Why is it Called a Squirrel Cage Rotor? Unraveling the Motor’s Unique Name

Of course. Here is the article, written according to all your instructions.

Table of Contents

- The Simple Truth: A Striking Visual Resemblance

- Understanding the Squirrel Cage Rotor: More Than Just a Name

- A Glimpse into History: When and Why the Name Stuck

- How a Squirrel Cage Rotor Works (Simplified)

- Applications of Squirrel Cage Motors: Powering Our Everyday

- Addressing Common Misconceptions

- Conclusion: An Enduring Name for an Essential Innovation

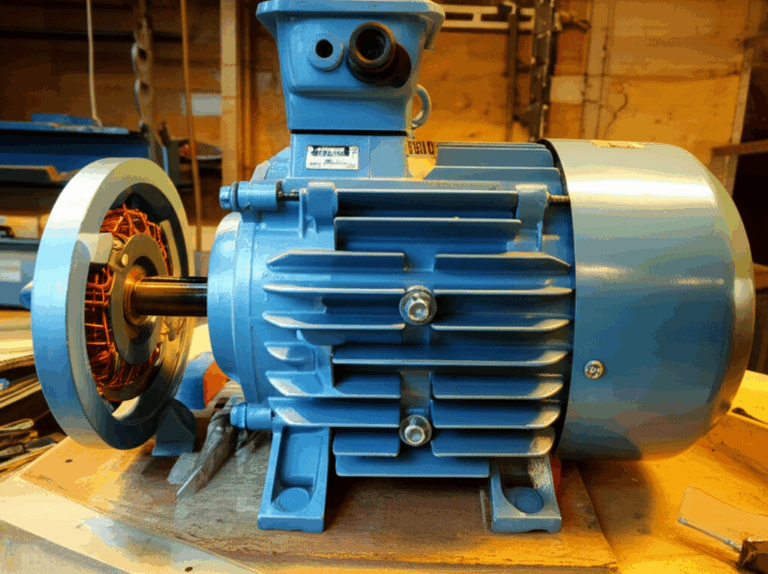

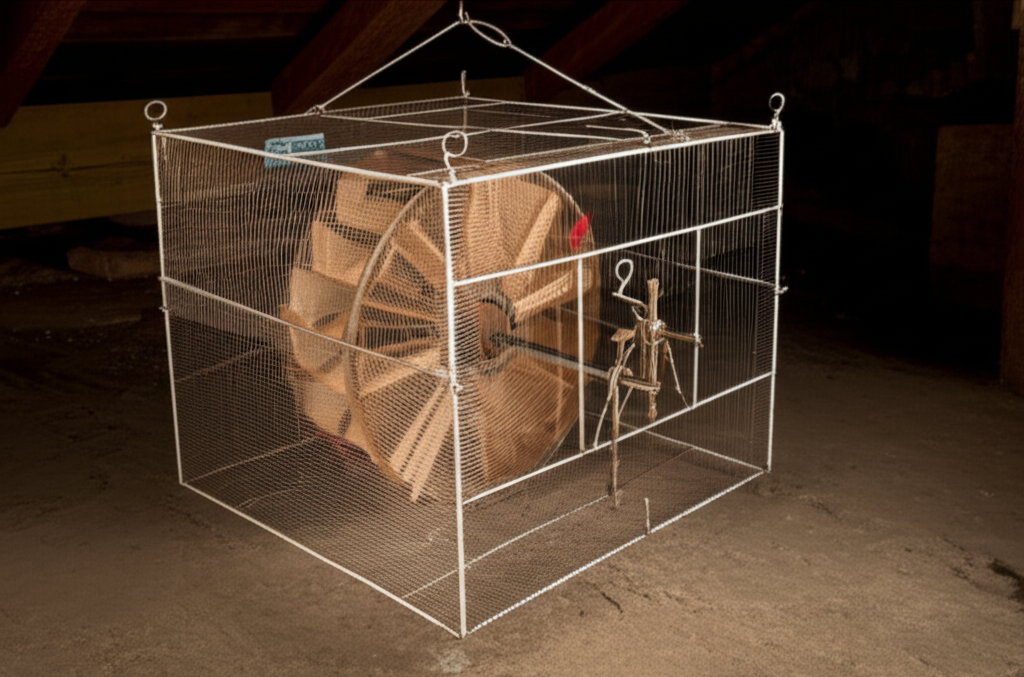

I’ll never forget the first time I worked on an old industrial fan motor. As an apprentice, my job was to help a senior technician with a full teardown and maintenance check. He pulled the rotor out of the motor housing, set it on the workbench, and said, “Alright, clean up that squirrel cage.” I just stared at it. I’d heard the term “squirrel cage induction motor” a dozen times in textbooks but seeing it in person was a lightbulb moment. It looked exactly like one of those old-fashioned, spinning rodent wheels.

The name, which had always seemed a bit strange and random, suddenly made perfect sense. It’s one of those brilliant bits of engineering slang that’s so descriptive you can’t unsee it once you’ve made the connection. If you’ve ever wondered why this essential piece of technology has such a quirky, animal-themed name, you’ve come to the right place. I’m going to walk you through exactly why it’s called a squirrel cage, how it works, and why this simple, robust design is the unsung hero powering so much of our modern world.

The Simple Truth: A Striking Visual Resemblance

Let’s get straight to the point because the answer is delightfully simple. The component is called a “squirrel cage” because its structure bears an uncanny resemblance to the exercise wheels found in old-timey cages for squirrels or other rodents.

It’s all about the visual analogy. When you look at the rotor stripped bare of its surrounding motor components, you can immediately see the comparison. Imagine a classic hamster wheel. What do you see? A series of parallel bars running lengthwise, all connected at each end by a solid, circular ring.

Now, look at the squirrel cage rotor. It has the same fundamental structure:

- Conductive Bars: Running along the length of the rotor, you’ll find a series of thick bars, typically made of aluminum or copper. These are the equivalent of the running slats on the animal’s wheel.

- End Rings: At both ends of the rotor, these conductive bars are all connected—and short-circuited—by a solid conducting ring. These rings are the spitting image of the circular frame that holds the animal wheel together.

When you hold one in your hands, the resemblance is undeniable. It’s a hollow, cylindrical “cage” made of metal bars and rings. It’s a perfect example of metaphorical naming in engineering where form dictates the name. The first engineers and technicians who saw this design likely didn’t need a formal committee to name it; the resemblance was so obvious that “squirrel cage” was the most intuitive and descriptive term they could use. It stuck because it was simple, memorable, and, most importantly, accurate.

Understanding the Squirrel Cage Rotor: More Than Just a Name

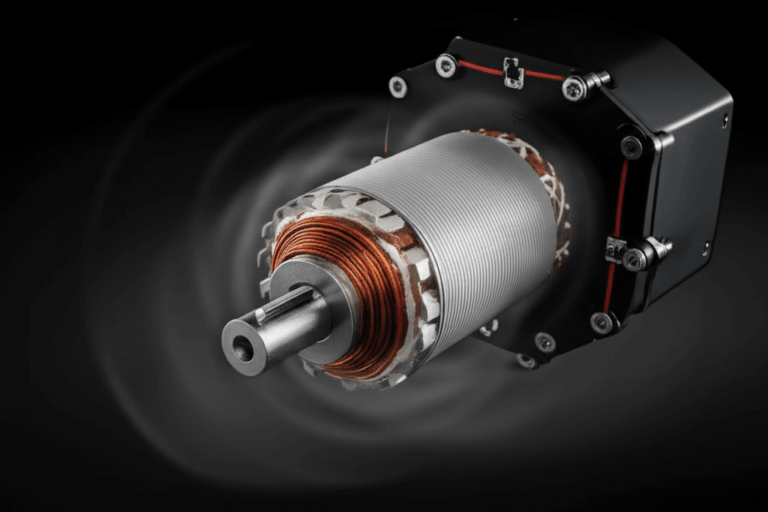

So, we know what it looks like, but what exactly is a squirrel cage rotor? In the simplest terms, the squirrel cage is the rotating part of the most common type of electric motor in the world: the AC induction motor.

Every basic electric motor has two primary parts that work together to create motion. There’s the stationary part, called the stator, and the rotating part, the rotor. The dynamic interplay between the stator and rotor is what turns electrical energy into the mechanical force that drives everything from your kitchen blender to massive industrial conveyors.

The squirrel cage rotor’s main job is to chase a rotating magnetic field created by the stator, which causes it to spin and produce torque. What makes it so special isn’t just its name but its brilliant simplicity. Unlike other motor designs, it has no brushes, no slip rings, and no direct electrical connections to the outside world. It’s just a solid, self-contained unit of laminated steel and conductive metal.

This elegant design is why the squirrel cage induction motor is an absolute workhorse. It’s estimated that these motors account for a staggering 80-90% of all industrial electric motors used globally. Why? Because their design makes them:

- Rugged and reliable: With no parts designed to wear out, like brushes, they can run for years with minimal maintenance.

- Cost-effective: Their simple construction makes them cheaper to manufacture than more complex motor types.

- Efficient: Modern designs convert a high percentage of electrical energy into useful mechanical work.

From the moment you wake up until you go to bed, you’re constantly interacting with devices powered by squirrel cage motors. They’re in your refrigerator’s compressor, your home’s air conditioning fan, the water pump for your city, and the power tools in your garage. It is, without a doubt, one of the most important and widespread inventions of the modern era.

A Glimpse into History: When and Why the Name Stuck

To fully appreciate the name, it helps to step back in time. The concept of the AC induction motor, the machine that houses the squirrel cage rotor, was developed independently by two brilliant minds in the late 1880s: Nikola Tesla in the United States and Galileo Ferraris in Italy. A few years later, Mikhail Dolivo-Dobrovolsky in Germany took the concept and evolved it into the practical three-phase squirrel cage motor we know today.

However, it’s important to note that these inventors were focused on the motor principle—the physics of the rotating magnetic field and electromagnetic induction. They patented the motor, not the name “squirrel cage.”

The term itself likely emerged organically from the shop floors and engineering departments of the late 19th and early 20th centuries. As these motors became more common during the Second Industrial Revolution, people needed a way to talk about them. The language of technology was still being forged and engineers often relied on vivid, real-world analogies to describe their newfangled creations.

Think about other terms from that era. We have “horsepower” to describe engine output and “caterpillar tracks” for tanks. Using animal analogies in technology was a common and effective way to make complex ideas relatable. The term “squirrel cage” for an actual animal enclosure was already part of the popular lexicon, making it a perfect, ready-made descriptor for this new motor component. The name’s simplicity and visual accuracy ensured it spread quickly and became the standard term, a testament to the practical, no-nonsense language of the people who built, installed, and maintained these machines.

How a Squirrel Cage Rotor Works (Simplified)

Okay, so we know it looks like a cage and it spins, but how does it actually work without any wires connected to it? This is where the magic of physics comes in and it’s something that fascinated me from day one. The whole operation is a clever dance of magnetism.

The fundamental motor principle at play here is electromagnetic induction, a concept discovered by Michael Faraday. In essence, it says that a changing magnetic field will create, or “induce,” an electric current in a nearby conductor. The squirrel cage motor is a masterclass in applying this principle.

Here’s a step-by-step breakdown of what happens, which I’ll try to keep as simple as possible:

The construction of the rotor core lamination is also incredibly important. It’s made of thin, insulated steel sheets stacked together. This design helps minimize energy losses from phenomena like eddy currents, which are wasteful circular currents induced in the core material.

So, in the end, the “cage” isn’t just a visual descriptor; it’s a functionally perfect design. It acts as a series of closed electrical loops, perfectly positioned to have currents induced within them, turning the rotor into a temporary electromagnet that is forced to chase the stator’s rotating field forever.

Applications of Squirrel Cage Motors: Powering Our Everyday

Once I understood the elegant simplicity and sheer toughness of the squirrel cage motor design, I started seeing them everywhere. Their dominance in both industrial and domestic settings is no accident. Their advantages make them the default choice for an incredible range of applications.

Because they are so durable and require very little maintenance, you’ll find them in places where reliability is paramount. Think about industrial motor applications where a failure could shut down an entire production line. They are the heart of:

- Pumps: Moving water, chemicals, and other fluids in manufacturing plants and municipal water systems.

- Fans and Blowers: Providing ventilation and air conditioning for everything from massive skyscrapers to your home furnace.

- Compressors: Supplying compressed air for power tools and industrial processes.

- Conveyors: Keeping assembly lines and baggage handling systems moving.

- Mixers and Grinders: Used in food processing, chemical production, and mining.

In our daily lives, we’re just as dependent on them. The motors in many of your home appliances are smaller versions of these industrial giants:

- Washing machines and dryers

- Refrigerators and freezers

- Dishwashers

- Garage door openers

- Most power tools like drills, saws, and sanders

In modern systems, you’ll often find these motors paired with a Variable Frequency Drive (VFD). A VFD is an electronic controller that can change the frequency of the AC power supplied to the motor, which in turn allows for precise control over the motor’s speed. This combination has revolutionized industrial automation, improving efficiency and giving engineers incredible control over their machinery.

Addressing Common Misconceptions

Given its funny name, it’s no surprise that a few misconceptions have popped up over the years. Whenever I explain the name to someone new to the field, I often get a chuckle and a few follow-up questions. Let’s clear up the most common one.

The biggest misconception is, of course, that the name has anything to do with an actual squirrel. I’ve heard jokes about a tiny squirrel running inside, powering the motor like a futuristic hamster wheel. While it’s a fun image, the reality is purely about the visual metaphor. No animals were involved in the naming or operation of this motor!

The analogy is about the structure’s resemblance to the cage, not the function of a creature running inside it. The name describes the rotor’s form, which indirectly enables its function through electromagnetic induction. It’s a testament to the power of a good analogy—so powerful, in fact, that it can sometimes create these amusing mental images.

Conclusion: An Enduring Name for an Essential Innovation

The journey from a curious apprentice staring at a greasy motor part to understanding the elegant physics behind it has been a rewarding one for me. The “squirrel cage” name is more than just a quirky label; it’s a perfect piece of engineering history. It captures the essence of the design in a way that a technical term like “short-circuited bar-wound rotor” never could.

It’s a name born from observation, practicality, and the human need to relate new, complex ideas to familiar concepts. It beautifully describes the simple, robust form of a component that is central to the powerful principle of the induction motor—a motor that quietly and reliably powers the machinery of our civilization.

So, the next time you hear the hum of a fan, the rumble of a factory, or the whir of a power tool, take a moment to appreciate the genius inside. At the heart of it all is a simple, elegant cage of metal, forever chasing a magnetic field. It’s a design that’s as clever as it is common, with a name that’s as memorable as it is fitting.