Why the AC Motor Is Indispensable: Powering Modern Life and Industry

Table of contents

- Introduction: The unseen force driving our world

- What is an AC motor? A brief overview

- The core advantages that make AC motors critical

- Unmatched efficiency and reliability

- Versatility and adaptability

- Robustness and power output

- Ubiquitous applications: Where AC motors shape our world

- Powering industry and manufacturing

- Essential in commercial and residential settings

- Driving modern transportation and infrastructure

- The economic and environmental impact of AC motors

- A pillar of global electrification

- Energy consumption and efficiency standards

- Lifecycle costs and predictive maintenance

- The future of AC motors: Continued innovation

- Practical guidance from the field: How I choose and run AC motors

- Conclusion: Beyond importance — an indispensable foundation

- FAQ

Introduction: The unseen force driving our world

I still remember the first time I walked onto a factory floor as a young engineer. The place hummed. Not with noise exactly. With motion. Conveyor belts flowed. Pumps moved water and chemicals. Fans breathed life into the space. Compressors fed air to tools and machines. I asked the obvious question. What makes all of this spin?

The answer was simple and a little mind-blowing. AC motors. They sit inside machine housings and behind elevator doors and under the hood of HVAC systems. They drive robots and blowers and cranes and lathes. You rarely see them yet you feel their impact everywhere. If you enjoy cold air on a hot day or clean water on demand or a train that arrives on time you benefit from an AC motor.

In my experience AC motors aren’t just important. They are fundamental. They deliver the power and control modern life demands with a mix of efficiency, reliability, and versatility that no other technology matches. Let me show you why.

What is an AC motor? A brief overview

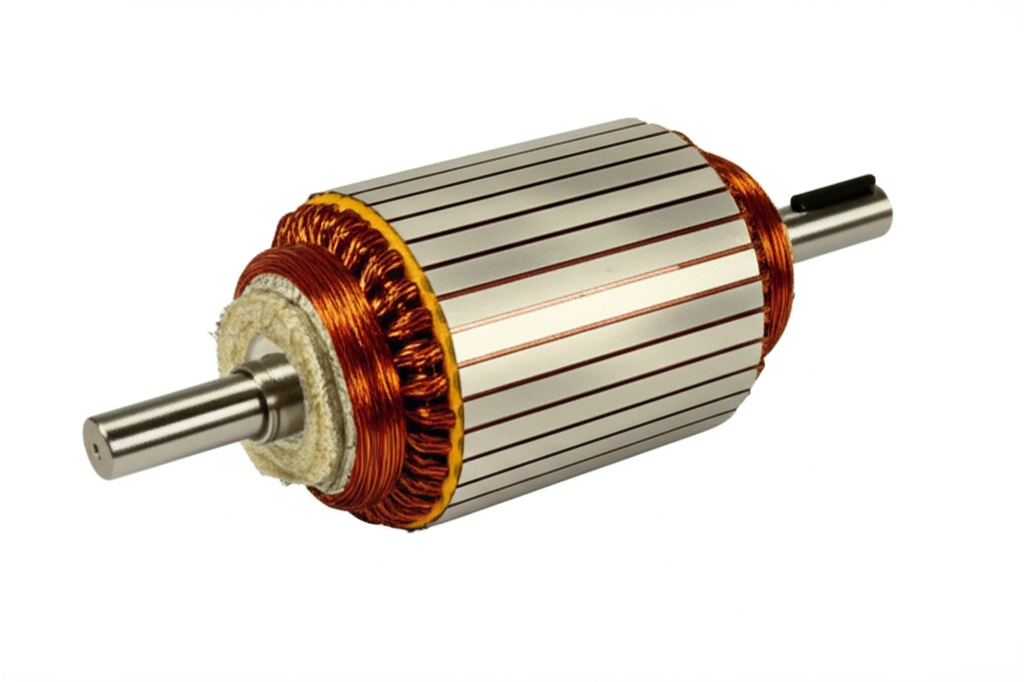

At its core an AC motor converts electrical energy from alternating current into mechanical rotation. The principle sounds elegant because it is. Alternating current creates a changing magnetic field in the stator. That shifting field induces current in the rotor or locks it in step depending on the motor type. The interaction between magnetic fields produces torque. Torque makes the shaft spin. That rotation does the useful work.

If you want a quick primer on the two main parts start with the stator and rotor. The stator is the stationary outer section with windings. The rotor sits inside and turns. The dance between those magnetic fields is the motor’s heartbeat.

Two families dominate:

- Induction motors: The workhorse of industry. The rotating magnetic field in the stator induces current in the rotor bars. That current creates its own field and the rotor follows the stator’s field with a slight speed difference called slip. No brushes. No commutator. Simple and tough.

- Synchronous motors: The rotor locks in step with the stator’s rotating field. You can use permanent magnets or a wound field on the rotor. Permanent magnet synchronous motors (PMSMs) and many brushless AC motors give you high efficiency and precise speed control.

Contrast that with DC motors. DC motors can deliver great low-speed torque and simple speed control with voltage. Yet they often need brushes and a commutator which wear with time. AC motors avoid those wear parts in most designs which is one reason they dominate industrial and HVAC applications.

You’ll also hear about single-phase and three-phase AC motors. Single-phase motors show up in homes and small appliances. Three-phase motors run factories and infrastructure because they deliver smoother torque and better efficiency. Three-phase power is the backbone of industrial automation for good reasons.

The core advantages that make AC motors critical

Unmatched efficiency and reliability

When people ask why AC motors matter I start with efficiency. Motors convert electricity into motion. The better they do that the less energy we waste and the less we spend. The numbers are stark. Electric motors use an estimated 45–50% of global electricity every year according to the International Energy Agency and other industry reports. In industry the share rises to roughly 70–80% of electricity use based on studies from the European Commission and the U.S. Department of Energy. If you move those efficiency numbers even a little you move national energy bills and carbon footprints.

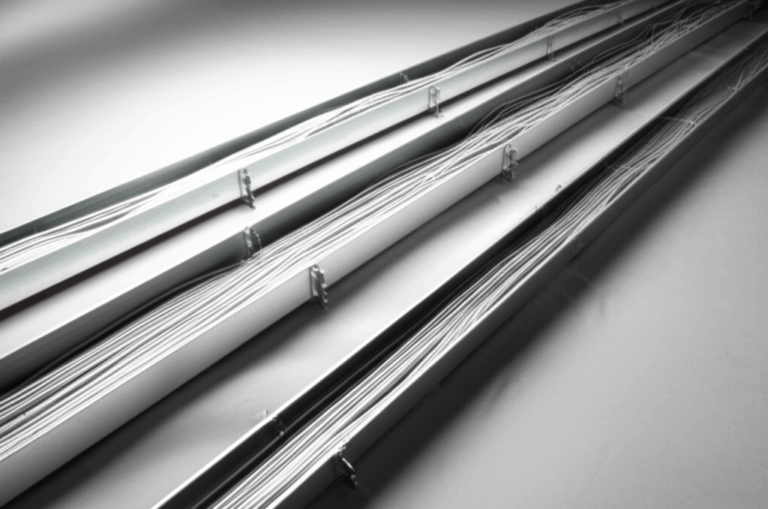

Modern AC motors deliver high efficiency through smart electromagnetic design and good materials. I learned early on that what goes into the core matters as much as the motor’s nameplate. The quality of the stator core lamination directly influences losses. So does the precision of the rotor core lamination. When manufacturers use high-grade electrical steel laminations and optimize slot geometry and winding fill they cut core losses and heat. Less heat means longer life and less energy wasted.

I have seen induction motors run for 20–30 years in continuous service when you keep them clean and within spec. That kind of durability isn’t an accident. It comes from a design that avoids brushes, distributes heat well, and tolerates tough environments. Fewer wear parts means less maintenance which means fewer shutdowns and lower lifecycle costs.

Standards help too. NEMA in North America and IEC globally define efficiency classes like IE3 and IE4. Upgrading from older IE1 motors to IE3 can reduce energy use by about 10–15% in common applications. I worked on a project where a plant replaced a bank of older motors and the payback came quick simply from the energy savings. No drama. Just lower kilowatt-hours and a flatter demand curve.

Versatility and adaptability

AC motors shine because they fit almost any job. I have spec’d small single-phase motors for blenders and pumps in homes and I have commissioned massive three-phase machines for compressors and conveyor belts in heavy industry. Fans, pumps, compressors, machine tools, textile lines, robotics, material handling systems, blowers, and mixers all run on AC. You’ll find them in HVAC systems, refrigeration plants, escalators, and elevators. You’ll find them in mining rigs and agricultural irrigation. That range is unmatched.

Then there’s control. Variable Frequency Drives (VFDs) changed the game. A VFD lets you control motor speed and torque by adjusting frequency and voltage. For fans and pumps the affinity laws are your best friend because power scales roughly with the cube of speed. Slow a fan by 20% and you can slash energy use by up to 50%. Case studies often report 30–60% energy savings for pumps and fans with VFDs. I helped a water treatment facility install VFDs on a handful of large pumps. Their annual electricity bill dropped by six figures and the operators got smoother process control and fewer water hammer events.

Cost matters as well. Induction motors offer simple construction and robust performance which often makes them more cost-effective upfront and over time. You can scale them from fractional horsepower for small appliances to megawatt-class machines for heavy industry. That scalability is a big reason AC motors underpin global electrification.

Robustness and power output

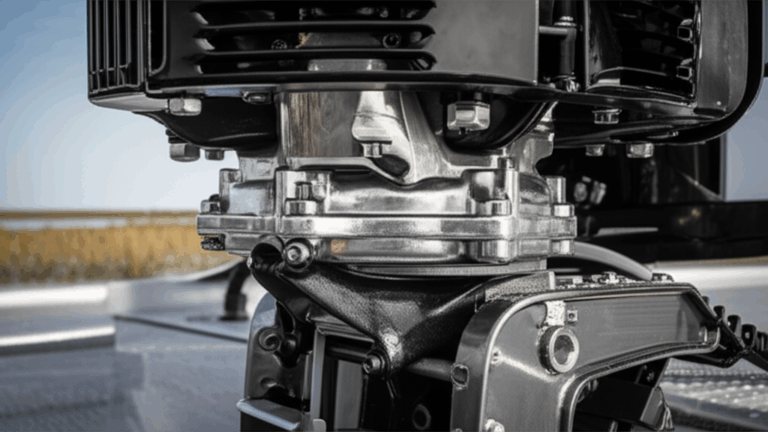

Factories need torque. Cranes, extruders, mills, and compressors ask a lot from their drives. AC motors deliver. Three-phase designs provide smooth torque and high power density. They handle heavy loads and continuous duty with grace when you size and cool them correctly. I have watched induction motors start stubborn loads with soft-start or VFD control and settle into steady operation without complaint.

Power quality matters. AC motors interact with voltage and frequency on the grid. Good drive systems manage harmonics and protect power factor with filters and power factor correction where needed. Get that right and your motors run cooler and your utility charges stay in check.

Ubiquitous applications: Where AC motors shape our world

Powering industry and manufacturing

Walk any factory and you’ll spot AC motors everywhere. They drive:

- Conveyor systems that move parts and products

- Pumps that feed cooling water and process fluids

- Fans and blowers that manage ventilation and combustion air

- Compressors that deliver plant air and refrigeration

- Machine tools that cut, drill, and finish

- Robotics and automation lines in automotive and electronics

- Mixers and agitators in chemical and food processing

- Crushers, hoists, and mills in mining operations

- Irrigation and harvest systems in agriculture

Motor Control Centers (MCCs) organize these drives. VFDs and soft starters live there with protective relays and power electronics. Integrate them with PLCs and SCADA and you get industrial automation that runs 24/7.

Data centers depend on AC motors more than most people realize. Not for compute of course. For cooling. Chillers, cooling towers, CRAH units, and pumps keep servers in their happy temperature window. If those motors fail your cloud gets hot fast.

Essential in commercial and residential settings

You feel AC motors at home every single day. HVAC systems use them in air handlers, furnaces, condensers, and ventilation fans. Refrigerators, washing machines, dishwashers, and vacuum cleaners rely on them too. Elevators and escalators keep buildings moving. In commercial buildings variable air volume boxes and roof fans use small motors to fine tune airflow and comfort.

Smart homes bring motors into the Internet of Things. Think of variable-speed compressors in high-efficiency heat pumps or ECM-based blowers that adjust airflow to match demand. You get quiet operation and serious energy savings.

Driving modern transportation and infrastructure

Transportation runs on AC machines as well. Electric vehicles use AC traction motors with permanent magnets or induction designs. PMSMs dominate new EVs because they offer high efficiency and great torque density. Industry analyses show permanent magnet synchronous motors power more than 80% of new EVs in recent years. Some automakers use induction motors on one axle for performance and auxiliary drive flexibility.

Trains and trams use rugged three-phase traction motors with VFD control. The result is high torque from zero speed and smooth acceleration. Elevators use AC gearless synchronous machines for whisper-quiet rides and excellent energy performance. You also see AC motors in marine propulsion and in airport baggage systems. They are the quiet force behind infrastructure we take for granted.

Water and wastewater plants lean on AC motors too. Pumps move raw water and treated effluent. Blowers aerate basins. Mixers keep chemistry stable. VFDs help them balance process control with energy use which matters in municipalities with tight budgets.

The economic and environmental impact of AC motors

A pillar of global electrification

AC motors sit at the center of modern electrification. Three-phase power distribution lets utilities move large amounts of power efficiently and it pairs beautifully with three-phase motors that deliver smooth torque and strong power density. Nikola Tesla’s work on AC systems and induction motors set the stage for this. The industrial revolution did not finish in the 19th century because it keeps evolving with automation and electrification across every sector.

AC motors enable manufacturing, mining, agriculture, chemical processing, and logistics. They form the backbone of HVAC and refrigeration which protect food supply chains and keep people safe during extreme heat. They support hospitals and labs through pumps and blowers and centrifuges. Without them modern life gets very uncomfortable very fast.

Energy consumption and efficiency standards

Because motors consume such a large share of electricity even modest efficiency gains matter. Here are the key points I share with teams and clients:

- Electric motors use about 45–50% of global electricity. In industry they use roughly 70–80%. These estimates appear consistently in IEA and government energy analyses.

- Upgrading to IE3 or IE4 motors lowers losses. Moving from IE1 to IE3 can cut energy use on the order of 10–15% for many applications. That looks small until you multiply it across thousands of running hours each year.

- Variable Frequency Drives deliver outsized savings in pumps and fans. Case studies often show 30–60% reductions in energy use with VFDs because you can match speed to load.

- Power quality and power factor matter. Good drive systems and power factor correction keep utilities happy and protect equipment.

- Standards from IEC and NEMA guide motor selection and testing which builds trust in the nameplate numbers.

I like to frame it with a real story. A chemical plant I worked with retrofitted VFDs on a dozen large pumps. They tuned control loops to avoid surging and throttling. They saved well over a hundred thousand euros in the first year and maintenance calls dropped because the pumps ran smoother. The team did not change the process recipe. They just stopped wasting energy as heat across valves.

Lifecycle costs and predictive maintenance

When you calculate total cost of ownership for a motor-driven system energy dominates. For many motors 90% or more of lifetime cost comes from the electricity they consume. That is why sizing and efficiency choices matter. Oversize a motor and you may pay a penalty in part-load efficiency. Undersize it and you risk overheating and early failure. Get the sizing right and you win for 20 years.

Condition monitoring adds another layer. Vibration analysis, bearing temperature trends, and current signature analysis can spot problems early. Predictive maintenance keeps machines running and avoids catastrophic failures. With IoT sensors and digital twins you can get alerts before operators hear a squeal or feel heat. I have seen plants move from reactive to predictive maintenance and cut unplanned downtime in half. You protect the motor and the process. Your maintenance crew sleeps better too.

The future of AC motors: Continued innovation

The future looks bright and practical. I see a few clear trends.

- Smart motors and drives: Built-in sensors and connectivity bring real-time data to dashboards. Predictive maintenance models flag anomalies. Remote monitoring lets small teams manage big fleets.

- Better materials and designs: High-grade electrical steel and refined lamination profiles continue to reduce core losses. Copper rotor technology and improved die-cast aluminum rotors push efficiency further without exotic costs. Manufacturers keep squeezing loss out of every watt.

- Tighter integration with power electronics: SiC and GaN devices improve drive efficiency and shrink cooling needs. That means more compact VFDs and better part-load performance.

- Renewable energy and grid integration: Motors play a role in wind turbine yaw and pitch systems and in the balance-of-plant for solar and storage sites. Smart grid strategies coordinate motor loads for demand response which helps grid stability without sacrificing production.

- Transportation evolution: EV drive units keep improving with better PMSM designs, oil-cooled stators, and compact reducers. AC traction remains the king for efficiency and control.

None of this changes the basics. It refines them. The physics stay the same yet the engineering gets sharper and more connected.

Practical guidance from the field: How I choose and run AC motors

I have made good choices and a few mistakes. Here is the checklist I wish I had from day one.

1) Start with the load profile

- Know the torque-speed curve of your load. Fans and pumps follow the affinity laws. Positive displacement pumps and conveyors need higher torque at lower speeds.

- Map the duty cycle. Continuous, intermittent, cyclic. This drives thermal class and cooling choices.

- Understand starting requirements. High-inertia loads might need a VFD or soft starter to limit inrush and mechanical stress.

2) Pick the right motor type

- Induction motor for general-purpose rugged service. It’s the default choice for conveyors, pumps, fans, and compressors.

- Synchronous motor or PMSM for high efficiency and precise speed control. Great for EV traction, servo-like motion, and high-performance HVAC.

- Single-phase for small residential or light commercial loads. Three-phase for anything serious in industry.

3) Mind the power supply

- Verify voltage and frequency. Voltage tolerance and frequency stability affect performance and heat.

- Consider harmonics. Drives introduce harmonics so plan for filters or design choices that limit Total Harmonic Distortion in sensitive systems.

- Pay attention to power factor. Synchronous motors can correct power factor. Drives and capacitors can help too.

4) Choose the right materials and construction

- Core losses matter. Good motor core laminations and winding design reduce heat and extend life.

- Bearings and lubrication need love. Pick sealed bearings where appropriate and set a sane lubrication schedule.

- Enclosure and cooling matter. TEFC vs ODP vs explosion-proof depends on environment. Dust, moisture, and chemicals change the game.

5) Use drives wisely

- Size VFDs with headroom. Program acceleration and deceleration ramps to protect mechanical components.

- Exploit energy savings with control. Static pressure reset in HVAC. Trim and respond logic for pumps. Sync with building or process setpoints.

- Respect EMC and grounding. Good drive installation prevents interference with controls.

6) Keep maintenance practical

- Keep motors clean and dry. Dust insulates and moisture corrodes.

- Trend vibration and temperature. Catch bearing wear early.

- Check alignment and balance. Misalignment eats bearings. Imbalance shows up in vibration signatures.

- Listen to operators. They spot changes first.

7) Don’t forget standards and testing

- Use NEMA or IEC efficiency classes to compare apples to apples.

- Verify nameplate data under your site conditions. Altitude and ambient temperature change allowable loads.

- Commission with measurements. Measure current, temperature rise, and vibration. If it looks wrong fix it now not after a failure.

An anecdote to bring it home. We had a packaging line with recurring seal failures on a pump. The team swapped seals and cursed the brand. The root cause was a motor running hot because the cooling path sat choked with dust. We cleaned the fins, added a simple shroud, and put a reminder in the CMMS to blow down the motor monthly. Failures vanished. Sometimes the fix is boring which is another way of saying it works.

Conclusion: Beyond importance — an indispensable foundation

When I strip this topic down to the studs I land here. AC motors are the muscle of modern life. They power industry, protect comfort, and keep cities running. They do it with efficiency we can measure and reliability we can trust. They scale from a blender on your counter to a megawatt compressor in a refinery. They pair with VFDs to save energy at scale. They play well with modern grids and smart control.

You can take many pieces of technology out of a factory and keep production limping along. Take out the AC motors and everything stops. That is why they are not just important. They are indispensable.

FAQ

What is the main difference between AC and DC motors?

AC motors run on alternating current and typically use a stator’s rotating magnetic field to induce torque in the rotor. Induction motors have no brushes and rely on electromagnetic induction. Synchronous motors lock the rotor to the stator’s field. DC motors run on direct current and often use brushes and a commutator to switch coil polarity. AC motors tend to offer lower maintenance and better suitability for three-phase power and industrial loads.

Why are AC motors more common in industrial applications?

Three-phase AC power is standard in industry and three-phase AC motors deliver smooth torque, strong power density, and high efficiency. Induction motors are robust and low maintenance which suits continuous duty. VFDs make speed control precise and efficient which expands their use across pumps, fans, conveyors, and machine tools.

How do AC motors contribute to energy efficiency?

They convert electrical to mechanical power with high efficiency especially in IE3 and IE4 designs. When paired with VFDs AC motors match speed to load. Fans and pumps often see 30–60% energy savings with speed control. Since motors consume a large share of global electricity even small efficiency gains create big environmental and cost benefits.

Can AC motors be used in electric vehicles?

Yes. Most modern EVs use AC traction motors. Permanent magnet synchronous motors dominate because they provide high efficiency, strong torque density, and precise control. Some EVs also use induction motors for performance or auxiliary drive flexibility. The combination of AC motors and power electronics is what makes EV drivetrains so responsive and efficient.

Who invented the AC motor?

Nikola Tesla pioneered the practical AC induction motor and made major contributions to AC power systems. His work laid the foundation for the wide adoption of AC motors in industry and daily life. Many engineers and companies since then have improved materials, designs, and controls to reach today’s performance levels.

—

Final internal link check

- stator and rotor: https://nfdyzyo.top/stator-and-rotor/ (used once)

- stator core lamination: https://sinolami.com/stator-laminations/ (used once)

- rotor core lamination: https://sinolami.com/rotor-laminations/ (used once)

- electrical steel laminations: https://sinolami.com/electrical-steel-laminations/ (used once)

Total internal links used: 4. Each URL is unique and used only once.