Why Three-Phase Motors Don’t Need a Neutral Wire: The Science Behind Balanced Power

Have you ever looked at the wiring for a big machine, like an industrial motor, and felt a little confused? You might see three thick wires going into it and wonder, “Where’s the neutral wire?” Your lamp at home has one, so why doesn’t this powerful motor? It’s a great question that confuses many people. The answer is surprisingly simple and smart. This article will show you the magic behind three-phase power and why these motors work perfectly without that extra wire. It’s all about teamwork and balance.

Table of Contents

- What is a Neutral Wire For, Anyway?

- So, What Makes Three-Phase Power Special?

- How Do the Three Phases Work Together?

- Why Doesn’t a Three-Phase Motor Need a Neutral?

- What are the Motor’s Winding Connections?

- What Makes a Motor a “Balanced Load”?

- Are There Times a Neutral Wire is Near a Motor?

- What are the Perks of a Neutral-Less Connection?

- A Simple Comparison: Power Systems at a Glance

- Frequently Asked Questions

- Key Things to Remember

What is a Neutral Wire For, Anyway?

Before we talk about big motors, let’s look at something simple: your toaster. The power that comes to your house is usually single-phase power. Think of it like a simple loop.

Electricity needs a complete path to flow, like a race car on a track. It leaves the source, goes through the “hot” wire, powers your toaster, and then needs a road to get back home. The neutral wire is that return road. It provides the return path for current. Without it, the electricity gets stuck, and your toaster won’t heat up. It’s a one-way street in and a one-way street out. The neutral wire carries all the used electricity back to the source.

This makes sense for simple things. But when you need a lot of power for big jobs, using a single phase is like trying to move a house with one person. It’s not very efficient. That’s where three-phase power comes in, and it changes the rules completely.

So, What Makes Three-Phase Power Special?

If single-phase power is one person doing a job, three-phase power is like having three people working together perfectly. Imagine three identical waves of electricity, all following each other. They aren’t all at their peak power at the same time. Instead, they are spaced out perfectly, exactly 120 degrees apart.

What does this mean? It means you get a smooth, constant stream of power. With single-phase power, the power level goes up and down. With three-phase power, just as one wave starts to go down, the next one is coming up. This constant power delivery is why it’s the top choice for industrial electricity and big machinery.

Think of it like pedaling a bicycle. If you only use one foot (single-phase), you get a jerky push-coast-push-coast motion. If you use both feet, alternating pushes (like three-phase), you get a much smoother and more powerful ride. This smoothness and efficiency make a three-phase power system ideal for running large motors.

How Do the Three Phases Work Together?

Here’s where the real magic happens. The reason three-phase power is so special is because the three currents are balanced. Let’s try an analogy.

Imagine you have a post in the ground with three ropes tied to it. Three people grab these ropes. If only one person pulls, the post will lean in their direction. But what if all three people pull with the exact same strength, but they are standing in a perfect circle around the post? The post won’t move at all! Each person’s pull is cancelled out by the other two.

The three phase currents in a three-phase system act just like those three people. At any given moment, the electricity flowing through the three wires is pulling in different “directions.” Because they are perfectly out of sync by 120 degrees, the vector sum of currents is always zero. This is the secret sauce. It’s a perfect balancing act.

Why Doesn’t a Three-Phase Motor Need a Neutral?

Now you know the secret! Since the three currents in a balanced three-phase system always cancel each other out, there is no leftover current that needs a road back home. The current cancellation is so perfect that a neutral wire would have nothing to do. It would just sit there with zero current flowing through it.

The three “hot” wires do all the work themselves. The electricity flows from the power source, through one wire, into the motor, and then returns to the source through the other two wires. The roles of “going out” and “coming back” are shared between the three wires constantly.

This is a huge difference from your toaster, where the neutral wire has to carry all the return current. In a balanced load like a three-phase motor, the other phases act as the return path for each other. It’s an incredibly efficient system that saves wire and money.

What are the Motor’s Winding Connections?

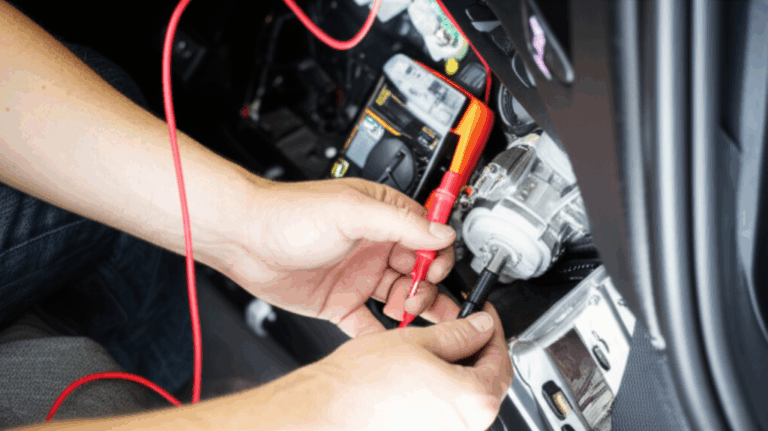

To make this work, three-phase motors are wired in two special ways. You don’t need to be an electrical engineer to understand the basics. The internal motor winding configurations are designed to take advantage of this balancing act.

Imagine the three sets of wires inside the motor all meeting at one central point. This is called a star connection or Wye connection. Each wire from the power source connects to one end of a winding, and the other ends are all tied together at a neutral point. But here’s the trick: because the system is balanced, the current at that central meeting point is zero. It’s like a “virtual neutral” that doesn’t need an actual wire connected to it. The electricity just balances itself out right there.

The other style is called a Delta connection. In this setup, the wires inside the motor are connected end-to-end, forming a triangle (like the Greek letter Delta, Δ). There is no central meeting point at all. The three power wires connect to the three corners of the triangle. The current just flows around the triangle, creating a rotating magnetic field that makes the motor spin. Since it’s a closed loop, there’s nowhere for a neutral wire to even connect. The currents circulate happily inside the motor windings.

Both of these designs cleverly use the principles of three-phase power so that no neutral wire is needed for the motor to do its job.

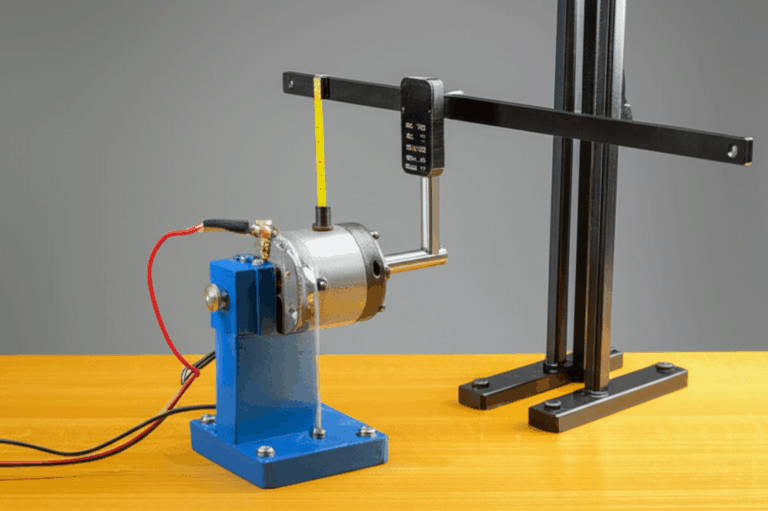

What Makes a Motor a “Balanced Load”?

This whole idea only works if the load is “balanced.” So, what does that mean? A balanced load is something that draws the exact same amount of current on all three phases.

A three-phase induction motor is the perfect example of a balanced load. Inside the motor, there are three identical sets of windings, one for each phase. The relationship between the stator and rotor is precisely engineered. Because these windings are built to be identical, they all have the same electrical impedance (a type of electrical resistance). This means each phase does the same amount of work, pulling the same amount of current.

The precision of these internal parts is key. For example, the quality of the stator core lamination and rotor core lamination directly impacts how balanced and efficient the motor is. When all parts are made perfectly, the motor runs smoothly and the currents stay balanced, eliminating the need for a neutral. This is unlike a building’s electrical panel, which might have different single-phase loads (lights, computers, etc.) that create an unbalanced load.

Are There Times a Neutral Wire is Near a Motor?

Yes, and this is where it can get a little tricky. Sometimes you might see a four-wire system running to an area where a motor is located. So, you’ll see three phase wires and a neutral. However, that neutral is almost never for the motor itself.

Often, that neutral is there to power other things nearby. For instance, the motor control circuits, like a starter or a light on a control panel, might need 120V to operate. To get 120V from a three-phase system, you can tap into one phase wire and the system’s neutral.

So, the neutral wire is there for the smaller, single-phase auxiliary devices, not for the main three-phase motor power. The motor will still be connected using only the three phase wires. It’s a common setup in commercial electrical wiring where you have mixed loads.

What are the Perks of a Neutral-Less Connection?

Designing a system where big motors don’t need a neutral wire isn’t just a cool science trick. It has real-world benefits.

- Reduced Wiring Costs: Copper is expensive! By eliminating one whole conductor for every motor, you save a lot of money, especially on big industrial projects. You only need 3 wires instead of 4. This is a huge cost savings.

- Simpler Installation: With fewer wires to pull and connect, electricians can work faster and the wiring is less complex. This reduces the chance of errors during installation.

- Improved Reliability: Every extra wire and connection is another potential point of failure. A simpler three-wire system is often more robust and reliable over the long run.

- Enhanced Efficiency: In this system, there is no energy lost in a neutral conductor. All the power is delivered directly to the motor windings where it can be used to do work. This contributes to the high efficiency of 3 phase motors.

These advantages are why three-phase power is the backbone of modern industry, and it’s all thanks to the simple principle of balance. Manufacturers of high-quality motor components, like our core lamination stacks, focus on creating parts that maximize this efficiency.

A Simple Comparison: Power Systems at a Glance

Sometimes a table makes things clearer. Here’s a quick look at how different systems use a neutral wire.

| Feature | Single-Phase System (Your House) | Three-Phase Motor (Balanced Load) |

|---|---|---|

| Purpose of Neutral | Essential return path for current. | Not needed. Return path is shared. |

| Current in Neutral | Carries the full amount of current. | Zero (theoretically). |

| Number of Wires | 2 (Phase + Neutral) + Ground | 3 (3 Phases) + Ground |

| How it Works | Simple in-and-out loop. | Three currents cancel each other out. |

| Best For | Lights, small appliances, electronics. | Big motors, industrial machines. |

Frequently Asked Questions

Q: Can I use a neutral with a three-phase motor?

A: You generally don’t connect a neutral to the main power terminals of a three-phase motor. The motor is not designed for it, and it would serve no purpose because the currents are balanced.

Q: What happens if a three-phase motor becomes unbalanced?

A: If one of the windings inside the motor fails, it can cause an unbalanced load. This is a serious problem that can cause the motor to vibrate, overheat, and eventually burn out. Overcurrent protection devices like overload relays are designed to shut the motor off if this happens.

Q: Is grounding the same as a neutral wire?

A: No, they are very different! A neutral wire is a normal part of the circuit that carries current. A ground wire (electrical grounding) is a safety feature. It’s a path for electricity to go safely into the earth if something goes wrong, like a short circuit. It prevents you from getting an electric shock. Motors always need a ground wire for safety.

Q: Do single-phase motors need a neutral?

A: Yes. Just like your toaster or any other single-phase device, a single-phase motor needs a neutral wire to complete the circuit and provide a return path for the current.

Key Things to Remember

- A neutral wire acts as the return path for electricity in single-phase systems, like in your home.

- Three-phase power uses three currents that are perfectly balanced and 120 degrees apart.

- Because they are balanced, the three currents cancel each other out. This means there is no leftover current that needs a return path.

- Three-phase motors are balanced loads, meaning they draw the same amount of power on all three phases.

- Motor connections like Star (Wye) and Delta are designed to work without a neutral.

- Leaving out the neutral saves money, simplifies installation, and makes the system more efficient.