Why Single-Phase Induction Motors Aren’t Self-Starting: The Physics and Solutions

Have you ever turned on a fan or an old fridge and heard a “hmmm” sound, but the blades didn’t move? That’s the sound of a single-phase induction motor struggling to start. It’s a common problem, and it points to a very interesting piece of science. These motors, which power so many things in our homes, have a secret: they can’t start spinning all by themselves. In this article, I’ll show you exactly why that is. We’ll explore the simple physics behind this puzzle and look at the clever tricks engineers use to give these motors the push they need.

Table of Contents

- What’s the Big Deal with Single-Phase Power?

- Why Does a Single-Phase Motor Just Hum and Vibrate?

- How Can We Picture This Problem?

- So, Why Do Three-Phase Motors Start So Easily?

- What’s the Secret to Getting a Single-Phase Motor Started?

- How Does a Starting Winding Work?

- What Does a Capacitor Do for a Motor?

- What Are the Different Ways to Start These Motors?

- What Are the Important Parts in a Starting System?

- If They Can’t Start, Why Are They Everywhere?

What’s the Big Deal with Single-Phase Power?

Most homes around the world use what’s called a single-phase AC supply. Think of it like a river where the water flows one way and then quickly flows back the other way, over and over. This alternating current (AC) is great for powering lights and heaters. But for a motor, it creates a real headache.

The problem is that this back-and-forth flow of electricity creates a magnetic field that also just goes back and forth. It gets strong, then weak, then strong in the opposite direction. We call this a pulsating magnetic field. It pushes and pulls along one single line. It has no natural spin or rotation to it. For a motor to work, its rotor needs something to chase. A pulsating field is like someone standing in front of you and just waving their arms back and forth—it doesn’t make you want to run in a circle.

Why Does a Single-Phase Motor Just Hum and Vibrate?

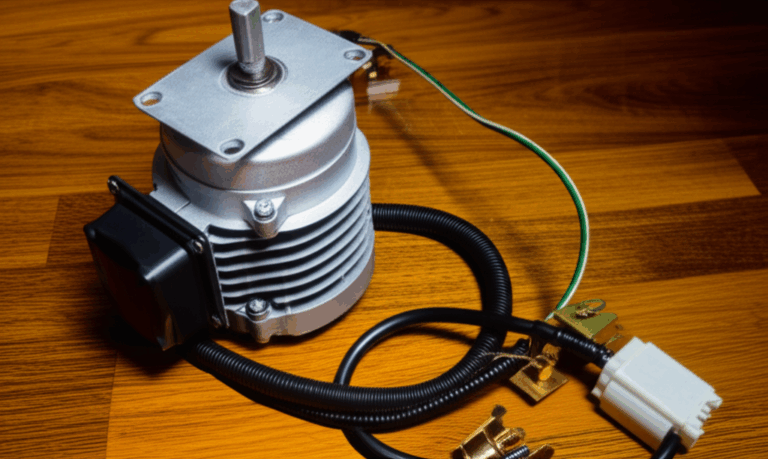

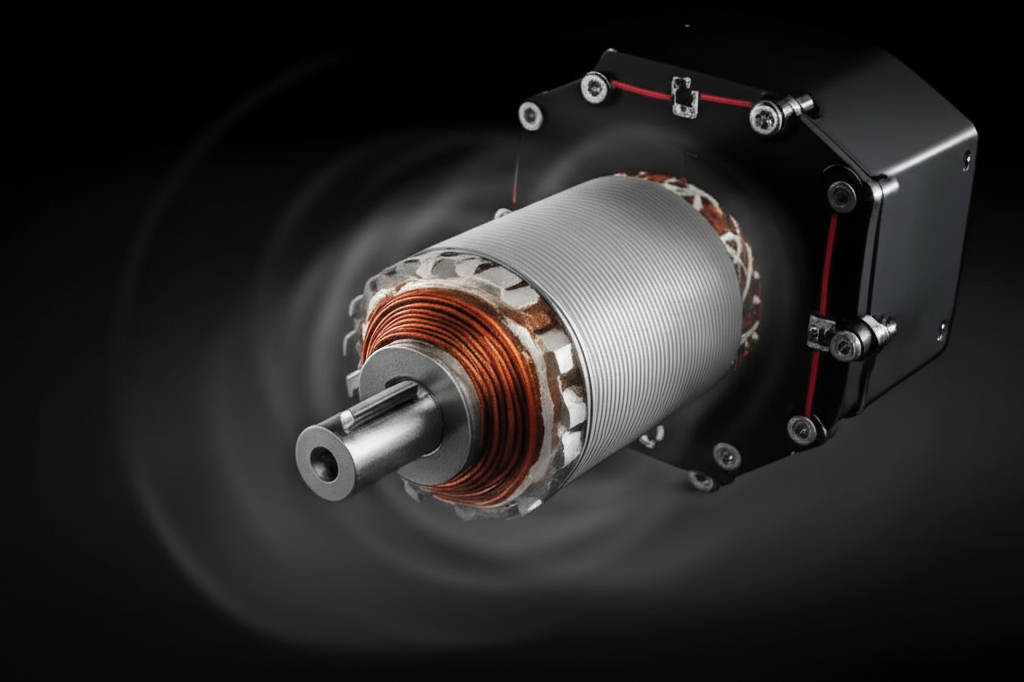

So, you have this pulsating magnetic field inside the motor’s stator. The stator is the stationary part of the motor that the wires are wrapped around. Inside the stator sits the rotor, the part that is supposed to spin. The pulsating field from the stator creates a current in the rotor bars of the squirrel cage rotor. This is thanks to Faraday’s law of induction.

Now, Lenz’s law tells us that this new current in the rotor will create its own magnetic field to oppose the first one. This creates a push, or a torque. Here’s the problem: because the stator’s field is just pulsing back and forth, it pushes the rotor equally in both directions at the same time. The push to go clockwise is perfectly canceled out by the push to go counter-clockwise. The result? A net zero starting torque. The rotor is stuck. It can’t decide which way to go, so it just sits there and hums from the magnetic forces pulling it apart.

How Can We Picture This Problem?

To make this easier to understand, scientists use something called the Double Revolving Field Theory. It sounds complicated, but the idea is simple. Imagine that our one pulsating field is actually made of two separate magnetic fields. Both fields are spinning at the same speed (we call this synchronous speed), but in opposite directions.

When the motor is not moving, the rotor feels an equal pull from both of these imaginary spinning fields. The forward-spinning field says, “Go this way!” and the backward-spinning field says, “No, go this way!” Since they are equally strong, the rotor is locked in place. There is no initial rotation. However, if you were to walk up and give the motor shaft a good spin by hand, one of those fields would “win,” and the motor would happily continue spinning in that direction. But we can’t have people manually spinning their washing machines to get them started!

So, Why Do Three-Phase Motors Start So Easily?

You might wonder why this is only a problem for single-phase motors. Big industrial machines often use three-phase induction motors, and these are famous for being self-starting. The difference is in the power they use. Three-phase power is like having three separate electrical signals arriving one after another in a perfect sequence.

This sequence creates a truly rotating magnetic field right from the start. Imagine three friends standing around a merry-go-round. The first person pushes, then the second, then the third, over and over in a perfect circle. The merry-go-round starts spinning smoothly and powerfully without any help. That’s what happens inside a three-phase motor. The rotor immediately has a spinning field to chase, giving it a strong starting torque. The stator and rotor work in perfect harmony from the first moment.

What’s the Secret to Getting a Single-Phase Motor Started?

Since we can’t change the single-phase power coming from our walls, engineers had to get creative. They figured if they couldn’t have a naturally rotating field, they would make one. The solution is called phase splitting. The idea is to create a second, out-of-sync magnetic field inside the motor for just a few seconds to give the rotor that first crucial push.

To do this, they added a second set of wires to the stator. This is called the auxiliary winding or starting winding. The original set of wires is called the main winding. By making these two windings electrically different, the currents flowing through them become out of step with each other. This creates two pulsating magnetic fields that are slightly offset in time and position. When they work together, they mimic a real rotating magnetic field, and the motor finally starts to turn.

How Does a Starting Winding Work?

The split-phase motor is the simplest example of this trick. The starting winding is made of thinner wire and has a higher electrical resistance than the main winding. When you turn the motor on, the current flows through both windings. Because of their different properties (resistance and inductive reactance), the magnetic fields they create are out of sync.

This creates a weak rotating field—just enough to get the rotor moving. Once the motor gets up to about 75% of its full speed, a special device called a centrifugal switch clicks open. This switch is designed to disconnect the starting winding from the power. The motor then continues to run smoothly using only the main winding. This simple starting mechanism is perfect for things that don’t need a huge push to get going, like small fans and blowers.

What Does a Capacitor Do for a Motor?

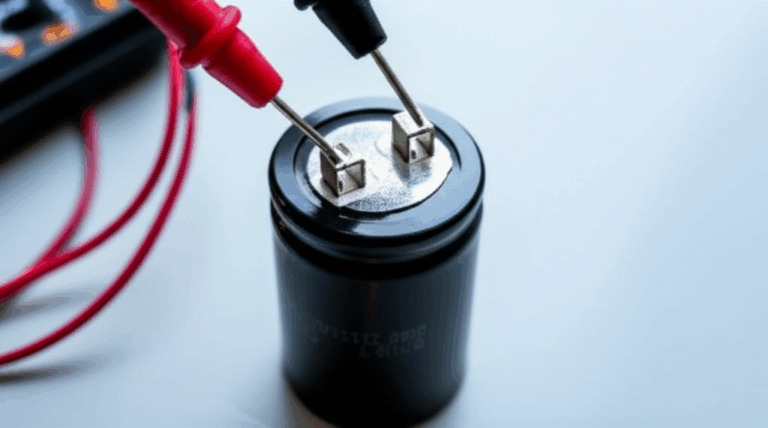

For machines that need a bigger kick to start, like an air compressor or a refrigerator, a simple split-phase motor isn’t strong enough. The starting torque is too low. This is where a little electronic part called a capacitor becomes a hero. In a capacitor-start motor, a capacitor is connected in a series with the starting winding.

A capacitor is like a tiny, super-fast battery. It stores and releases electrical energy in a way that creates a much larger phase difference between the main and auxiliary windings. This time lag between the two magnetic fields is much closer to the ideal 90 degrees, creating a powerful rotating magnetic field at the start. The result is a huge boost in starting torque, often two or three times what a split-phase motor can provide. Just like before, a centrifugal switch disconnects the capacitor and the starting winding once the motor is up to speed.

What Are the Different Ways to Start These Motors?

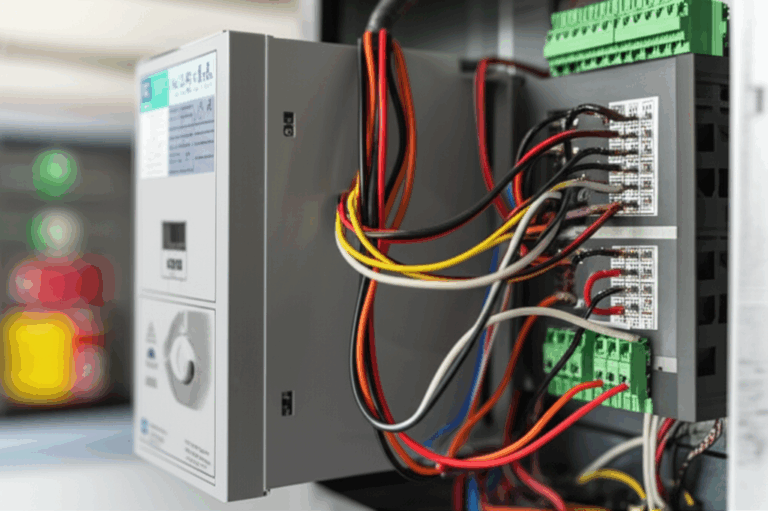

Engineers have developed several clever methods to solve this starting problem, each with its own pros and cons. The method used depends on how much starting torque is needed and how much the motor costs to build.

Here is a quick look at the most common types of single-phase motors and how they work.

Comparison of Single-Phase Motor Starting Methods

| Motor Type | Starting Method | Starting Torque (% of Full Load) | Key Starting Parts | Common Uses | |

|---|---|---|---|---|---|

| Split-Phase | Auxiliary Winding | 100% – 125% | Auxiliary Winding, Centrifugal Switch | Small Fans, Blowers | Low cost, good for easy-to-start loads. |

| Capacitor-Start | Capacitor + Auxiliary Winding | 200% – 300% | Electrolytic Capacitor, Winding, Switch | Compressors, Pumps | High starting torque for heavy loads. |

| PSC Motor | Permanent Capacitor | 50% – 100% | Oil-filled Capacitor, Winding | HVAC Fans, Quiet Appliances | Smooth and quiet, no switch needed. |

| Shaded-Pole | Shading Coils | 25% – 50% | Copper Shading Coils | Small Toy Motors, Timers | Very cheap, very low torque. |

A Permanent Split Capacitor (PSC) motor uses a capacitor that stays connected all the time. It helps with starting and also makes the motor run more efficiently and quietly. A shaded-pole motor is the simplest of all. It uses a small copper ring to create a very weak rotating field, which is just enough for tiny fans or other low-power devices.

What Are the Important Parts in a Starting System?

The success of these starting mechanisms depends on a few key components working together perfectly. The auxiliary winding must have the right electrical properties to create the phase shift. The centrifugal switch must be reliable, opening at just the right speed to prevent the starting winding from overheating.

The capacitor is often the most critical part in high-torque motors. A starting capacitor is usually an electrolytic capacitor, designed for short, powerful bursts of use. If this part fails, the motor will lose its starting power and just hum. All these windings are wrapped around a core made of thin metal sheets. The quality of the stator core lamination is incredibly important, as it helps focus the magnetic fields and makes the motor efficient. Poor quality here can lead to energy loss and overheating. The same goes for the spinning part, where the design of the rotor core lamination affects the motor’s overall performance.

If They Can’t Start, Why Are They Everywhere?

This might be the biggest question of all. If single-phase motors have this fundamental flaw, why are they in almost every home appliance we own, from washing machines to grinders to air conditioners? The answer is simple: they are practical and cost-effective.

Our entire electrical grid for homes and small businesses is built on single-phase AC power. It’s easy to distribute and use. The clever starting mechanisms we’ve talked about completely solve the starting problem. While they add a little complexity, the designs are incredibly reliable and have been perfected over decades. For most household tasks, these motors provide the perfect balance of power, efficiency, and cost. Understanding the basic motor principle shows us how a simple problem led to brilliant engineering solutions that power our daily lives.

In Summary

Let’s wrap up with the most important things to remember about why single-phase induction motors are not self-starting:

- Pulsating Field: Single-phase AC power creates a magnetic field that only pulses back and forth, it doesn’t rotate.

- Zero Starting Torque: This pulsating field pushes the rotor equally in opposite directions at the start, resulting in zero net force to get it spinning.

- The Solution is Phase Splitting: To fix this, motors use a second “auxiliary” winding to create an artificial rotating magnetic field for a few seconds.

- Capacitors Add Power: A capacitor can be added to the starting circuit to create a much stronger rotating field and a powerful starting torque for heavy loads.

- They Are Everywhere: Despite this issue, these motors are incredibly common because they are a reliable and affordable solution for the single-phase power found in our homes.