Why Does My Motor Shake? An Expert’s Guide to Causes, Diagnosis, and Fixes

Table of contents

- Introduction: What motor vibration really means

- Top mechanical reasons your motor shakes

- Rotor imbalance

- Misalignment in shafts and couplings

- Worn or damaged bearings

- Loose mounts, soft foot, and foundation problems

- Bent motor shaft

- Structural looseness in pulleys, fans, and fasteners

- Electrical causes behind motor shaking

- Voltage imbalance and fluctuations

- Faulty windings and stator issues

- Loose electrical connections

- Variable frequency drive (VFD) problems

- Environmental and operational factors

- Resonance

- External vibrations

- Cavitation in pump systems

- Excessive or uneven load

- How I diagnose a shaking motor step by step

- Visual inspection

- Listen and feel

- Basic checks with power off and locked out

- Advanced tools and when I call a pro

- Solutions and repairs that actually work

- Mechanical fixes

- Electrical fixes

- Operational adjustments

- Preventing future motor shake: best practices

- When to call a professional

- Conclusion: Don’t ignore the shake

Introduction: What motor vibration really means

I still remember the first time a motor shook my whole workbench. It was a small pump motor that sounded like a toolbox tumbling down stairs. I wanted to ignore it. I didn’t. That decision saved the bearings and the shaft because the shake wasn’t just noise. It was a warning.

Motor shaking signals energy going somewhere it shouldn’t. Sometimes the fix is simple like tightening loose motor mounts. Other times the root cause is serious like rotor imbalance or misalignment or damaged bearings or faulty windings. In my experience a vibrating motor costs more in the long run. It can shorten the motor’s lifespan, boost energy consumption, and increase safety risks. I treat vibration like a smoke alarm. I look for the fire.

In this guide I’ll walk you through the causes I see most often. You’ll learn how to diagnose the problem, how to fix it, and how to keep things smooth. I’ll share practical examples from the field and I’ll keep the jargon to a minimum. If you care about uptime, reliability, and safety, you’re in the right place.

Top mechanical reasons your motor shakes

Mechanical issues cause most motor vibration. If you feel the motor wobble as speed increases or you notice rattling or grinding, start here.

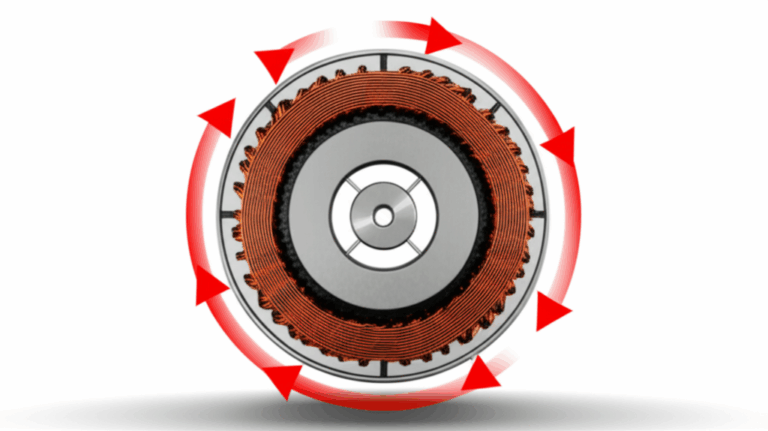

Rotor imbalance

What it is

- The rotor’s mass isn’t evenly distributed around its centerline. That uneven weight throws the rotor off balance which creates centrifugal forces that shake the motor.

Common causes I’ve found

- Dirt or debris stuck to the rotor or unbalanced impeller

- Manufacturing tolerances that slipped

- Wear over time on a fan, pulley, or impeller

- Loose or missing balancing weights

- Bent fan blades or broken rotor bars contributing to uneven forces

Symptoms that tip me off

- Vibration increases as speed rises

- A consistent radial vibration that peaks at 1× running speed

- Bearings run warmer than usual

- The motor housing vibrates more than connected piping or driven equipment

What I do

- Clean the rotor and the cooling fan

- Inspect and balance the rotor dynamically

- Check pulley or belt drive hardware for runout and wobble

- Verify that the impeller on pump motors isn’t chipped or clogged

Related ideas you’ll hear

- Rotor unbalance, dynamic balancing of motors, unbalanced impeller pump, wobbling motor pulley

If you want a primer on how the stator and rotor work together inside a motor you can skim this simple overview of the stator and rotor. Understanding that relationship makes the imbalance problem easier to picture.

Misalignment in shafts and couplings

Misalignment shows up constantly. I see it after rushed installations or when foundations settle or after someone swaps a coupling without checking alignment.

Types I see in the field

- Parallel (offset) misalignment: shafts are parallel but not colinear

- Angular misalignment: shafts meet at an angle

- Combined misalignment: both offset and angular errors

Why it happens

- Improper installation or bolt tightening sequence

- Thermal growth that shifts alignment as the machine warms up

- Soft foot on the motor base that distorts the frame

- Settling concrete or poor grout under the motor base

- Bent or damaged coupling hubs

Symptoms

- Axial vibration that rises at 1× or 2× running speed

- Premature coupling wear or hot spots

- Bearing stress and seal leakage

- Shaft fretting or unusual wear patterns

Best tools and fixes

- Use laser alignment equipment for precision

- Correct soft foot with shims

- Replace worn elastomeric elements in the coupling

- Re-torque mounting bolts in the right pattern

You’ll see terms like laser alignment motor, shaft coupling problems, and soft foot in many alignment guides because they matter.

Worn or damaged bearings

Bearings keep everything spinning true. When they wear out the motor starts to talk. It growls or rumbles. It heats up.

Common bearing issues

- Pitting, spalling, and flaking from fatigue

- Contaminated bearings with dust or moisture

- Lubrication issues like over-greasing or dry races

- Electrical discharge damage from stray currents with VFDs

- Misaligned housings that load the bearing unevenly

Symptoms I look for

- Grinding or growling noise

- Roughness when I spin the shaft by hand with power off

- Heat at the bearing housing

- Increased vibration in higher frequency bands

- Grease leakage with metallic dust

Fix the root cause

- Replace bearings and seals

- Correct lubrication practices and intervals

- Add insulated bearings or grounding brushes with VFDs

- Fix misalignment and soft foot so the new bearings last

You’ll hear phrases like bearing housing vibration and rolling element bearings and lubrication issues motor because they sit at the heart of this problem.

Loose mounts, soft foot, and foundation problems

Motor mounts and bases matter more than most people think. I’ve seen a single loose bolt make a sturdy motor look like a jackhammer.

What causes looseness

- Loose mounting bolts

- Worn isolators

- Cracked or hollow concrete under the base

- Baseplate distortion that creates soft foot

- Incorrect shimming that twists the frame

Classic symptoms

- The whole motor unit vibrates

- You chase alignment over and over because it won’t hold

- Vibration spikes at certain speeds due to motor resonance problems

- Rattling from brackets or guards

How I correct it

- Verify bolt torque and re-torque in a cross pattern

- Check for soft foot with feeler gauges and shim properly

- Regrout or repair the foundation if needed

- Add vibration isolation pads where appropriate

- Make sure the base plate sits flat and stress free

Keywords you’ll see: motor mounting bolts, foundation vibration motor, vibration isolation motor, motor base plate issues.

Bent motor shaft

A bent shaft turns every revolution into a wobble. The result isn’t pretty.

Causes I’ve encountered

- Impact damage during handling or coupling installation

- Excessive belt tension on a belt drive

- Sudden jams on the driven machine

- Heat damage that relieved material and warped the shaft

Symptoms

- High radial runout at the coupling or pulley

- Seal leaks and premature bearing failure

- High 1× vibration with sidebands in the spectrum

- Visible wobble at lower speeds

What I do

- Measure shaft runout with a dial indicator

- Inspect keyways for wear or distortion

- Replace or straighten the shaft if tolerances don’t pass

Related phrases: shaft runout measurement, bent armature shaft, worn keyways motor.

Structural looseness in pulleys, fans, and fasteners

Sometimes you don’t have a system-level problem. Sometimes a single piece is loose. I’ve caught loose fan blades that buzzed like a hornet. I’ve also found cracked motor casings on older machines that amplified vibration like a drum.

Check these

- Loose fan blades or cooling fan set screws

- Worn keyways on pulleys and couplings

- Cracked housings or mounting ears

- Loose guards and brackets

- Chain or belt drives with poor tension or alignment

Symptoms

- Rattling or chirping noises

- Localized vibration near the loose part

- Wear dust near the pulley or coupling

- Temperature rise at the loose joint

Keywords to note: loose fan blades, chain drive motor shake, belt drive motor vibration, cracked motor casing, looseness motor components.

Electrical causes behind motor shaking

Not all vibration comes from mechanical issues. Electrical faults can create uneven magnetic forces that make a motor hum, buzz, or shake. When mechanical checks look good I move to the electrical side.

Voltage imbalance and fluctuations

What happens

- Uneven voltage on the phases creates unequal currents which distort the rotating magnetic field. The motor pulls unevenly and starts to vibrate. It also heats up faster.

Symptoms I’ve seen

- Uneven current draw on each phase

- Overheating at normal loads

- Noticeable vibration changes when the power source changes

Fixes

- Check incoming power quality and tighten lugs

- Balance single-phase loads on the supply

- Use a line reactor or filter with VFDs if harmonics cause trouble

- Verify transformer taps and connections

Related terms: motor current imbalance, power quality, electrical faults, energy consumption motor vibration.

Faulty windings and stator issues

Shorted turns or insulation breakdown change the magnetic field. That change pulls the rotor off center which leads to vibration and noise.

What I check

- Winding resistance and insulation with a megger

- Hot spots on the stator using thermal imaging

- Air gap eccentricity that hints at stator or frame distortion

Symptoms

- Growling or humming under load

- Pulsating vibration at electrical frequencies

- Localized heating and a distinctive smell

Fixes

- Rewind or replace the motor if tests confirm winding damage

- Repair the frame if distortion causes uneven air gaps

- Improve cooling and ventilation to protect insulation

You might see phrases like stator issues motor, insulation breakdown motor, air gap eccentricity motor, motor winding problems.

A quick aside. The quality of your stator core lamination and the matching rotor core lamination influences losses, heat, and magnetic vibration. Poor laminations can boost stray magnetic forces and noise which only makes vibration worse over time. If you work with specialty motors or rebuilds you’ll also look at the overall stack quality with motor core laminations.

Loose electrical connections

Loose terminals can arc. They can heat. They can make your motor surge or stumble which shows up as shake.

What I do

- Inspect and re-torque terminals

- Look for discoloration, soot, or melted insulation

- Check the motor connection box for cracked lugs and loose crimps

Symptoms

- Intermittent operation or sudden vibration spikes

- Localized hot spots on the terminal box

- Audible crackling or popping under load

Keywords: loose terminal connections motor, motor electrical faults, wiring.

Variable frequency drive (VFD) problems

VFDs give you control. They can also create unique vibration patterns.

Issues I see

- Improper tuning with low carrier frequency that adds audible noise

- Drive harmonics that line up with structural resonance

- Torque ripple at low speeds that excites the system

- Poor grounding that sends common-mode currents through bearings

Symptoms

- Vibration peaks at specific VFD frequencies

- Erratic speed control or surging

- Bearing fluting in extreme cases

Fixes

- Adjust carrier frequency and tuning parameters

- Add line or load reactors and proper filters

- Improve grounding and bonding

- Use insulated bearings or shaft grounding rings

Related terms: variable frequency drive issues, harmonics, torque ripple, motor performance degradation.

Environmental and operational factors

Sometimes the motor is healthy. The environment or the load isn’t.

Resonance

Every structure has a natural frequency. If you run the motor at or near that frequency the vibration can explode. I’ve watched readings double with a small speed change.

What it looks like

- Severe vibration at specific speeds

- Smooth running below and above that narrow band

- Guards or panels that buzz like a kazoo

What I do

- Sweep the speed range and watch vibration trends

- Shift operating speed to avoid the peak

- Stiffen the structure or change mass to move the natural frequency

- Tune the VFD ramp to skip resonance zones

Keywords: critical speed motor, resonance frequency motor, motor resonance problems.

External vibrations

Your motor can catch vibrations from a neighbor. I’ve seen motors shake from a nearby press or conveyor. They weren’t the culprits. They were victims.

Signs

- Vibration appears even when the motor is off but nearby equipment is on

- The whole frame vibrates uniformly

- The vibration direction lines up with the external source

Fixes

- Add isolation pads or change the base

- Separate the foundation from other machines if you can

- Adjust operating schedules to avoid overlap

Cavitation in pump systems

Pump motors deal with fluid dynamics. If the suction head drops too low or the flow turns turbulent, the impeller can cavitate. Cavitation eats away at metal and shakes the machine.

Tell-tale clues

- A gravelly or crackling sound

- Vibration in both the motor and the pump casing

- Erosion on impeller blades over time

What I change

- Increase Net Positive Suction Head Available

- Open blocked strainers and remove air pockets

- Correct piping to smooth the inlet

- Balance the impeller after repairs

Keywords: cavitation pump motor, unbalanced impeller pump, hydraulic motor vibration, vibrating pump motor.

Excessive or uneven load

Ask a motor to do more than it’s designed for and it will let you know. It runs hot. It vibrates. It drinks energy.

Common situations

- Conveyor jams that spike torque

- Compressor surging

- Uneven belt loads on multi-belt drives

- Gearbox problems that add torsional ripple

What I do

- Measure current and torque trends

- Fix the root cause in the driven equipment

- Right-size the motor or add overload protection

- Improve ventilation and cooling to prevent overheating

Keywords: excessive load motor, compressor motor shake, gearbox motor vibration, motor overheating and shaking.

How I diagnose a shaking motor step by step

I follow a simple path. I start with eyes and ears. I move to hands. I finish with instruments. Safety first every time.

Visual inspection

I lock out and tag out the power. Then I look for the obvious.

- Loose bolts or cracked paint around bolts that hint at movement

- Worn or sagging motor mounts and isolators

- Belt dust under a belt drive which suggests misalignment or wrong tension

- Oil or grease coming out near bearings

- Clogged air vents and a dirty cooling fan

- Obvious wobble on the pulley or coupling

- Cracked motor casing or bent guards

Keywords to keep in mind: motor inspection checklist, loose motor mounts, cooling fan vibration, clogged air vents motor.

Listen and feel

When I can run it safely I listen. Then I feel.

- Grinding suggests bearing damage

- Rattling points to structural looseness

- A low growl hints at electrical or magnetic forces

- I feel for localized hot spots on housings

- I feel for pulsating vibration versus steady vibration

This simple step often tells me if the problem is mechanical or electrical.

Basic checks with power off and locked out

I shut it down and verify zero energy. Then I dig in.

- Check mounting bolts and torque

- Inspect the coupling and look for dust or misalignment witness marks

- Check belt tension and alignment with a straightedge or laser

- Turn the shaft by hand and feel for smoothness and bearing play

- Measure soft foot with feeler gauges

- Verify terminal tightness inside the motor junction box

Keywords: troubleshooting guide motor, motor inspection checklist, soft foot motor alignment.

Advanced tools and when I call a pro

When the basics don’t nail it I use instruments or call a specialist.

- Vibration analysis with an accelerometer to look at frequency content. 1× or 2× speed points to misalignment or imbalance. High frequency spikes point to bearing faults. Sidebands can reveal broken rotor bars or gear mesh issues

- Laser alignment tools for precise coupling alignment

- Thermal imaging to spot hot windings, bearings, or terminals

- Electrical testing with a megger and current analysis for winding or power issues

- Resonance checks with bump tests or speed sweeps

- Shaft runout measurement to confirm straightness

Keywords: vibration analysis motor, accelerometer, laser alignment tool, thermal imaging, electrical testing, shaft runout measurement, predictive maintenance motor.

Solutions and repairs that actually work

Once I understand the root cause I don’t patch symptoms. I fix the source.

Mechanical fixes

- Precision balancing for rotor imbalance. Clean the rotor and fan. Balance dynamically at operating speed when you can

- Laser alignment for misalignment. Correct soft foot with proper shimming. Recheck after warm-up if thermal growth is a factor

- Bearing replacement with the right type and fit. Use proper tools to avoid brinelling. Set preload or clearances to spec

- Tighten or replace mounts and fasteners. Fix the base plate. Regrout or rebuild foundations that move

- Shaft repair or replacement if runout fails the tolerance

- Replace damaged pulleys, fans, and worn keyways. Set proper belt tension and alignment

- Add vibration isolation motor pads where structure-borne vibration transfers in from outside

Keywords to include: dynamic balancing motors, laser alignment motor, bearing housing vibration, motor mounting pads, motor structural integrity.

Electrical fixes

- Power quality correction. Balance phases and fix loose lugs. Add line reactors or filters to tame harmonics

- Winding repair or rewind if tests confirm insulation breakdown. Don’t ignore air gap eccentricity or frame distortion

- Secure terminals and replace damaged connectors. Check for overheating and arcing marks

- VFD tuning or repair. Adjust carrier frequency and acceleration ramps. Add shaft grounding rings and insulated bearings to protect against common-mode currents

Related phrases: motor current imbalance, winding repair, VFD tuning, electrical faults.

Operational adjustments

- Adjust operating speed to avoid resonance bands. Use the VFD to skip critical ranges

- Manage load. Clear jams. Fix process surges. Right-size the motor or alter the gear ratio for the duty cycle

- System design tweaks. Improve pump inlet conditions to prevent cavitation. Increase ventilation and cooling. Upgrade guards and structural bracing that act like sounding boards

Keywords: load management, system design modifications, adequate motor ventilation, motor noise reduction.

Preventing future motor shake: best practices

I love fixes that last. Prevention beats repair every time.

- Build a preventive maintenance schedule. Include visual inspections, lubrication, terminal torque checks, and periodic vibration analysis

- Use proper installation techniques. Level the base. Correct soft foot. Align with lasers. Torque in sequence. Don’t rush the coupling

- Monitor continuously when the application is critical. Add vibration monitoring systems, temperature sensors, and current monitoring. Set alerts for trends not just alarms for failures

- Lubricate right. Grease the correct amount at the right interval with the specified lubricant. Over-greasing can be as bad as no grease

- Keep motors clean and well ventilated. Clear dust from cooling fins and protect air intakes with filters if needed

- Invest in quality components. Bearings, couplings, belts, isolators, and even the steel and laminations inside the motor matter. Poor quality materials can introduce uneven magnetic forces and higher losses which raise heat and vibration over time

- Keep a root cause analysis mindset. Don’t just swap parts. Document symptoms and measurements so you can spot patterns across your plant

If you want a quick refresher on core materials and why they matter over the life of the machine take a look at high level resources on stator core lamination, rotor core lamination, and full motor core laminations. Better core stacks reduce stray magnetic losses and heat which helps cut vibration and noise.

When to call a professional

I’ve done plenty of DIY fixes. I also know when I’m out of runway.

Call a pro when you see

- Rapid temperature rise in bearings or windings

- Severe vibration at startup that makes the machine unsafe

- Cracks in the base, frame, or mounting ears

- Electrical smells, arcing, or smoke

- Repeated bearing failures that point to misalignment or electrical discharge damage

- Vibration that only grows despite your adjustments

A seasoned vibration analyst can run spectrum analysis and pinpoint root causes fast. A motor service technician can rewind, balance, and rebuild to spec. They also bring tools like laser alignment rigs, calibrated accelerometers, and thermal cameras. The cost of a visit is often less than one round of unscheduled downtime.

Conclusion: Don’t ignore the shake

When a motor shakes it’s asking for help. Sometimes it wants a wrench. Sometimes it wants a new bearing or a better foundation. Sometimes it’s telling you that the power coming in isn’t balanced or that the VFD needs a tune.

Here’s what I’ve learned the hard way

- Mechanical issues like misalignment, rotor imbalance, and bearing wear cause most vibration

- Electrical issues can mimic mechanical problems so test power quality and windings

- Environmental and operational factors like resonance, cavitation, and uneven load can make a healthy motor look sick

- A simple step-by-step process catches the obvious and points you to the fix

- Precision tools like laser alignment and vibration analysis pay for themselves

- Preventive maintenance and quality components build quiet, reliable machines

Act early. Small shakes turn into big bills. If you handle the root cause you extend the motor’s lifespan, reduce energy consumption, cut downtime, and protect your people. That’s a win in any shop.

Key phrases and ideas you may recognize from your own experience

- motor vibration troubleshooting, diagnosing motor shake, excessive motor vibration

- misalignment motor vibration, rotor unbalance, bent motor shaft, structural looseness

- worn motor bearings, lubrication issues motor, contaminated bearings

- loose motor mounts, soft foot motor alignment, foundation vibration motor

- electrical motor issues, motor current imbalance, faulty windings, insulation breakdown motor

- variable frequency drive issues, harmonics, torque ripple

- resonance frequency motor, critical speed motor, vibration monitoring systems

- pump cavitation, unbalanced impeller pump, compressor motor shake

- predictive maintenance motor, vibration analysis motor, laser alignment tool

- motor noise reduction, overheating, energy consumption motor vibration

- safety hazards motor vibration, premature motor failure, motor lifespan reduction

If you’re new to motors and want a bit more theory in plain language take a moment to read up on the basics of the stator and rotor. It ties everything together so the symptoms you see make more sense.

Stay safe. Lock out and tag out before you touch anything. Then let the machine tell you its story. It always does if you listen.