar installations require extensive copper wiring to collect and transmit the generated power.

- Smart Grids and Digitalization: Modernizing the electrical grid to be more efficient, responsive, and resilient requires a backbone of highly reliable copper conductors, transformers, and switchgear to manage complex power flows.

Conclusion: Copper Remains the Gold Standard

When you examine the complete picture, it becomes clear why copper has been and continues to be the premier choice for electrical wiring and motors. It’s not just one property but a unique and powerful combination of advantages that sets it apart.

From its unmatched electrical and thermal conductivity to its physical strength, ductility, and chemical stability, copper delivers a level of performance, safety, and long-term reliability that is simply unrivaled by other scalable materials. While the initial cost may be a factor, its lifecycle value—driven by energy efficiency, low maintenance, and unparalleled safety—makes it the most intelligent engineering and economic choice for virtually every application. In a world powered by electricity, copper remains the indispensable element that makes it all possible.