Yes, Steel Troughs Are Designed for Electrical Wire & Cable: A Comprehensive Guide to Their Use, Standards, and Benefits

Of course. Here is a comprehensive, long-form article written from a first-person perspective, adhering to all your instructions.

Table of Contents

- The Definitive Answer: A Story from the Field

- What Exactly Are Steel Electrical Troughs (or Wireways)?

- Why They’re Built for Wire & Cable: The Core Design Purpose

- Ultimate Protection for Your Conductors

- Bringing Order to Chaos: Support & Organization

- My Favorite Feature: Unbeatable Accessibility

- Letting Off Some Steam: Heat Dissipation

- The Rulebook: Following the National Electrical Code (NEC) & Industry Standards

- NEC Article 376: Our Guiding Star for Metal Wireways

- The UL Stamp of Approval

- Understanding NEMA Ratings for the Real World

- The Lifesaving Step: Grounding and Bonding

- Key Features & Design Considerations I Always Check

- Material Matters: Galvanized vs. Stainless Steel

- Construction Types: Lay-in, Hinged, Solid, and More

- Sizing for Today and Tomorrow

- The Big Wins: Advantages of Using Steel Troughs for Electrical Wiring

- Know the Limits: When to Consider Other Options

- Steel Troughs vs. The Competition: A Quick Comparison

- Wireway vs. Conduit

- Wireway vs. Cable Tray

- Final Thoughts: The Indispensable Role of Steel Electrical Troughs

The Definitive Answer: A Story from the Field

Let’s cut right to the chase. You’re asking, “Are steel troughs designed to carry electrical wire and cable?”

The answer is an absolute, unequivocal yes.

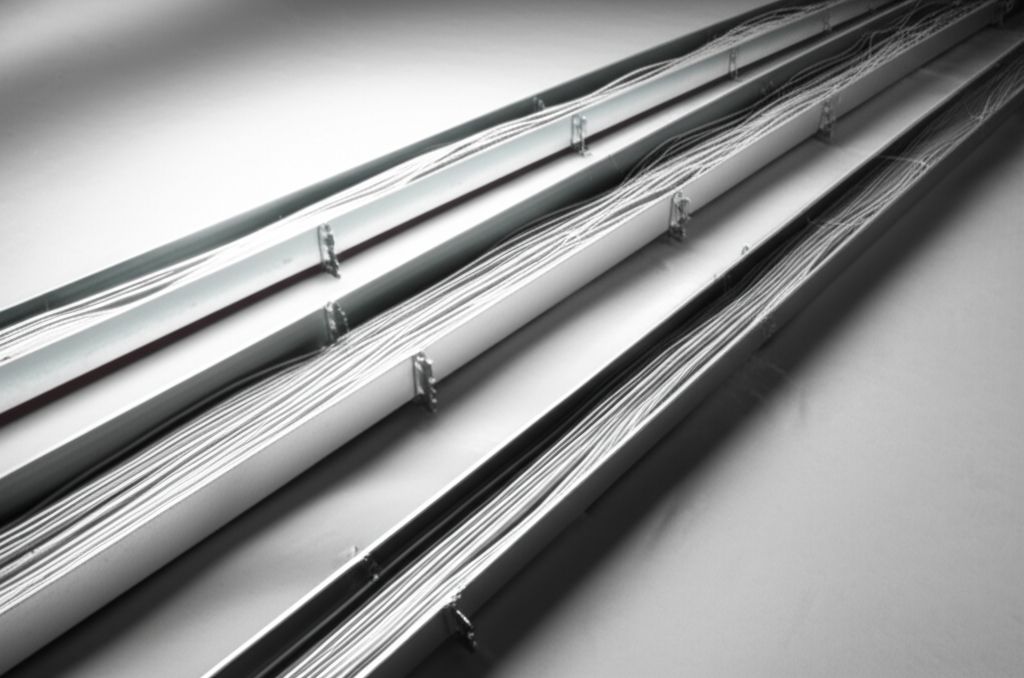

In fact, that’s their entire reason for existing. Steel troughs—which in the electrical world we usually call “wireways” or “metal wire troughs”—are purpose-built electrical raceway systems. I’ve spent years on job sites, from sprawling industrial plants to shiny new commercial buildings, and I can tell you that wireways are one of the most valuable tools in our arsenal for managing complex wiring.

I remember my first big industrial job as a younger electrician. We were tasked with wiring a massive assembly line. There were dozens of motors, sensors, and control panels, meaning hundreds of individual wires needed to run from a central cabinet to various points on the machinery. My initial thought was, “This is going to be a nightmare of conduit bending.”

Then, the lead electrician pointed to a stack of long, rectangular steel boxes with removable lids. “That’s our highway,” he said. That was my introduction to steel wireways. Instead of running dozens of individual conduits, we installed a single, robust steel trough. We laid the wires inside, organized them neatly, and simply snapped the cover on. It turned a week-long spaghetti-wiring nightmare into a clean, two-day job. It was a lightbulb moment for me. I realized these weren’t just metal boxes; they were a brilliantly designed solution for organization, protection, and accessibility, all governed by strict safety standards like the National Electrical Code (NEC).

So, if you’re wondering whether you’re on the right track, you are. Now, let’s dive into the why and how.

What Exactly Are Steel Electrical Troughs (or Wireways)?

If you’re new to the term, don’t let the different names confuse you. Whether you hear “steel trough,” “wire trough,” “metal wireway,” or “raceway,” we’re all talking about the same thing: an enclosed channel designed to house and protect electrical wires and cables.

Think of it like this: if a single wire in a conduit is a car in a tunnel, a wireway is a multi-lane, covered highway.

At its core, a wireway is a trough, typically made from sheet metal like galvanized or stainless steel. It comes in standard lengths (like 5 or 10 feet) and various cross-sectional sizes (e.g., 4×4 inches, 6×6 inches, etc.). The key feature is a removable or hinged cover that gives you full access to the interior along its entire length.

This isn’t just a simple box, though. It’s a complete system with a whole family of components:

- Straight Sections: These are the main “highway” parts.

- Elbows: To make 90-degree or 45-degree turns around corners.

- Tees and Crosses: To create intersections and branch off in different directions.

- Reducers: To transition from a larger wireway to a smaller one.

- End Caps: To safely terminate the end of a run.

- Mounting Hardware: Brackets and straps to secure the wireway to walls, ceilings, or machinery.

This modular wireway design allows us to build a custom, continuous path for our electrical conductors, no matter how complex the route.

Why They’re Built for Wire & Cable: The Core Design Purpose

So, why choose a steel trough over just running a bunch of conduits? In my experience, it boils down to four fundamental design benefits that are engineered right into the product.

Ultimate Protection for Your Conductors

The most obvious job of a steel trough is protection. The wires inside an industrial facility or a commercial building are its central nervous system. Leaving them exposed is asking for trouble. A steel wireway acts as armor, providing robust mechanical protection for cables against impacts, abrasions, and crushing forces. I’ve seen them shrug off bumps from carts and ladders that would have easily damaged unprotected cables or even dented weaker raceways.

But it’s not just about physical damage. Depending on their NEMA rating (more on that later), they also provide excellent environmental protection, shielding sensitive wiring from dust, dirt, dripping liquids, oil, and even hose-directed water.

Bringing Order to Chaos: Support & Organization

A wireway provides a structured pathway. It prevents cables from sagging over long distances and keeps them organized. When you open the cover of a well-planned wireway, you see neatly arranged conductors, often bundled and labeled. This is a lifesaver for troubleshooting.

Imagine trying to trace a single faulty wire in a bundle of 50 that are just pulled through a ceiling space. It’s a mess. Now, imagine opening a wireway where that wire is neatly laid in and clearly marked. You can find and fix the problem in minutes, not hours. This level of organization is crucial for maintaining complex electrical distribution systems.

My Favorite Feature: Unbeatable Accessibility

This is the game-changer for me. With a conduit system, once the wires are pulled, they’re in for the long haul. Adding another circuit means pulling a whole new run of wire through another pipe. It’s time-consuming and labor-intensive.

With a steel trough, you just pop the cover off. Need to add a new machine to your assembly line? No problem. Run a new set of wires in the trough, make your connections, and put the cover back on. This accessibility makes it an ideal choice for any environment where you expect future expansion or changes. It saves incredible amounts of time and money over the life of a building.

Letting Off Some Steam: Heat Dissipation

Every wire carrying current generates a little bit of heat. When you pack too many current-carrying conductors into a small, tight space, that heat can build up and damage the wire’s insulation, creating a serious fire hazard.

The NEC knows this, which is why it puts strict limits on how full a wireway can be. Generally, you can’t fill more than 20% of its cross-sectional area with wires. This rule ensures there’s enough air space inside the trough for heat to dissipate effectively, keeping the conductors operating at a safe temperature. It’s a built-in safety feature of the entire system.

The Rulebook: Following the National Electrical Code (NEC) & Industry Standards

You can’t just install a steel trough however you’d like. This is the electrical field, and safety is everything. The use of wireways is strictly governed by a set of codes and standards that I live by on every job. These rules ensure that the system is safe, reliable, and does its job correctly.

NEC Article 376: Our Guiding Star for Metal Wireways

If you ever want to know the official rules, the National Electrical Code is the bible. Specifically, NEC Article 376 is dedicated to Metal Wireways. I always have my codebook handy, but here are the key takeaways I’ve committed to memory:

- Conductor Fill Limit (The 20% Rule): As I mentioned, NEC 376.22(A) states that the total cross-sectional area of all the wires inside can’t be more than 20% of the trough’s interior area. This is the single most important rule for preventing overheating.

- Splices and Taps (The 75% Rule): You are allowed to make connections (splices) and tap into wires inside a wireway, which is a huge advantage over conduit. However, NEC 376.56 limits the total area of these connections at any single point to 75% of the trough’s area. This ensures you still have room to work and aren’t creating a dangerous “log jam” of connections.

- Support Requirements: You can’t just let a wireway hang. NEC 376.30 requires it to be securely supported at least every 5 feet, unless it’s a special rigid design. This prevents sagging and ensures the trough maintains its structural integrity.

The UL Stamp of Approval

When I’m sourcing materials, I always look for a UL Listed mark. This means Underwriters Laboratories, a trusted third-party safety organization, has tested the product (under standard UL 870 for wireways) and certified that it meets critical safety and performance standards. A UL listing is my assurance that the steel trough is built correctly and won’t fail under normal conditions, reducing the risk of fire or electric shock.

Understanding NEMA Ratings for the Real World

NEMA, the National Electrical Manufacturers Association, sets standards for electrical enclosures. The NEMA rating on a steel trough tells you exactly what kind of environment it’s designed to protect against. This isn’t just technical jargon; it’s how I match the right product to the job site.

Here are the ones I encounter most often:

- NEMA 1: Your basic, general-purpose indoor wireway. Great for dry, clean places like office buildings or utility rooms. It protects against fingers touching live parts but not much else.

- NEMA 3R: Built for the outdoors. It’s rainproof and will keep out sleet and snow. I use these for routing cables on rooftops or on the exterior of buildings.

- NEMA 4/4X: These are the workhorses for tough environments. NEMA 4 is watertight, meaning you can spray it down with a hose. NEMA 4X offers the same protection plus corrosion resistance. I always specify stainless steel NEMA 4X troughs for food processing plants, wastewater treatment facilities, and marine environments where harsh chemicals and constant moisture are a reality.

- NEMA 12: This is the standard for many indoor industrial settings. It’s designed to keep out dripping oil, circulating dust, and non-corrosive liquids.

The Lifesaving Step: Grounding and Bonding

Because wireways are made of metal, they are electrical conductors. This is why grounding and bonding them properly per NEC Article 250 is not optional—it’s a critical safety requirement. A proper ground ensures that if a live wire ever accidentally touches the metal trough, the fault current has a safe path to the earth, which will trip the breaker immediately instead of energizing the entire raceway and turning it into a massive shock hazard.

Key Features & Design Considerations I Always Check

When I’m designing a wireway system, I’m not just grabbing parts off the shelf. I’m thinking through the specific needs of the project.

Material Matters: Galvanized vs. Stainless Steel

The choice of material is my first decision.

- Galvanized Steel: This is the most common and cost-effective option. The zinc coating provides good corrosion resistance for most indoor and many outdoor applications. It’s the go-to for commercial buildings and general industrial use.

- Stainless Steel: When the environment is harsh, stainless is the only answer. Its superior corrosion resistance is a must-have in places with chemical exposure or high moisture. It costs more, but it prevents you from having to replace a rusted-out system in a few years. It’s an investment in longevity.

Construction Types: Lay-in, Hinged, Solid, and More

Wireways come in a few different styles, and the choice depends on the application.

- Lay-in vs. Hinged Cover: A standard lay-in trough has a cover that you fully remove. A hinged cover wireway is fantastic for locations where you need frequent access, as the cover stays attached and just swings open. It’s also safer when working on a ladder, as you don’t have to juggle a loose 5-foot steel cover.

- Solid vs. Ventilated: Most wireways are solid bottom (non-ventilated). However, in some cases where heat is a major concern, a ventilated or louvered trough can help improve air circulation.

Sizing for Today and Tomorrow

I always plan for the future. Based on the number and size of the initial wires, I calculate the required trough size using the 20% fill rule. But then, I almost always go up one size. Why? Because six months or two years down the line, the client will inevitably want to add another machine or more lighting. Having that extra space in the wireway makes future expansion incredibly simple and cost-effective.

The Big Wins: Advantages of Using Steel Troughs for Electrical Wiring

To sum it up, here’s why I reach for steel wireways so often:

- Durability: They are tough and provide excellent protection.

- Versatility: With all the available fittings and NEMA ratings, I can design a system for almost any commercial or industrial environment.

- Ease of Installation & Maintenance: For runs with multiple conductors, they are much faster to install than running many parallel conduits. And maintenance is a breeze.

- Cost-Effectiveness: The labor savings during installation and future modifications often make wireways a more economical choice in the long run. The efficient wiring of equipment directly impacts the overall operational costs, especially for machinery where the internal stator and rotor components require reliable power.

- Clean Aesthetics: A well-installed wireway system provides a neat, organized look for exposed wiring, which many clients appreciate.

Know the Limits: When to Consider Other Options

As much as I love wireways, they aren’t the perfect solution for every situation. Being a good electrician means knowing the right tool for the job. Here are times when I’d consider an alternative:

- Hazardous Locations: In areas with explosive gases or combustible dust (classified as hazardous locations), you typically need specialized, explosion-proof conduit systems.

- Extreme Physical Abuse: If a raceway is in a location where it could be run over by a forklift or hit by heavy machinery, I’d opt for heavy-wall rigid conduit for maximum protection. The integrity of the wiring is paramount, as a single failure can lead to significant downtime or damage to sensitive equipment components like the rotor core lamination inside a motor.

- Very Tight Spaces: Wireways are bulkier than conduit. In very congested areas, a few small conduits might be a better fit.

- Sensitive Data Cables: While you can run data cables in a wireway, they often require separation from power cables to prevent electromagnetic interference (EMI). Sometimes a dedicated data cable tray is a better option.

Steel Troughs vs. The Competition: A Quick Comparison

People often ask me how wireways compare to other common systems. Here’s my simple breakdown:

vs. Conduit

Conduit is like a small, armored tunnel for one or a few wires. It offers superior physical protection for individual circuits but is less accessible and much more labor-intensive for routing many cables. If I need to get power to a single large motor, understanding the fundamental motor principle tells me that a dedicated, protected conduit run is often the best choice. But for grouping the control wires for ten motors, a wireway is far more efficient.

vs. Cable Tray

A cable tray is like an open-air bridge. It’s a support system, not an enclosed raceway. It’s great for supporting huge quantities of power and data cables over long distances, like in a data center. However, because it’s typically open, it doesn’t offer the same level of protection from dust, debris, or moisture as an enclosed steel trough.

Final Thoughts: The Indispensable Role of Steel Electrical Troughs

So, let’s circle back to where we started. Are steel troughs designed to carry electrical wire and cable? Yes, 100%. They are a safe, code-compliant, and incredibly efficient solution engineered specifically for this purpose.

From my experience on countless job sites, I can tell you that a well-designed wireway system is a sign of a professional installation. It shows foresight, an understanding of the electrical code, and a commitment to creating a system that is not only safe and robust today but also adaptable for the needs of tomorrow. When you need to protect, organize, and provide access to multiple electrical conductors, a steel trough is often the best tool you can choose.