Why is it Called a Squirrel Cage Motor? Unraveling the Iconic Name of Induction Motors

Of course. Here is a comprehensive, long-form article based on your instructions.

Table of Contents

- The Curious Case of the Squirrel Cage Motor Name

- What Exactly is a Squirrel Cage Motor? A First Look Inside

- The “Squirrel Cage” Analogy: A Visual Explanation

- The Rotor’s Unique Design: Bars and End Rings

- Making the Connection: The Animal Cage Comparison

- How the Squirrel Cage Rotor Actually Works (The Magic of Induction)

- Step 1: The Stator Creates a Rotating Magnetic Field

- Step 2: Current is Induced in the Rotor Bars

- Step 3: The Rotor’s Field Fights Back and Creates Torque

- The Genius of the Squirrel Cage Design: Why It’s Everywhere

- Unmatched Simplicity and Robustness

- Low Maintenance for a High-Reliability World

- Cost-Effectiveness in Manufacturing

- Widespread Applications: The Unseen Workhorse

- A Glimpse into History: The Minds Behind the Motor

- Conclusion: A Name That Stuck for Good Reason

The Curious Case of the Squirrel Cage Motor Name

Have you ever heard a technical term and just thought, “Where on earth did that name come from?” I’ve been in the engineering world for a long time and I still have those moments. One of the best examples I can think of is the “squirrel cage motor.” It sounds more like something you’d find in a pet store than the workhorse that powers a huge chunk of our modern world.

The first time I heard the name, I pictured a tiny rodent on a wheel, somehow generating electricity. It’s a funny image but the reality is far more elegant and frankly, quite clever. So, why is it called a squirrel cage motor?

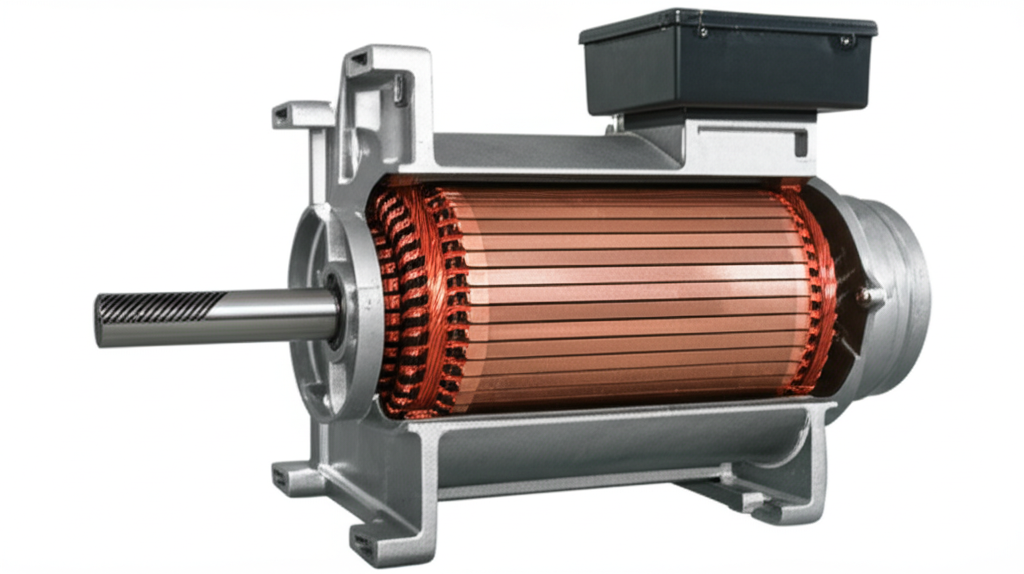

Let me give you the short answer right away: it’s named for the striking visual resemblance of its rotor—the rotating part—to the spinning exercise wheel in a squirrel’s cage.

There’s no actual squirrel involved, of course. It’s just a fantastic piece of descriptive naming that has stuck for over a century because it perfectly captures the look of the motor’s most defining component. In this article, I want to walk you through not just the name but the beautiful simplicity and power of this design. I’ll show you what it looks like, how it works, and why this invention became one of the most important of the modern era.

What Exactly is a Squirrel Cage Motor? A First Look Inside

Before we dive deep into the name, let’s get our bearings. What is this thing we’re talking about?

At its core, a squirrel cage motor is a type of AC induction motor. “AC” stands for alternating current which is the type of electricity that powers our homes and factories. “Induction” is the key to how it works which we’ll explore in a bit. These motors are the backbone of industry. In fact, various reports estimate that squirrel cage induction motors account for a staggering 80-90% of all motors used in industrial applications globally. That’s massive.

When I first started taking motors apart, what struck me was their simplicity. You have two primary components:

The relationship between the stator and rotor is where the magic happens. Unlike many other motor types, there are no wires or direct electrical connections to the rotor. It just sits inside the stator, separated by a tiny air gap, and spins as if by magic. This lack of direct connection is what makes it an “induction” motor and it’s also the secret to its legendary robustness.

The “Squirrel Cage” Analogy: A Visual Explanation

Alright, let’s get to the heart of the matter. I remember the first time a senior engineer showed me a bare rotor from one of these motors. He held it up and said, “See? Squirrel cage.” And suddenly, the name clicked perfectly into place.

The Rotor’s Unique Design: Bars and End Rings

To understand the name, you have to picture the rotor stripped of its surrounding iron core. What you’d be left with is a cylindrical structure that looks incredibly like a hamster or squirrel wheel. This structure is made of two key parts:

- Rotor Bars: These are thick, conductive bars that run the length of the rotor. They are typically made of cast aluminum or sometimes copper for higher efficiency applications. These bars are the pathways for the electrical current that makes the motor spin.

- End Rings: At each end of the cylinder, all the rotor bars are connected by a solid, conductive ring. These end rings electrically short-circuit all the bars together, creating a closed-loop circuit. Think of them as the circular frames that hold the spokes of a wheel together.

This complete assembly—the bars connected by end rings—forms a self-contained, robust electrical circuit. When this “cage” is embedded within a core made of laminated steel, you have a complete squirrel cage rotor. The quality of this core is critical and using high-grade rotor core lamination is essential for minimizing energy losses and maximizing motor efficiency.

Making the Connection: The Animal Cage Comparison

Now, imagine that classic pet cage wheel. It has a series of rungs (the rotor bars) that the animal runs on and these rungs are held together by circular frames on each side (the end rings).

The resemblance is uncanny.

The engineers who first developed this technology in the late 19th century coined the term “squirrel cage” because it was the most immediate and intuitive visual analogy. It’s a name born from practical observation not complex theory. It’s a testament to the idea that sometimes the simplest description is the best one. There’s no deeper meaning, no hidden code—it just looks like a squirrel cage.

How the Squirrel Cage Rotor Actually Works (The Magic of Induction)

So, we know what it looks like. But how does this simple cage design create the powerful rotational force that drives everything from factory conveyors to your home’s HVAC fan? The answer lies in a beautiful physics principle called electromagnetic induction.

I’ll break it down into three simple steps. Grasping the fundamental motor principle here is what separates a casual observer from someone who truly understands how things work.

Step 1: The Stator Creates a Rotating Magnetic Field

First, you supply three-phase AC power to the windings in the stationary stator. Because the alternating current in each winding peaks at a different time, it creates a magnetic field that isn’t static—it rotates around the inside of the stator at a constant speed, known as the synchronous speed.

Think of it like three people standing around a circle, each holding a flashlight. If they turn their flashlights on and off in a perfect sequence, the spot of light will appear to move smoothly around the circle. The stator’s magnetic field does the same thing, but it’s invisible.

Step 2: Current is Induced in the Rotor Bars

This rotating magnetic field from the stator is absolutely crucial. As its magnetic lines of flux sweep across the conductive bars of the squirrel cage rotor, it “induces” a voltage in them. This is thanks to Faraday’s Law of Induction, the same principle that makes electrical transformers work.

Because the rotor bars are short-circuited by the end rings, this induced voltage immediately creates a powerful electrical current that flows through the bars. You now have a rotor with a significant amount of electricity flowing through it, all without a single wire touching it!

Step 3: The Rotor’s Field Fights Back and Creates Torque

Here’s the final piece of the puzzle. According to another law of physics (Lenz’s Law), the current flowing in the rotor bars creates its own magnetic field. And this new magnetic field is created in such a way that it opposes the stator’s field that created it in the first place.

It’s like the rotor is trying to push back against the rotating field from the stator.

This magnetic “fight” between the stator’s field and the rotor’s induced field is what generates torque, or rotational force. The rotor is essentially dragged along by the stator’s rotating magnetic field, always trying to catch up but never quite making it. That little bit of lag is called “slip,” and it’s essential for induction to keep happening. If the rotor ever reached the same speed as the magnetic field, there would be no relative motion, no induced current, and no torque.

The result? The rotor spins, and you get useful mechanical work. All from a simple, elegant cage of metal bars spinning inside a magnetic field.

The Genius of the Squirrel Cage Design: Why It’s Everywhere

The name is clever, and the working principle is brilliant. But the real reason the squirrel cage induction motor dominates our world is its incredible design advantages. From my experience in the field, these motors are loved for three main reasons: they are simple, they are tough, and they are cheap.

Unmatched Simplicity and Robustness

Take another look at the rotor design. What’s missing?

There are no brushes, no commutators, and no slip rings. These are all components found in other types of motors (like DC motors or wound rotor motors) that are prone to wear and tear. Brushes are blocks of carbon that physically press against a rotating part to conduct electricity; they wear down and create dust, requiring regular replacement.

The squirrel cage rotor has none of that. It’s essentially a solid chunk of metal. There are no wearing parts other than the bearings it spins on. This makes the design incredibly robust and resistant to harsh environments, vibration, and shock. I’ve seen these motors running for decades in dusty factories and damp processing plants with minimal intervention.

Low Maintenance for a High-Reliability World

This simplicity directly translates to extremely low maintenance requirements. As I mentioned, the absence of brushes is a game-changer. In industrial settings, downtime is a killer. Having to shut down a critical production line to replace motor brushes is a costly affair. With a squirrel cage motor, the maintenance schedule is basically just “lubricate the bearings every so often and keep it clean.”

This inherent reliability is why they are the go-to choice for applications that need to run continuously for long periods without failure. Think of pumps, fans, and compressors in large industrial facilities—these are often powered by squirrel cage motors that run 24/7 for years.

Cost-Effectiveness in Manufacturing

The design isn’t just simple to maintain; it’s also simple to build. A key manufacturing innovation that made these motors so affordable is the use of die-casting.

In this process, the laminated iron core of the rotor is placed into a mold, and molten aluminum is injected under high pressure. This single shot forms all the rotor bars and the end rings as one solid, integrated piece. It’s an incredibly fast, efficient, and cost-effective method for mass production. This ease of manufacturing is a huge factor in the motor’s economic viability and its resulting global dominance.

Widespread Applications: The Unseen Workhorse

Because of their ruggedness, low cost, and reliability, you’ll find squirrel cage motors in an astonishing variety of applications. They are the true unseen workhorses of our infrastructure.

- Industrial Automation: They drive conveyor belts, machine tools (lathes, mills), and robotic arms.

- HVAC Systems: The fans that circulate air in buildings and the compressors in air conditioning units are almost always powered by them.

- Pumps and Fans: From water treatment plants to industrial cooling towers, these motors are responsible for moving massive amounts of fluids and air.

- Household Appliances: Your refrigerator’s compressor, your washing machine’s drum, and your garage door opener likely all contain a version of this motor.

- Emerging Technologies: While specialized motors are used in electric vehicles, the principles of induction motors are still fundamental, and they are heavily used in the charging infrastructure and manufacturing plants that support the EV industry.

The motor’s performance is heavily influenced by the quality of its components. For instance, the design and material of the stator core lamination play a massive role in overall energy efficiency, determining how much electrical energy is lost as waste heat.

A Glimpse into History: The Minds Behind the Motor

You can’t talk about the induction motor without tipping your hat to the brilliant minds who brought it to life. While the concept was being explored by several people, two names stand out:

The work of these pioneers laid the foundation for the electrical grid and the powered machinery that defined the 20th century. The squirrel cage design was a key part of that revolution.

Conclusion: A Name That Stuck for Good Reason

So, we come full circle. The squirrel cage motor got its name from a simple, direct, and frankly perfect visual analogy. The rotor, with its conductive bars and shorting end rings, looks just like a rotary exercise wheel for a small animal.

I think the name’s endurance is a beautiful thing. In a world filled with complex acronyms and impenetrable jargon, “squirrel cage” is refreshingly straightforward. It’s a name that invites curiosity and tells a story of form following function.

The next time you hear the hum of a fan, the rumble of a conveyor belt, or the kick of a compressor, take a moment to appreciate the elegant genius spinning away inside. It’s likely a squirrel cage motor, the simple, tough, and brilliantly named workhorse that quietly and reliably powers our world.